Vertical cement mixing pile forming device and forming construction method

A technology of cement mixing piles and forming equipment, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve problems such as uneven mixing of soil and cement slurry, uneven layering of pile cement density, and different cement content. Achieve the effect of convenient realization, easy guarantee of construction quality and simple construction method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

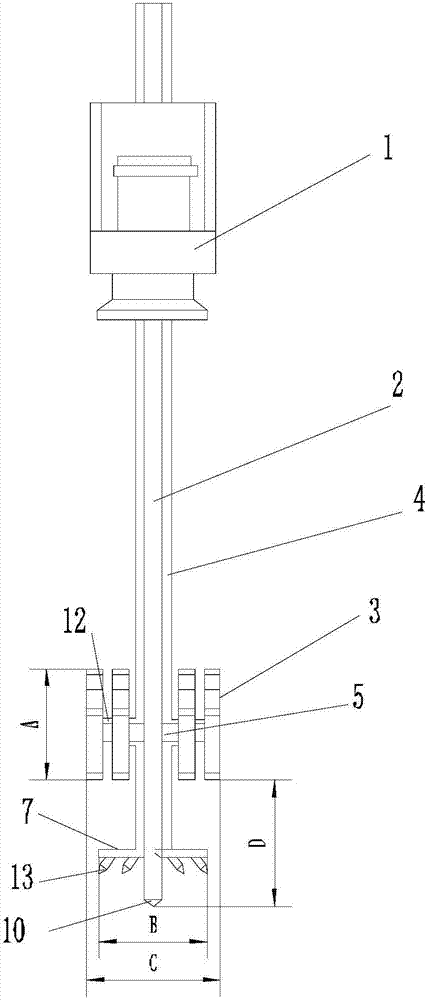

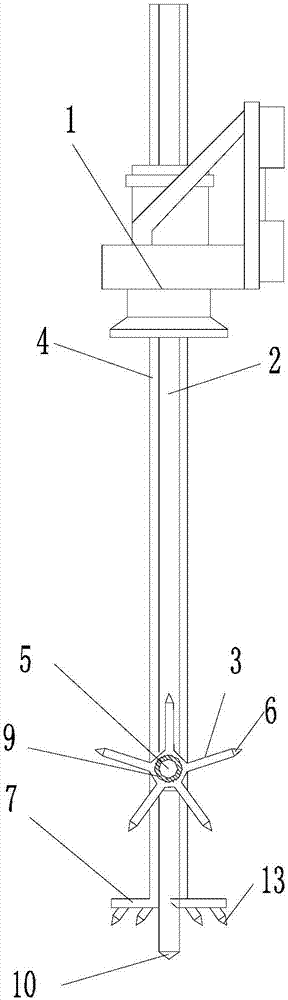

[0052] Such as figure 1 , figure 2 The vertical cement mixing pile forming equipment shown includes a vertical driving rod 2 arranged vertically, a driving device that drives the vertical driving rod 2 to rotate continuously and makes the vertical driving rod 2 drill downward and lift upward, and simultaneously The shaft sleeve is set on the vertical outer casing 4 outside the vertical driving rod 2 and the stirring device installed on the lower part of the vertical driving rod 2, and the outer casing 4 is connected with the cement slurry pumping device;

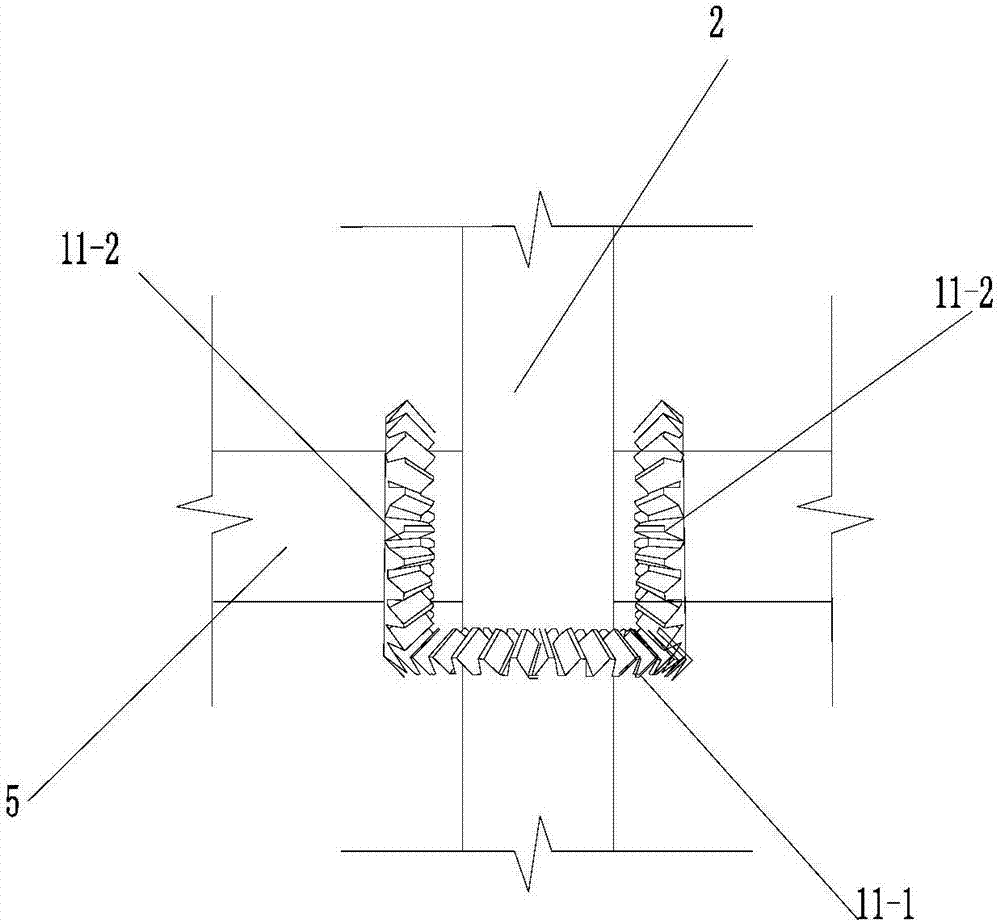

[0053] The stirring device includes a vertical stirring mechanism, which includes two horizontal drive rods 5 that can continuously rotate around their central axis and two groups of stirring impellers 3 that are symmetrically arranged and perform vertical stirring synchronously. Two described horizontal driving rods 5 are symmetrically installed on the bottom of the vertical driving rod 2, and the two described horizontal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com