Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

61results about How to "Low Curie temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Alloy materials

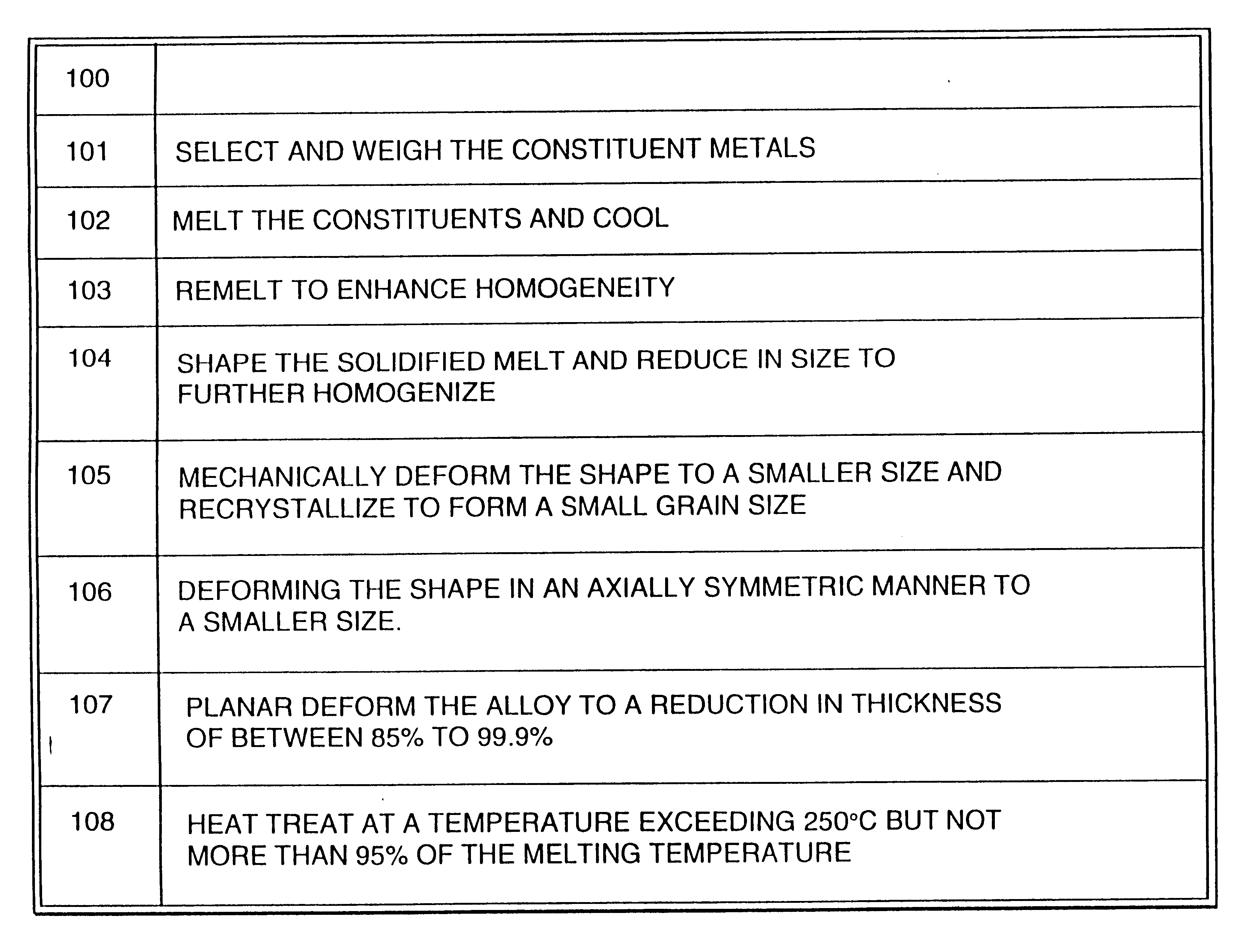

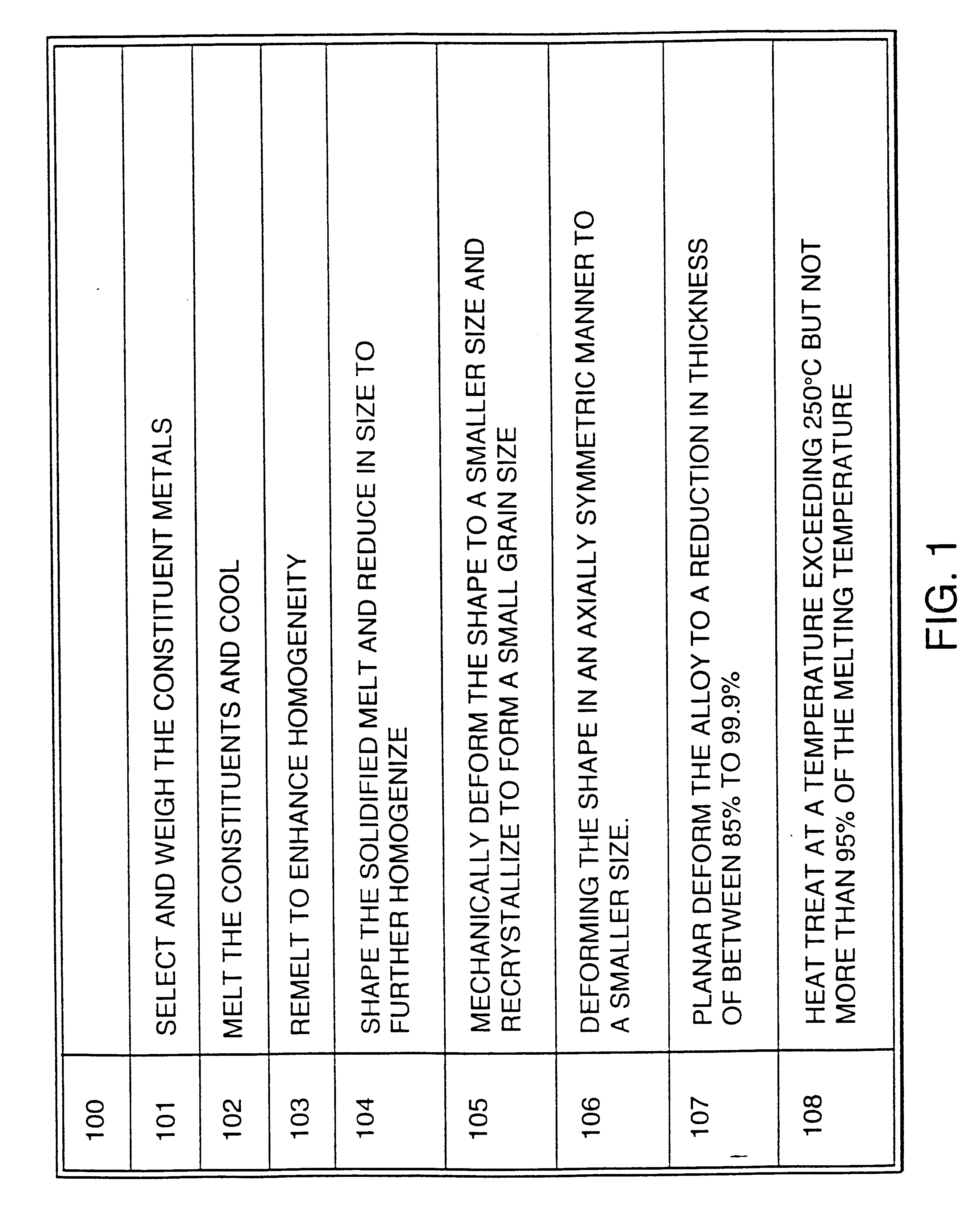

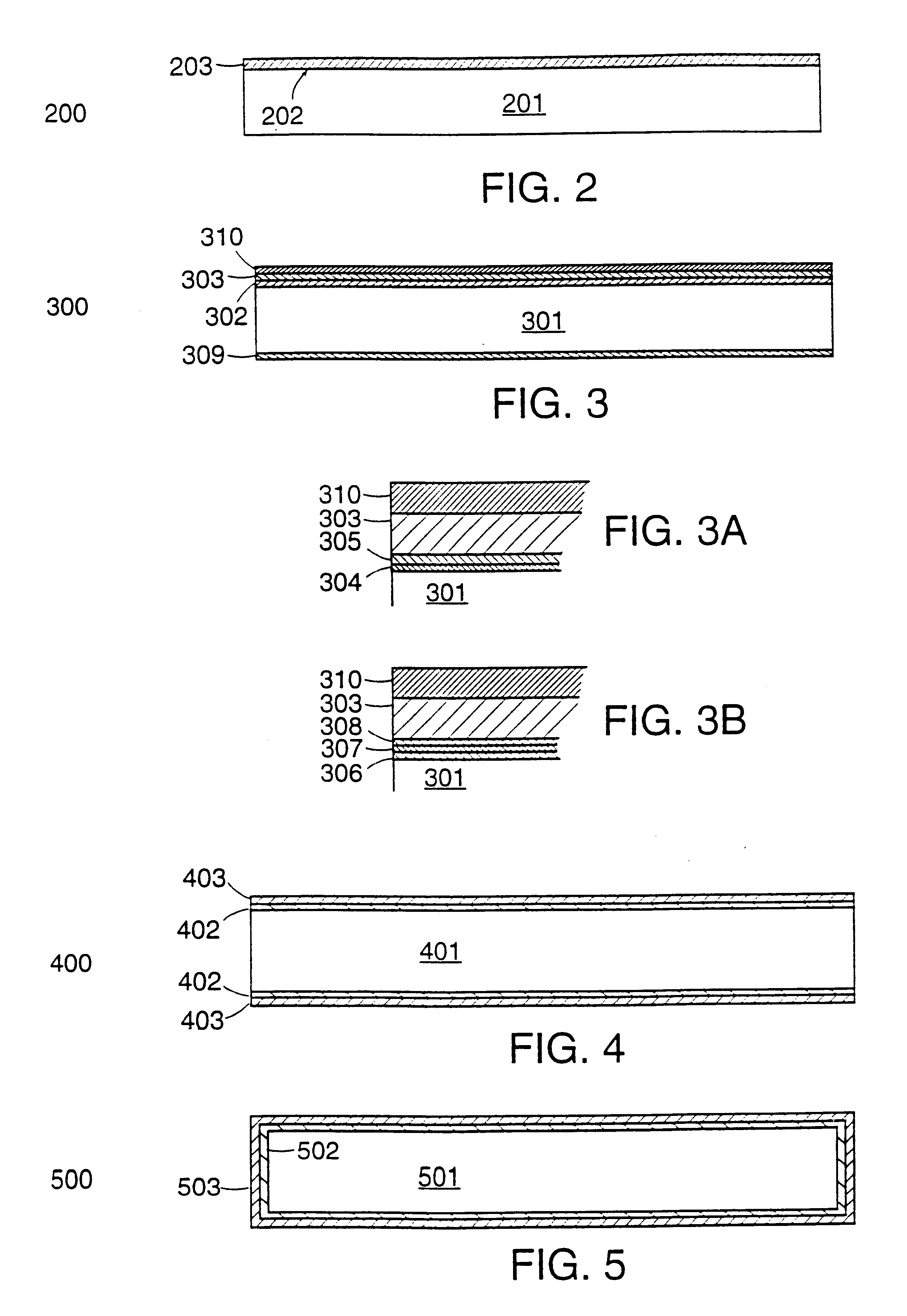

InactiveUS6475311B1Improve the immunityLow Curie temperatureMetal layered productsAlloyVolume percent

An alloy having a cube textured substrate is disclosed. The alloy includes two different metals. The alloy can be used as a substrate for a superconductor. Optionally, one or more buffer layers can be disposed between the substrate and the superconductor material. The alloy can be prepared using a process that includes rolling the alloy and annealing the alloy. The alloy can have a relatively large volume percent that is formed of grains with cube texture.

Owner:AMERICAN SUPERCONDUCTOR

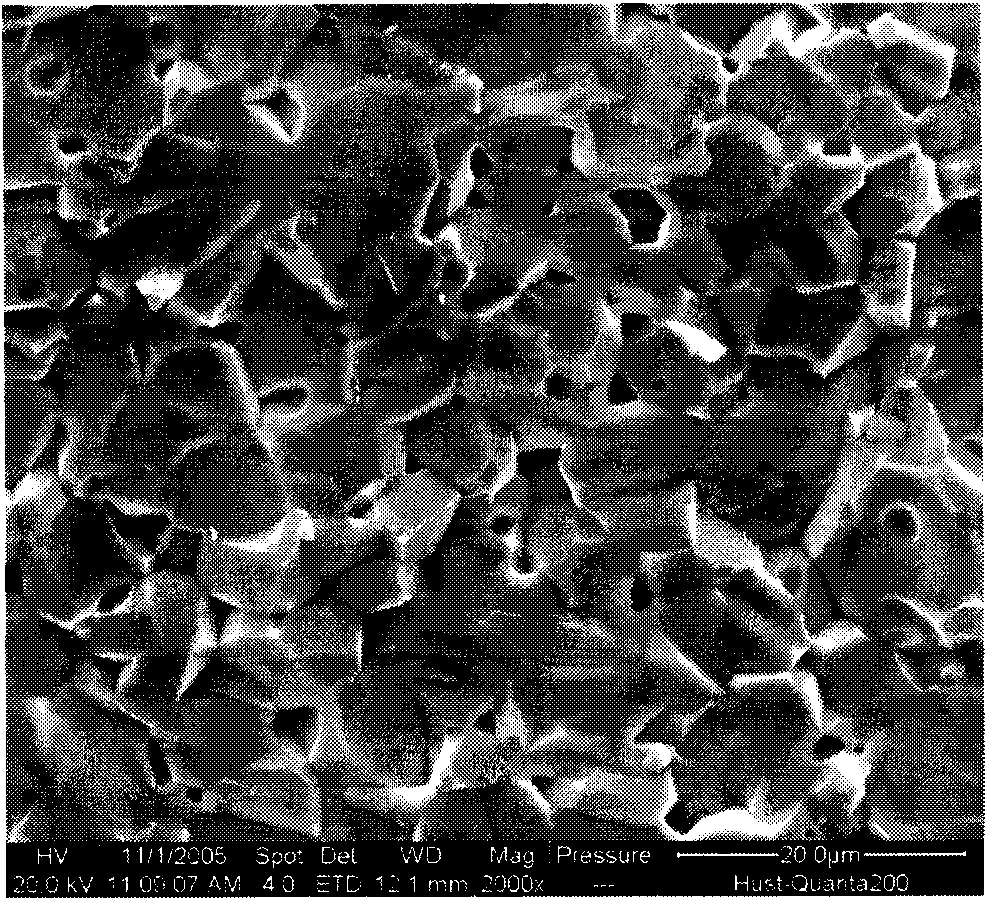

High performant low consumption manganese zine ferrite material and preparation process thereof

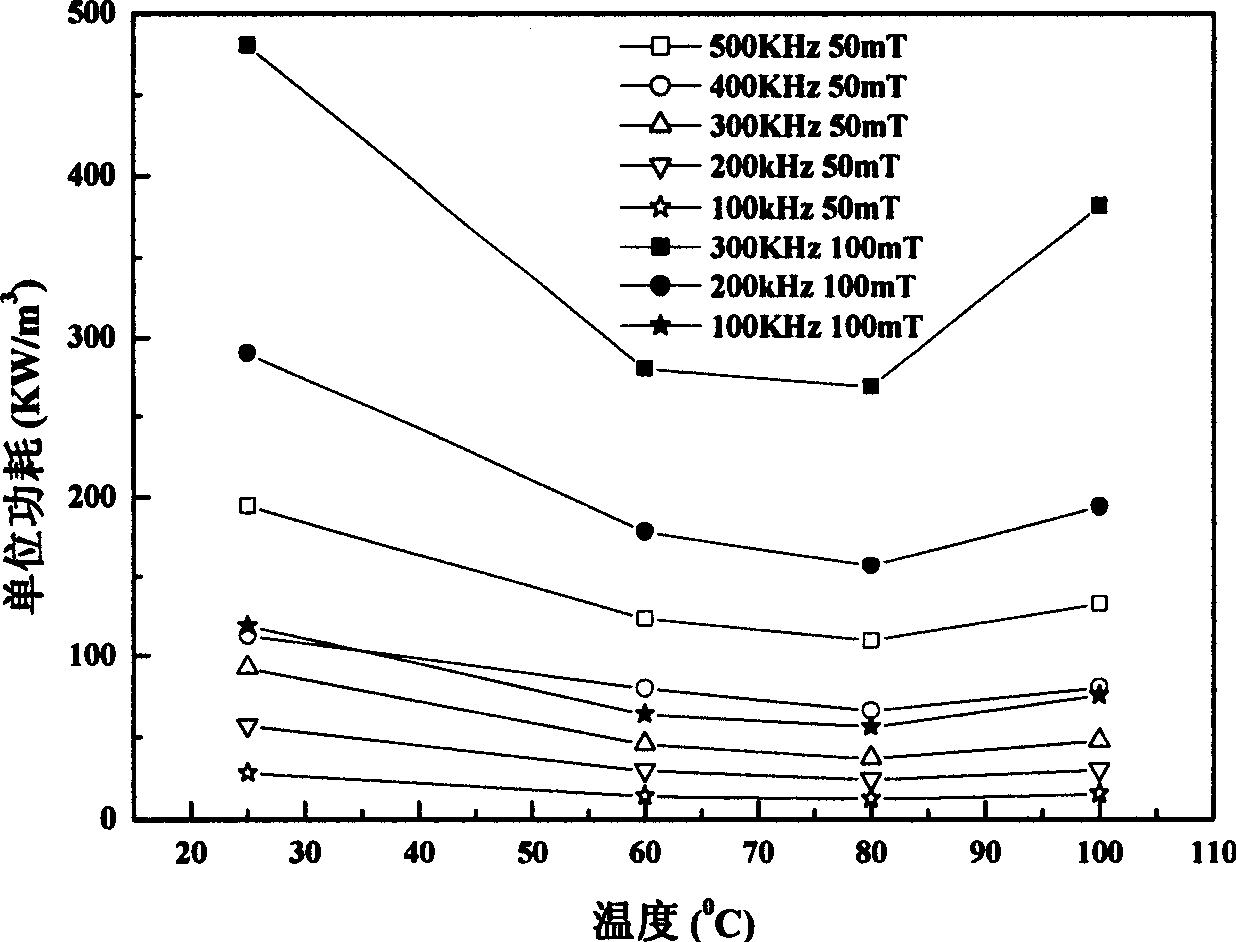

The invention relates to a high capacity low power consumption manganese-zinc ferrite material manufacturing method. The constituents includes 69.1-72.5wt% Fe2 O3, 22-24wt% Mn3O4, and ZnO. In the process of grinding and sintering, two or more from TiO2, Gd2 O3, SnO2, Co2O3, Ta2O5, Nb2O5, CaCO 3 could be added into the raw material. After grinding, pressure molding, sintering following certain temperature curve, the manganese-zinc ferrite material would be gained. The invention is simple and cost low. It has the feature of wide bandwidth and wide temperature.

