Rare earth nitride dispersion strengthened titanium-doped copper alloy and preparation method thereof

A rare earth nitride and dispersion strengthening technology is applied in the field of copper-titanium alloys, which can solve the problems of inhomogeneous distribution of titanium powder particles, cumbersome processes, and reduced mechanical properties of alloy materials, and achieves high electrical conductivity and thermal conductivity. Wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] This embodiment is a rare earth nitride dispersion strengthened titanium-doped copper alloy, the copper alloy is composed of copper, rare earth nitride and titanium; the mass percentage of each component in the copper alloy is: copper: 71.2%, rare earth nitride: 6.4% , the balance is titanium.

[0049] Rare earth nitride is uniformly mixed with cerium nitride powder particles, yttrium nitride powder particles and lanthanum nitride powder particles of the same mass and diameter less than 0.5um.

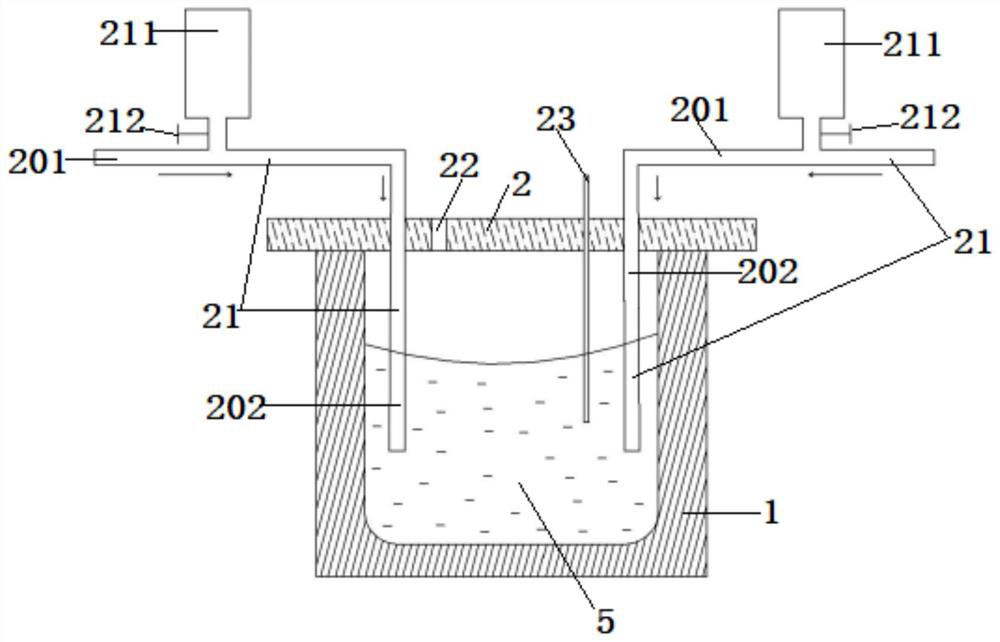

[0050] like figure 1 , figure 2 A method for preparing a rare earth nitride dispersion-strengthened titanium-doped copper alloy as shown, includes a furnace body 1 with an open upper end, a cover plate 2 arranged on the furnace body, and two use In the air inlet pipe 21 ventilating into the furnace body, the stirrer arranged on the cover plate, the exhaust hole 22 and the temperature sensor 23 arranged on the cover plate; The vertical rotating shaft 32 extending downward, th...

Embodiment 2

[0070] The mass percentage of each component in the copper alloy in this embodiment is: 70% of copper ingot, 4.3% of rare earth nitride particles, and 25.7% of titanium powder. The mechanical stirring temperature was 1175°C; the degassing temperature was 840°C, and the treatment time was 3.5h;

Embodiment 3

[0072] The mass percentage of each component in the copper alloy in this embodiment is as follows: the mass percentage of each component is: 80% of copper ingot, 1.7% of rare earth nitride particles, and 18.3% of titanium powder. The mechanical stirring temperature was 1200°C; the degassing temperature was 600°C, and the treatment time was 5h;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com