High-solid-solubility relaxation-type nano leadless piezoelectric ceramic and preparation method thereof

A lead-free piezoelectric and solubility technology, applied in the field of piezoelectric ceramics, can solve problems such as uneven grain size, insufficient powder purity, and abnormal growth of grains, and achieve dielectric constant, high dielectric constant, The effect of avoiding harm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] ①First follow Ba 0.8 Ca 0.2 Ti 0.9 Zr 0.1 o 3 The stoichiometric ratio, that is, the molar ratio is 0.8:0.2:0.1:0.9 to take BaCl 2 2H 2 O(s), CaCl 2 (s), ZrOCl 2 ·8H 2 O(s) and TiCl 4 (1) Dissolve in deionized water, mix after the four are completely dissolved, and let stand until the solution becomes transparent to obtain a mixed solution.

[0038] ② Add weighed NaOH solids to the above transparent mixed solution to adjust the acidity and alkalinity so that the pH value is > 14, stir in the air for 1 min until boiling, and obtain a milky white suspension after the boiling is over, which is Ba 0.8 Ca 0.2 Ti 0.9 Zr 0.1 o 3 Powder precursor.

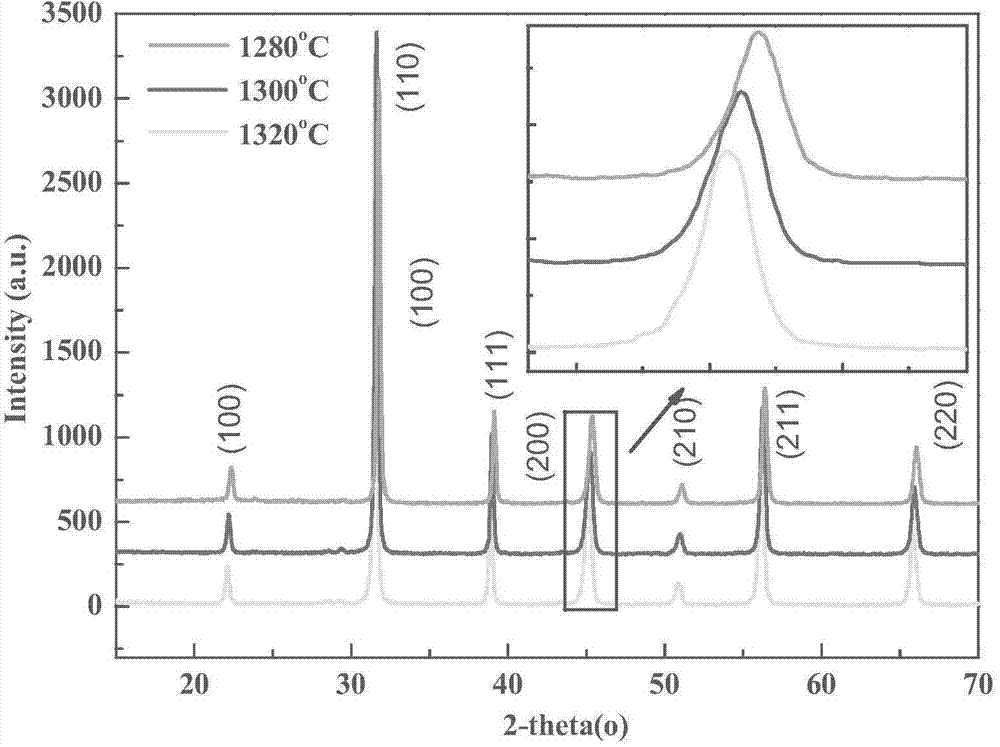

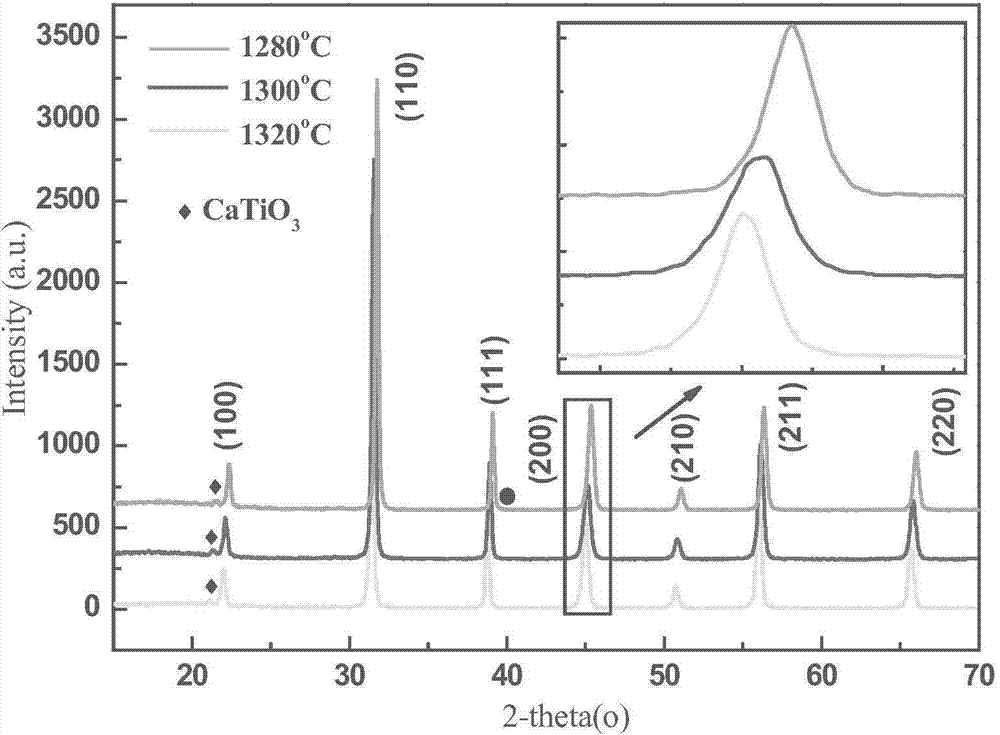