Owner:SHANGHAI JIAO TONG UNIV

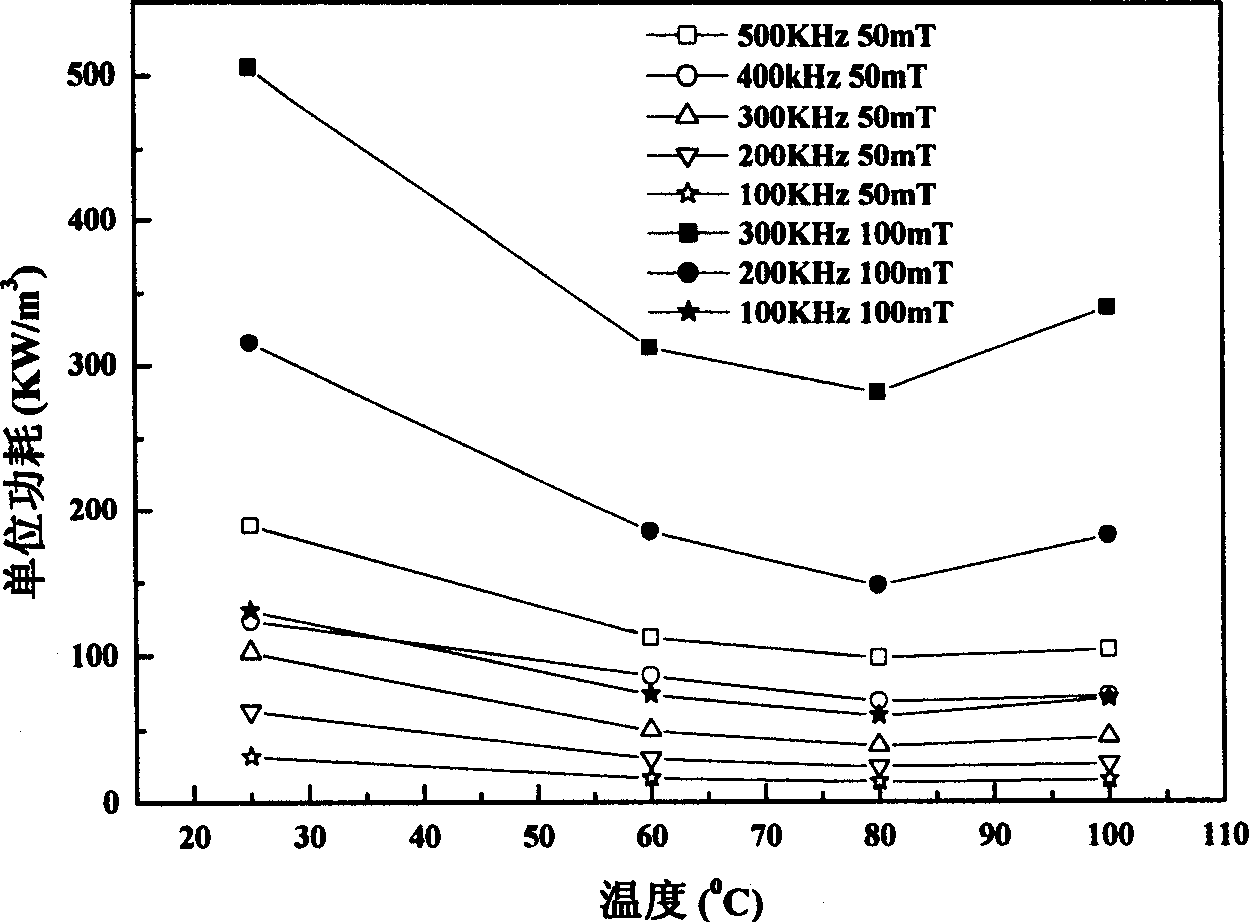

Broadband high impedance MnZn ferrite material and manufacture method thereof

The invention provides a broadband high impedance MnZn ferrite material, which comprises main components and assistant components. The main components comprise 47 to 50 mol percent of Fe203, 29 to 35 mol percent of Mn3O4 by MnO and 16 to 21 mol percent of ZnO. The assistant components are at least one kind from SiO2, CaCO3, V205 and Nb2O5. Total weight based on the main components is that SiO2 is0.002 to 0.01 wt percent, CaCO3 is 0.01 to 0.08 wt percent, V205 is 0.01 to 0.07 percent, and Nb2O5 is 0.01 to 0.07 percent. The broadband high impedance MnZn ferrite material has DC resistivity larger than 103 omega meter, curie temperature higher than 115 degrees centigrade and 2000 plus or minus 20 percent initial permeability. Moreover, the low frequency impedance of the material is larger than the common NiZn ferrite material, the high frequency impedance thereof is equal to the common NiZn ferrite material and the material does not contain expensive raw material NiO. The invention further provides the manufacture method of the broadband high impedance MnZn ferrite material, which comprises the steps of mixing, drying, preburning, ball-milling, granulation, molding, sintering and thelike.

Owner:江门江益磁材有限公司

High-frequency nickel-copper-zinc ferrite and preparation thereof

The invention relates to a high frequency nickel-copper-zinc ferrite and a method for preparing the same, which belong to the technical field of nickel series soft magnetism ferrite. The main components of the ferrite are ferric oxide, nickel oxide, zinc oxide, and copper oxide, the accessory components comprise cobalt oxide, bismuth oxide, and silicon oxide, and the ferrite is prepared by an oxide method. The invention adopts an iron deficiency formulation, a low calcination temperature, and a low sintering temperature so that the prepared high frequency nickel-copper-zinc ferrite has good performances of low initial permeability, low relative dissipation factor between 50MHz and 200MHz, and high Curie temperature, and can better satisfy the use requirement of communication electronic parts and components; besides, the preparation process is stable, and the production process has low energy consumption.

Owner:TDG HLDG CO LTD

High-dielectric-constant microwave ferrite material, preparation method and microwave communication device

PendingCN111285673AHigh dielectric constantLow Curie temperatureInorganic material magnetismHigh dielectric permittivityDielectric

The invention discloses a high-dielectric-constant microwave ferrite material, a preparation method and a microwave communication device. The chemical formula of the microwave ferrite material is Bi<1.25>Ca<0.25+2x>Y<1.5-2x>Zr<0.25>Al<x>Mn<y>Fe<4.75-x-y>, x is greater than or equal to 0.05 and less than or equal to 0.3, and y is greater than or equal to 0.05 and less than or equal to 0.15. The preparation method comprises the following steps: preparing raw materials according to the molecular formula Bi<1.25>Ca<0.25+2x>Y<1.5-2x>Zr<0.25>Al<x>Mn<y>Fe<4.75-x-y> (0.05<=x<=0.3, and 0.05<=y<=0.15),and preparing the microwave ferrite material by using the raw materials. The dielectric constant of the high-dielectric-constant microwave ferrite material is about 28, 4piMs is 1850-1950 Gs, delta His 45-50 Oe, Tc is 200 DEG C or above, and the miniaturization and integration application of a microwave circulator and an isolator can be well met.

Owner:SHENZHEN SUNLORD ELECTRONICS

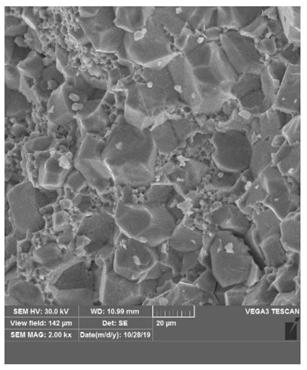

Vanadium-containing non-magnetic Ti(C, N)-based metal ceramic and preparation method thereof

The invention provides vanadium-containing non-magnetic Ti(C, N)-based metal ceramic and a preparation method thereof, and belongs to metal ceramic and preparation methods. The vanadium-containing non-magnetic Ti(C, N)-based metal ceramic comprises a hard phase and a binding phase, and raw materials are powder and comprise, by weight, 42.11%-53.48% of TiC, 7.91%-9.99% of TiN, 27.78%-32.82% of Ni, 9.30%-15.16% of Mo and 0.50%-1.99% of VC. The metal ceramic is prepared by mixing, wet grinding, drying, compression molding, degreasing and vacuum sintering. The preparation method of the metal ceramic sequentially includes the steps of mixing, wet grinding, drying, compression molding, degreasing and vacuum sintering. The preparation method is simple, low in cost and suitable for industrial production. The prepared metal ceramic is simple in composition and does not contain scarce strategic resource W, the hardness can reach 89 HRA, the bending strength can reach 2673 MPa, the metal ceramic has no magnetism at the room temperature, the relative permeability is not higher than 1.003, the abrasion resistance and the chemical stability are good, and the friction coefficient with materials such as steel is small; and the metal ceramic has good application prospects in the aspects of molding tools and molds for magnetic elements and wear-resistant parts of electronic products and automobile instruments.

Owner:HUAZHONG UNIV OF SCI & TECH

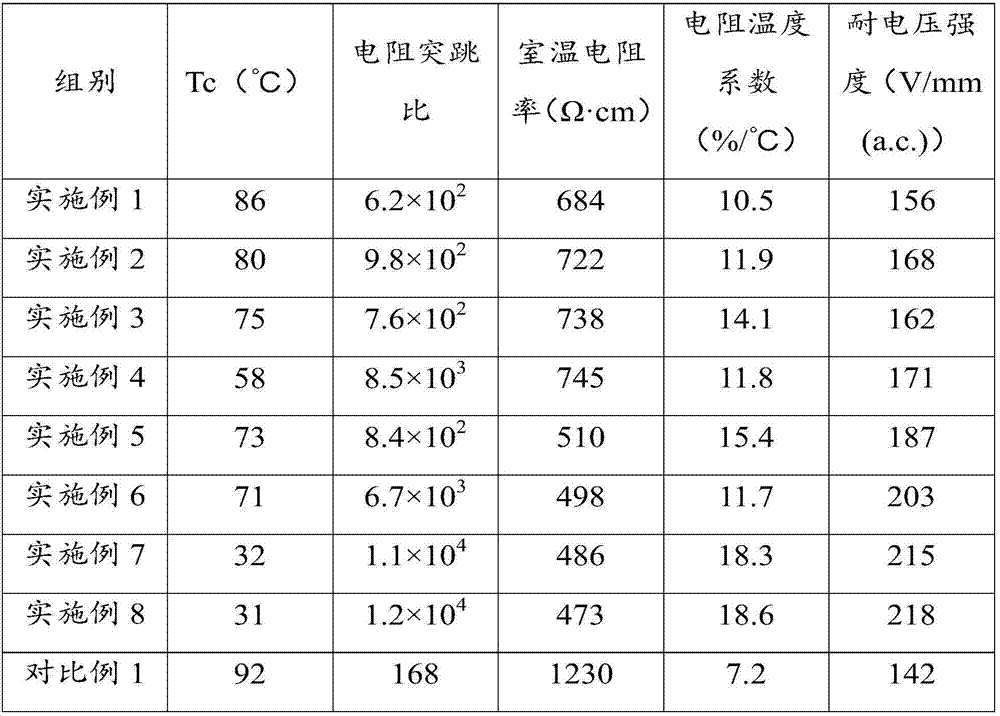

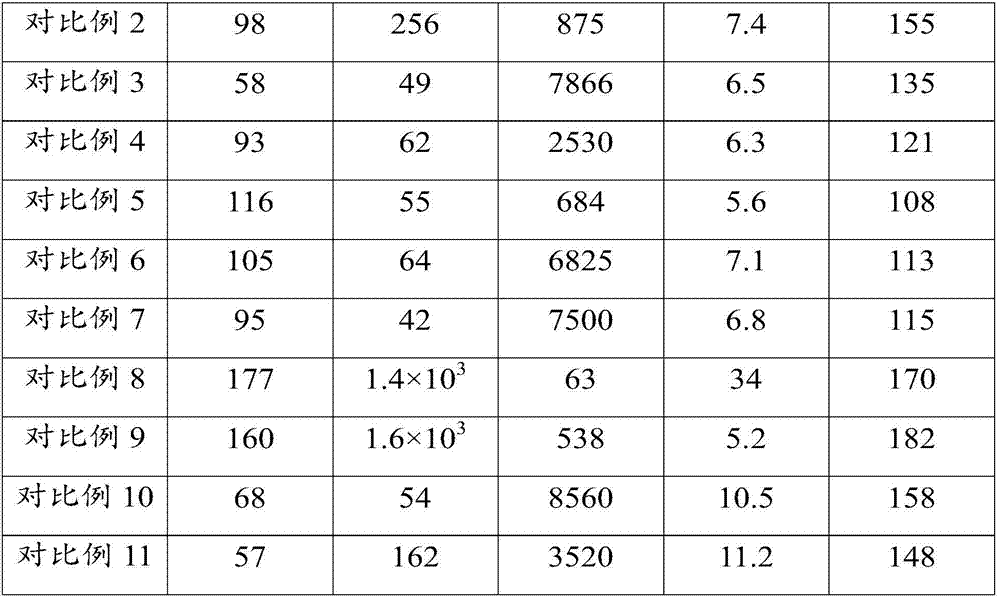

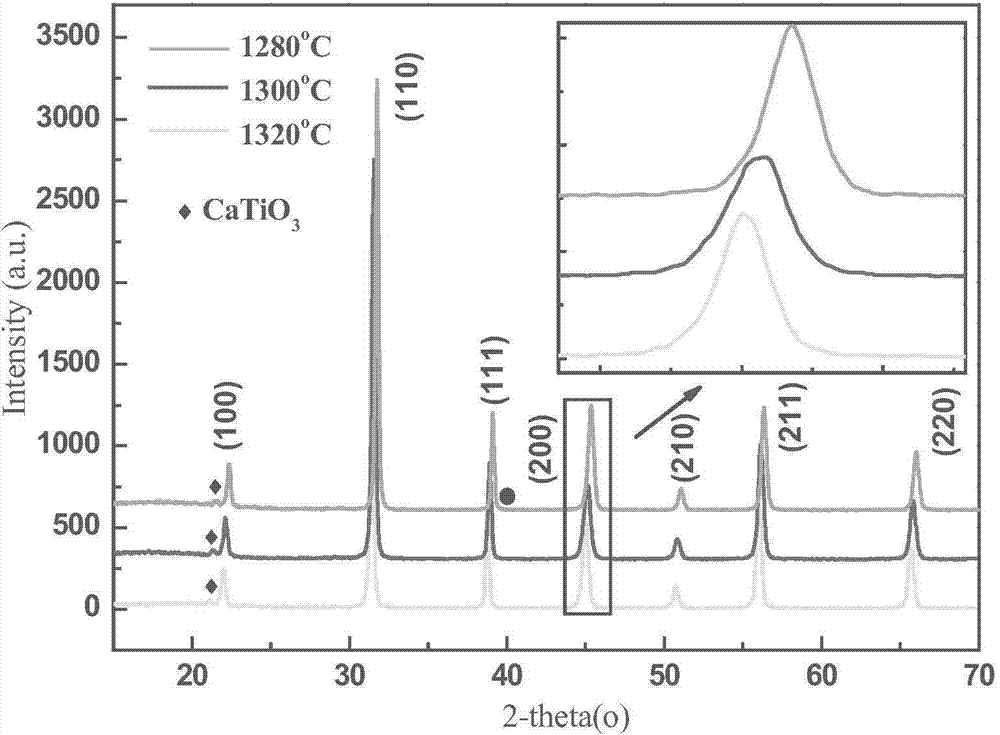

PTCR ceramic material and preparation method and application thereof

ActiveCN107226694AImprove microstructureUnique physical propertiesPositive temperature coefficient thermistorsHigh resistanceCurie temperature

The invention relates to the field of electronic ceramics and provides a PTCR ceramic material and a preparation method and application thereof. The PTCR ceramic material has a general formula x(BaTiO3)-y(SrTiO3)-(1-x-y)(CaTiO3)+a mol% M+b mol% N, x is greater than or equal to 0.6 and less than or equal to 0.9, y is greater than or equal to 0.1 and less than or equal to 0.4, a is greater than or equal to 0.1 and less than or equal to 1, b is greater than or equal to 0 and less than or equal to 3, the sum of x and y is less than or equal to 1, M represents any one or more of Y2O3, Bi2O3, La2O3, Sm2O3, Nb2O5, Ta2O5 and Sb2O5, and N represents any one or more of MnO2, CuO, Fe2O3, ZrO2, Al2O3, SiO2, TiO2, BN and B2O3. The PTCR ceramic material has the advantages of low Curie temperature, high resistance abrupt change ratio and high resistance temperature coefficient.

