Slag tailing metal recovery system based on big data and recovery process method thereof

A recovery system and big data technology, applied in chemical instruments and methods, magnetic separation, solid separation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention in conjunction with the accompanying drawings, technical solutions in the embodiments of the present invention will be clearly and completely described, obviously, the described embodiments are merely part of embodiments of the present invention rather than all embodiments. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

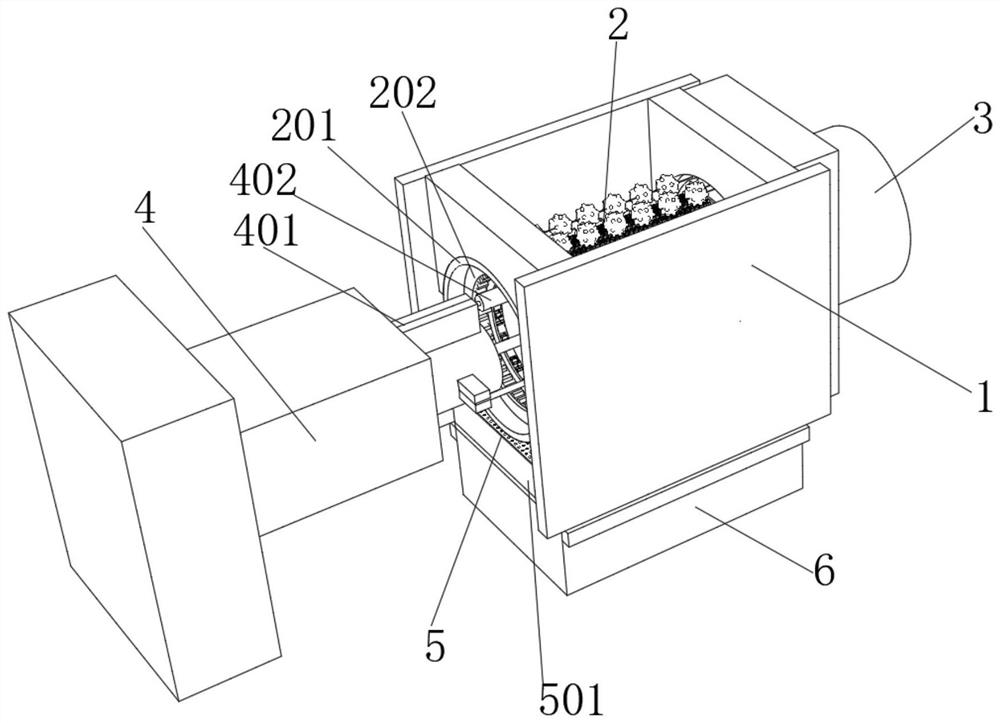

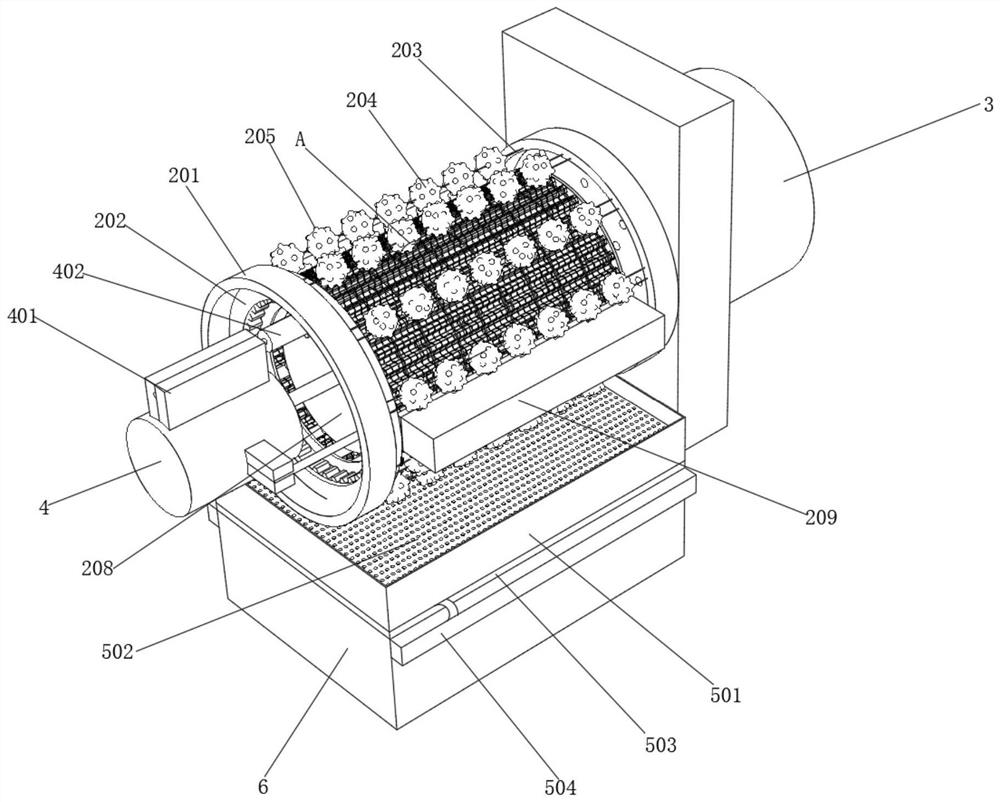

[0031] like Figure 1-7 Shown embodiment the present invention provides a metal slag tailings recycling system based on the large data, comprising a housing 1, magnetic means 2, 3, 4 telescopic drive means, screening means 5 supply means, a collecting box 6, the housing 1 with the central magnetic means 2, the left and right sides of the housing 2 is fixedly connected to a magnetic separation mechanism, the housing 1 is provided with the right air supply means 3, 3 through the left and right side of the housing 1 is fixedl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com