Magnetic roasting system and process for powder of refractory iron ore

A technology of magnetized roasting and iron ore, which is applied in the field of roasting technology, can solve the problems that steam is difficult to be used effectively, the magnetized roasting plant is not practical, and it is difficult to find and use steam, etc., so as to achieve high heat utilization efficiency, reduce energy consumption, and improve efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

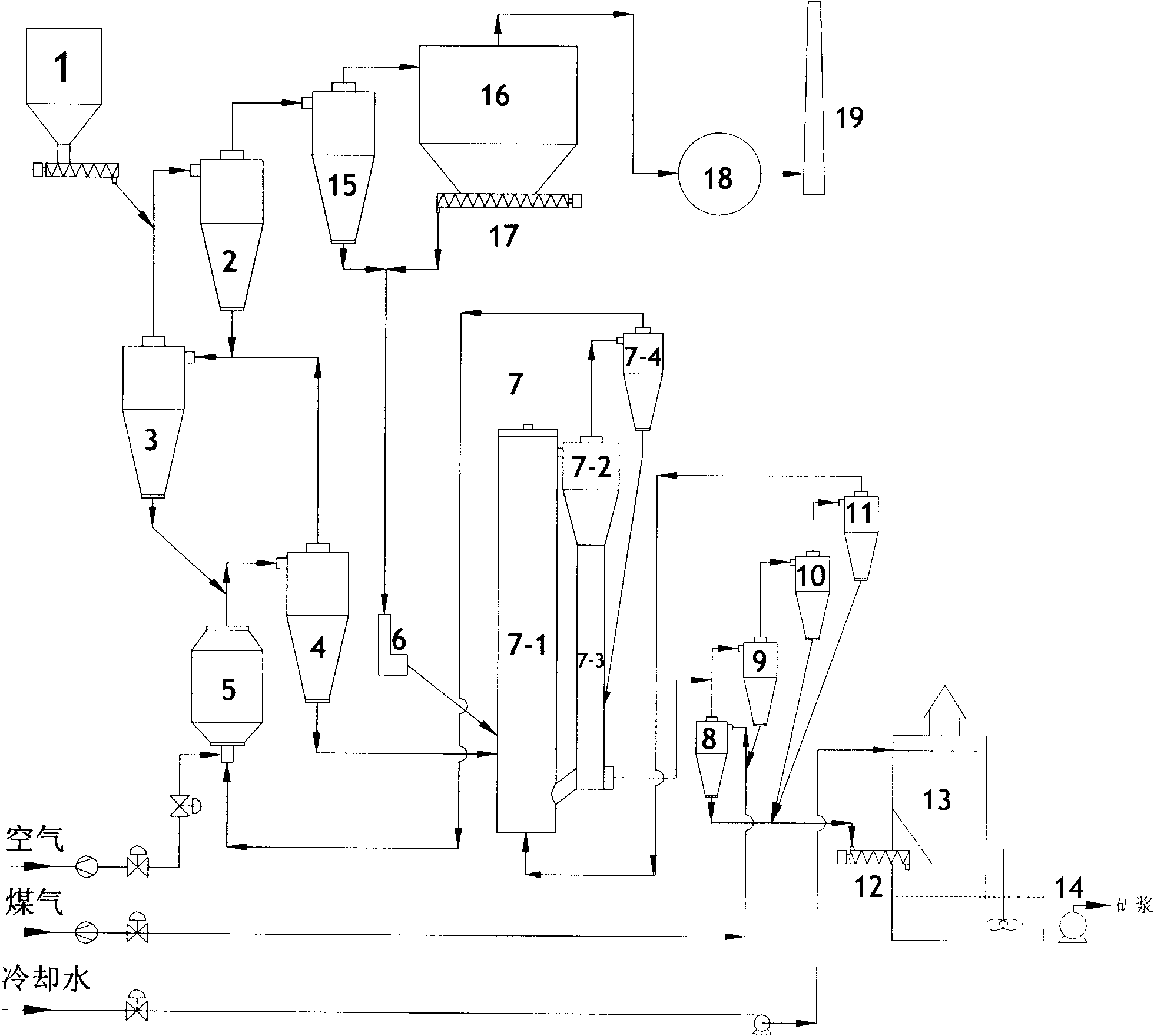

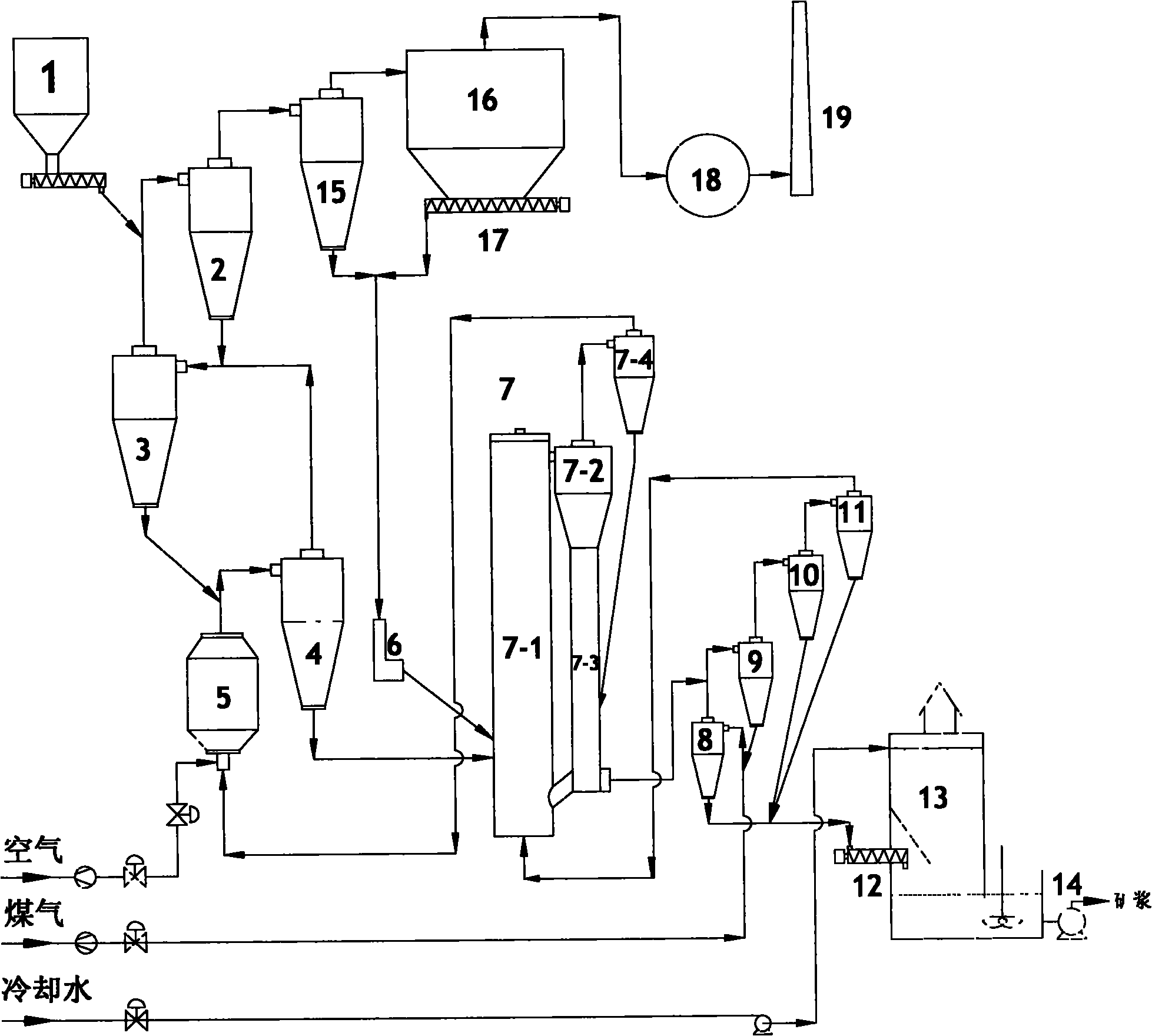

[0051] See figure 1 . Taking the magnetic roasting process of refractory iron ore powder as an example, the two-stage cyclone cooler is used. The system of magnetic roasting of refractory iron ore powder consists of a silo 1, including a first-stage cyclone preheater 2, and a second-stage cyclone preheater. Multi-stage cyclone preheater of device 3 and three-stage cyclone preheater 4, cyclone dust collector 15, bag dust collector 16, screw conveyor 17, combustion chamber 5, feeder 6, by riser 7-1, a A circulating fluidized bed reactor 7 composed of a first-stage cyclone separator 7-2, a material leg 7-3 and a second-stage cyclone separator 7-4, a first-stage cyclone cooler 9, a second-stage cyclone cooler 8, a preheated gas A first-stage cyclone dust collector 10, a preheated gas two-stage cyclone dust collector 11, a screw discharger 12, a roasted ore cooling tower 13, a slurry pump 14, an air fan, a gas compressor, an induced draft fan 18 and a chimney 19 are combined.

[...

Embodiment 2

[0070] For the magnetization roasting system of the refractory iron ore powder, the first-stage cyclone cooler can also be used to carry out the magnetization roasting of the refractory iron ore powder, and the magnetization roasting system and magnetization roasting of the refractory iron ore powder The process is basically the same as in Example 1, except that when the first-stage cyclone is used for cooling, the inlet of the first-stage cyclone cooler 9 is connected with the outlet of the lower part of the material leg 7-3 and the outlet of the gas compressor through the pipeline respectively. The air port is connected, the gas outlet of the primary cyclone cooler 9 is connected with the air inlet of the preheated gas primary cyclone dust collector 10 through the pipeline, and the discharge port of the lower part of the primary cyclone cooler is connected with the screw discharger 12 through the pipeline. The feeding port is connected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com