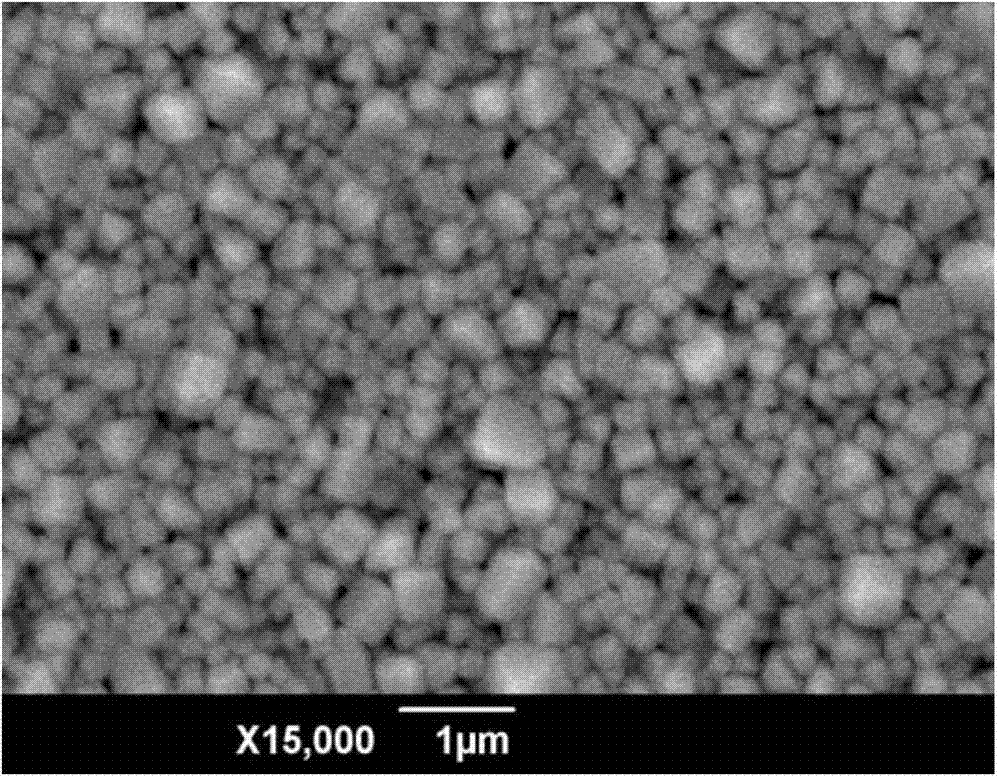

[0039] ③The Ba obtained in step ② 0.8 Ca 0.2 Ti 0.9 Zr 0.1 o 3 The powder precursor was poured into a hydrothermal reactor, and reacted in a hydrothermal environment at 150°C for 12 hours to obtain Ba 0.8 Ca 0.2 Ti 0.9 Zr 0.1 o 3 Ceramic powder, the Ba 0.8 Ca 0.2 Ti 0.9 Zr 0.1 o 3 The ceramic powder was ...

Embodiment 2

[0042] ①First follow Ba 0.8 Ca 0.2 Ti 0.9 Zr 0.1 o 3 The stoichiometric ratio, that is, the molar ratio is 0.8:0.2:0.1:0.9 to take BaCl 2 2H 2 O(s), CaCl 2 (s), ZrOCl 2 ·8H 2 O(s) and TiCl 4 (1) Dissolve in deionized water, mix after the four are completely dissolved, and let stand until the solution becomes transparent to obtain a mixed solution.

[0043] ② Add weighed NaOH solids to the above transparent mixed solution to adjust the acidity and alkalinity so that the pH value is > 14, stir in the air for 1 min until boiling, and obtain a milky white suspension after the boiling is over, which is Ba 0.8 Ca 0.2 Ti 0.9 Zr 0.1 o 3 Powder precursor.

[0044] ③The Ba obtained in step ② 0.8 Ca 0.2 Ti 0.9 Zr 0.1 o 3 The powder precursor was poured into a hydrothermal reactor, and reacted in a hydrothermal environment at 180°C for 13 hours to obtain Ba 0.8 Ca 0.2 Ti 0.9 Zr 0.1 o 3 Ceramic powder, the Ba 0.8 Ca 0.2 Ti 0.9 Zr 0.1 o 3 The ceramic powder was ...

