Technique for processing high-iron-carbonate mixed ore

A mixed-type, high-carbonic acid technology, applied in the field of mineral processing technology, can solve the problems of not being able to obtain qualified iron concentrate that meets the smelting requirements, and can not eliminate the capping effect of iron carbonate on hematite, so as to achieve low environmental pollution and simple process flow Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

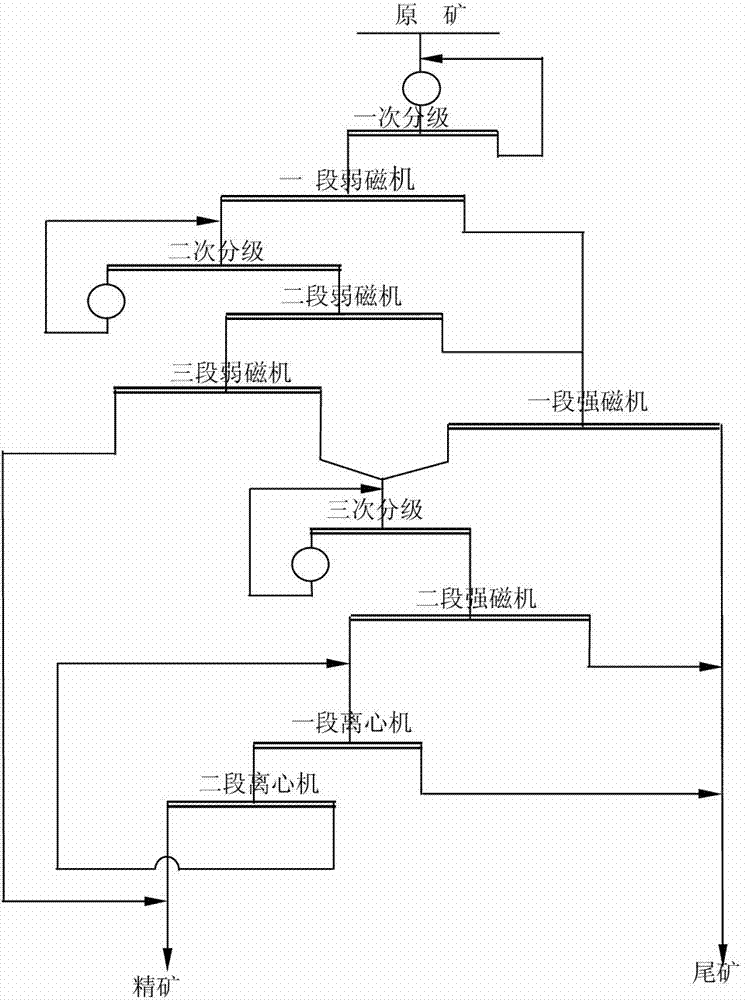

[0016] like figure 1 Shown, the technology of processing high carbonate mixed type ore of the present invention is characterized in that adopt stage grinding, weak magnetic-strong magnetic-centrifuge technology, carry out grinding separately to separate high carbonate mixed type ore, specifically Proceed as follows:

[0017] a) Stage grinding: The raw ore is crushed to <12mm and sent to the primary ball mill and the primary cyclone for classification to form a closed-circuit grinding. Grind until the first-stage classification overflow has a -200 mesh particle size content of 60%-70%, and the primary cyclone The graded overflow is fed into a field weakening machine;

[0018] b) The concentrate of the first-stage magnetic field weakening machine is fed into the secondary cyclone for classification, and it is classified into two kinds of m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com