Method for preparing microwave absorbing material from red mud and coal gangue and application of microwave absorbing material

A microwave absorbing material, coal gangue technology, which is applied in application, ceramic material production, chemical instruments and methods, etc., can solve the problems of complex process, high cost, low utilization rate, etc., and achieves simple preparation process and enhanced microwave absorption performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

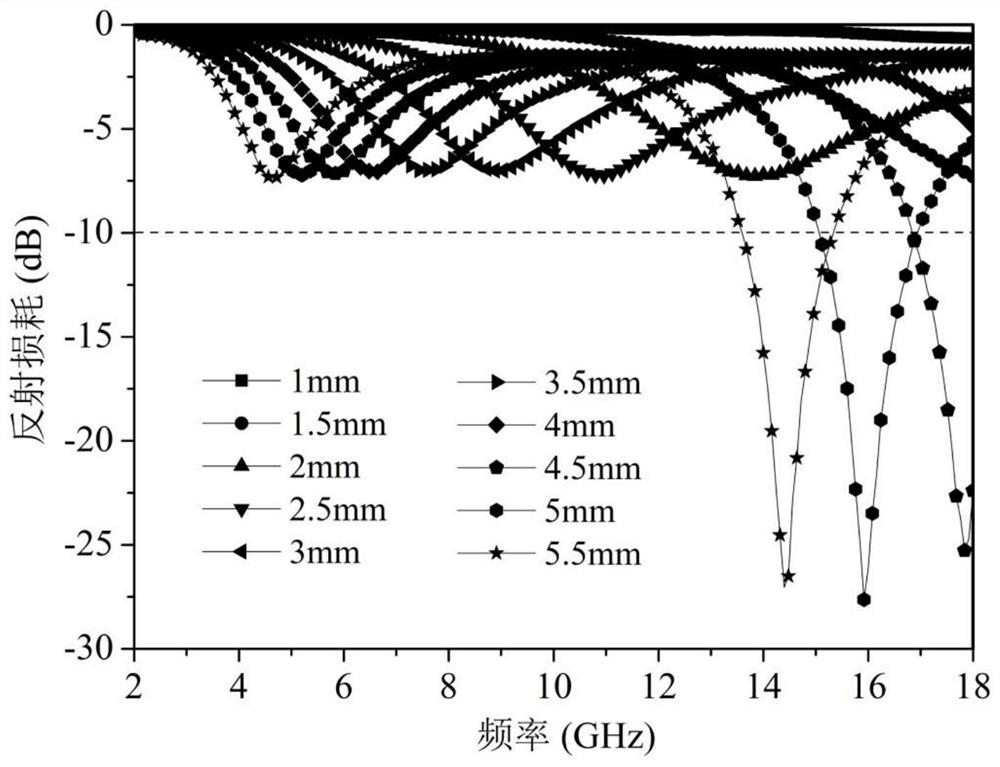

Image

Examples

Embodiment 1

[0027] A method for preparing a microwave absorbing material by utilizing red mud and coal gangue, comprising the following steps:

[0028] (1), the red mud slurry that produces in the factory production process is carried out pressure filtration treatment, and the filtrate after pressure filtration treatment is returned to factory as alkali source and continues to use, and the low moisture red mud mass (the weight percentage content of water is 22%) for dispersion treatment, and leave it for later use; wherein, the composition and weight percentage content of the active ingredient red mud in the red mud slurry are: 20wt% SiO 2 , 2wt% CaO, 20wt% Al 2 o 3 , 45wt% Fe 2 o 3 , 10wt%Na 2 O, 3wt%TiO 2 ;

[0029] (2), the coal gangue is crushed, ball milled, and then sieved through a standard sieve to obtain a coal gangue powder with a particle size of 150 meshes, which is reserved for later use; wherein, the composition of the coal gangue and its weight percentage content are:...

Embodiment 2

[0034] A method for preparing a microwave absorbing material by utilizing red mud and coal gangue, comprising the following steps:

[0035](1), the red mud slurry that produces in the factory production process is carried out pressure filtration treatment, and the filtrate after pressure filtration treatment is returned to factory as alkali source and continues to use, and the low moisture red mud mass (the weight percentage content of water is 20%) for dispersion treatment, and leave it for later use; wherein, the composition and weight percentage content of the active ingredient red mud in the red mud slurry are: 15wt% SiO 2 , 8wt% CaO, 25wt% Al 2 o 3 , 40wt% Fe 2 o 3 , 8wt%Na 2 O, 4wt%TiO 2 ;

[0036] (2), the coal gangue is crushed, ball milled, and then sieved through a standard sieve to obtain a coal gangue powder with a particle size of 200 meshes, which is reserved for later use; wherein, the composition and weight percentage of the coal gangue are: 40wt% SiO 2...

Embodiment 3

[0040] A method for preparing a microwave absorbing material by utilizing red mud and coal gangue, comprising the following steps:

[0041] (1), the red mud slurry that produces in the factory production process is carried out pressure filtration treatment, and the filtrate after pressure filtration treatment is returned to factory as alkali source and continues to use, and the low moisture red mud mass (the weight percentage content of water is 22%) for dispersion treatment, and leave it for later use; wherein, the composition and weight percentage content of the active ingredient red mud in the red mud slurry are: 20wt% SiO 2 , 2wt% CaO, 20wt% Al 2 o 3 , 45wt% Fe 2 o 3 , 10wt%Na 2 O, 3wt%TiO 2 ;

[0042] (2), the coal gangue is crushed, ball milled, and then sieved through a standard sieve to obtain a coal gangue powder with a particle size of 200 meshes, which is reserved for later use; wherein, the composition and weight percentage of the coal gangue are: 40wt% SiO ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com