Method for preparing micro-wave dielectric adjustable strontium bismuth titanate film

A strontium bismuth titanate and microwave dielectric technology, applied in the direction of inorganic insulators, ceramics, etc., can solve the problems of high dielectric loss, film adjustable characteristics and quality factor reduction, etc., to achieve reduced dielectric loss, good market prospects, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

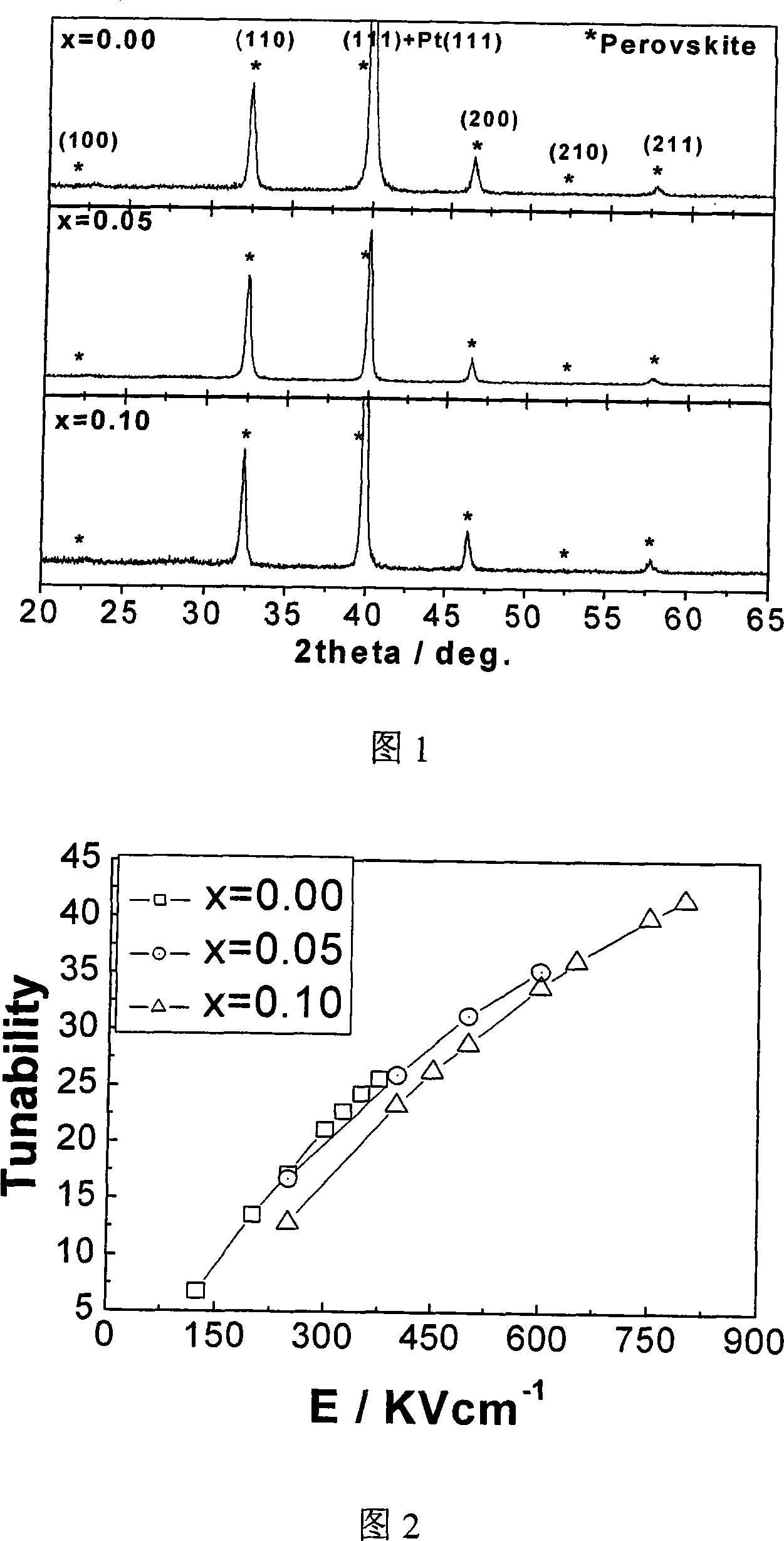

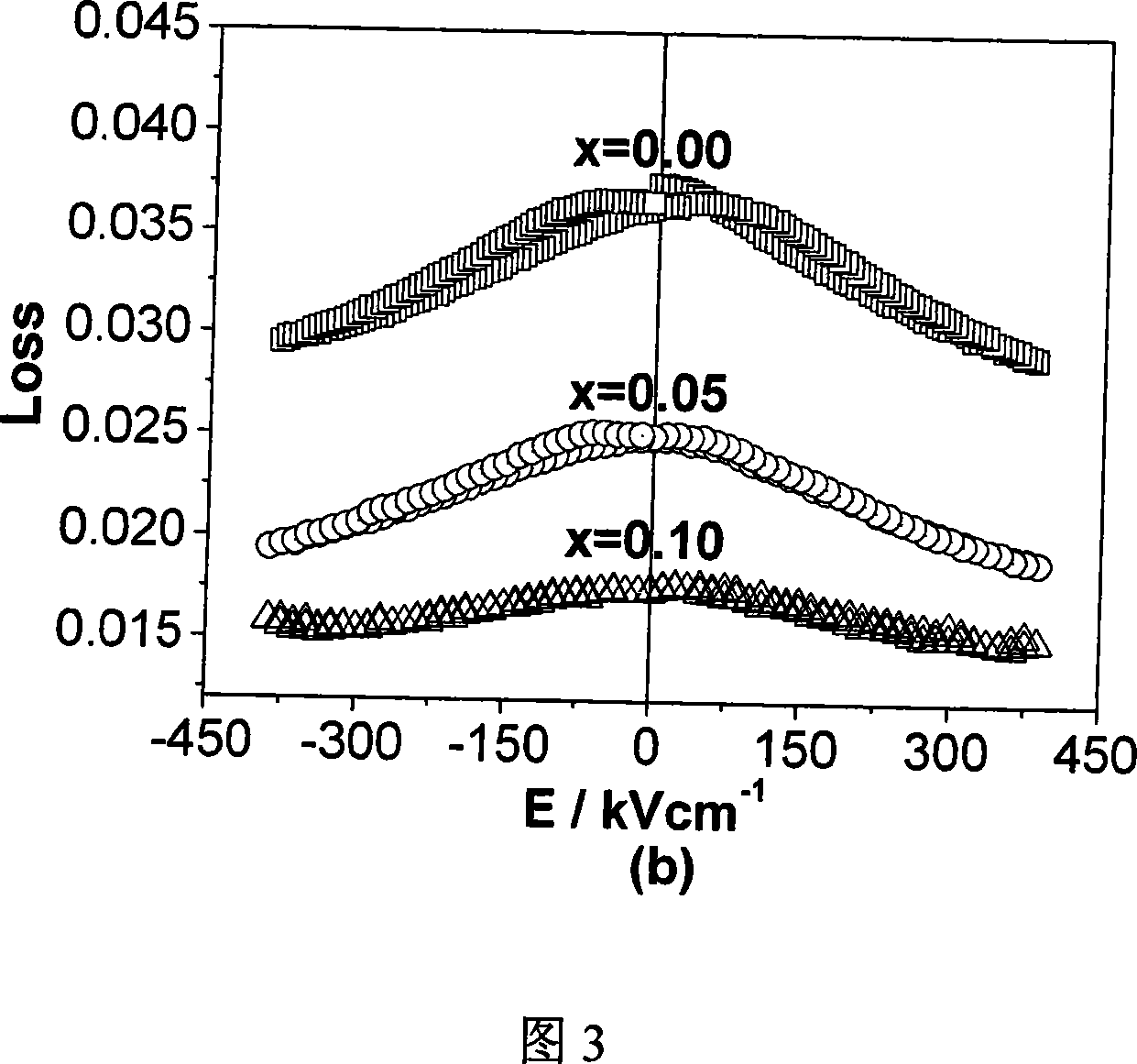

[0021] a. Weigh 0.7 grams of analytically pure bismuth nitrate and 5.95 grams of strontium acetate and dissolve them in 30ml of glacial acetic acid with full stirring at 80°C, and azeotrope at 120°C for 5 minutes to remove crystal water and part of the solvent. After cooling, 10.2 grams of titanium Tetrabutyl acetate and 6 grams of acetylacetone were mixed uniformly at a molar ratio of 1:2 and then added to the mixed solution of bismuth nitrate and strontium acetate. At the same time, 40ml of ethylene glycol ether was added and stirred at room temperature for 30 minutes to finally obtain a clear The concentration is 0.5mol / L, satisfying the stoichiometric ratio Bi 0.05 Sr 0.925 TiO 3 60ml of strontium bismuth titanate sol precursor;

[0022] b. Using the spin coating process, the obtained stable strontium bismuth titanate precursor solution is deposited on the sapphire substrate, and the film is homogenized at 3000 rpm for 25 seconds, and the obtained wet film is placed in a...

Embodiment 2

