Method for treating hazardous wastes

A technology of hazardous waste and flue gas treatment system, applied in the field of industrial waste treatment, can solve the problems of large floor space and complex hazardous waste treatment process, and achieve the effects of small floor space, improved recovery rate and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

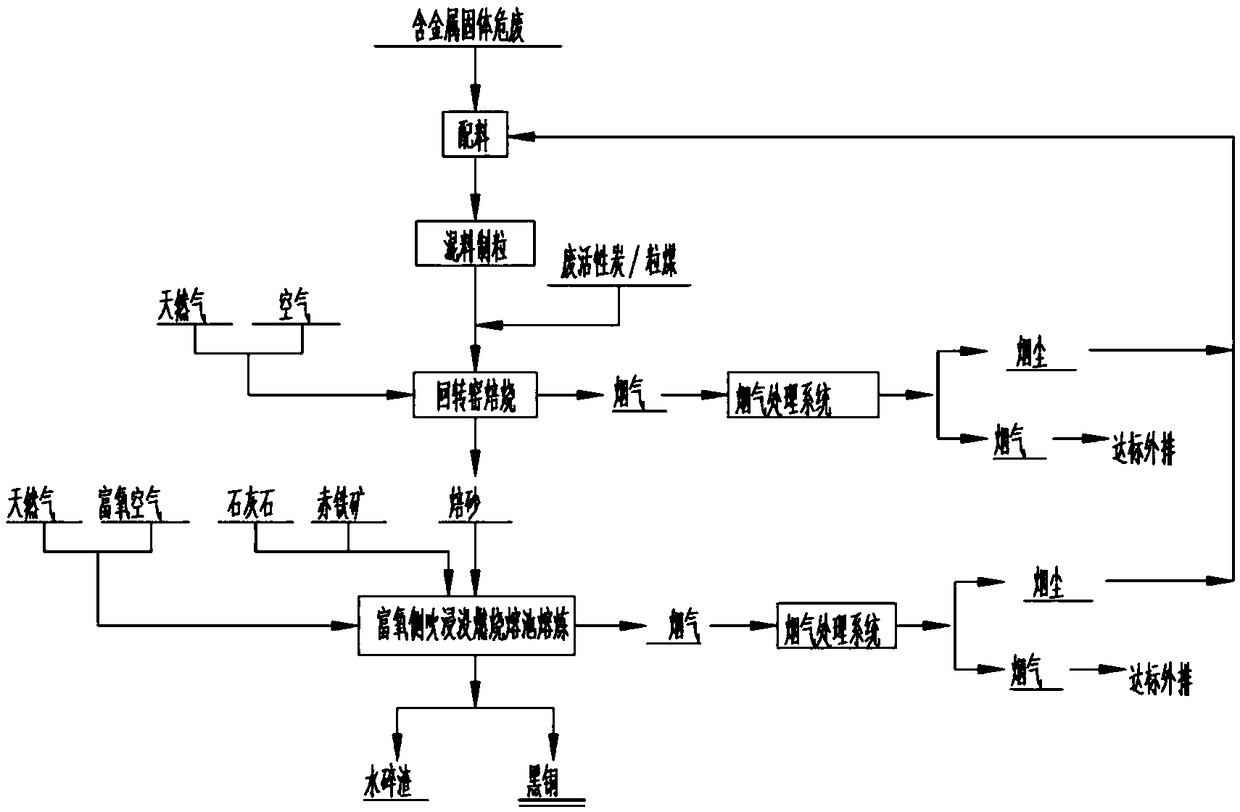

[0044] 1. The process scheme is as follows (see figure 1 ):

[0045] Solid hazardous waste materials containing heavy metal sludge, soot, residue, spent catalysts (referred to as solid hazardous waste containing metal), after batching, enter the disc granulator for granulation (or mixing machine for mixing), and the prepared granules (or mixed materials) and waste activated carbon are mixed in proportion and then sent to the rotary kiln. The rotary kiln uses granular coal as auxiliary fuel, and the granular coal is sprayed into the rotary kiln by a spray gun. The free water and crystal water are removed from the material in the rotary kiln, and calcined and decomposed. The calcined material at 800°C is discharged from the kiln head, and then transported to the side-blown submerged combustion bath melting furnace by means of hot charging and hot delivery.

[0046] A weakly reducing atmosphere is maintained in the rotary kiln, and the flue gas is fully burned in the secondary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com