Owner:TONGREN UNIV

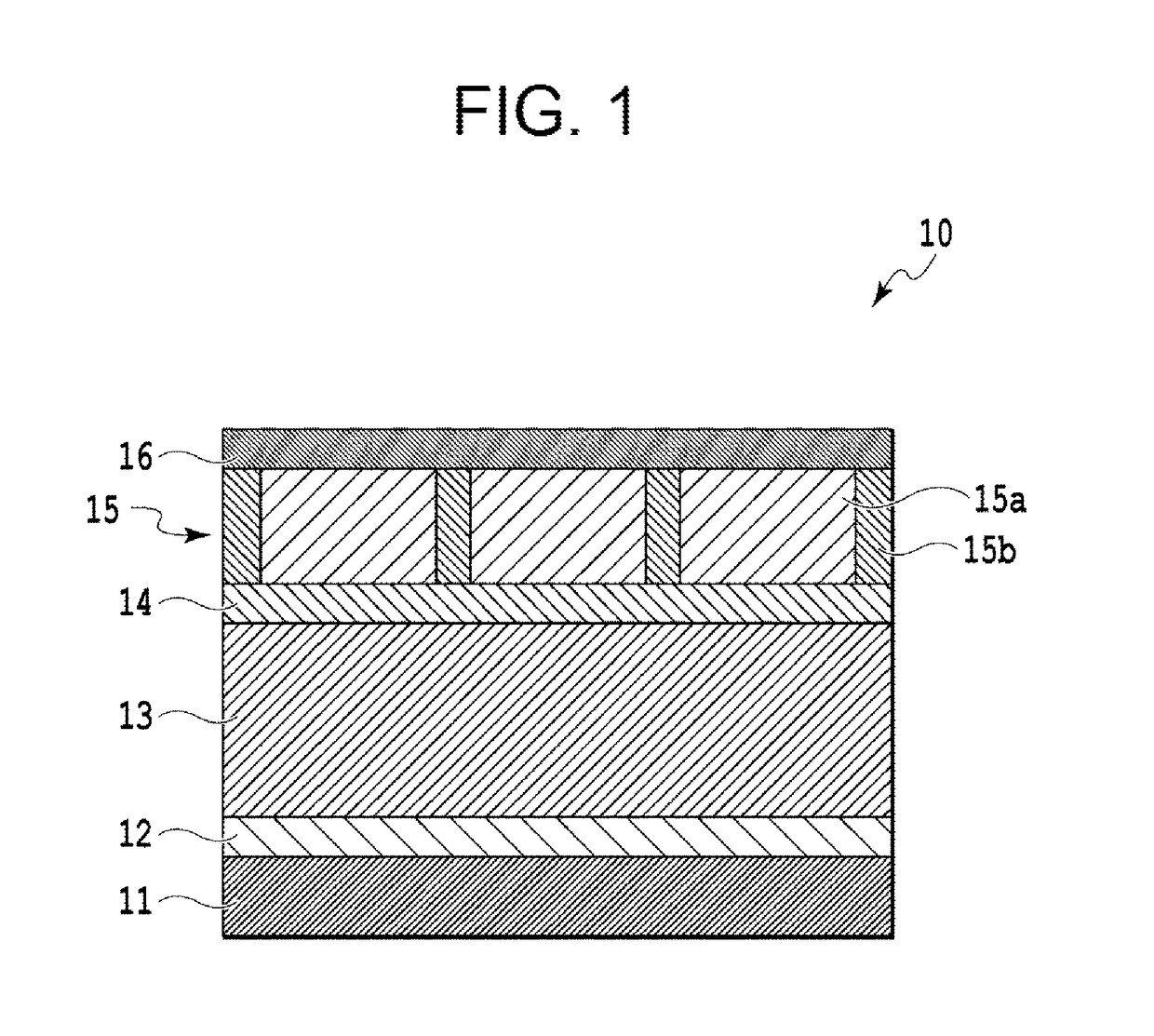

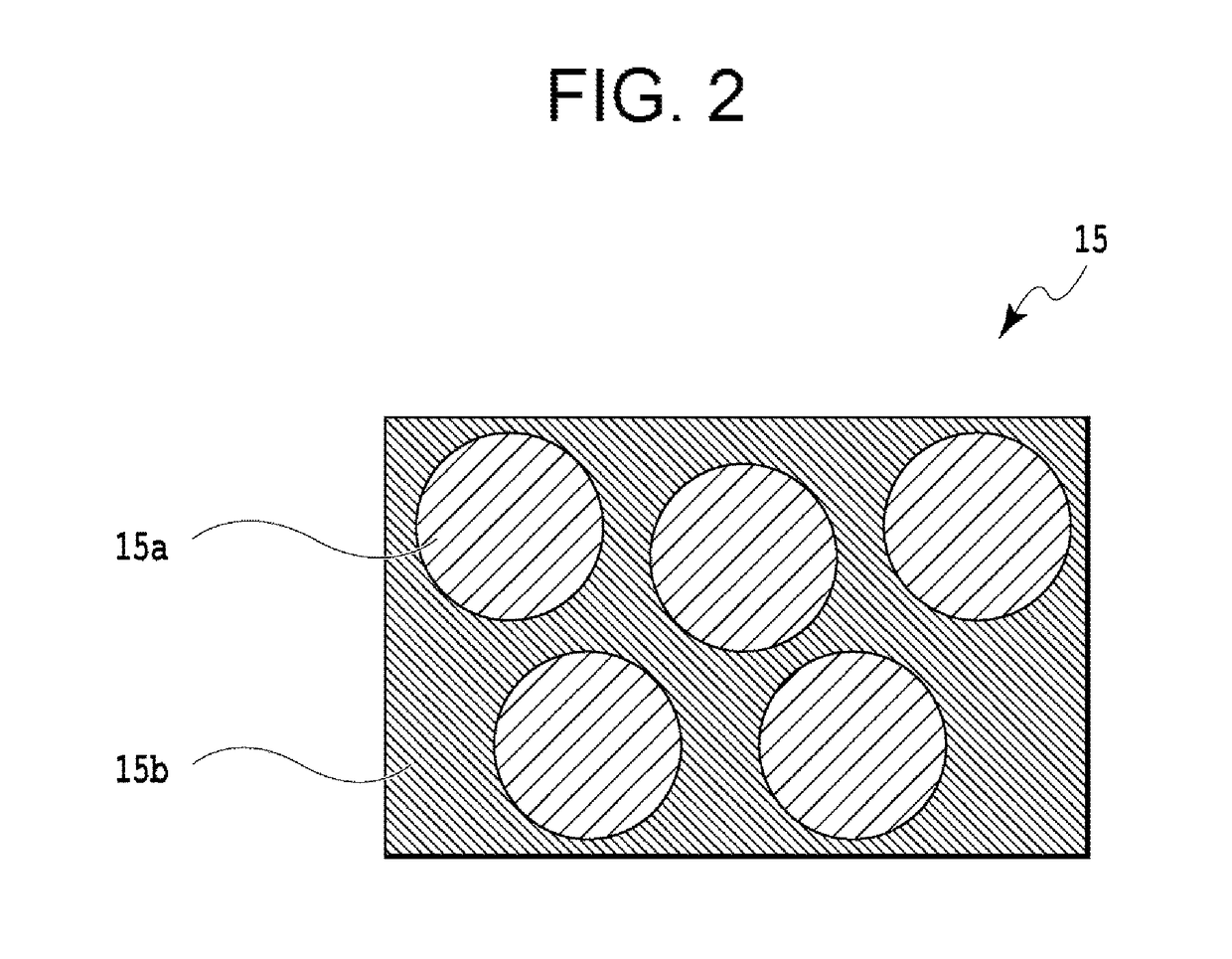

Perpendicular magnetic recording medium

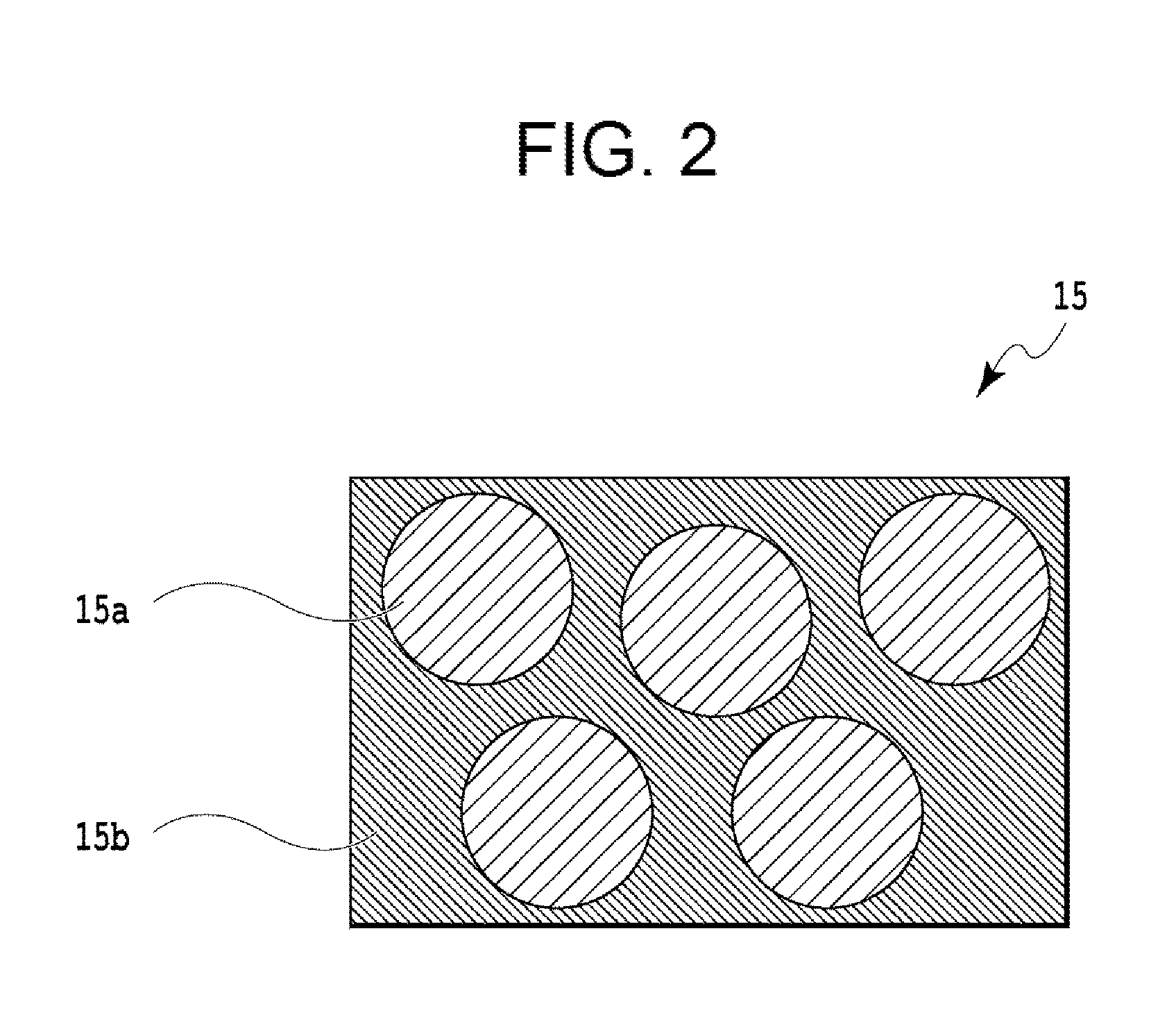

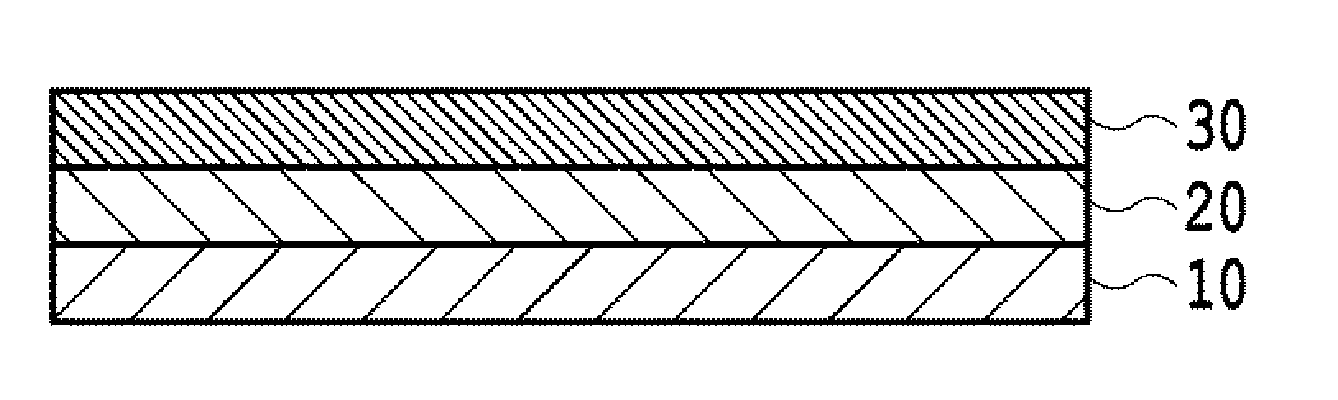

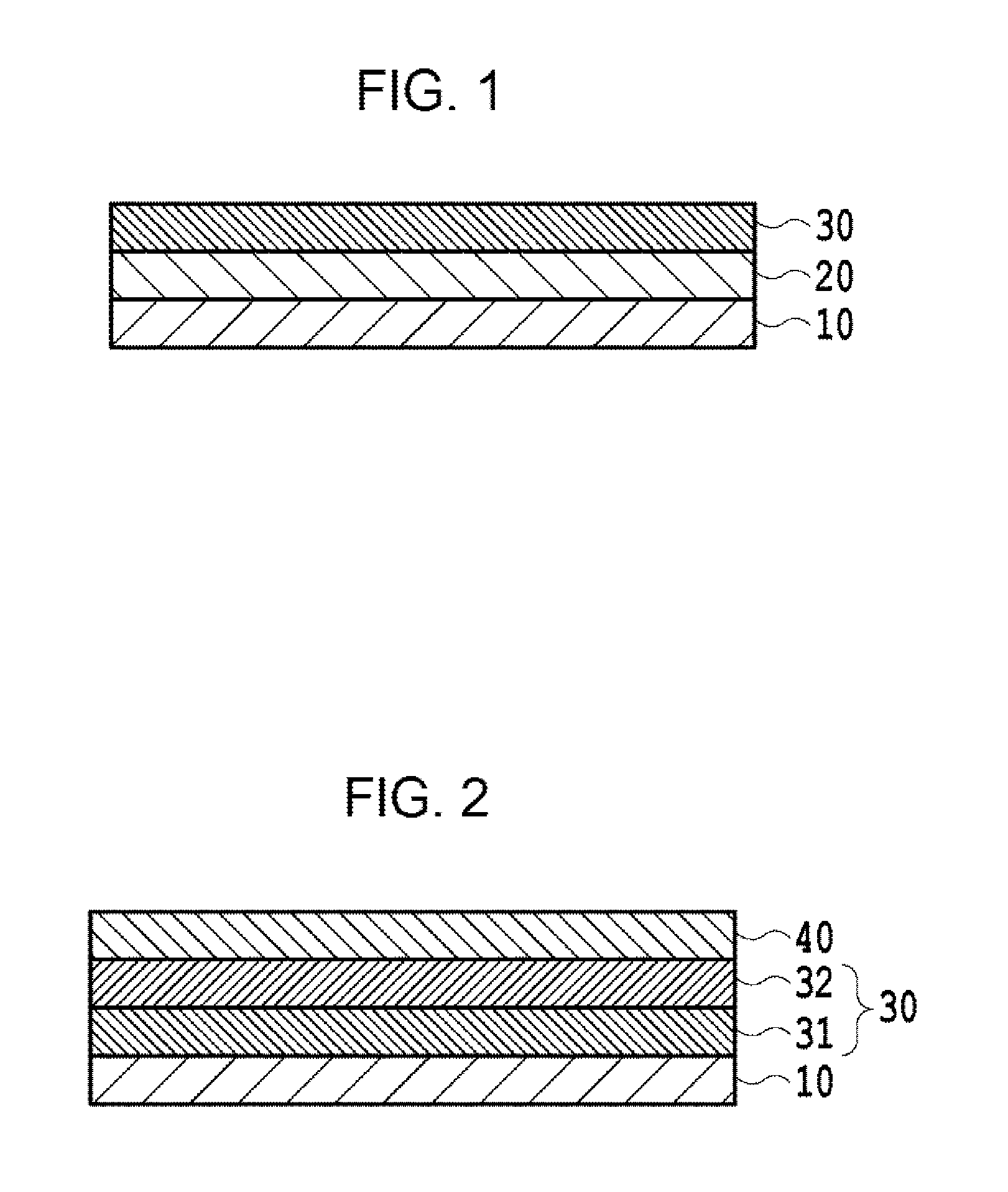

ActiveUS20150213821A1High magnetic anisotropy constantImprove coercive forceRecord information storageMagnetic recordingMagnetic anisotropyAlloy

A perpendicular magnetic recording medium includes a non-magnetic substrate; and a magnetic recording layer that includes magnetic crystal grains and a non-magnetic crystal grain boundary that surrounds the magnetic crystal grains, wherein the magnetic crystal grains contain an ordered alloy and the non-magnetic crystal grain boundary contains Ge oxides. The magnetic recording layer may have a granular structure. The magnetic crystal grains may be micronized to be sufficiently ordered and separated, and the perpendicular magnetic recording medium may have a high magnetic anisotropy constant Ku and high coercivity Hc.

Owner:FUJI ELECTRIC CO LTD

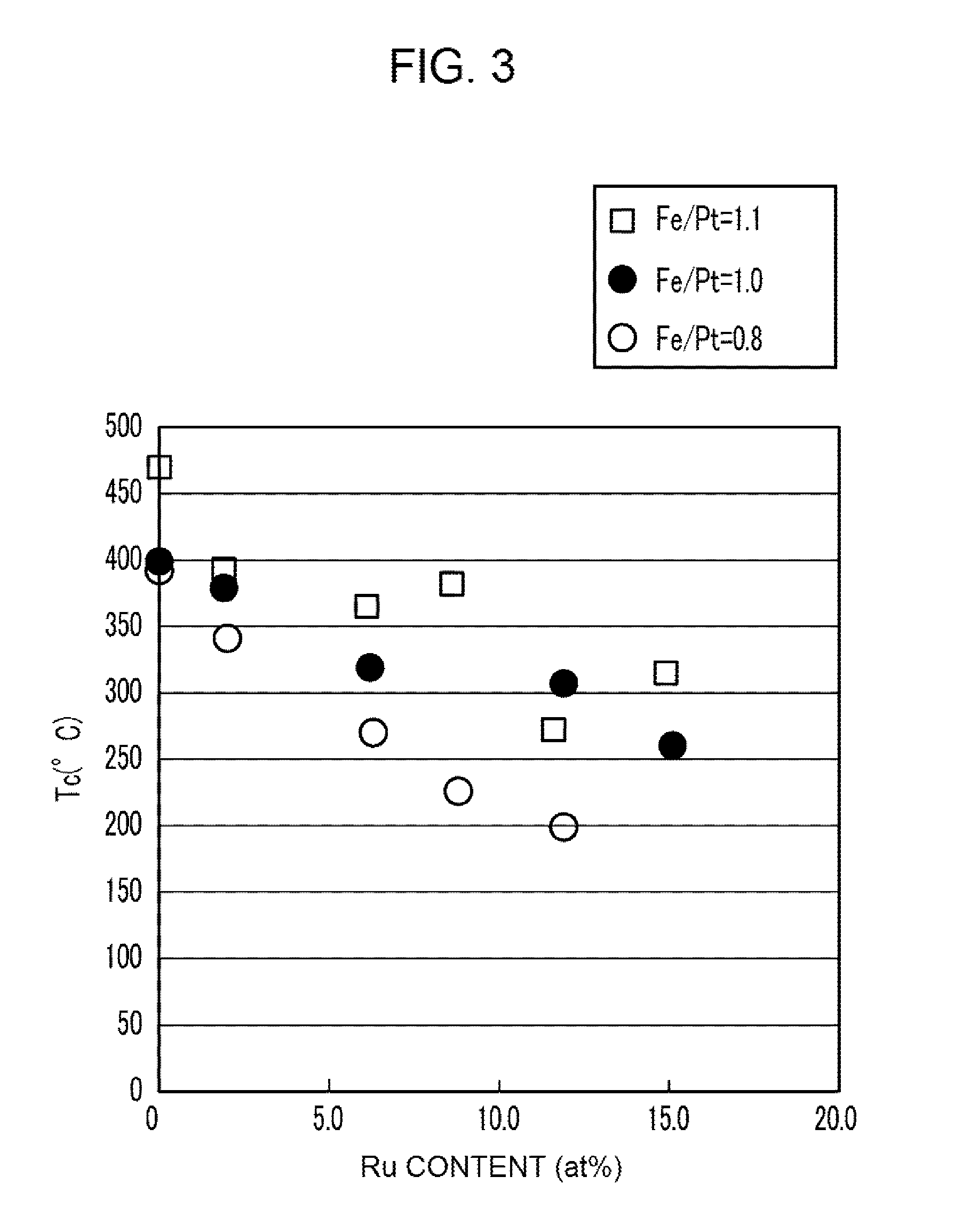

Magnetic recording medium

ActiveUS20160225394A1Improve thermal stabilityHigh constantRecord information storageMagnetic recordingMagnetic anisotropyCurie temperature

The present invention provides a magnetic recording layer that has a high magnetic anisotropy constant Ku and a low Curie temperature Tc, as well as a magnetic recording medium that incorporates such a magnetic recording layer. The magnetic recording medium of the present invention includes a nonmagnetic substrate and a magnetic recording layer containing an ordered alloy. The ordered alloy may contain at least one element selected from the group consisting of Fe and Ni; at least one element selected from the group consisting of Pt, Pd, Au, Rh and Ir; and Ru.

Owner:FUJI ELECTRIC CO LTD

Piezoelectric ceramic material with high voltage electric response and high Curie temperature and preparation method thereof

ActiveCN109626988APrecise and controllable stoichiometric ratioShort preparation cycleAdhesiveSlurry

The invention relates to a piezoelectric ceramic material with high voltage electric response and a high Curie temperature and a preparation method thereof. A stoichiometric ratio accords with a chemical general formula (1-x)(K0.48Na0.52)(Nb1-ySby)O3-xBi0.5(Na0.8K0.2)0.5ZrO3; wherein x is more than or equal to 0.02 and less than or equal to 0.04, and y is more than or equal to 0.02 and less than or equal to 0.04. The preparation method comprises the following steps of: (1), preparing a base material according to the stoichiometric ratio and a sodium niobate (NaNbO3) sheet template for texturegrowth of crystal grains; (2), weighing the base material, the template and a MnO2 sintering aid according to the stoichiometric ratio, placing the weighed base material, template and MnO2 sintering aid in a nylon tank, adding a solvent, a dispersant and a binder, and uniformly stirring the mixture to obtain casting slurry with good fluidity; (3) casting the slurry to obtain a strip-shaped thick film, cutting the thick film after the thick film is dried, laminating and hot pressing the thick film into a ceramic blank body; (4) removing the blank body from the adhesive, and sintering the blankbody by using a two-step sintering process to obtain lead-free textured piezoelectric ceramic, wherein the lead-free textured piezoelectric ceramic has high piezoelectric performance and a high Curietemperature. The environment-friendly lead-free piezoelectric ceramic material has higher practical value in the fields of low and medium temperature sensors, transducers, drivers and the like.

Owner:TONGJI UNIV

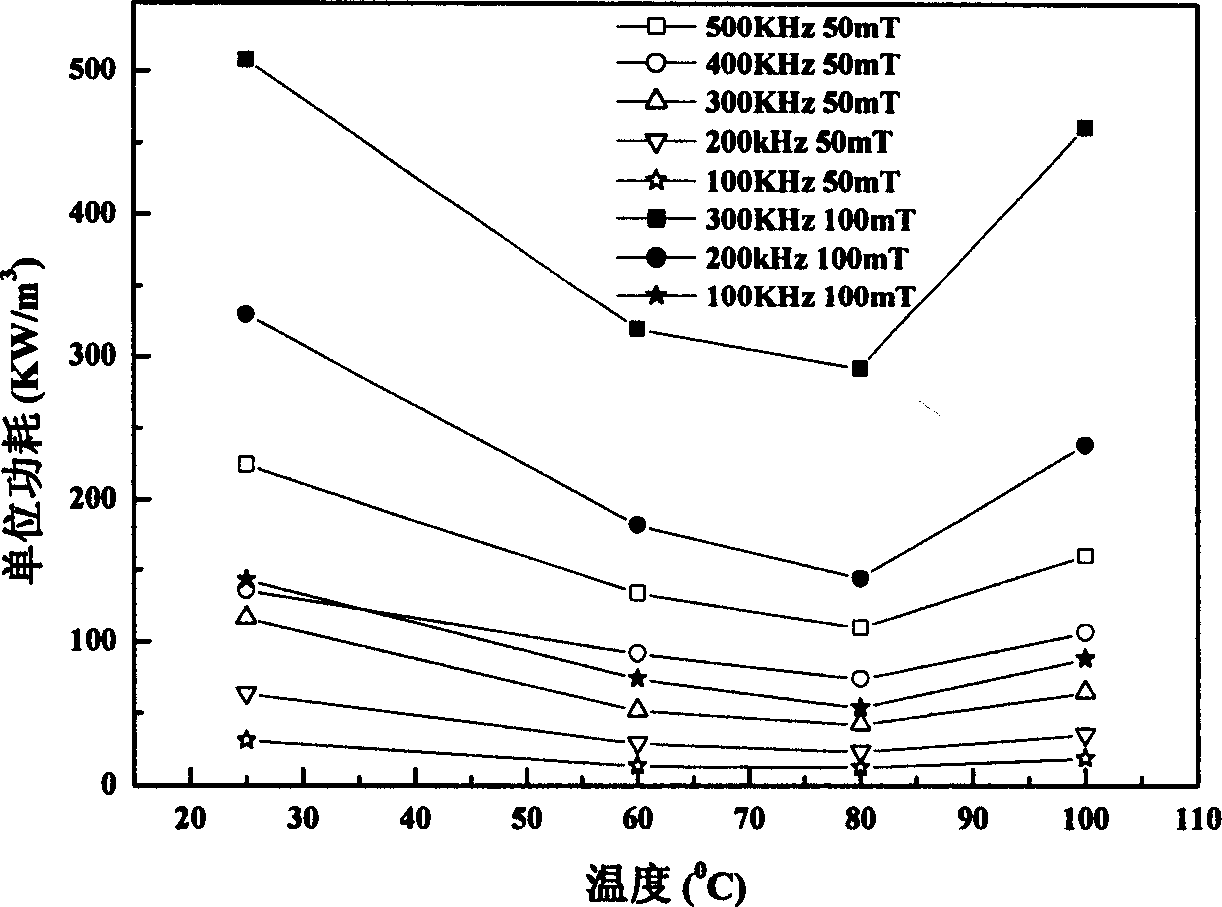

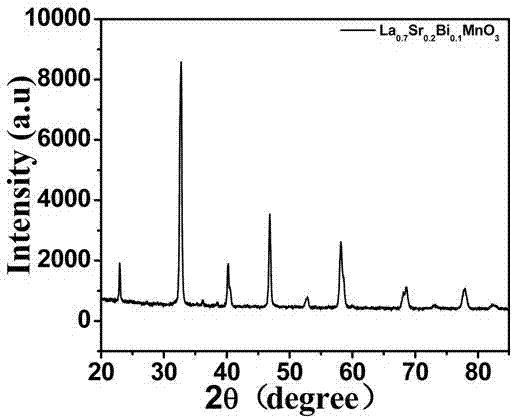

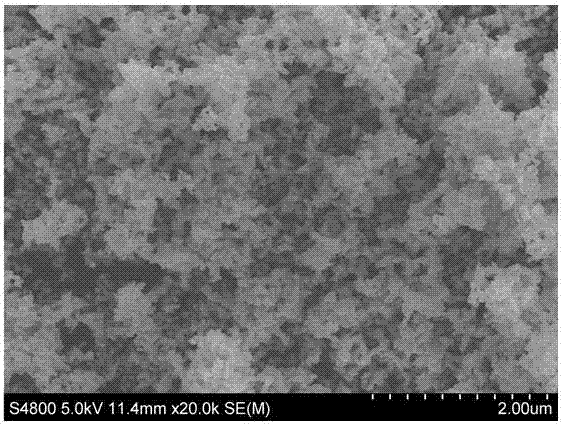

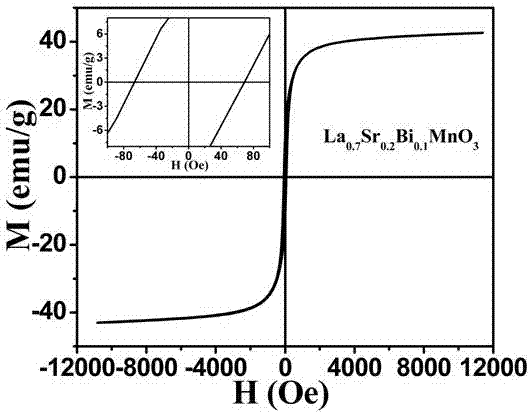

Magnetic nanoparticle, preparation method and application of magnetic nanoparticle

InactiveCN107452457AImprove performanceHigh purityEnergy modified materialsPharmaceutical non-active ingredientsMagnetic heatingCancer cell

The invention belongs to the field of biomedical materials, and particularly relates to a La0.7Sr0.2Bi0.1MnO3 magnetic nanoparticle, a preparation method and an application of the magnetic nanoparticle. The sodium hyaluronate modified La0.7Sr0.2Bi0.1MnO3 magnetic nanoparticle serves as a magnetic thermal therapy medium, a magnetic fluid takes the La0.7Sr0.2Bi0.1MnO3 magnetic nanoparticle as a core, and the surface of the magnetic nanoparticle is modified by the sodium hyaluronate to form stable magnetic hydrosol. The magnetic thermal therapy medium has good biocompatibility and chemical stability and high magnetic heating performance, can effectively kill cancer cells and has a wide application prospect in magnetic thermal therapy and thermo-chemotherapy combination and anti-tumor diagnosis and treatment integration.

