Method for extracting valuable elements from slag of melted high-iron high-silicon nonferrous metal

A technology of non-ferrous metals and valuable elements, applied in the field of metallurgical materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

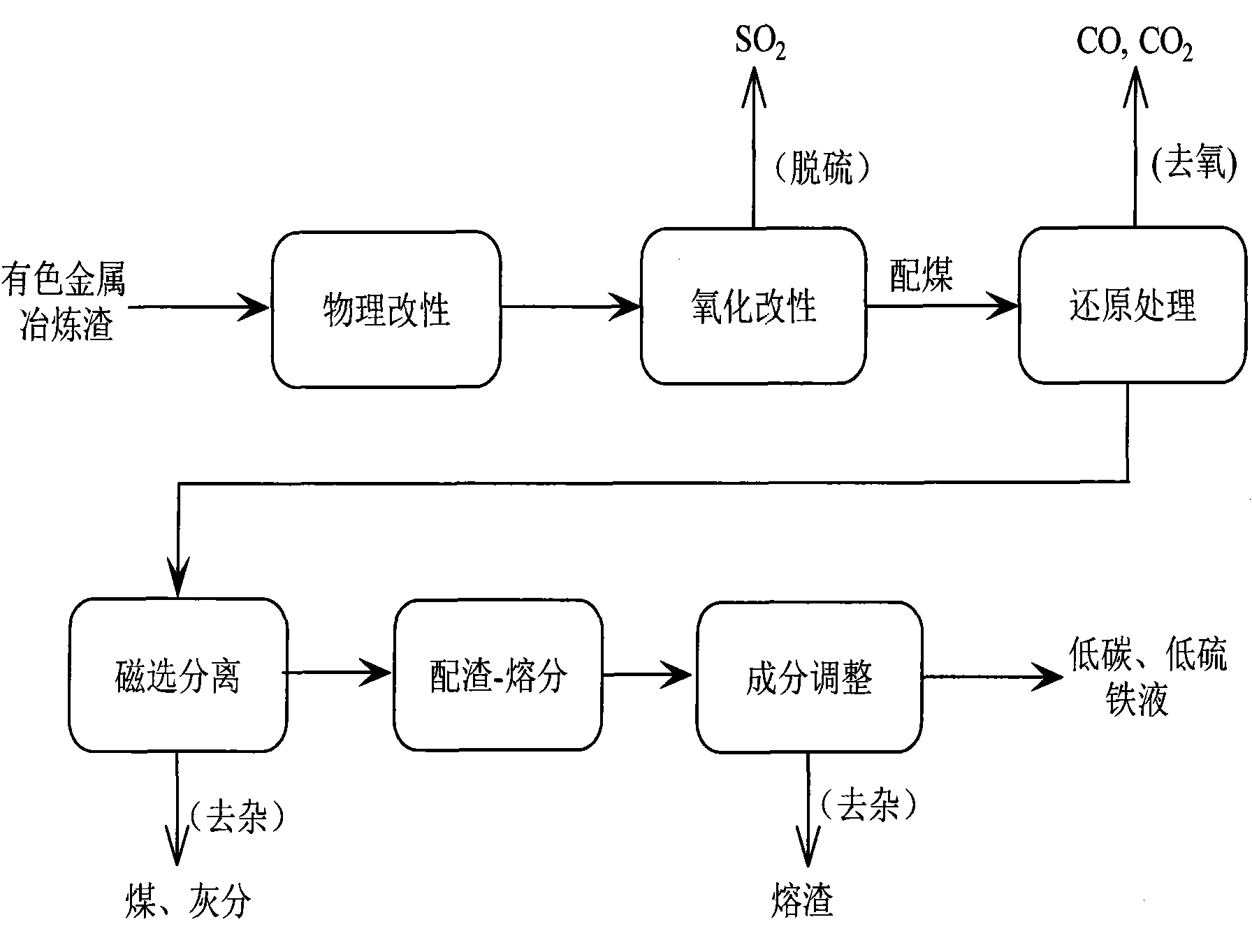

Method used

Image

Examples

Embodiment Construction

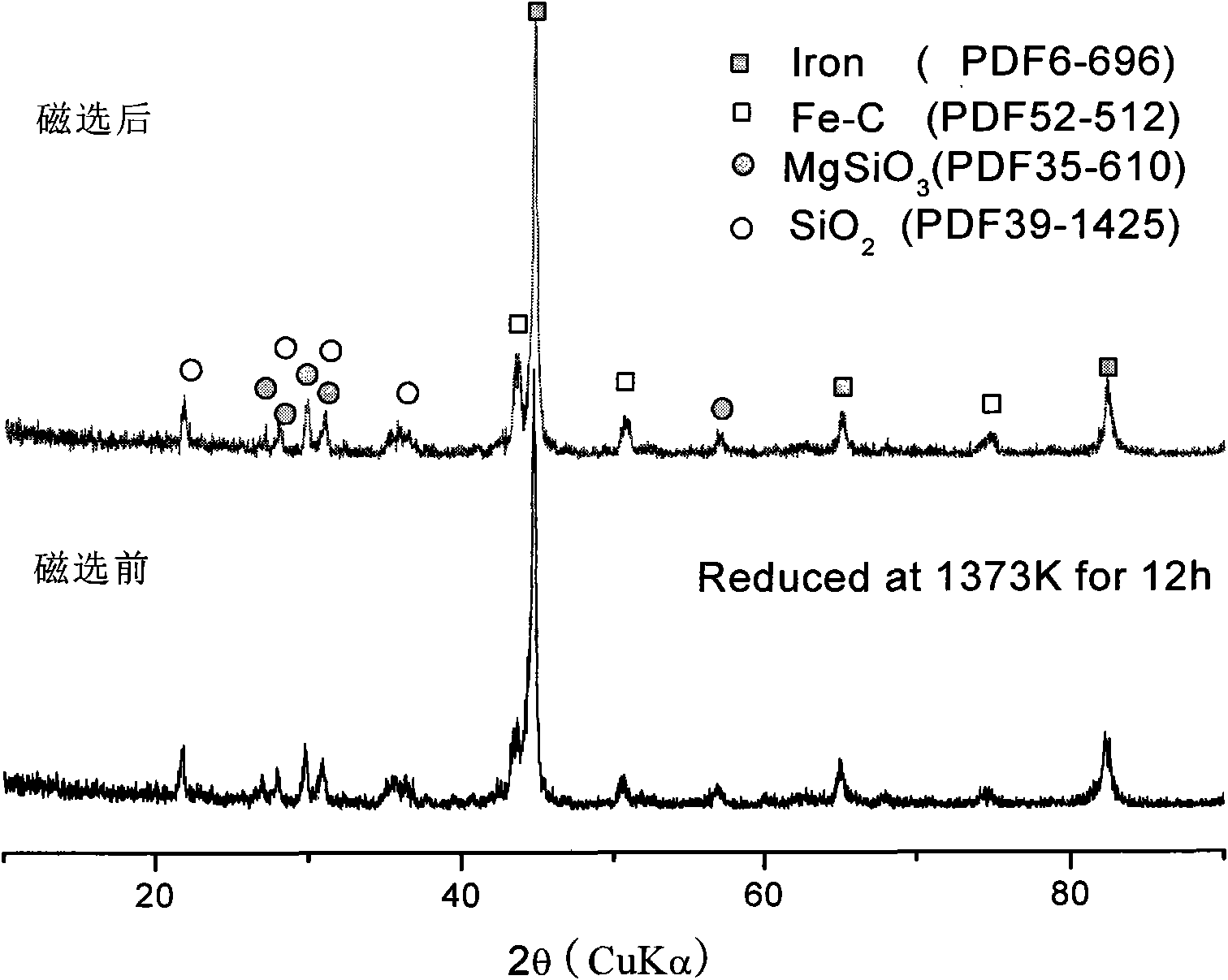

[0040] Choose a non-ferrous metal smelting slag, its chemical composition is shown in Table 1. Take 2kg of non-ferrous metal smelting slag, break it into a particle size smaller than 0.074mm for physical modification; put it into a φ120×160mm corundum crucible, pass air from the bottom at a flow rate of 1L / min in the resistance furnace, and carry out chemical modification at 1373K. The XRD curve after chemical modification for 5h, such as figure 2 As shown, it can be seen that fayalite is almost completely converted into hematite and quartz.

[0041] Take the non-ferrous smelting slag after chemical modification, grind and mix in the sample maker for 5 minutes after coal blending, the coal blending ratio is based on the theoretical oxygen content of valuable elements: carbon blending amount = 1: 1.1 (atomic ratio), and put it into φ120× Put the 160mm corundum crucible into the resistance furnace for reduction treatment. In order to prevent surface oxidation from burying a su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com