Preparation method of barium calcium zirconate titanate lead-free piezoelectric textured ceramic

A barium calcium zirconate titanate, lead-free piezoelectric technology, applied in the preparation of barium calcium zirconate titanate lead-free piezoelectric textured ceramics, textured barium calcium zirconate titanate ceramic materials and its preparation field, can solve the unfavorable Large-scale production and industrialization of materials, complex processes, expensive equipment, etc., to achieve good grain orientation, excellent performance, and improved piezoelectric coefficients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

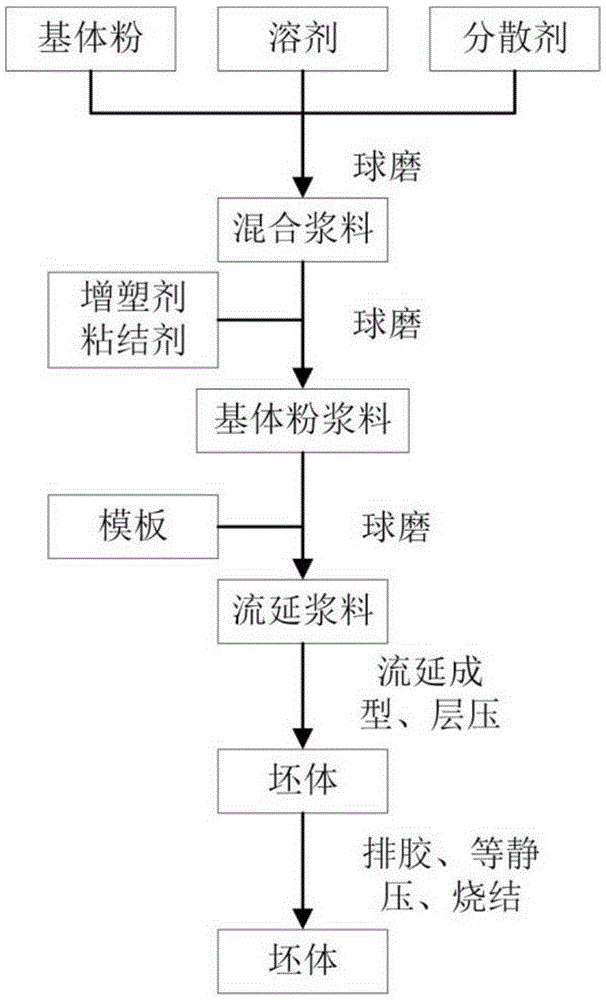

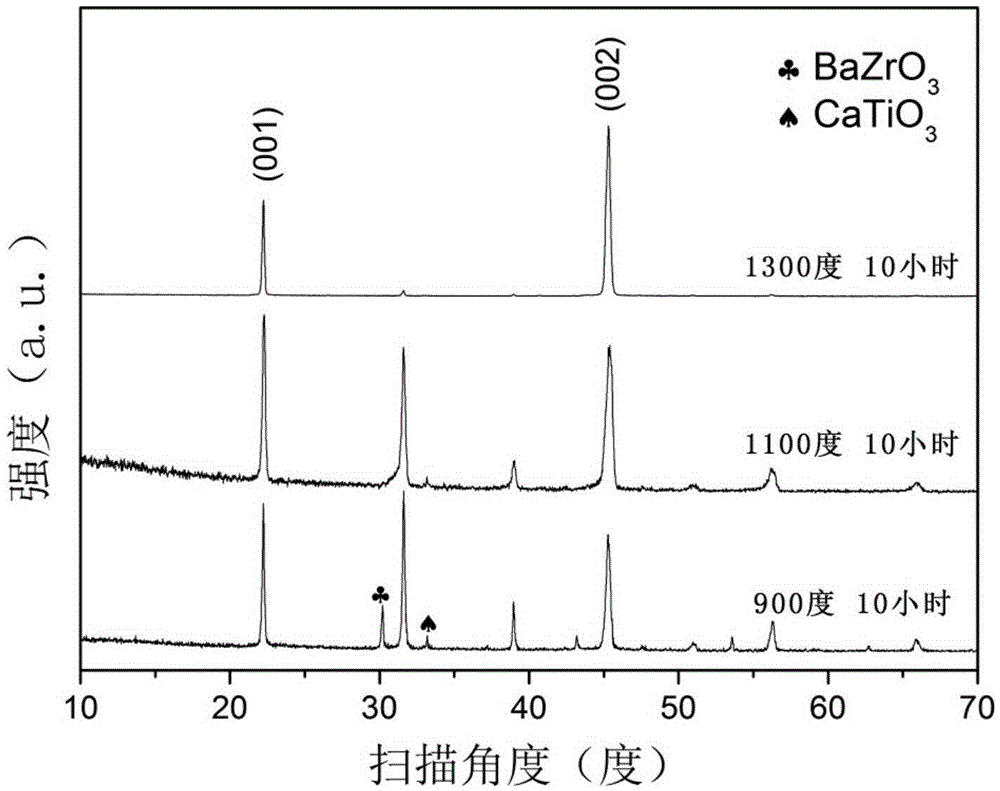

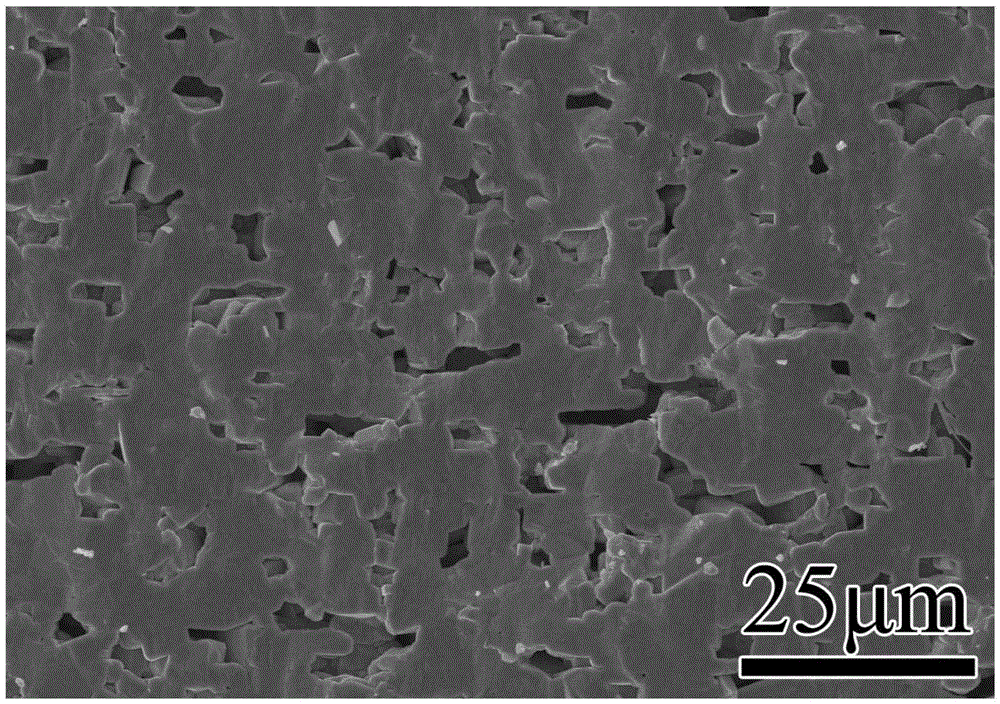

[0033] CaTiO 3 , BaZrO 3 , BaTiO 3 Powder, flaky BaTiO 3 Template according to molecular formula Ba 0.85 Ca 0.15 Ti 0.90 Zr 0.10 o 3 Dosing, where flaky BaTiO 3 The amount of template added is 0.30wt%; BaTiO will not be added 3 The matrix powder of the template is mixed with a solvent with a mass ratio of 1:0.82 (the solvent is a blend of ethanol and methyl ethyl ketone at a mass ratio of 2:3), and 2wt% dispersant polyvinyl alcohol is added, and the planetary ball mill is used for 4 hours; 1.5wt% Plasticizer polyethylene glycol 400, 2wt% plasticizer dibutyl phthalate, 4wt% binder polyvinyl alcohol, rolling ball mill for 24 hours; adding 0.30wt% flake BaTiO 3 The template is ball milled for 1 hour; the casting operation is performed with a tape casting machine, and cutting is performed after drying; then, the casting green sheet is laminated at a temperature of 70°C and a pressure of 100 MPa, and the laminated green sheet is cut and glued; After debinding, the green s...

