Thick steel for supporting nuclear steam generator and production method of thick steel

A steam generator and thick gauge technology, which is applied to the support steel and production field of thick gauge nuclear power steam generators, can solve the problems such as whether the performance of the steel plate not involved in the rolling process can meet the requirements, etc., and achieves segregation and inclusions in the core Improvement in grade reduction, reduction in production cost, effect of high strength level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

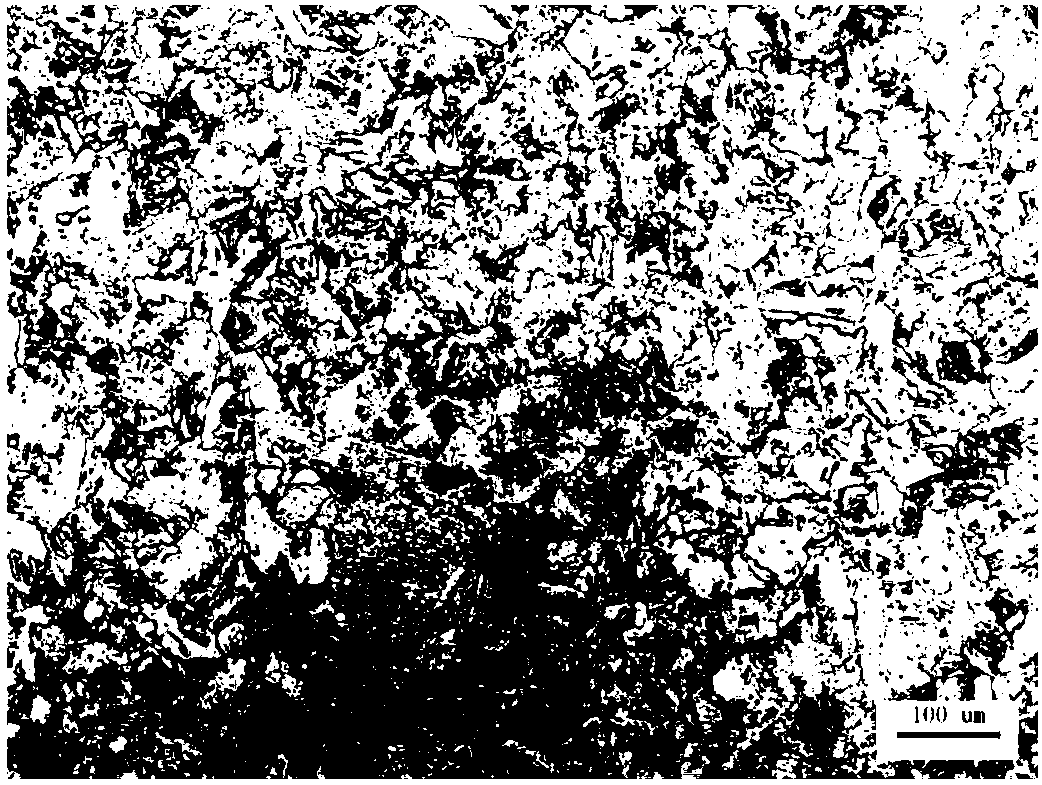

Image

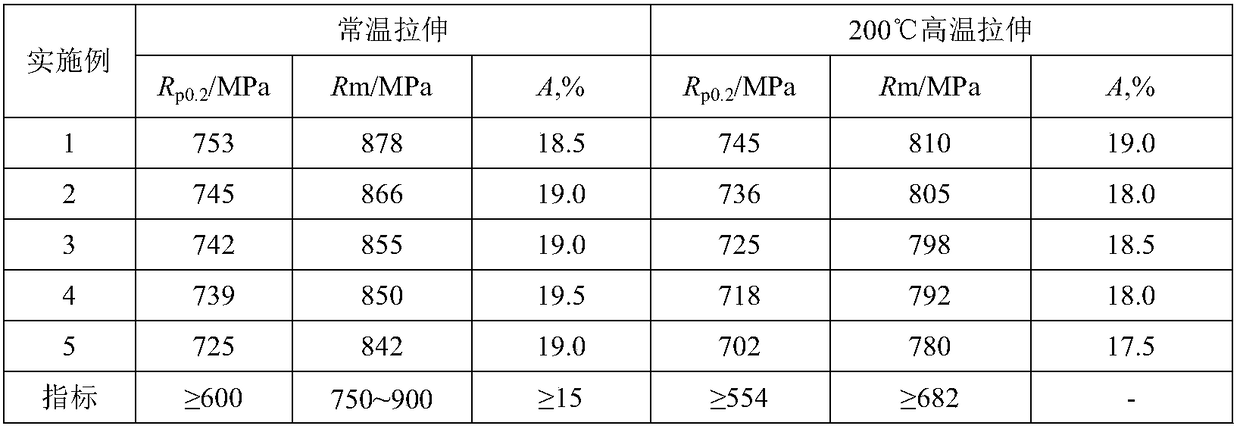

Examples

Embodiment Construction

[0041] The present invention will be described in detail below in conjunction with the accompanying drawings, but it should be pointed out that the implementation of the present invention is not limited to the following embodiments.

[0042] Steel for support of nuclear power steam generator in thick gauge contains the following chemical composition by weight percentage:

[0043] C 0.14%~0.20%, Si 0.25%~0.40%, Mn 0.30%~0.40%, P≤0.008%, S≤0.002%, Mo 0.30%~0.60%, Ni 1.20%~2.00%, Cr 0.80%~1.50 %, V 0.01% to 0.03%, Al 0.015% to 0.030%, and the rest are Fe and unavoidable impurities.

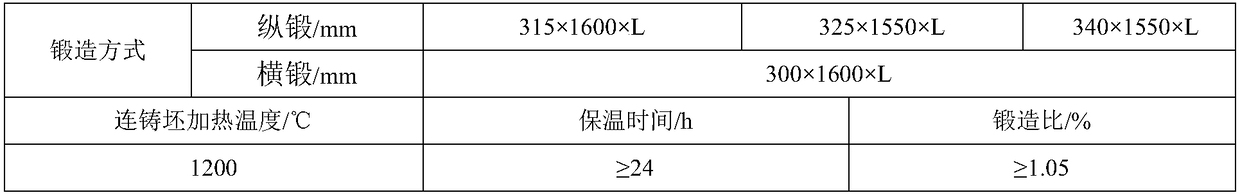

[0044] The production method of steel for support of nuclear power steam generator with thick specification comprises the following steps:

[0045] 1) Smelting:

[0046] Steel plate with a thickness of 80-120mm is continuously cast by converter: low P and low S molten iron is selected, P≤0.07% S≤0.03% in molten iron; LF furnace makes white slag to refine molten steel to ensure that [S]≤0.003% in st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com