Owner:LANZHOU UNIVERSITY

Cobalt ferrite based magnetostrictive materials for magnetic stress sensor and actuator applications

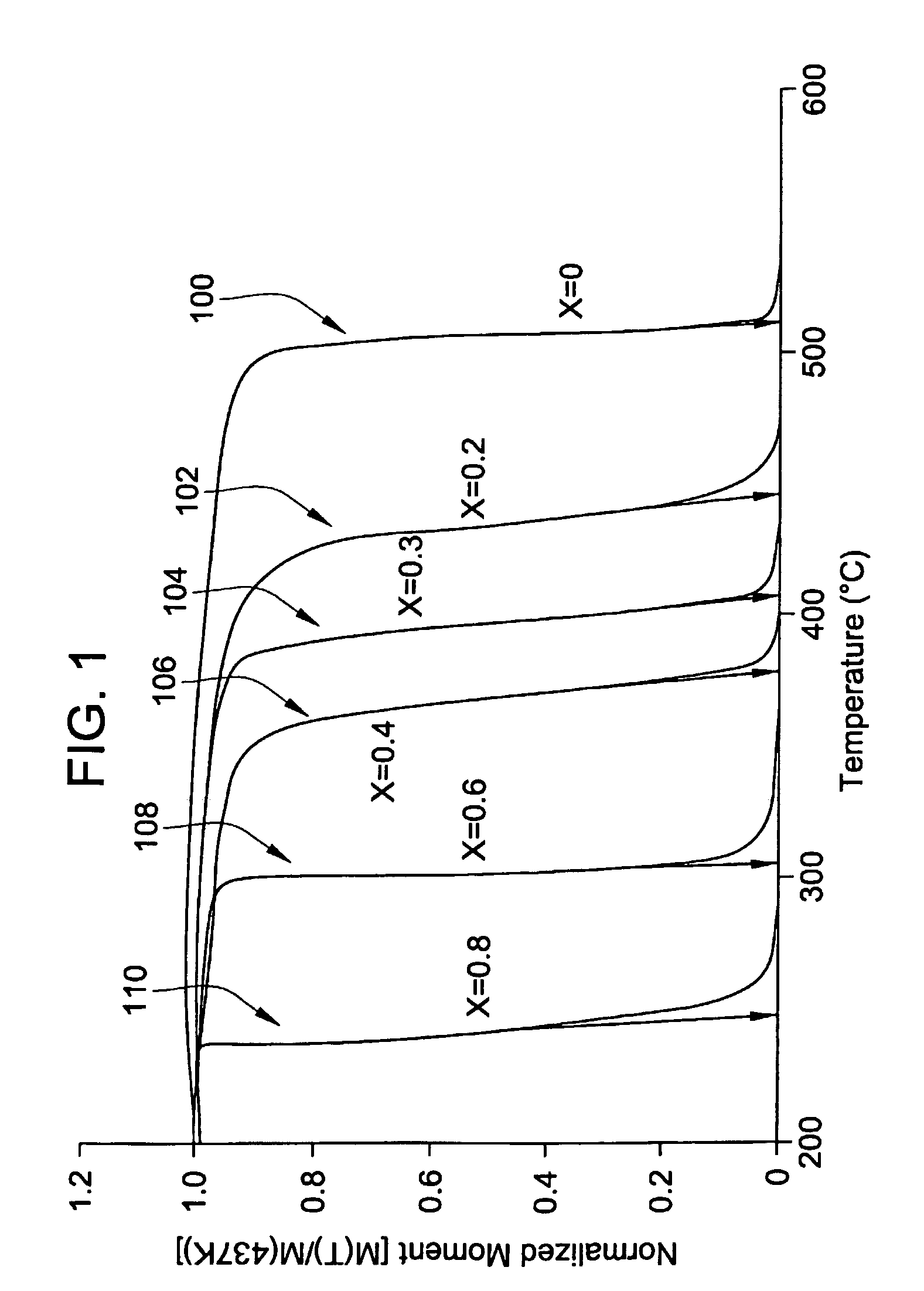

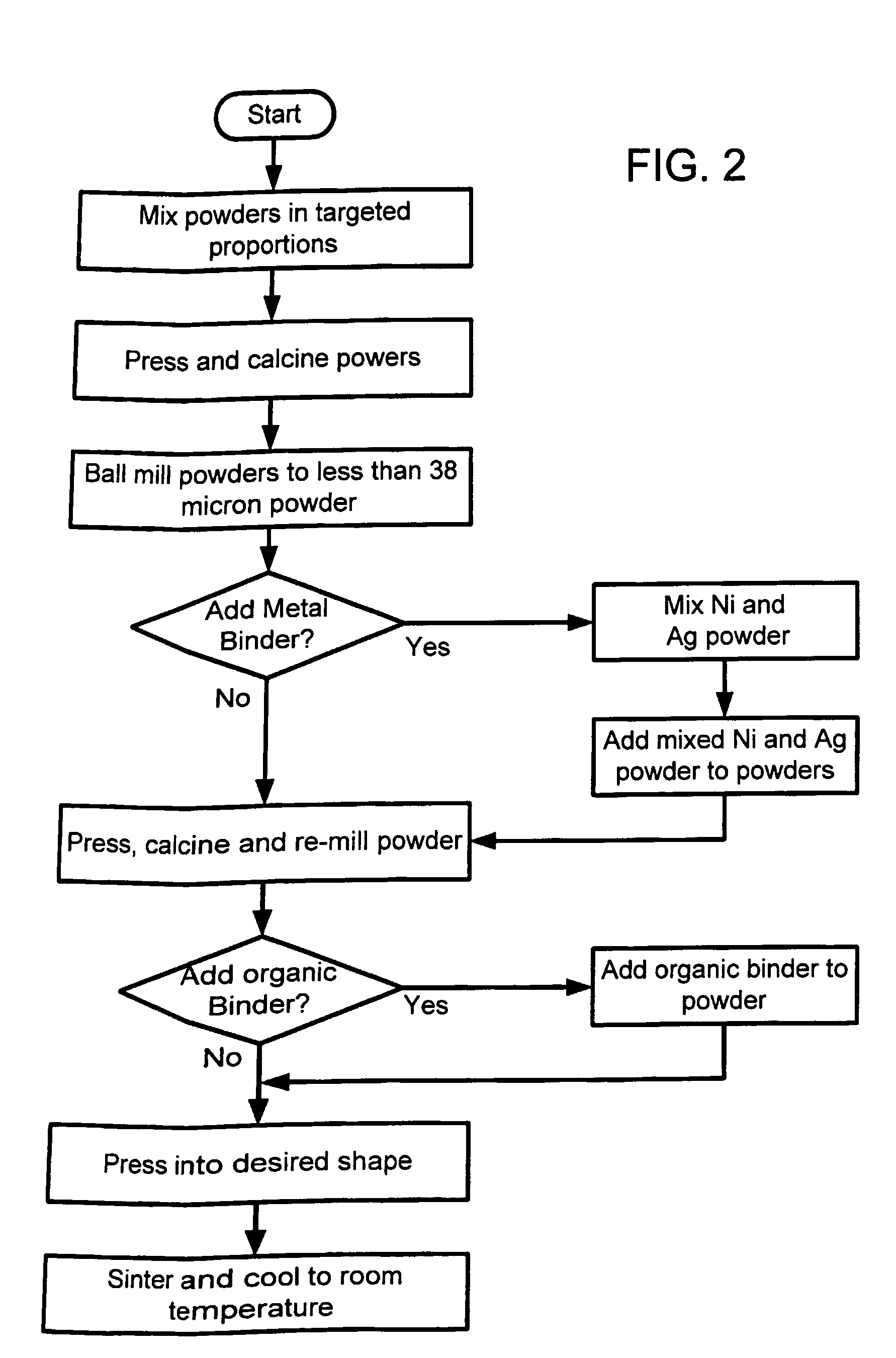

InactiveUS7326360B1Reduce hysteresisLow Curie temperatureMagnetic paintsInorganic material magnetismManganeseCurie temperature

Magnetostrictive material based on cobalt ferrite is described. The cobalt ferrite is substituted with transition metals (such manganese (Mn), chromium (Cr), zinc (Zn) and copper (Cu) or mixtures thereof) by substituting the transition metals for iron or cobalt to form substituted cobalt ferrite that provides mechanical properties that make the substituted cobalt ferrite material effective for use as sensors and actuators. The substitution of transition metals lowers the Curie temperature of the material (as compared to cobalt ferrite) while maintaining a suitable magnetostriction for stress sensing applications.

Owner:IOWA STATE UNIV RES FOUND

Method for manufacturing bonded magnet

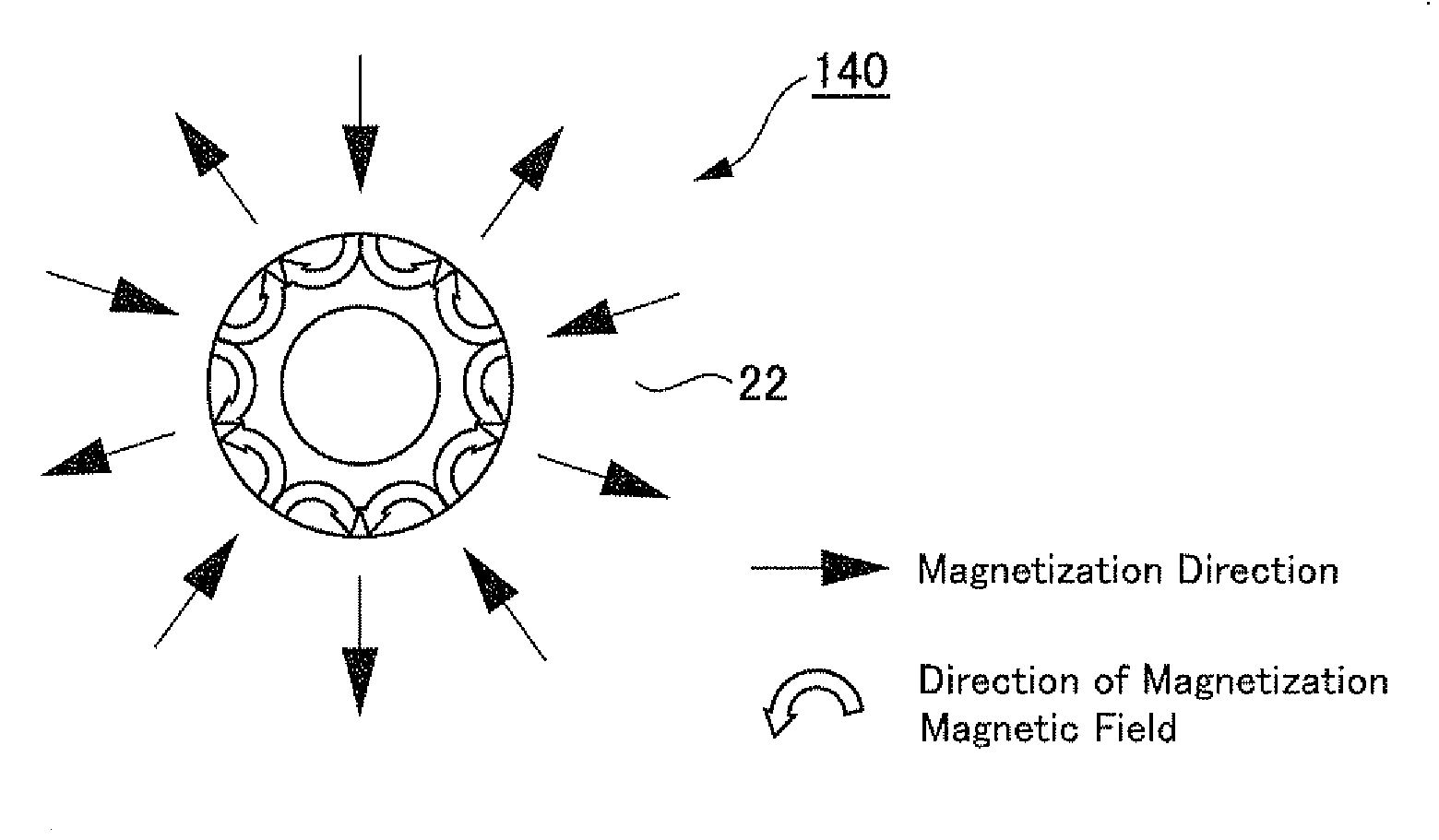

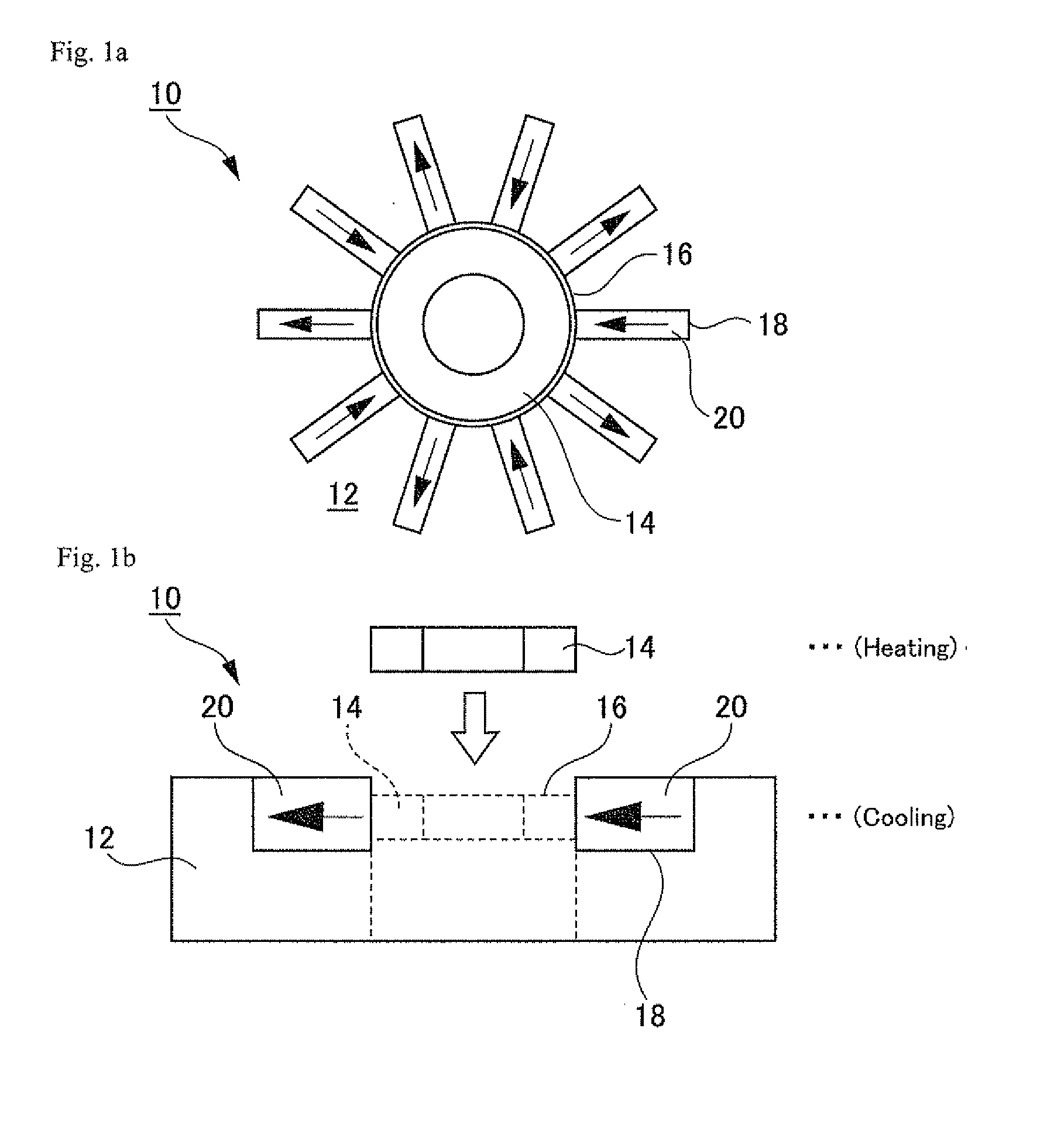

InactiveUS20130192723A1Reduce thermal demagnetizationExcellent magnetic propertiesInorganic material magnetismPermanent magnet manufactureRare-earth elementMagnetization

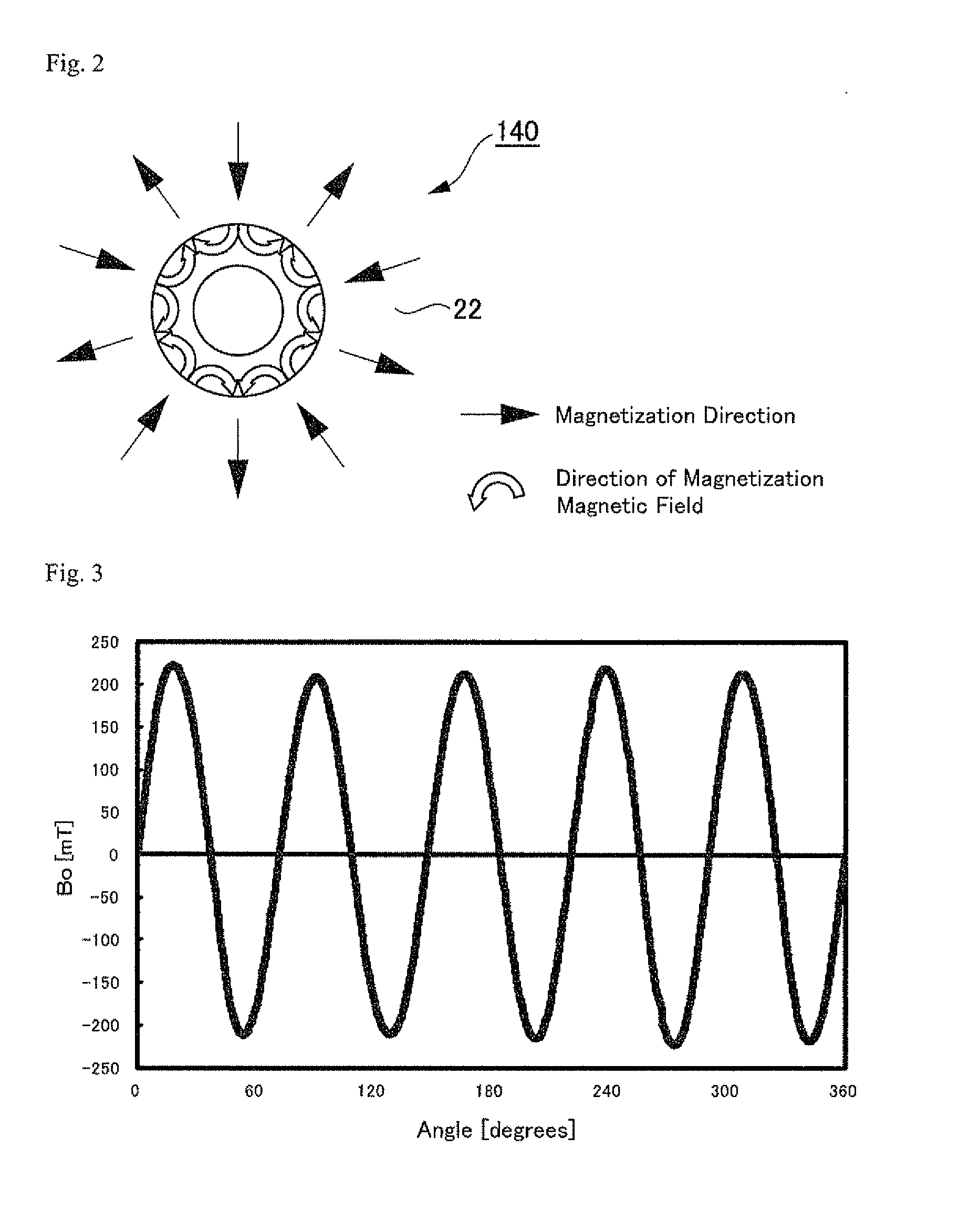

A method for manufacturing a magnetized bonded magnet, including the steps of: arranging a magnetization permanent magnet for magnetizing a magnetic field near a non-magnetized bonded magnet; heating the non-magnetized bonded magnet to a temperature of a Curie point thereof or higher; and continuously magnetizing the magnetic field to the non-magnetized bonded magnet by the magnetization permanent magnet for magnetizing the magnetic field while cooling the non-magnetized bonded magnet reached at the temperature of the Curie point thereof or higher to a temperature of less than the Curie point, wherein the non-magnetized bonded magnet is a rare-earth iron bonded magnet including two or more different rare-earth elements in magnet powder thereof.

