Method for treating arsenic-containing waste acid by taking fayalite as in-situ iron source

A technology of fayalite and arsenic polluted acid, which is applied in the fields of filtration treatment, water/sewage treatment, chemical instruments and methods, etc., can solve the problems of toxic elements polluting the environment, expensive treatment costs, difficult treatment, etc., and achieves broad market prospects, The effect of reducing stockpile and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Example 1: The composition of fayalite in this example is shown in Table 1. The polluted acid comes from the sulfuric acid workshop of a zinc smelter in Southwest China, which contains a large amount of impurities such as arsenic, which is produced after washing the smelting flue gas. The main components are shown in the table 2 shown;

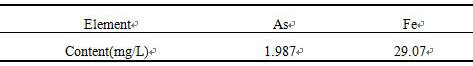

[0018] Table 1 Composition of Fayalite

[0019]

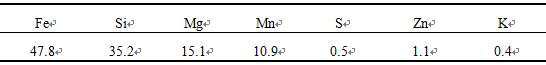

[0020] Table 2 Sewage Acid Components

[0021]

[0022] A method for treating arsenic-containing polluted acid with fayalite as an in-situ iron source, the specific steps are as follows:

[0023] (1) Mill fayalite for 11 minutes until the particle size is not greater than 45 μm to obtain fayalite powder; the milling speed is 760r / min, and the grinding time is 11 minutes;

[0024] (2) put H 2 o 2 Add it to the dirty acid and mix it evenly, then add the fayalite powder obtained in step (1) and mix it evenly, and stir at room temperature for pre-dissolution treatment for 6 hours t...

Embodiment 2

[0034] Example 2: The composition of fayalite in this example is shown in Table 5. The polluted acid comes from the sulfuric acid workshop of a zinc smelter in Southwest China, which contains a large amount of impurities such as arsenic, which is produced after washing the smelting flue gas. The main components are shown in the table as shown in 6;

[0035] Table 5 Composition of Fayalite

[0036]

[0037] Table 6 Sewage Acid Components

[0038]

[0039] A method for treating arsenic-containing polluted acid with fayalite as an in-situ iron source, the specific steps are as follows:

[0040] (1) Mill fayalite for 8 minutes until the particle size is not greater than 45 μm to obtain fayalite powder; the milling speed is 910r / min, and the grinding time is 8 minutes;

[0041] (2) put H 2 o 2 Add it into the dirty acid and mix evenly, then add the fayalite powder obtained in step (1) and mix evenly, and stir at room temperature for pre-dissolution treatment for 2 hours t...

Embodiment 3

[0051] Example 3: The composition of fayalite in this example is shown in Table 9. The dirty acid comes from the sulfuric acid workshop of a zinc smelter in Southwest China, which contains a large amount of impurities such as arsenic, which is produced after washing the smelting flue gas. The main components are shown in the table as shown in 10;

[0052] Table 9 Fayalite Composition

[0053]

[0054] Table 10 Sewage Acid Components

[0055]

[0056] A method for treating arsenic-containing polluted acid with fayalite as an in-situ iron source, the specific steps are as follows:

[0057](1) Mill fayalite for 9 minutes until the particle size is not greater than 45 μm to obtain fayalite powder; the ball milling speed is 850r / min, and the grinding time is 9.5 minutes;

[0058] (2) put H 2 o 2 Add to the dirty acid and mix evenly, then add the Tanggula powder obtained in step (1) and mix evenly, and stir at room temperature for pre-dissolution treatment for 2 hours to o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com