Embodiment 3

[0047] ①First follow Ba 0.8 Ca 0.2 Ti 0.9 Zr 0.1 o 3 The stoichiometric ratio, that is, the molar ratio is 0.8:0.2:0.1:0.9 to take BaCl 2 2H 2 O(s), CaCl 2 (s), ZrOCl 2 ·8H 2 O(s) and TiCl 4 (1) Dissolve in deionized water, mix after the four are completely dissolved, and let stand until the solution becomes transparent to obtain a mixed solution.

[0048] ② Add weighed NaOH solids to the above transparent mixed solution to adjust the acidity and alkalinity so that the pH value is > 14, stir in the air for 1 min until boiling, and obtain a milky white suspension after the boiling is over, which is Ba 0.8 Ca 0.2 Ti 0.9 Zr 0.1 o 3 Powder precursor.

[0049] ③The Ba obtained in step ② 0.8 Ca 0.2 Ti 0.9 Zr 0.1 o 3 The powder precursor was poured into a hydrothermal reaction kettle, and reacted in a hydrothermal environment at 200°C for 11 hours to obtain Ba 0.8 Ca 0.2 Ti0.9 Zr 0.1 o 3 Ceramic powder, the Ba 0.8 Ca 0.2 Ti 0.9 Zr 0.1 o 3 The ceramic powde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com