Owner:MINEBEA CO LTD

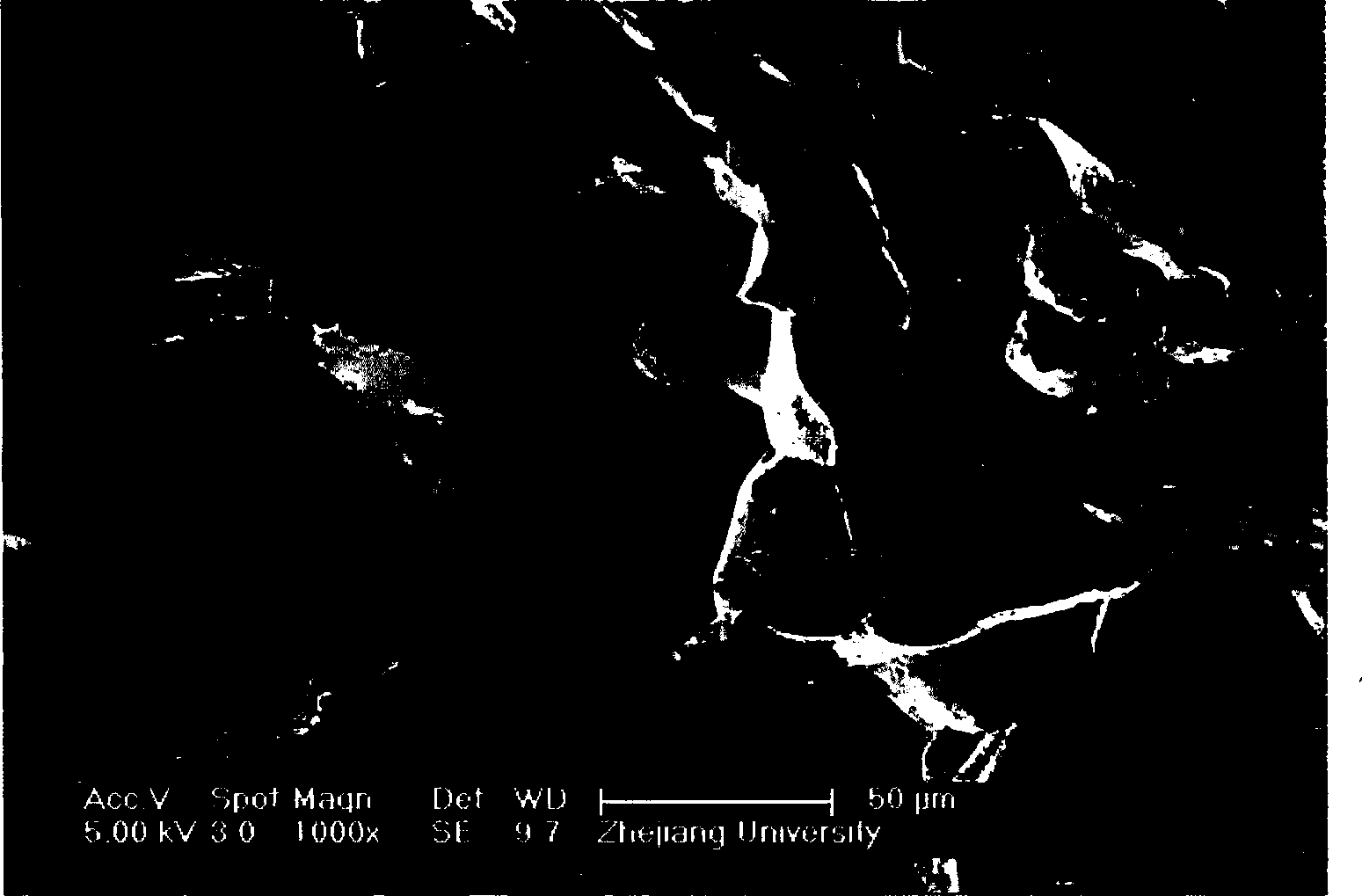

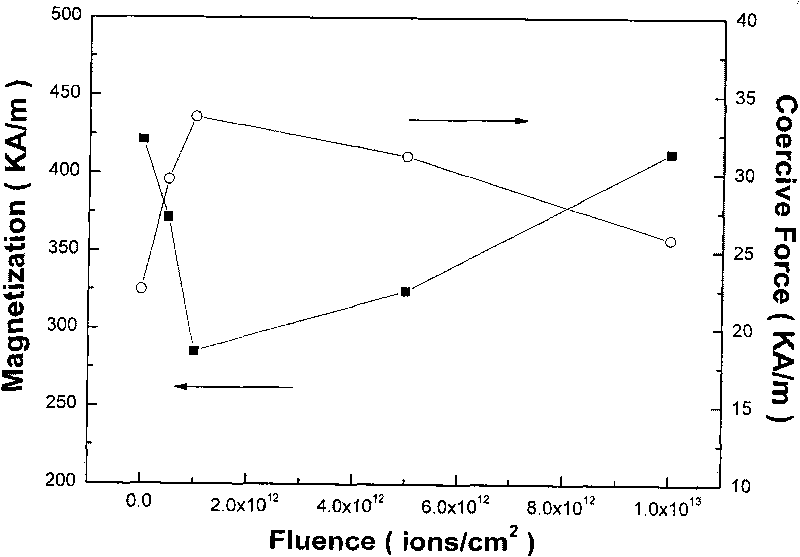

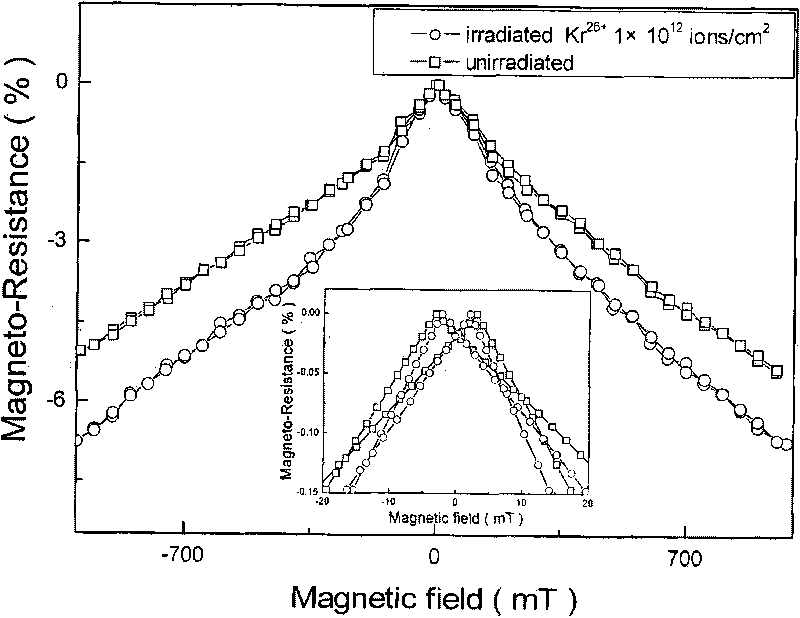

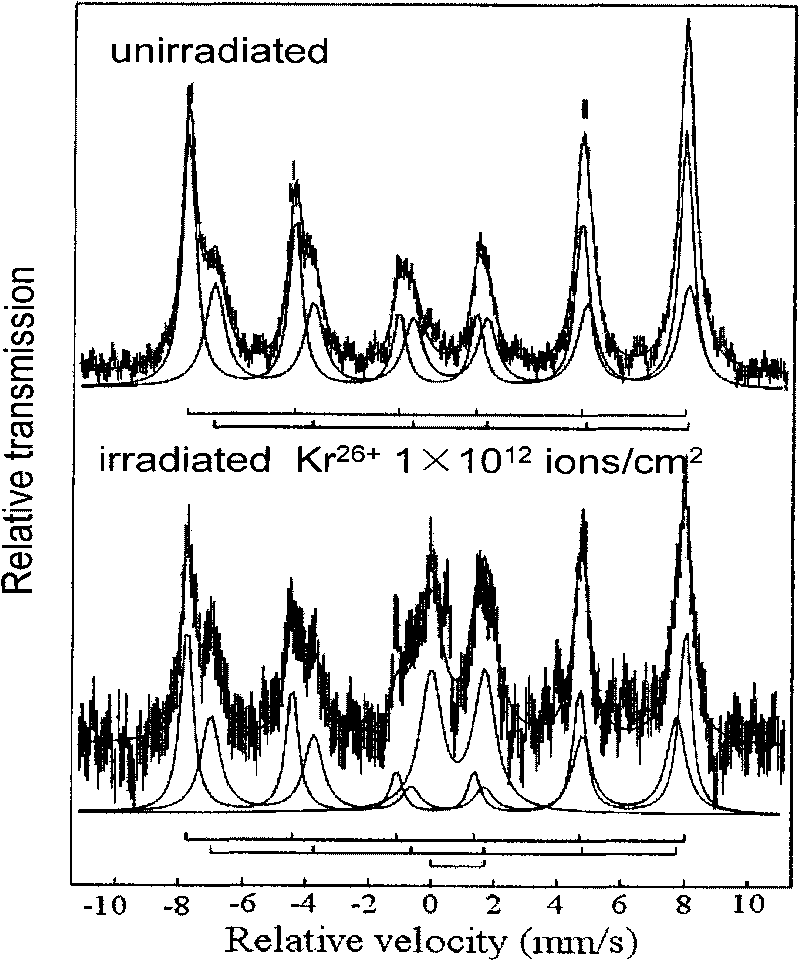

Method for improving and modulating magnetoresistance of semi-metallic thin film materials by high-energy heavy ion irradiation

InactiveCN101740715ARoom temperature magnetoresistance increasedAchieve the purpose of man-made modulationGalvano-magnetic device manufacture/treatmentSurface stressHigh energy

The invention relates to a method for improving and modulating magnetoresistance of semi-metallic thin film materials by high-energy heavy ion irradiation, which adopts the following measures: (1) the film thickness of a semi-metallic thin film is controlled between 100 nanometers and 10 micrometers; (2) the type of irradiation heavy ions is Aq+, wherein A is selected from one of elements with the atomic numbers of 10-92, q+ is the number of charges stripped by an accelerator, and q is greater than or equal to 1 and is less than or equal to the atomic number of A; (3) the energy range of the irradiation heavy ions is between 100keV and 10GeV; and (4) the irradiation range of the irradiation heavy ions is between 1010ions / cm<2> and 1017ions / cm<2>. The method of the invention can obviously increase the grain insulating boundary and reduce the surface stress of semi-metallic thin film materials represented by Fe3O4 nano-polycrystalline thin films, can obtain high-quality barrier layers and barrier interfaces, can obviously improve the magnetoresistance at room temperature, and can enable the magnetoresistance to be capable of being modulated manually.

Owner:INST OF MODERN PHYSICS CHINESE ACADEMY OF SCI

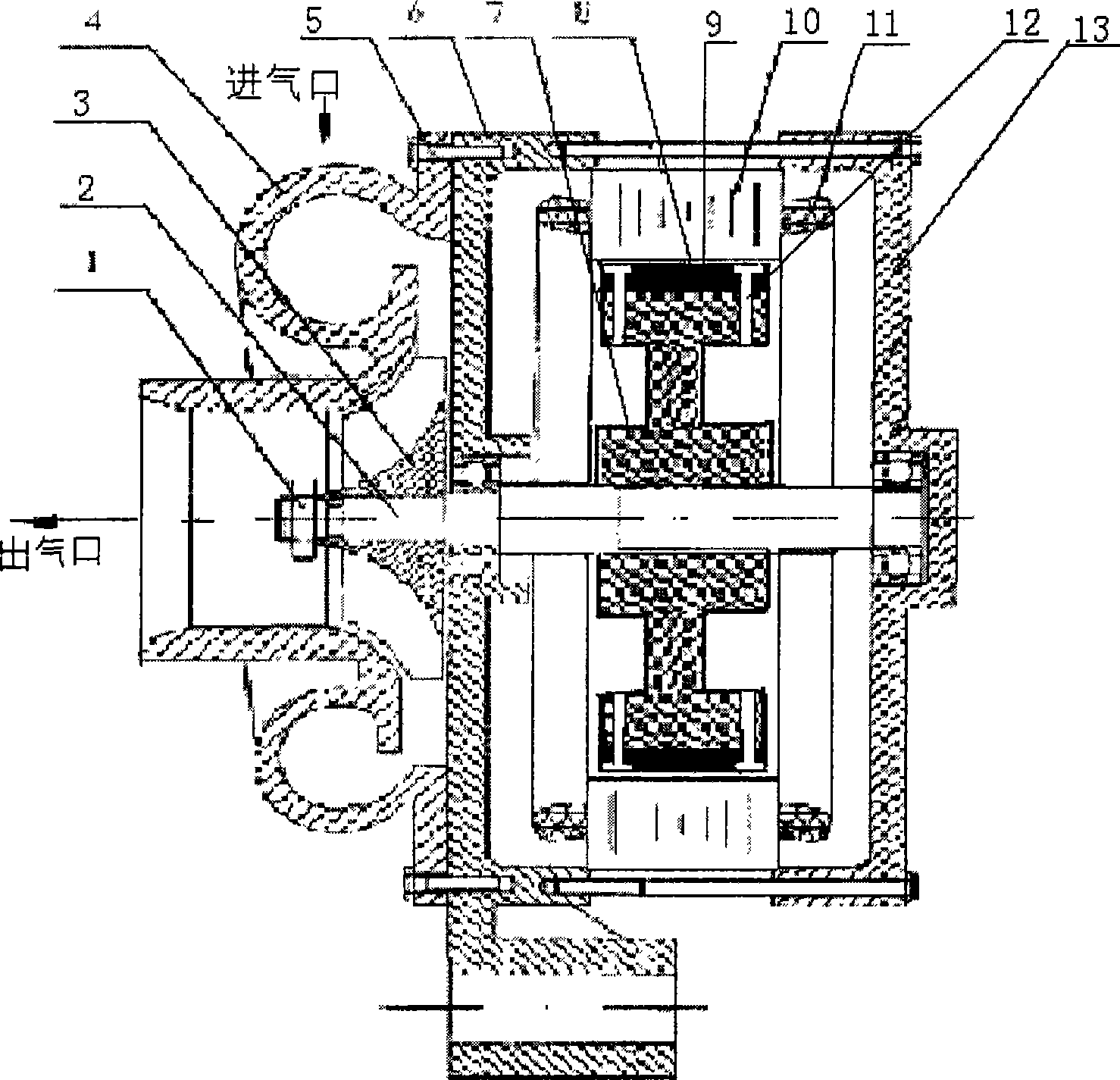

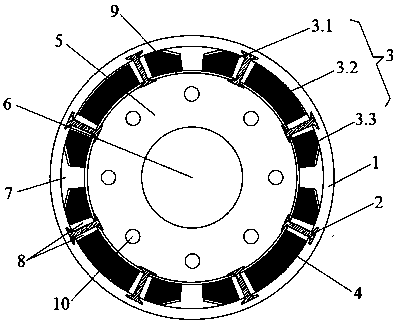

Vehicle waste gas driving three-phase generator

InactiveCN101503968ACompact structureSmall footprintMagnetic circuit rotating partsMagnetic circuit stationary partsSingle-phase generatorElectric machine

The invention provides a three-phase generator driven by vehicle waste gas, which belongs to the field of electrical appliances of automotive motors. The three-phase generator consists of a rotator, a stator, a front end cover, a rear end cover, a turbine and a turbine scroll; an armature winding of the stator is an armature winding with three same phases; the armature windings in three phases respectively cross over three poles of a stator core and sequentially inserting wires; each permanent magnet on a permanent magnetic rotor corresponds to every three poles on the stator core; a three-phase armature structure and a rectifying voltage stabilizing device are used for stabilizing the voltage and outputs the current with stabilizing voltage, thereby directly supplying power to a vehicle direct current electrical appliance and charging a storage battery; in addition, the turbine is fixed on the rear end cover of the generator by a bolt; the turbine and the generation shares with the same shaft; and the three-phase generator has compact structure, small occupied space and convenient mounting, and is the waste gas exhausted by the generator, thereby saving energy and reducing the cost.

