Method for construction of large head expanding combined pile

A construction method and technology of combined piles, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of increased project cost, low single pile bearing capacity, waste, etc., to reduce project cost and improve single pile bearing capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and specific embodiment, the construction method of big-end expanding-diameter composite pile of the present invention is described in further detail:

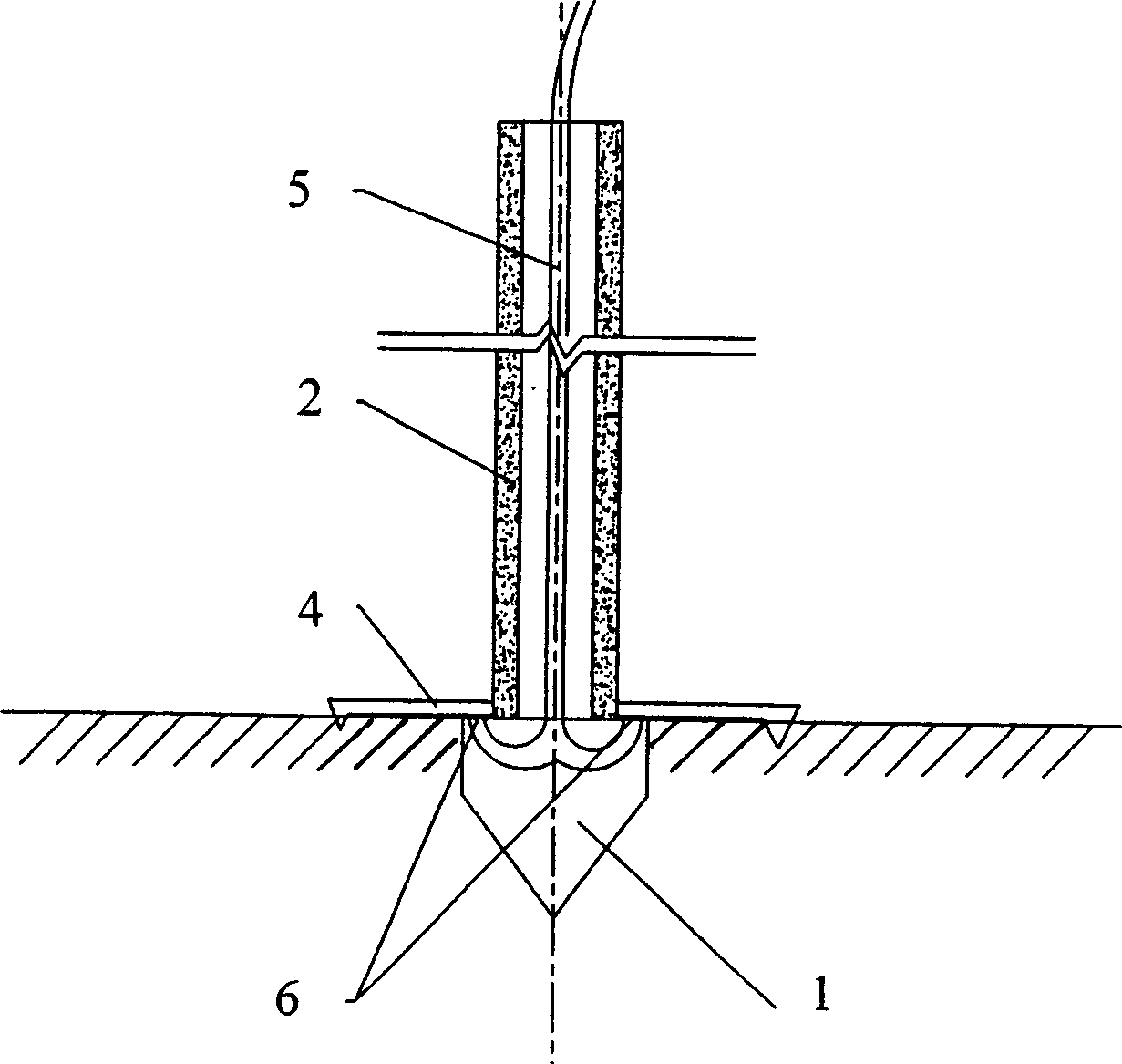

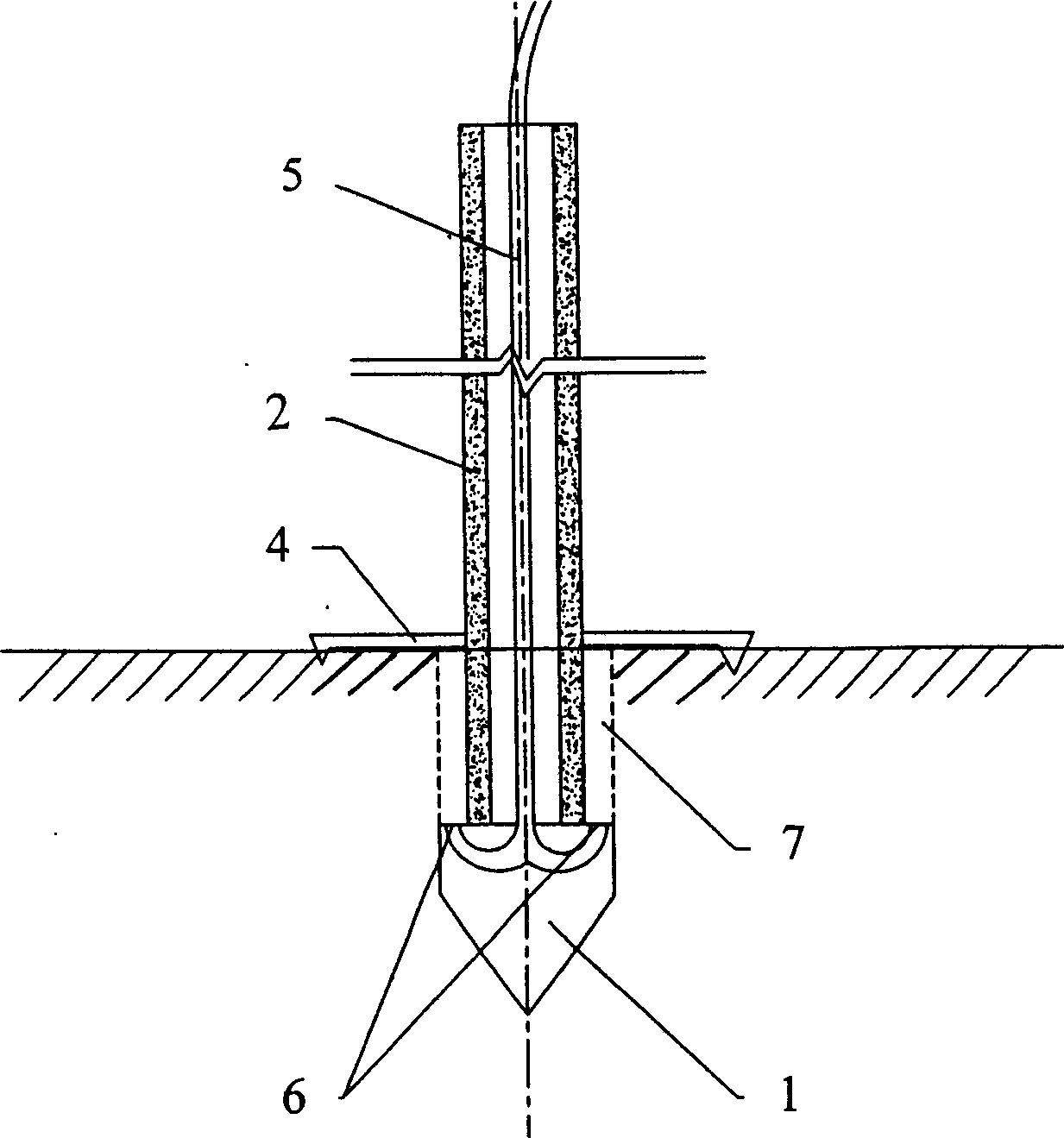

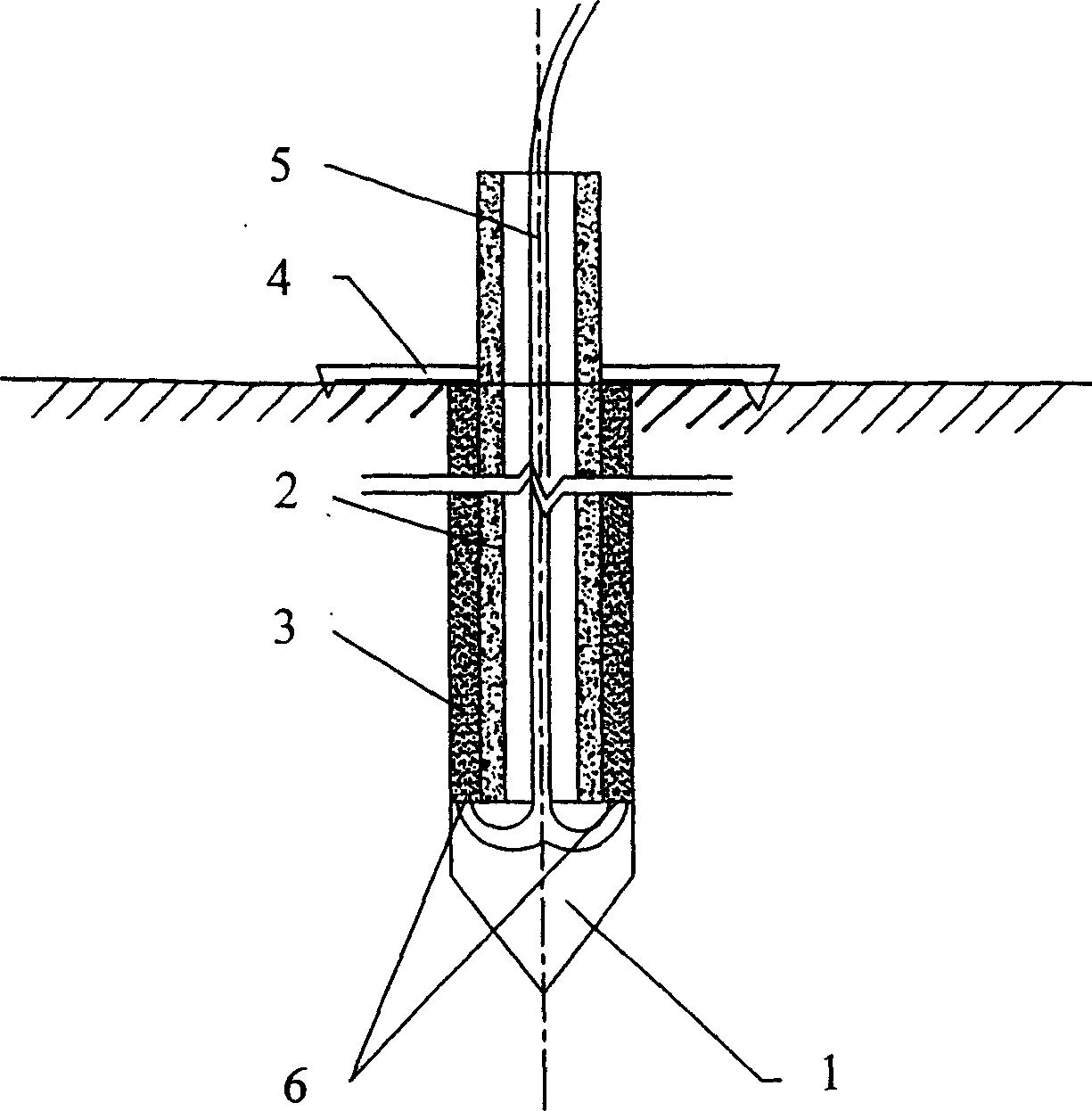

[0024] Such as figure 1 , 2 , 3, 4, 5, and 6, the present invention uses the hollow core pile 2 used as the pile foundation to bear the upper load as the pile sinking tool, and the diameter of the pile tip cylinder part at the lower end of the core pile 2 is larger than the diameter of the core pile The pile tip 1 is used as the expansion head, and a cover is added around the core pile 2 on the ground, which can cover and seal the formed annular pile hole 3, so that the filler in the annular pile hole 3 will not overflow. Capping 4, conduit 5 is located in the middle hole of core pile 5, concrete steps are as follows:

[0025] a. According to the parameters provided by the geological report, under the premise of meeting the single pile bearing capacity, pile foundation lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com