Pile mould for PCC pile and construction method for overlong PCC pile

A construction method and pile formwork technology, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of PCC pile length increase, etc., and achieve the effects of large processing depth, convenient transportation, and simple technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

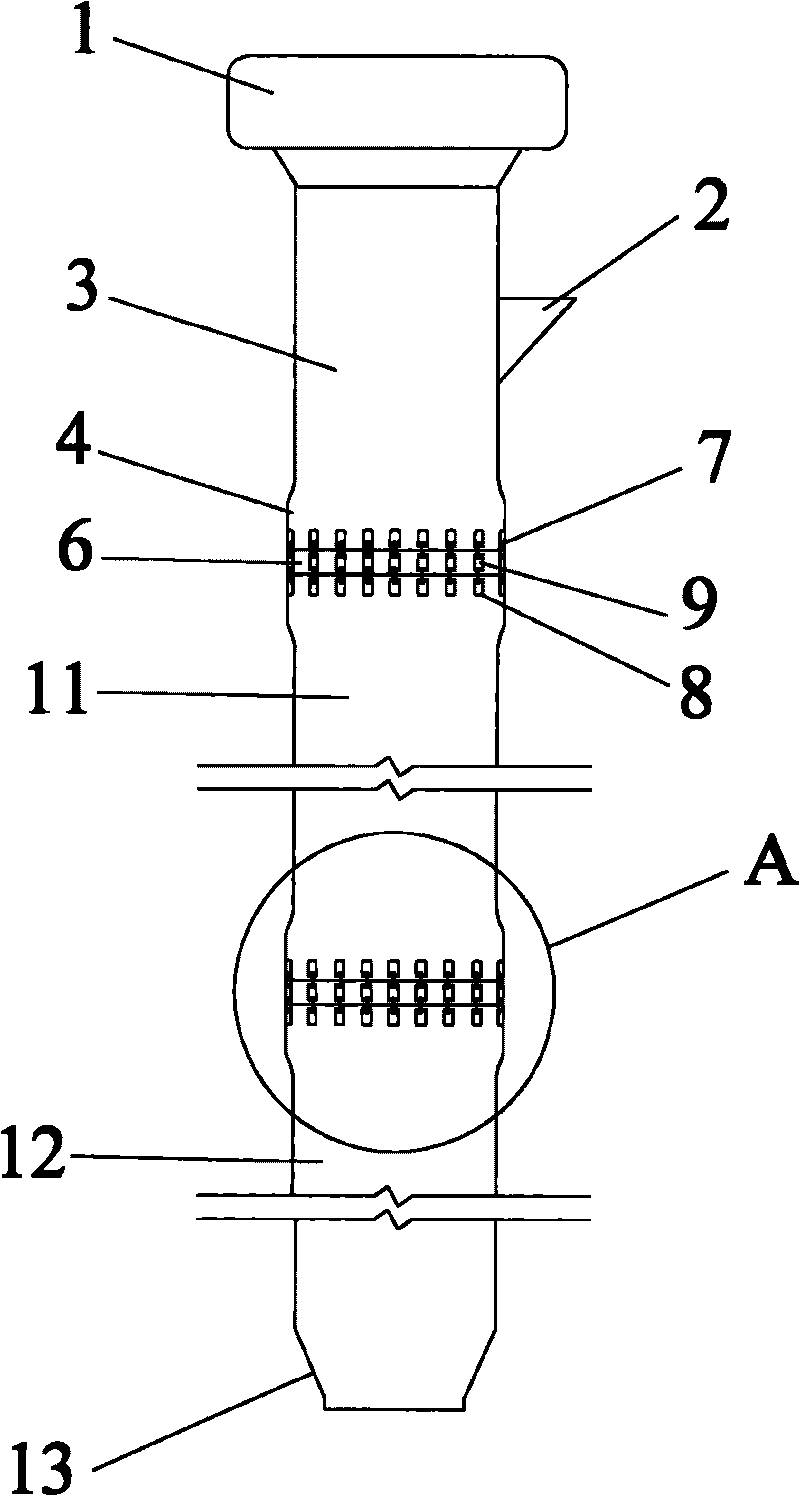

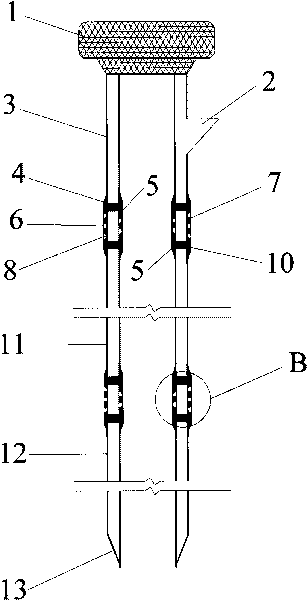

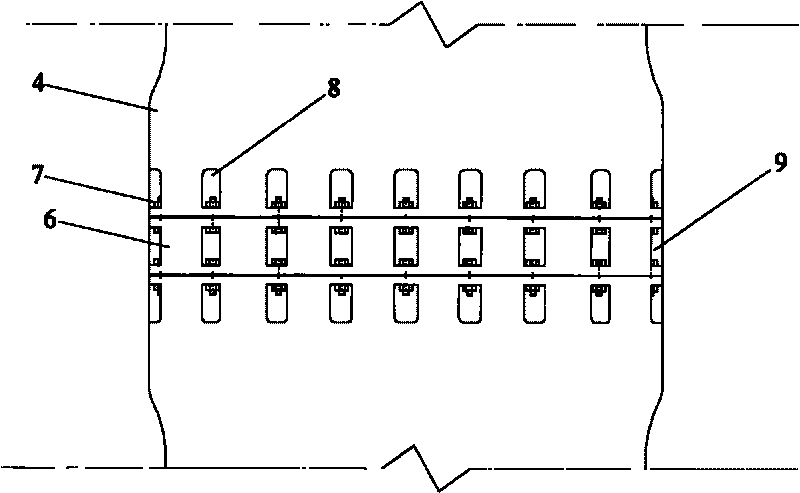

[0028] like Figure 1 to Figure 5 As shown, the PCC pile form is two layers of circular casing inside and outside, the diameter of the outer pipe is 1m, the diameter of the inner pipe is 0.7m, and the wall thickness of the casing is 1.5cm. The pile form is made up of feed section 3 , middle section 11 and pile tip section 12 . The feed section 3 of the pile form is 4m long, and the upper end is directly connected with the vibratory hammer 1, which is fixed and not disassembled during the construction process. In order to increase the active force during pile sinking, the vibratory hammer 1 can be a high-frequency hydraulic vibratory hammer. According to the design pile length, the middle section 11 can be one or more sections, and the length of every middle section 11 is 15m. The lower section of the pile tip section 12 is connected to the valve spud can 13, and the length of the pile tip section 12 is 15m. The joints at both ends of the pile formwork of each section are pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com