Owner:柳小伟

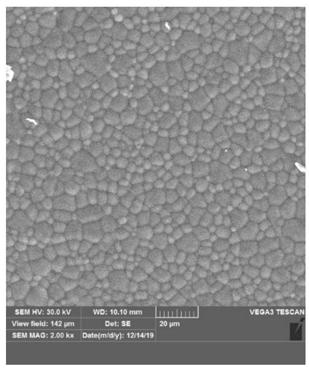

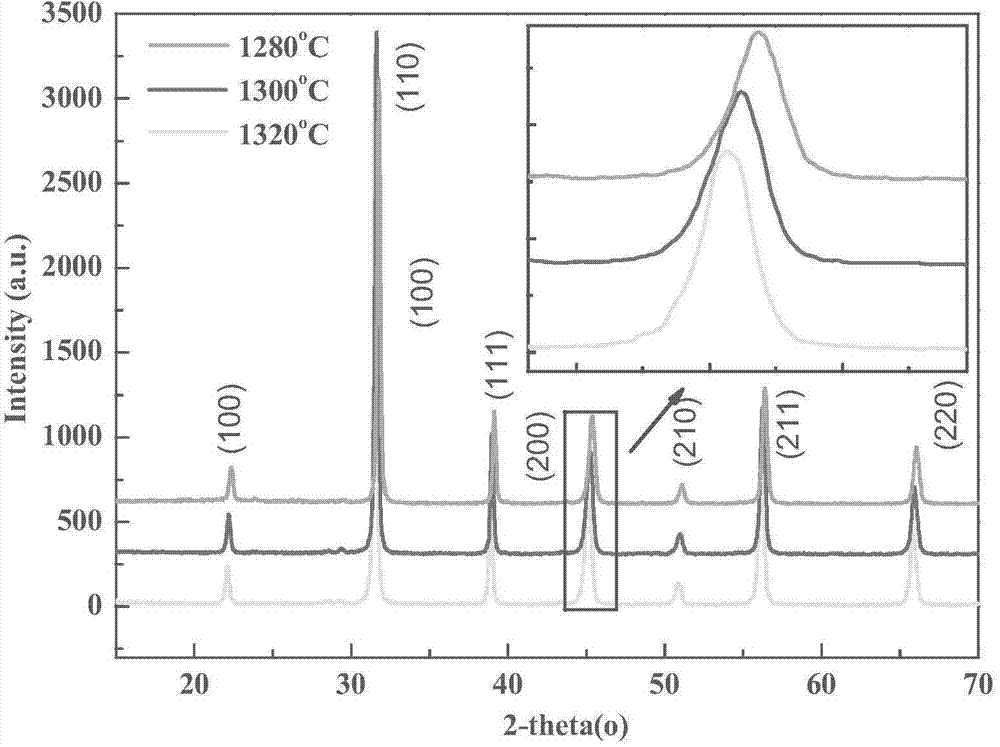

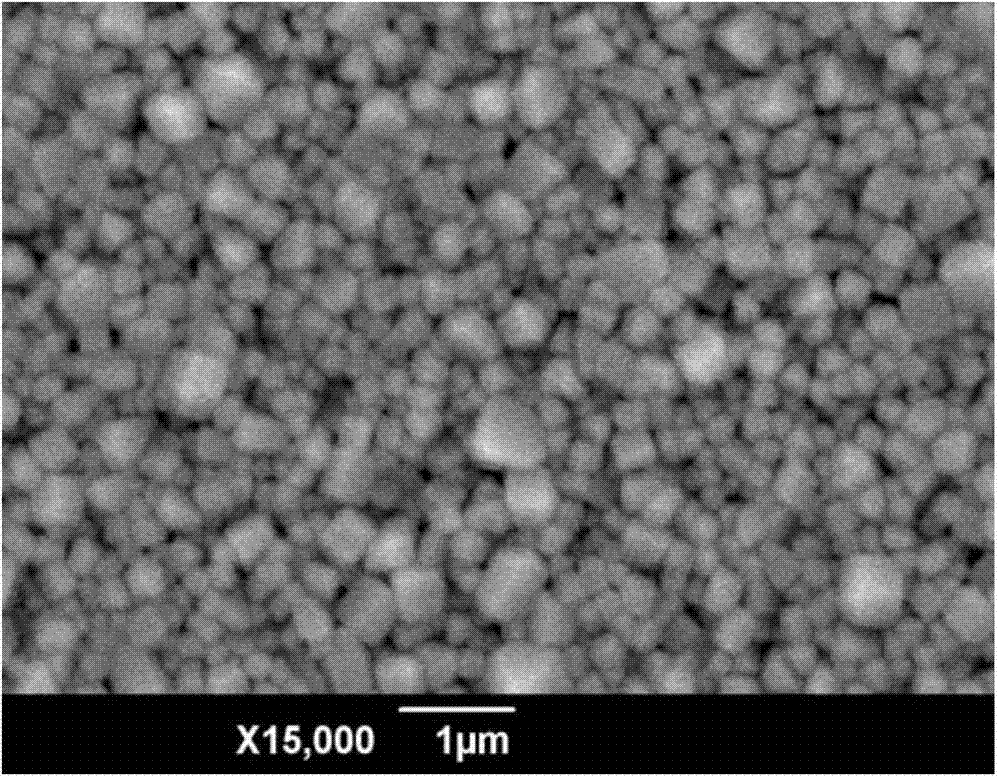

High-solid-solubility relaxation-type nano leadless piezoelectric ceramic and preparation method thereof

InactiveCN104496466AExcellent Dielectric Relaxation BehaviorHigh dielectric constantCurie temperatureMicrowave sintering

The invention relates to a high-solid-solubility relaxation-type nano leadless piezoelectric ceramic and a preparation method thereof. The method comprises the following steps: dissolving a soluble raw material in water according to the stoichiometric proportion of Ba0.8Ca0.2Ti0.9Zr0.1O3 to obtain a mixed solution; regulating the pH value of the mixed solution to obtain a powder precursor; reacting at 150-200 DEG C in a hydrothermal environment for 10-15 hours to obtain a billet; and carrying out microwave sintering on the billet at 1280-1320 DEG C to obtain the high-solid-solubility relaxation-type nano leadless piezoelectric ceramic. The ceramic, which is prepared by sintering the Ba0.8Ca0.2Ti0.9Zr0.1O3 ceramic powder at 1280-1320 DEG C, has the advantages of excellent dielectric relaxation behavior and high solid solubility for calcium ions, enhances the temperature stability of the material on the premise of effectively lowering the Curie temperature of the ceramic material, and still has excellent electric properties in some extreme environments.

Owner:SHAANXI UNIV OF SCI & TECH

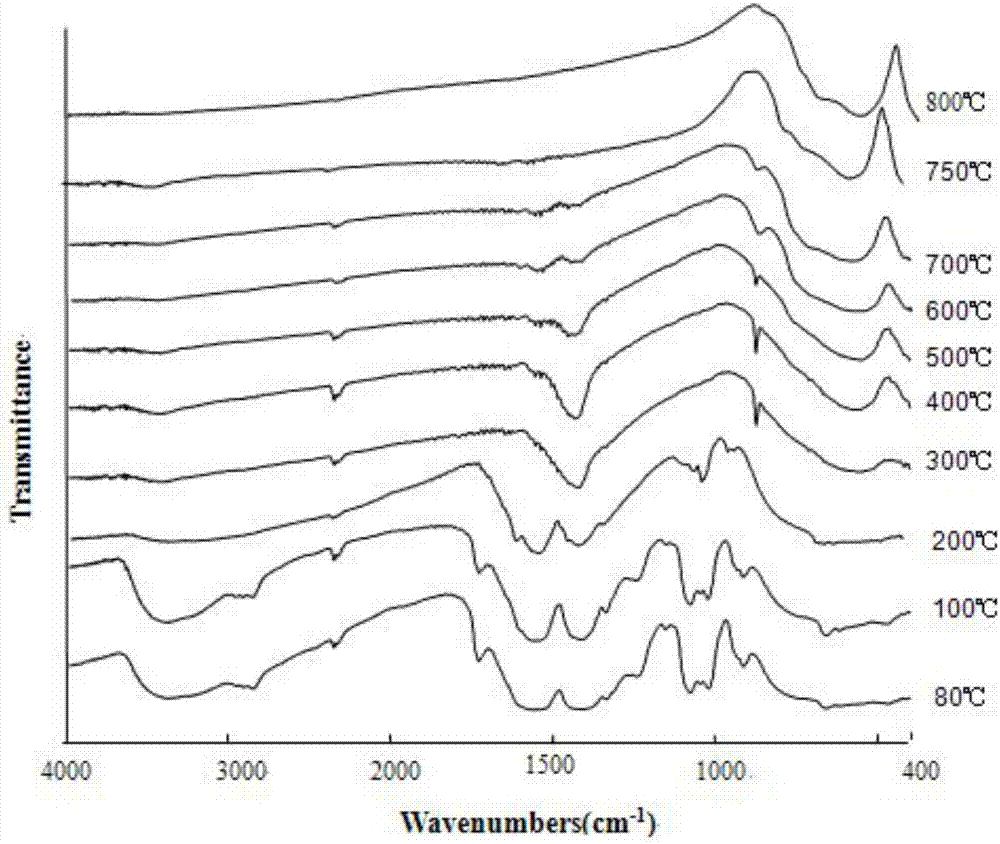

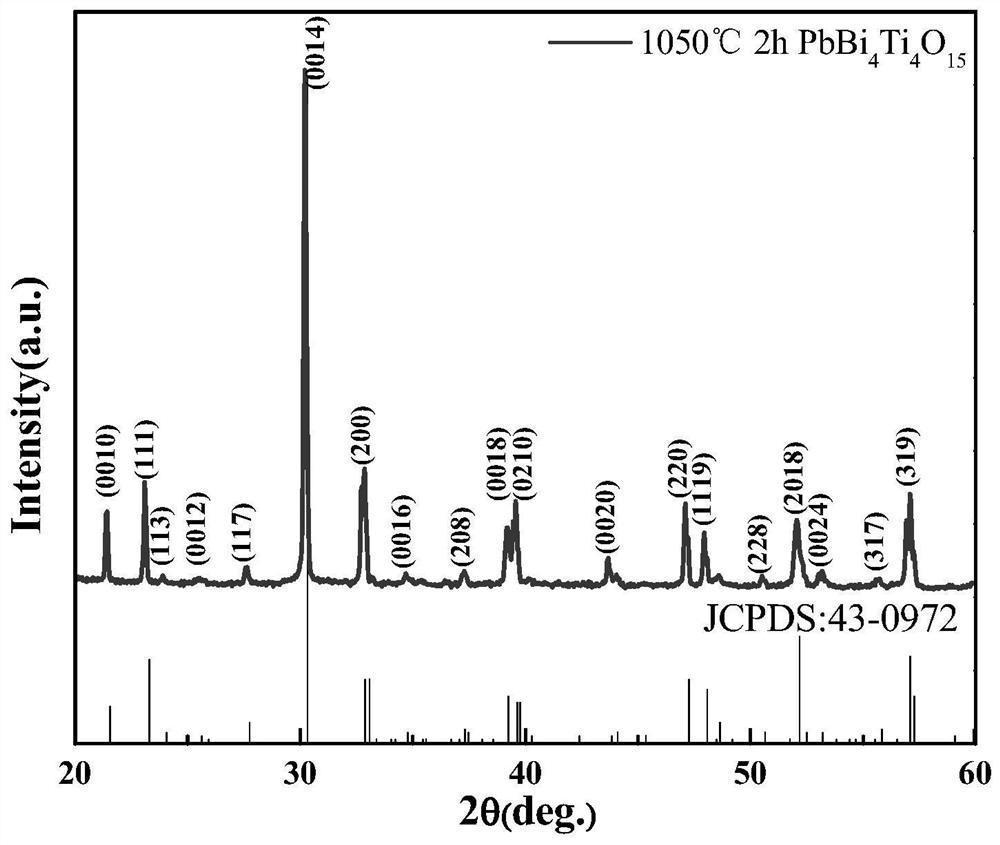

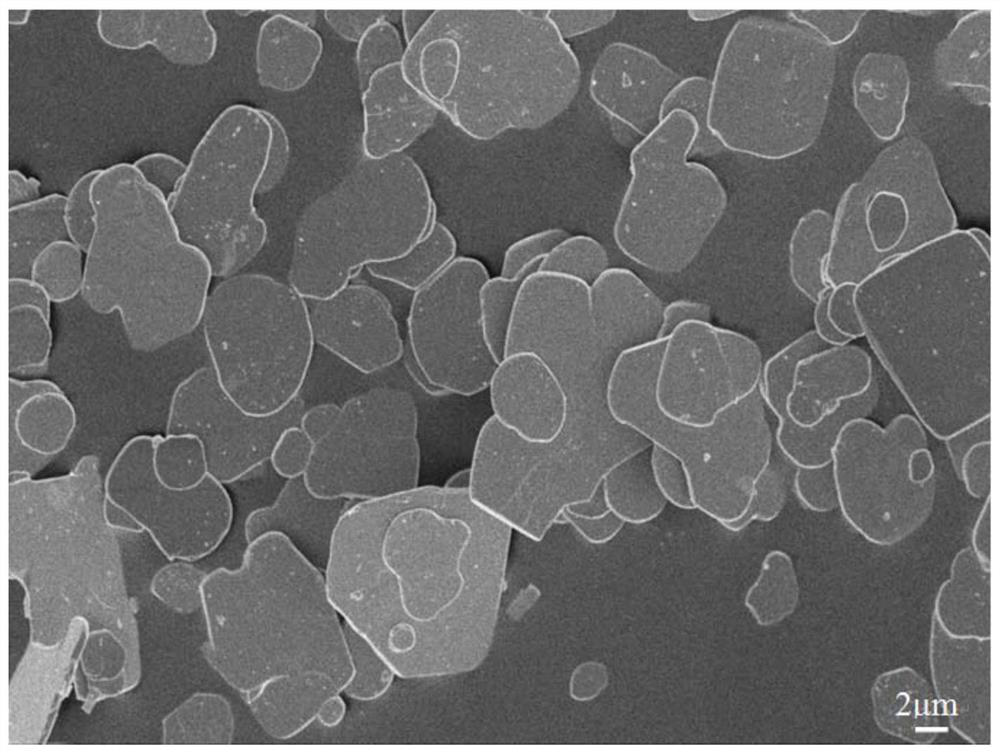

Preparation method of calcium doped lead titanate ceramic fiber

InactiveCN107164841AImprove uniformityMicrostructure is easy to controlFibre chemical featuresFiberHigh density

The invention relates to a preparation method of calcium doped lead titanate ceramic fiber, and the preparation method is characterized by comprising the following specific steps: (1) preparation of stable sol; (2) drawing and drying; (3) decomposition of dry gel fiber; and (4) sintering. The sintering conditions are as follows: the sintering temperature is 750 DEG C, the sintering time is 60min, and the heating rate is 2 DEG C / min. The preparation method has scientific and reasonable design, simple process, easy operation, low cost, and other advantages, the ceramic fiber prepared by the method has high strength, superior performance, smooth surface, high density, low tendency to fragmentation and other advantages, and the method has the advantages of convenient operation and easy implementation, and is a highly innovative preparation method of the calcium doped lead titanate ceramic fiber.

Owner:HEBEI CHEM & PHARMA COLLEGE

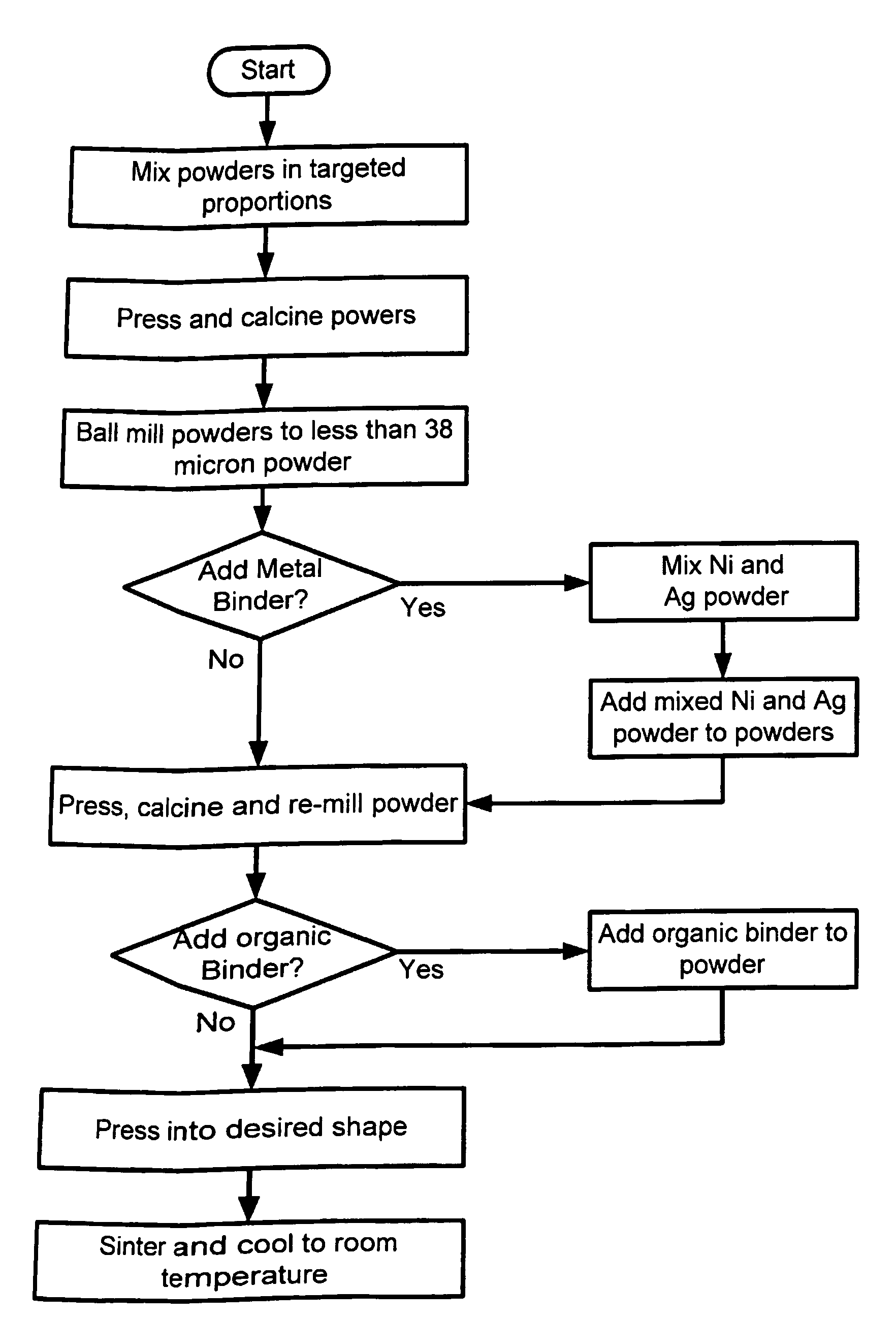

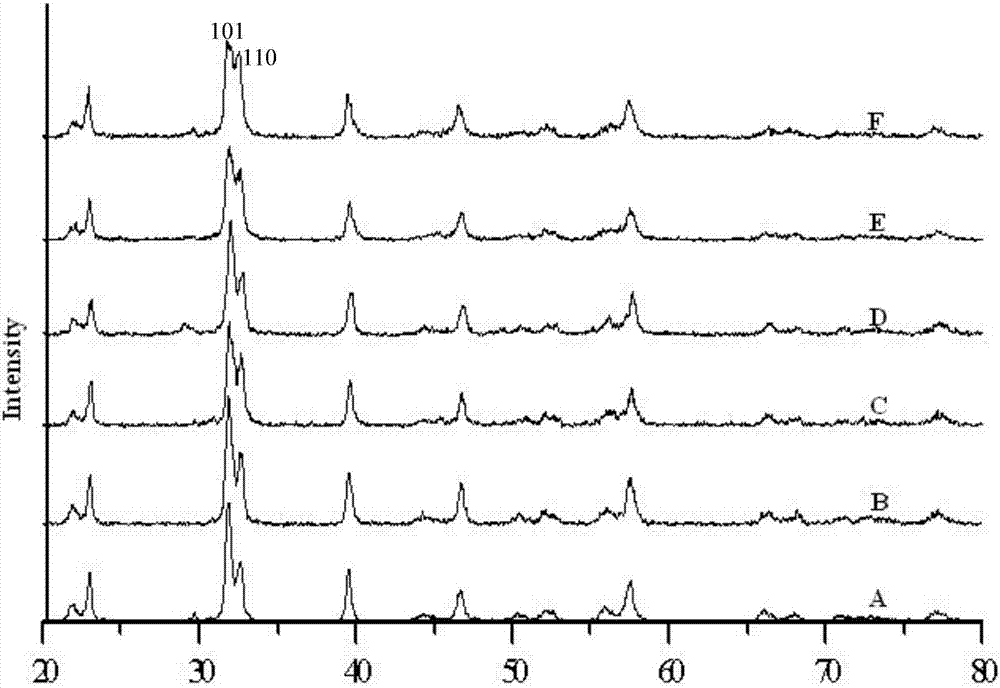

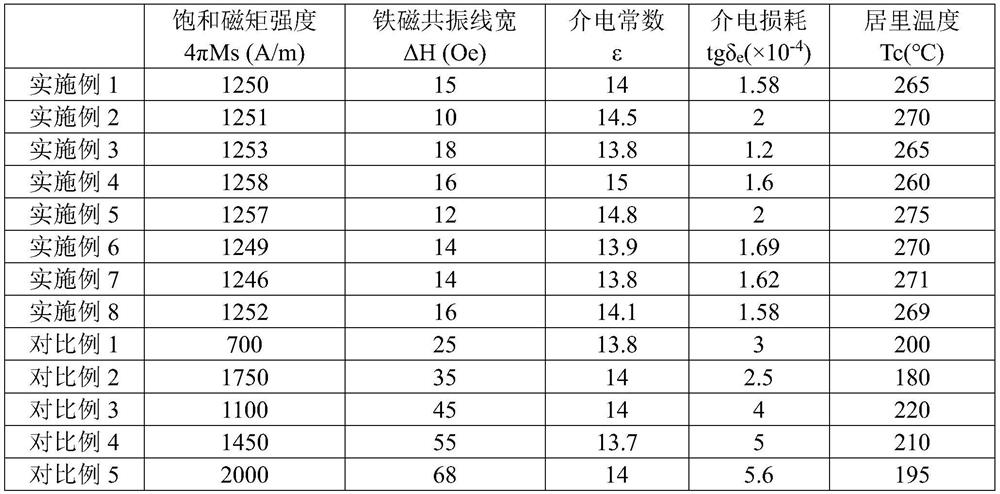

Two-component microwave ferrite material as well as preparation method and application thereof

ActiveCN113072372ASmall resonance line widthLow saturation magnetic momentWaveguide type devicesMicrowaveDielectric loss

The invention provides a two-component microwave ferrite material as well as a preparation method and application thereof. The two-component microwave ferrite material comprises a first microwave ferrite material and a second microwave ferrite material. The two-component microwave ferrite material can be applied to microwave communication devices. The preparation method comprises the following steps: (1) mixing a first microwave ferrite material and a second microwave ferrite material according to a formula ratio, and then carrying out wet ball milling to obtain a ball milling material; (2) drying the ball-milled material obtained in the step (1), conducting sieving, and conducting granulating; and (3) sequentially molding and sintering the granulated particles obtained in the step (2) to obtain the two-component microwave ferrite material. Tests show that the ferromagnetic resonance line width [delta]H of the obtained material is less than or equal to 18Oe, the saturation magnetic moment 4[pi]Ms is less than or equal to 1260Gs, the dielectric loss tg[delta]e is less than or equal to 2*10<-4>, and the Curie temperature Tc is more than or equal to 260 DEG C. The stability and reliability of the material are greatly improved, and the material is more beneficial to industrial production.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

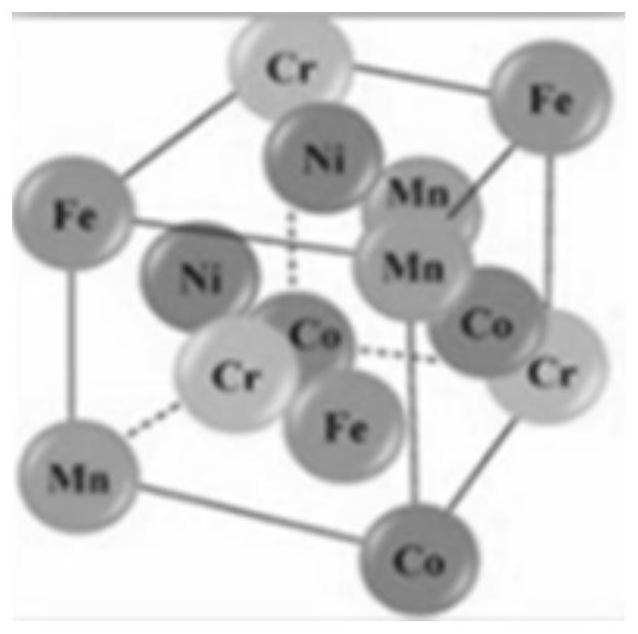

Magnetic conductive material, preparation method thereof and cooking utensil containing magnetic conductive material

PendingCN114649124AHigh thermal conductivitySmall temperature differenceInorganic material magnetismInductances/transformers/magnets manufactureHigh entropy alloysConductive materials

The invention relates to the technical field of cooking utensils, in particular to a magnetic conductive material, a preparation method thereof and a cooking utensil containing the magnetic conductive material. The magnetic conductive material comprises a high-entropy alloy and a filler, wherein the composition elements of the high-entropy alloy comprise at least four of Mg, Al, Ti, V, Cr, Mn, Fe, Co, Ni, Cu, Zn, Zr, Nb, Mo, Sn, Hf, Ta, W, Pb, Si and B, and the composition elements at least comprise one or more of Fe, Co and Ni; the filler comprises at least one of an inorganic porous material and a ceramic material. According to the cooking utensil, electromagnetic induction heating can be achieved, the heating efficiency is improved, and the cooking utensil has the advantages of being uniform in heating, resistant to deformation, constant in temperature and good in corrosion resistance in the using process.

