Friction stir welding method of medium plate AZ AZ1 magnesium alloy

A technology of friction stir and welding methods, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of immature welding process, etc., and achieve the effect of beautiful shape, good welding and good fusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

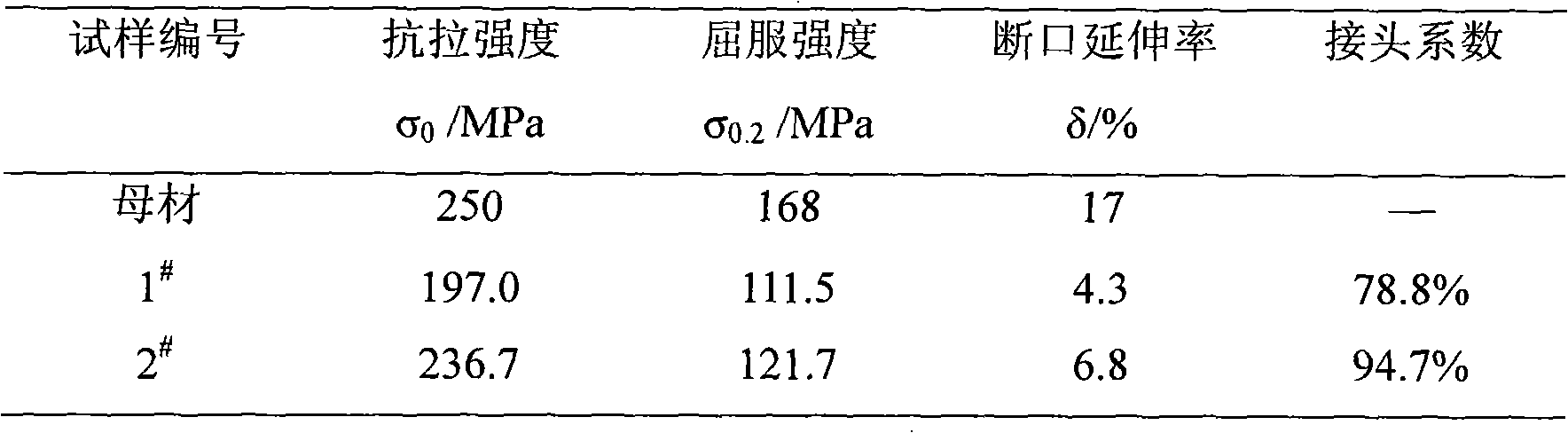

[0011] Friction stir welding of 10 mm thick AZ31 magnesium alloy sheets. Butt the two 10mm thick AZ31 magnesium alloy plates to be welded, rigidly fix them on the back pad, select the welding process parameters: the diameter of the stirring head shaft shoulder is 28mm, the root diameter of the stirring needle is 10.3mm, and the diameter of the stirring needle end is 7.8mm mm, the length of the stirring needle is 9.6mm; the welding inclination angle of the stirring head is 2.5°, the downward pressure is 0.1mm, the rotation speed is 800r / min, and the welding speed is 200mm / min. During welding, the stirring head rotates at high speed and presses into the workpiece along the butt surface of the workpiece until the shaft shoulder of the stirring head is in close contact with the workpiece; Stirring is aimed at the stirring and friction of the workpiece, causing the material in front of the stirring head to undergo strong plastic deformation. With the movement of the stirring head, ...

Embodiment 2

[0013] Friction stir welding of 10 mm thick AZ31 magnesium alloy sheets. Butt the two 10mm thick AZ31 magnesium alloy plates to be welded, rigidly fix them on the back pad, select the welding process parameters: the diameter of the stirring head shaft shoulder is 28mm, the root diameter of the stirring needle is 10.3mm, and the diameter of the stirring needle end is 7.8mm, the length of the stirring needle is 9.6mm; the welding inclination angle of the stirring head is 2.5°, the pressing amount is 0.1mm, the rotation speed is 800r / min, and the welding speed is 100mm / min. During welding, the stirring head rotates at high speed and presses into the workpiece along the butt surface of the workpiece until the shaft shoulder of the stirring head is in close contact with the workpiece; Stirring is aimed at the stirring and friction of the workpiece, causing the material in front of the stirring head to undergo strong plastic deformation. With the movement of the stirring head, the h...

Embodiment 3

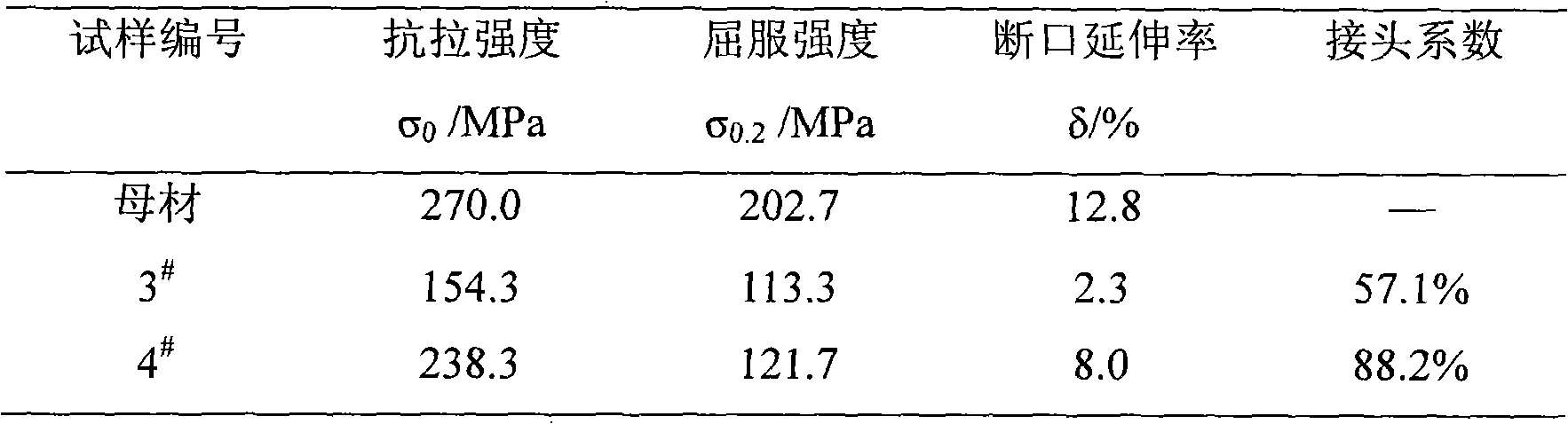

[0015] Friction stir welding of 20mm thick AZ31 magnesium alloy sheets. Butt the two 20mm thick AZ31 magnesium alloy plates to be welded, rigidly fix them on the back pad, select the welding process parameters: the diameter of the shoulder of the stirring head is 35mm, the diameter of the root of the stirring needle is 15.1mm, and the diameter of the end of the stirring needle is 9.3mm mm, the length of the stirring needle is 19.5mm; the welding inclination angle of the stirring head is 3°, the downward pressure is 0.2mm, the rotation speed is 1100r / min, and the welding speed is 150mm / min. During welding, the stirring head rotates at a high speed and the butt surface of the workpiece is pressed into the workpiece until the shoulder of the stirring head is in close contact with the workpiece; Stirring is aimed at the stirring and friction of the workpiece, causing the material in front of the stirring head to undergo strong plastic deformation. With the movement of the stirring...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com