Preset stiff core rammed concrete pile and its construction method

A technology of cement-soil piles and construction methods, applied in sheet pile walls, infrastructure engineering, construction, etc., can solve the problems of low single-pile bearing capacity, large pile body deformation, limiting the application scope of compacted cement-soil piles, etc. High pile bearing capacity, small pile deformation, obvious economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings.

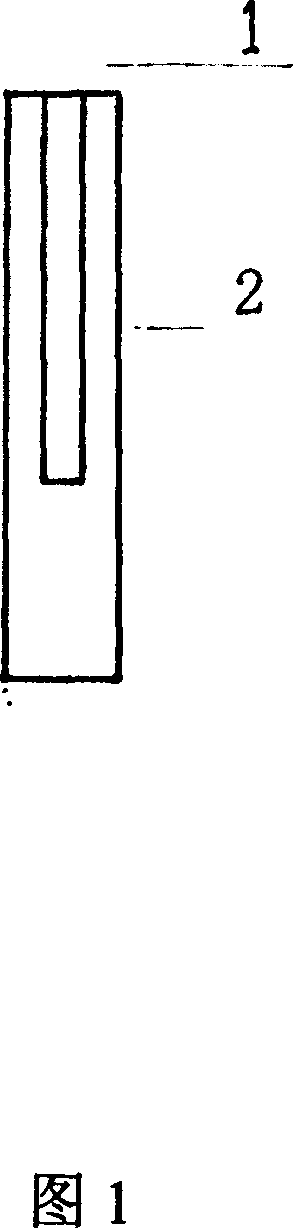

[0020] Fig. 1 is the pre-set strength core rammed soil-cement pile, which shows the structure of the pre-set strength-core rammed cement-soil pile, reflecting that the preset strength-core rammed cement-soil pile is composed of a rammed cement-soil pile and a strength core pile, Stiff piles are located in the rammed soil-cement pile core.

[0021] As shown in Fig. 1, the pre-set core rammed soil-cement pile of the present invention includes a rammed soil-cement pile. A cored pile is arranged in the body of the rammed soil-cement pile, and the pile length of the cored pile is greater than or equal to two-thirds of the length of the soil-cemented pile with a preset core. The pile top area of the core pile is greater than or equal to 20% of the pile top area of the core tamped cement-soil pile. Core piles are prefabricated piles with circular, circular or square c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com