Owner:WUHAN SUPOR COOKWARE

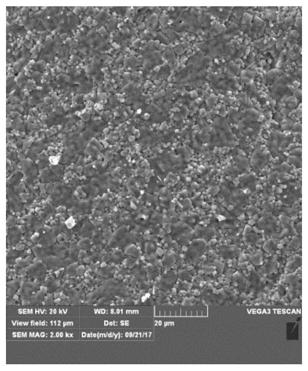

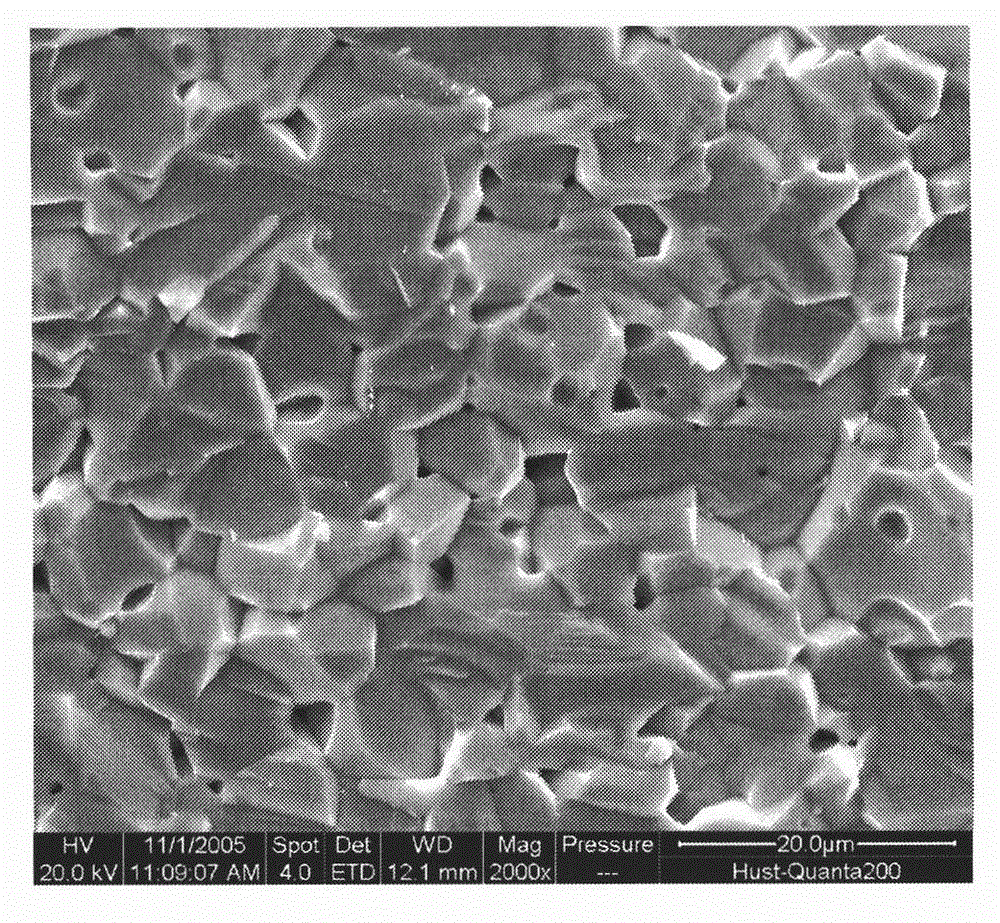

Preparation method of high-toughness non-magnetic Ti(C,N)-based metal ceramic

The invention discloses a preparation method of high-toughness non-magnetic Ti(C,N)-based metal ceramic. The preparation method includes the following steps that firstly, TiO2 powder, W powder and active carbon powder serve as raw materials for burdening, high-energy ball milling is adopted, and an intermediate reaction product is obtained; then the obtained intermediate reaction product, TiN powder, Ni powder, Mo powder, Ti2AlN powder and AlN powder serve as raw materials for preparation of a mixture, wherein the mixture is prepared from components by mass parts: 24.0-30.3 parts of Ti, 11.5-16.1 parts of O, 14.0-19.3 parts of C, 1.9-2.3 parts of N, 18-32 parts of Ni, 10.0-11.1 parts of Mo, 4.0-4.5 parts of W and 0.4-0.6 part of Al; and adding of a forming agent, press-forming, removing ofthe forming agent and sintering are carried out, and the high-toughness non-magnetic Ti(C,N)-based metal ceramic is obtained. The sintered metal ceramic is not magnetic at room temperature and has high toughness and excellent comprehensive performance, there is no special requirement on production equipment, the energy consumption is reduced, and industrial application and popularization are facilitated.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

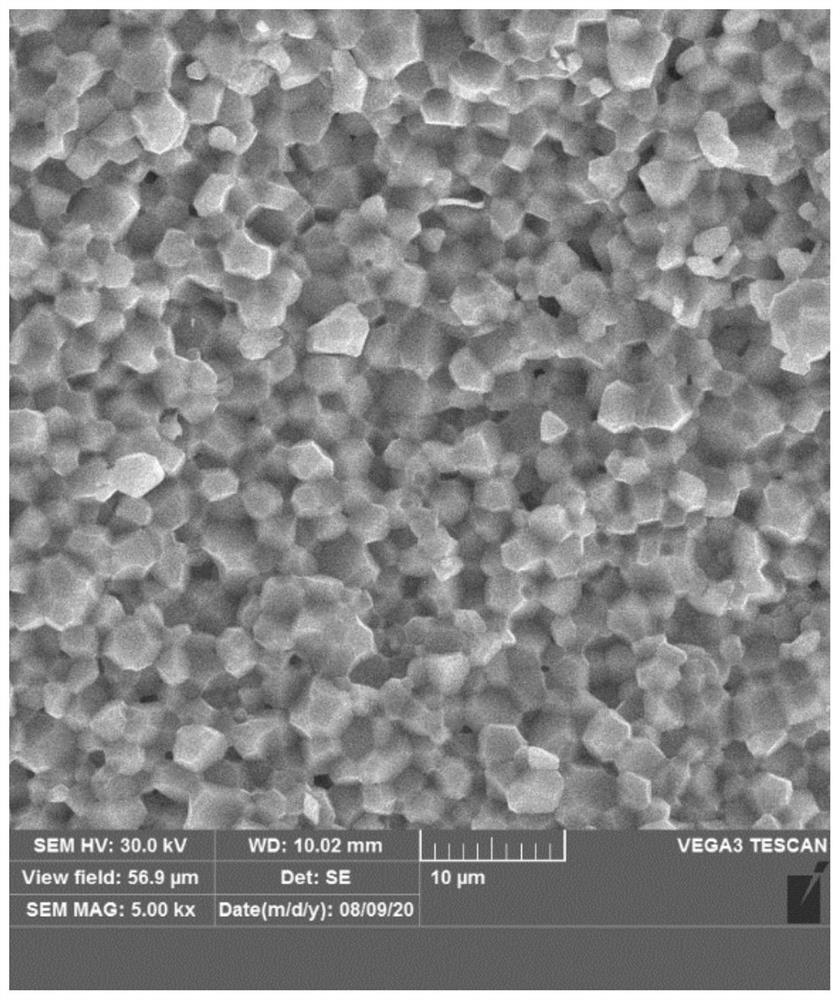

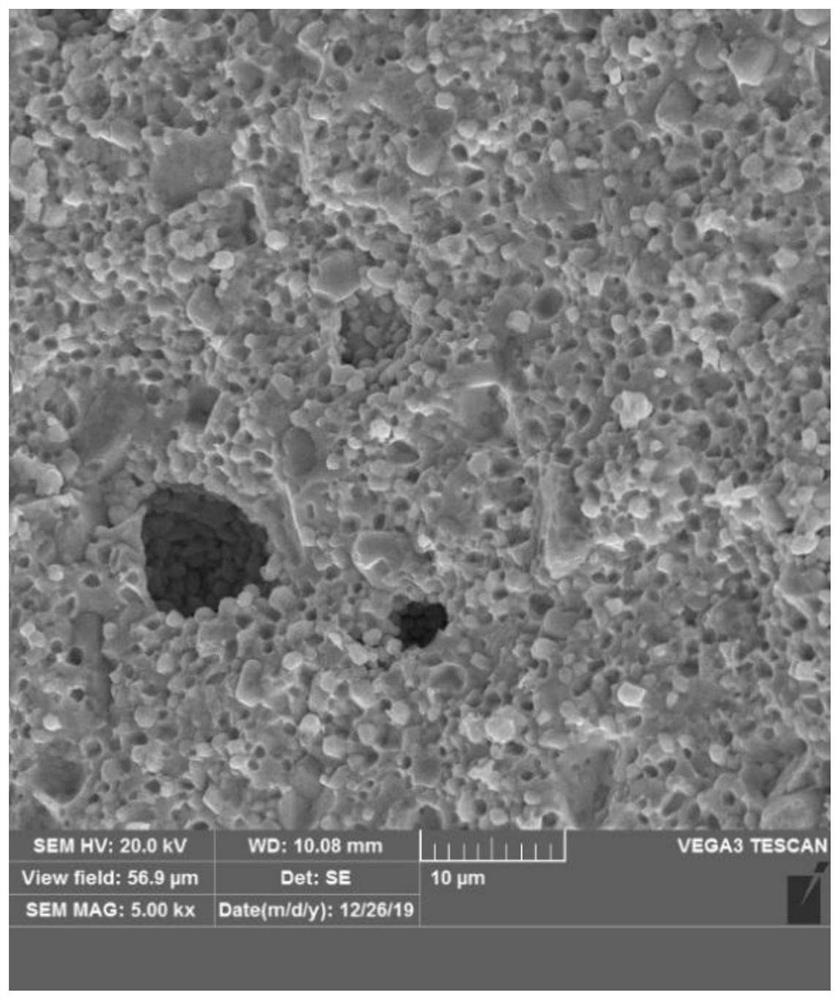

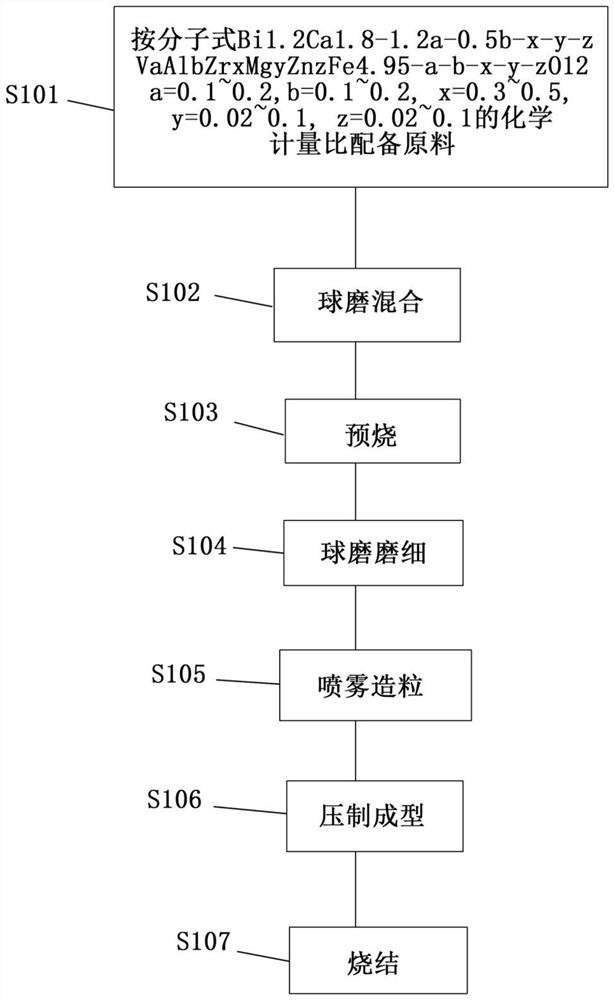

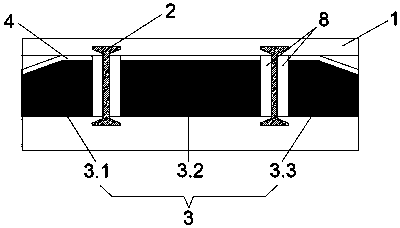

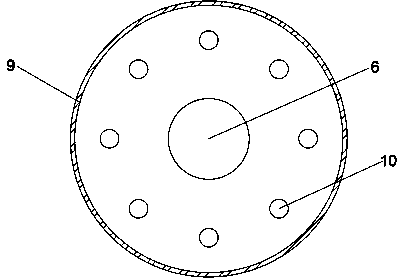

Yttrium-free high-dielectric-constant microwave ferrite material and preparation method and device thereof

PendingCN112390637ALow costConducive to mass production and popularization and applicationComposite materialYttrium

The invention provides a yttrium-free high-dielectric-constant microwave ferrite material and a preparation method and device thereof. The chemical formula of the microwave ferrite material is Bi1.2Ca1.8-1.2a -0.5b-x-y-zVaAlbZrxMgyZnzFe4.95-a-b-x-y-zO12, wherein a is equal to 0.1-0.2, b is equal to 0.1-0.2, x is equal to 0.3-0.5, y is equal to 0.02-0.1 and z is equal to 0.02-0.1. The preparation method comprises the following steps of: preparing Bi1.2Ca1.8-1.2a -0.5b-x-y-zVaAlbZrxMgyZnzFe4.95-a-b-x-y-zO12 according to the stoichiometric ratio that a is 0.1-0.2, b is 0.1-0.2, x is 0.3-0.5, y is0.02-0.1 and z is 0.02-0.1, and the microwave ferrite material is prepared by using the raw materials. The material disclosed by the invention has the characteristics of low cost, high dielectric constant and the like, the dielectric constant is 24-26, 4piMs is 1400-1650Gs, delta H is less than 50Oe, and Tc is greater than 190 DEG C, so that the application of a microwave ferrite device can be well met, and the problems of miniaturization and the like of the microwave device are solved.

Owner:深圳顺络微波器件有限公司

Broadband high impedance MnZn ferrite material and manufacture method thereof

ActiveCN101857426BLow Curie temperatureHigh resistivityInorganic material magnetismInitial permeabilityMetallurgy

The invention provides a broadband high impedance MnZn ferrite material, which comprises main components and assistant components. The main components comprise 47 to 50 mol percent of Fe203, 29 to 35 mol percent of Mn3O4 by MnO and 16 to 21 mol percent of ZnO. The assistant components are at least one kind from SiO2, CaCO3, V205 and Nb2O5. Total weight based on the main components is that SiO2 is0.002 to 0.01 wt percent, CaCO3 is 0.01 to 0.08 wt percent, V205 is 0.01 to 0.07 percent, and Nb2O5 is 0.01 to 0.07 percent. The broadband high impedance MnZn ferrite material has DC resistivity larger than 103 omega meter, curie temperature higher than 115 degrees centigrade and 2000 plus or minus 20 percent initial permeability. Moreover, the low frequency impedance of the material is larger than the common NiZn ferrite material, the high frequency impedance thereof is equal to the common NiZn ferrite material and the material does not contain expensive raw material NiO. The invention further provides the manufacture method of the broadband high impedance MnZn ferrite material, which comprises the steps of mixing, drying, preburning, ball-milling, granulation, molding, sintering and thelike.