Embodiment 2

[0035] CaTiO 3 , BaZrO 3 , BaTiO 3 Powder, flaky BaTiO 3 Template according to molecular formula Ba 0.85 Ca 0.15 Ti 0.90 Zr 0.10 o 3 Dosing, where flaky BaTiO 3 Template addition is 42wt%; BaTiO will not be added 3 The matrix powder of the template is mixed with a solvent with a mass ratio of 1:1 (the solvent is a blend of ethanol and methyl ethyl ketone at a mass ratio of 2:3), and 1wt% dispersant polyvinyl alcohol is added, and the planetary ball mill is used for 8 hours; 1.5wt% Plasticizer polyethylene glycol 400, 1wt% plasticizer dibutyl phthalate, 3wt% binder polyvinyl alcohol, rolling ball mill for 48 hours; adding 42wt% flake BaTiO 3 The template was ball milled for 3 hours; the cast operation was carried out with a tape casting machine, and then cut after drying; then the cast blank was laminated at a temperature of 80°C and a pressure of 80MPa, and the laminated blank was cut and glued; After debinding, the green sheet is isostatically pressed at room temper...

Embodiment 3

[0037] The green raw material obtained in this embodiment is BaCO 3 , CaCO 3 , ZrO 2 、TiO 2 Powder, flaky BaTiO 3 template, according to the formula Ba 0.85 Ca 0.15 Ti 0.90 Zr 0.10 o 3 Dosing, where flaky BaTiO 3 The added amount of the template is 42wt%; and sintered at 1500° C. for 5 hours, and the others are the same as in Example 2. The sintered dense sample is ground, polished and coated with silver, and its piezoelectric coefficient d is measured. 33 It is 483pC / N.

PUM

| Property | Measurement | Unit |

|---|---|---|

| piezoelectric charge coefficient | aaaaa | aaaaa |

| piezoelectric charge coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com