[0026] a. Weigh 0.485 grams of analytically pure bismuth nitrate and 3.972 grams of strontium acetate and dissolve them in 45ml of glacial acetic acid with full stirring at 80°C, and azeotrope at 120°C for 5 minutes to remove crystal water and part of the solvent. After cooling, 6.8 grams of titanium Tetrabutyl acetate and 4 grams of acetylacetone were mixed uniformly at a molar ratio of 1:2 and then added to the mixed solution of bismuth nitrate and strontium acetate, while adding 20ml of ethylene glycol ether and stirring at room temperature for 30 minutes to finally obtain clear The concentration is 0.4mol / L, satisfying the stoichiometric ratio Bi 0.05 Sr 0.925 TiO 3 50ml of strontium bismuth titanate sol precursor;

[0027] b, using spin coating process, the resulting stable strontium bismuth titanate precursor solution is deposited on the Pt plated substrate (Pt / Ti / SiO 2 / Si) at 3000 rpm for 25 seconds, and the obtained wet film was dried at 350° C. and annealed at 650...

Embodiment 3

[0031] a. Weigh 0.97g of analytically pure bismuth nitrate and 3.65g of strontium acetate and dissolve them in 48ml of glacial acetic acid with full stirring at 80°C, and azeotrope at 120°C for 5 minutes to remove crystal water and part of the solvent. After cooling, dissolve 6.8g of titanic acid Tetrabutyl ester and 4 grams of acetylacetone were mixed uniformly at a molar ratio of 1:2 and then added to the mixed solution of bismuth nitrate and strontium acetate. Simultaneously, 15ml of ethylene glycol ether was added and stirred at room temperature for 30 minutes to finally obtain clear The concentration is 0.4mol / L, satisfying the stoichiometric ratio Bi 0.1 Sr 0.85 TiO 3 50ml of strontium bismuth titanate sol precursor;

[0032] b, using spin coating process, the resulting stable strontium bismuth titanate precursor solution is deposited on the Pt plated substrate (Pt / Ti / SiO 2 / Si) at 3000 rpm for 25 seconds, and the obtained wet film was dried at 350° C. and annealed at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com