Prestressed concrete hollow square pile and production method thereof

A technology of hollow square piles and concrete, which is applied to sheet pile walls, buildings, and foundation structure engineering, etc., can solve problems such as large stress loss of steel bar skeleton, poor roll welding of main bars and stirrup bars, and uneven end faces of steel bar cages, etc., to achieve Good mechanical properties of pile body, good pile body integrity and high strength grade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The invention will be further described below in conjunction with the description of the accompanying drawings and specific embodiments:

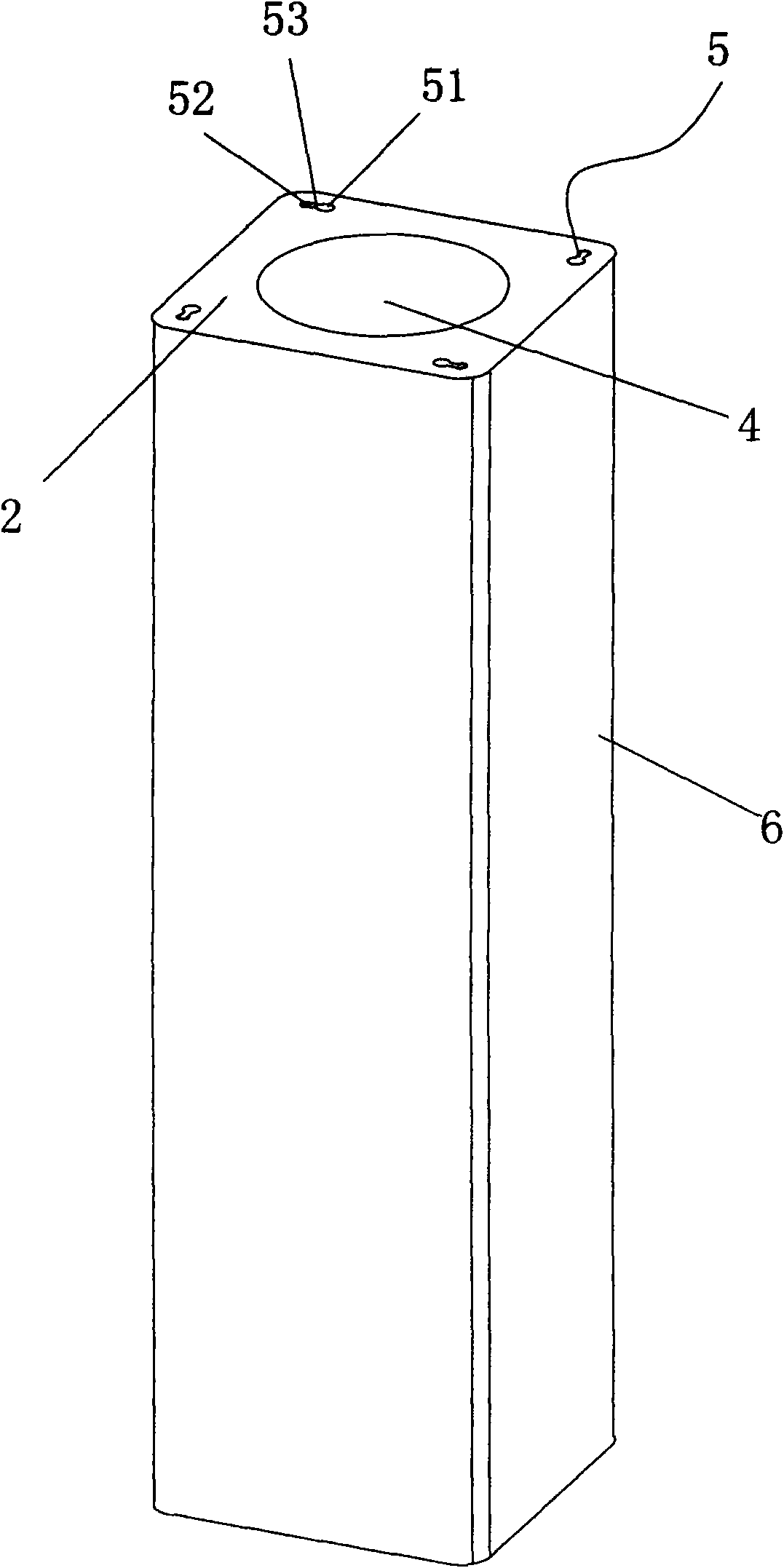

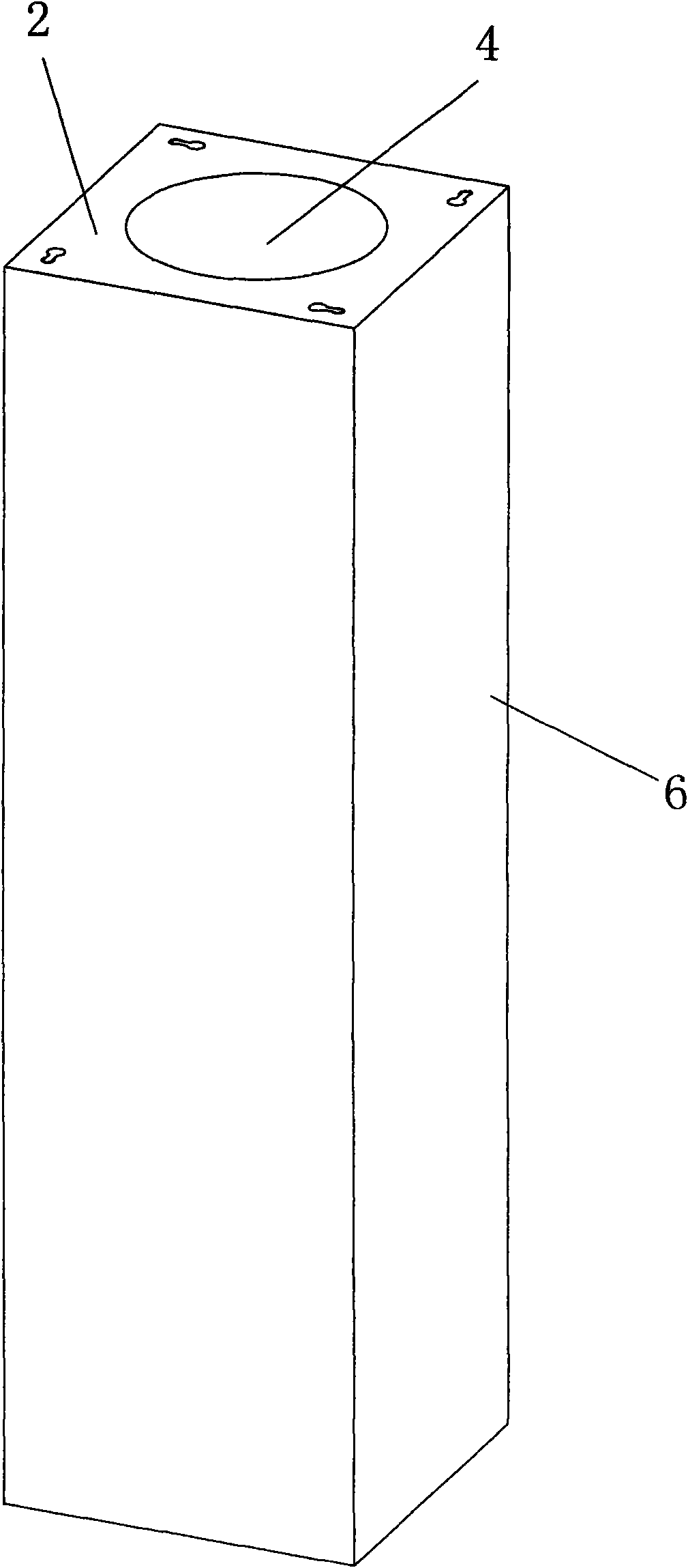

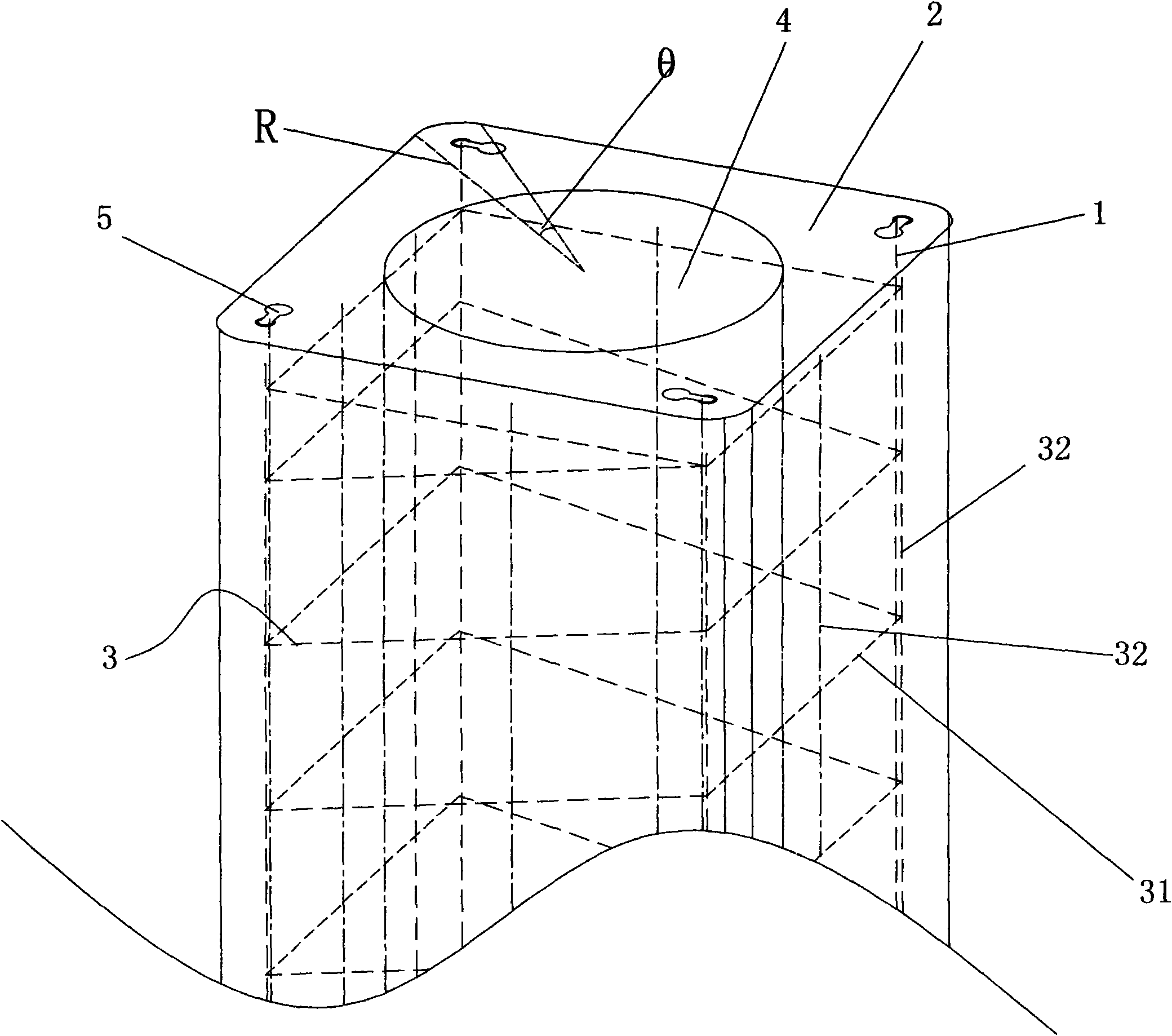

[0040] Such as figure 1 and 10 The shown prestressed concrete hollow square pile includes a plurality of independent main steel bars 1, square end plates 2 are respectively fixedly connected to the two ends of the main steel bar 1, and the outer cover of the main steel bar 1 is provided with Reinforcement cage 3, described reinforcement cage 3 comprises spiral reinforcement 31, on described spiral reinforcement 31 welding has many auxiliary reinforcement bars 32, its length of described auxiliary reinforcement 32 is smaller than the length of main reinforcement 1, Concrete is poured outside the main steel bar 1 and the steel cage frame 3, and the square pile 6 that is combined with the main steel bar 1 and the steel cage frame 3 is formed. The central circular hole 4 of square pile body 6.

[0041] Such as Figure 5 and 6 As sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com