Owner:江门江益磁材有限公司

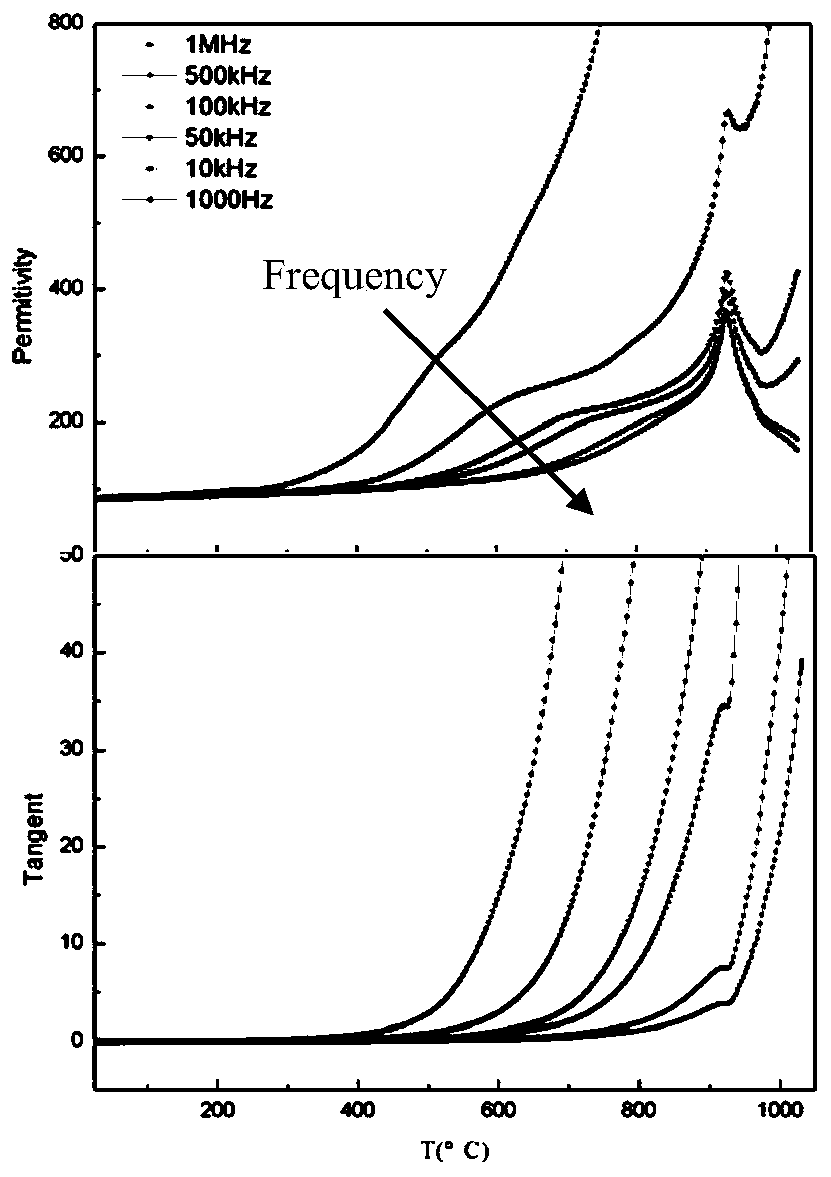

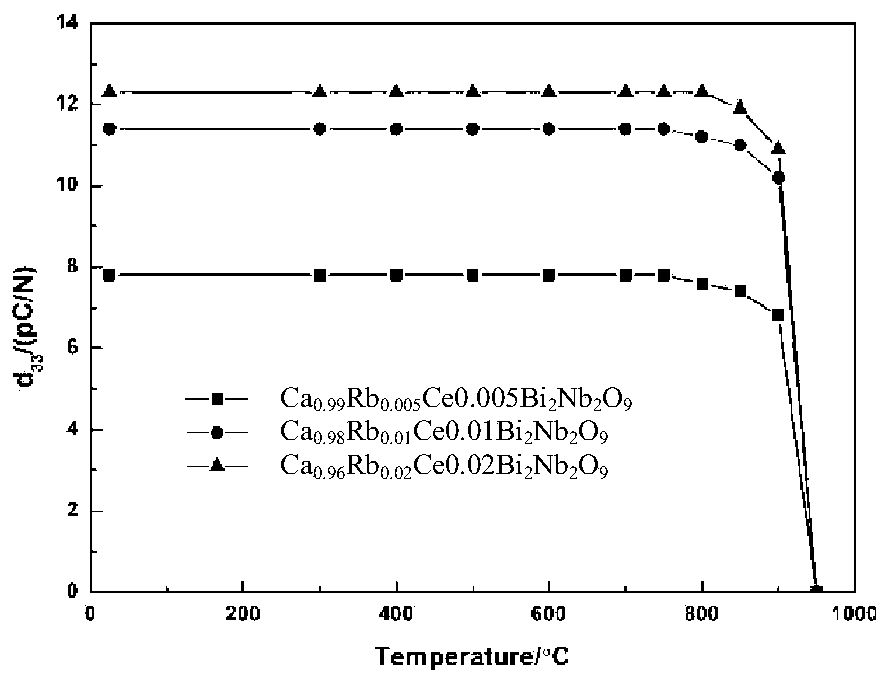

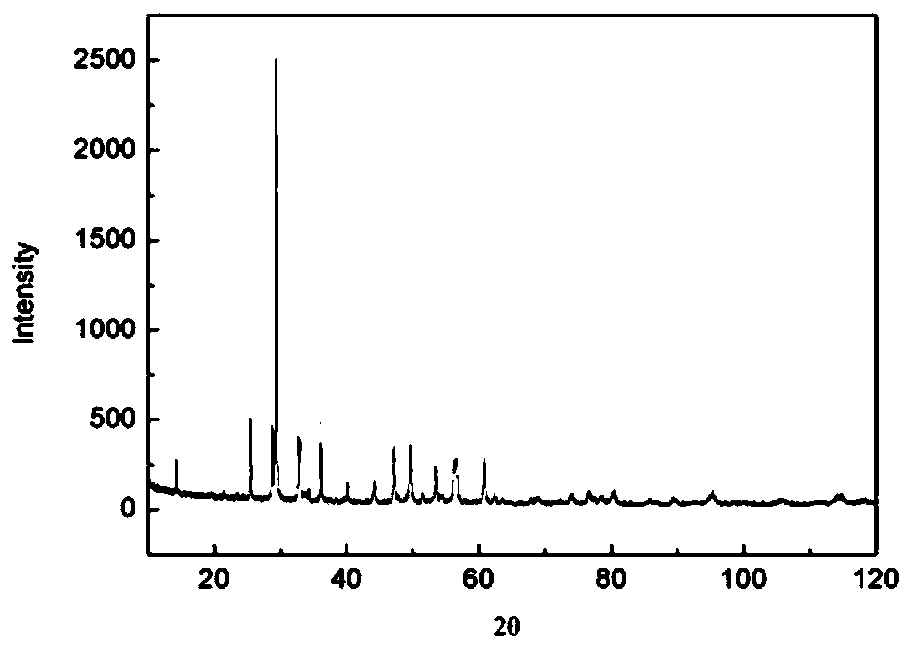

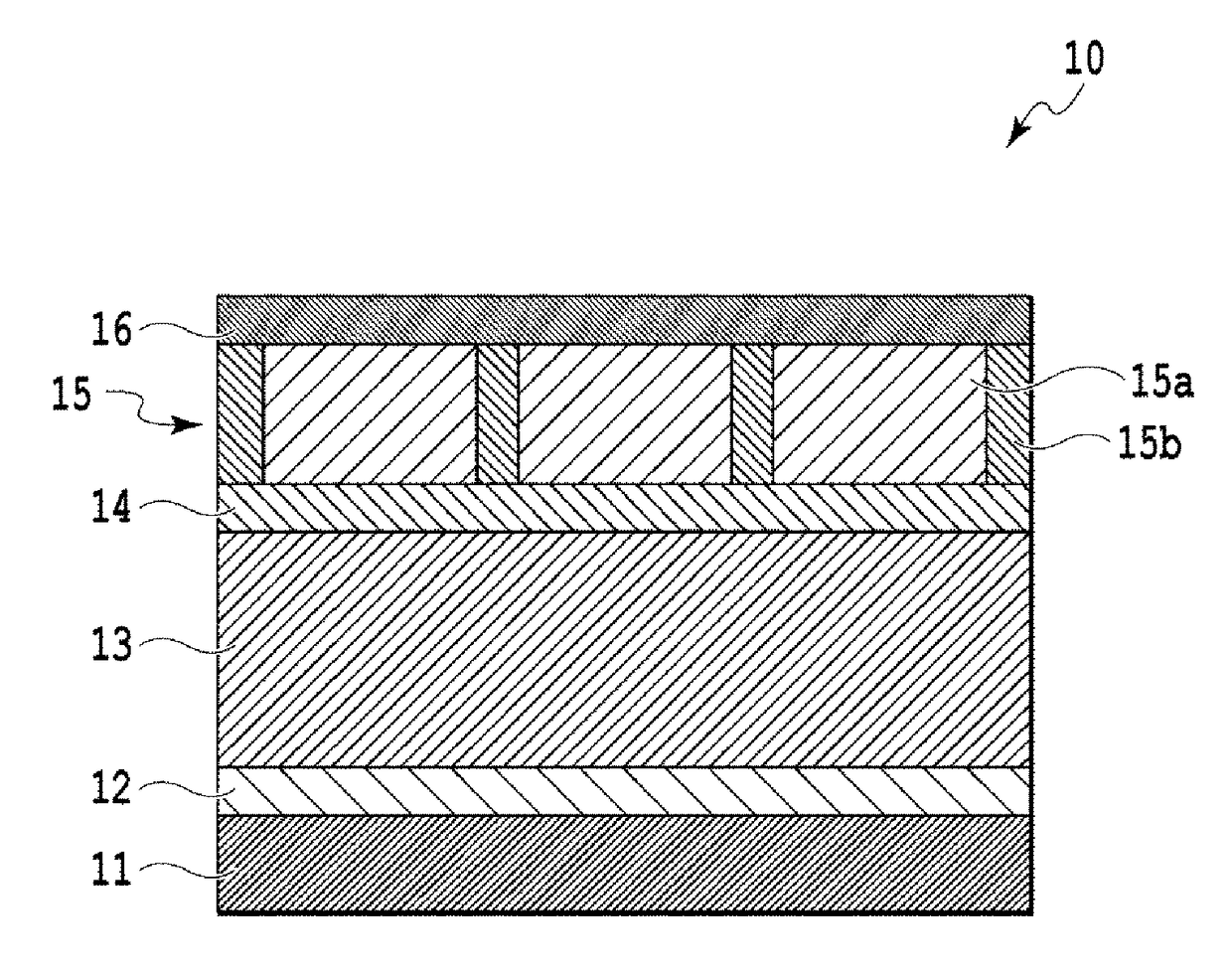

Rubidium-and-cerium co-doped calcium bismuth niobate-based high-temperature piezoelectric ceramic and preparing method thereof

The invention discloses a rubidium-and-cerium co-doped calcium bismuth niobate (CBNO)-based high-temperature piezoelectric ceramic and a preparing method thereof. The structural general formula of thepiezoelectric ceramic is Ca1-x-yRbxCeyBi2Nb2O9, 0<=x<=0.5, and 0<=y<=0.5, wherein x and y represent mole fractions of elements rubidium and cerium respectively. According to the rubidium-and-cerium co-doped calcium bismuth niobate (CBNO)-based high-temperature piezoelectric ceramic and the preparing method thereof, a solid-phase method is adopted for preparing level-A calcium bismuth niobate piezoelectric ceramic materials doped with Rb and Ce ions of different contents; then through the process of pelleting, forming, glue discharging and sintering, the rubidium-and-cerium co-doped CNBO-basedhigh-temperature piezoelectric ceramic is prepared. The piezoelectric ceramic has excellent piezoelectric activity and a good high-temperature resistance rate. Various piezoelectric sensors assembledby means of the materials can be widely applied in the aspects such as measurement, detection and automatic control under high-temperature conditions.

Owner:广州光鼎科技集团有限公司

Perpendicular magnetic recording medium

ActiveUS9940961B2High magnetic anisotropy constantImprove coercive forceRecord information storageMagnetic recordingMagnetic anisotropyAlloy

Owner:FUJI ELECTRIC CO LTD

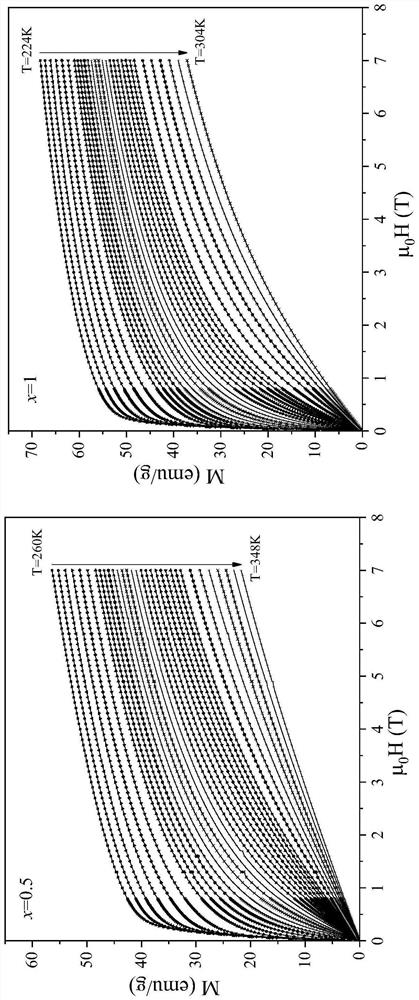

Near-room-temperature magnetic refrigeration manganese-germanium-based refrigeration material and preparation method thereof

ActiveCN112226659ALow Curie temperatureReduce hysteresis lossInorganic material magnetismSustainable buildingsPhysical chemistryManganese

The invention relates to a near-room-temperature magnetic refrigeration manganese-germanium-based refrigeration material and a preparation method thereof. The preparation method specifically comprisesthe steps that (1) manganese powder, germanium powder and titanium powder are weighed according to the stoichiometric ratio of Mn5Ge<3-x>Ti<x> (wherein x is 0.5 to 1) and heated, melted and mixed under the protection of inert gas, and a homogenized sample is obtained; and (2) the homogenized sample is taken out, cooled and annealed to obtain the target product. Compared with the prior art, the near-room-temperature magnetic refrigeration manganese-germanium-based refrigeration material and the preparation method thereof have the advantages that the manganese-germanium-based refrigeration material prepared by the preparation method disclosed by the invention has extremely small hysteresis loss, relatively large magnetocaloric effect and adjustable temperature width, meanwhile, the phase change property is secondary and is continuously adjustable at a near room temperature (265K-290K), so that the requirements of a near room temperature magnetic refrigeration technology are met.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

Low temperature resistant high speed permanent magnet motor high strength rotor structure

InactiveCN109873513ALow coercivityReduce the temperatureMagnetic circuit rotating partsFiberCarbon fibers

The invention provides a low temperature resistant high speed permanent magnet motor high strength rotor structure and belongs to the technical field of a motor structure. The rotor structure comprises a rotor core, permanent magnet poles, reinforcing ribs, a rotation shaft and heat dissipation holes. The permanent magnet poles which are equidistantly arranged along a peripheral direction are fixed at an outer side of the rotor core. The rotor core is connected with the permanent magnet poles through utilization of anaerobic adhesive layers. A copper plated layer is adhered at an outer side ofthe permanent magnet poles. A first heat dissipation branch is set between the adjacent permanent magnet poles. Each permanent magnet pole is dividedly into No.1 permanent magnet, No.2 permanent magnet and No.3 permanent magnet nonuniformly. Two ends of the reinforcing ribs are inlaid at the outer side of the rotor iron and an inner side of a carbon fiber sheath. The reinforcing ribs, the rotor core, the carbon fiber sheath and the permanent magnet poles form a second heat dissipation branch. The rotor structure has relatively high practicability. On the premise of ensuring rotation speed ofa high speed permanent magnet motor, cogging torque of a rotor is reduced, mechanical performance of the motor rotor in a low temperature environment is improved, and heat dissipation capability in the rotor is improved.

Owner:HARBIN UNIV OF SCI & TECH

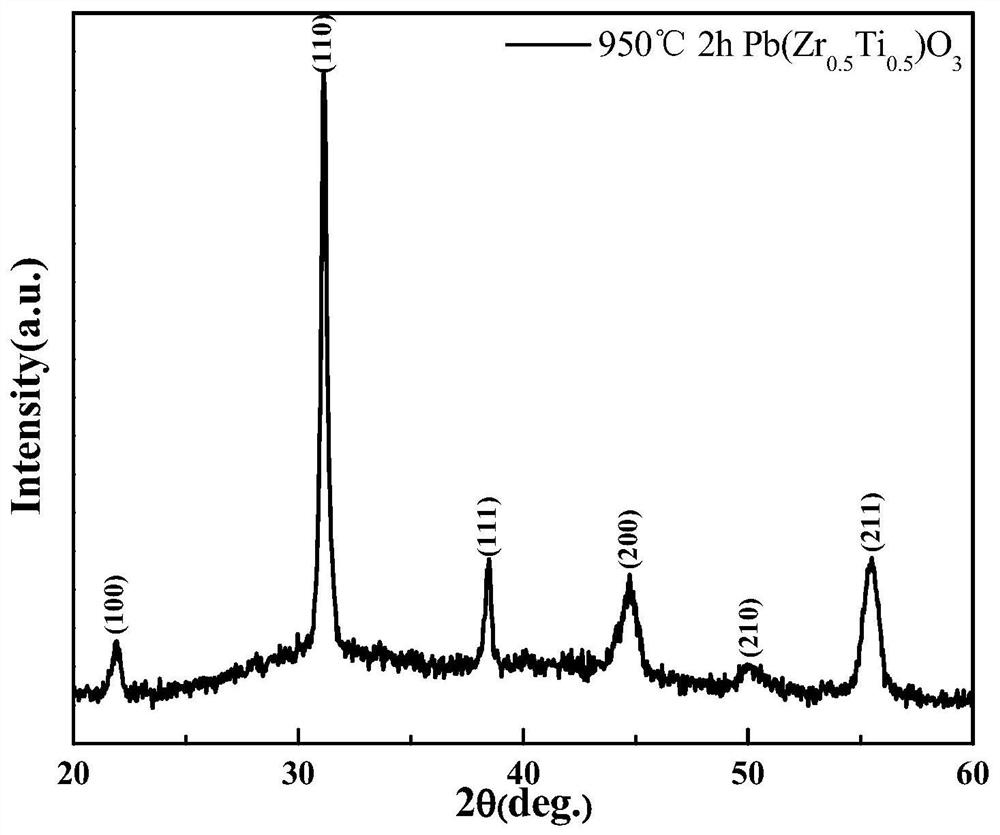

A kind of preparation method of micron flaky lead zirconate titanate crystal

ActiveCN108622931BGood orientationDoes not affect piezoelectricityMaterial nanotechnologyZirconium compoundsLead zirconate titanateZirconate

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

A temperature-controllable oxide thermoelectric material, a preparing method thereof and applications of the oxide thermoelectric material

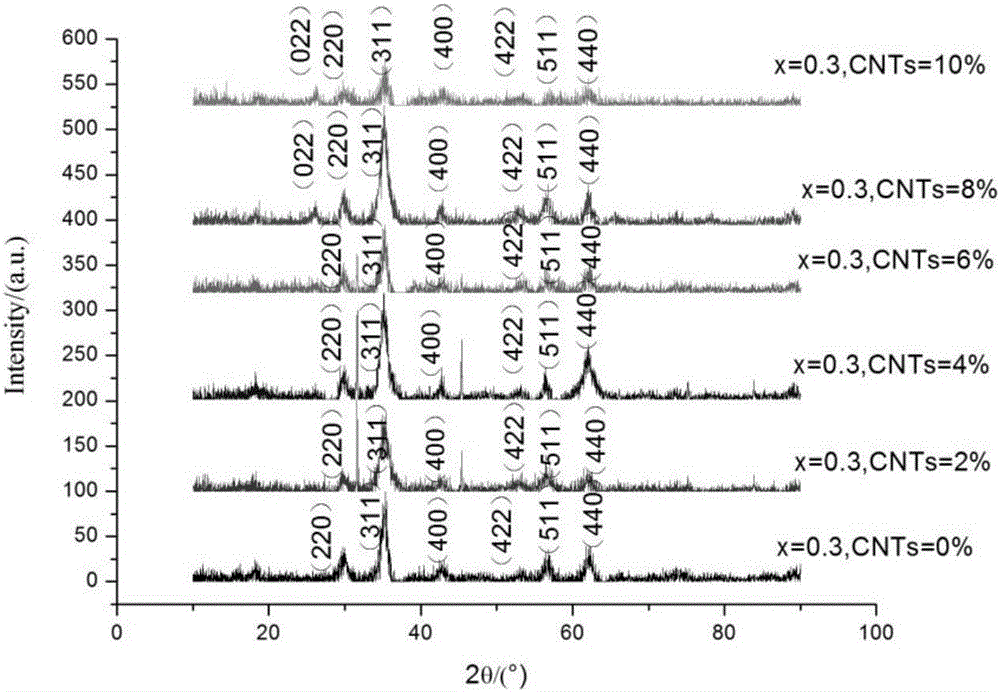

InactiveCN105859274ALow Curie temperatureImprove conductivityThermoelectric materialsTemperature control

A temperature-controllable oxide thermoelectric material, a preparing method thereof and applications of the oxide thermoelectric material are disclosed. The oxide thermoelectric material is prepared by preparing metal salts containing Mn<2+>, Fe<3+> and Zn<2+> into a solution, adding dropwise the solution into an alkali solution of carbon nanotubes, reacting, performing suction filtration, washing to obtain carbon nanotube-Mn<1-x>Zn<x>Fe2O4 composite powder, and finally sintering, wherein the objective of precise temperature controlling is achieved by controlling the adding amount of the carbon nanotubes, and the x is less than 1. The composite material formed by adding the carbon nanotubes into a manganese-zinc-iron ferrite has increased conductivity, a high Seebeck coefficient and low thermal conductivity. The composite material of the carbon nanotubes and the manganese-zinc-iron ferrite can control the temperature rising situation of the manganese-zinc-iron ferrite under actions of an alternating magnetic field through controlling the adding amount of the carbon nanotubes, thus achieving high thermoelectric performance and achieving a precise temperature controlling objective. The oxide thermoelectric material, the method and the applications have advantages of a simple process, a low cost, simple operation, short preparation time, a small grain size of the prepared material, and the like.

Owner:SHANDONG UNIV

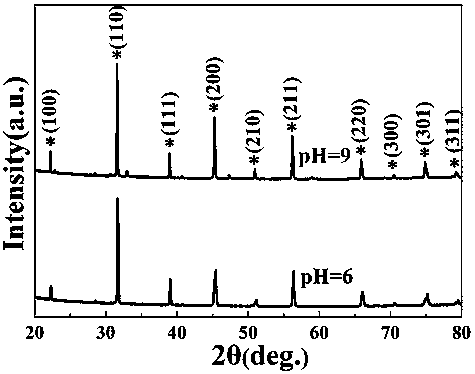

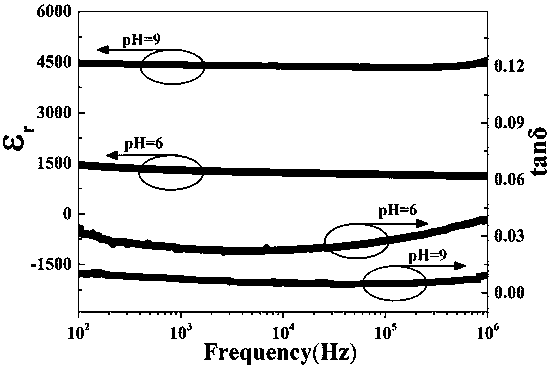

Method for preparing BCZT energy-storing ceramic material with adjustable Curie temperature

InactiveCN110600266ALow Curie temperatureHigh energy storage densityFixed capacitor dielectricSilver pasteSilver electrode

The invention discloses a method for preparing a BCZT energy-storing ceramic material with adjustable Curie temperature, comprising: preparing a solution in which the ratio of metal ions to Ba0.85Ca0.15Zr0.1Ti0.93 is 1.25: 1, and adjusting a pH value, and preparing a sol by heating; drying the sol in a blast drying box and grinding the sol into powders; calcining the prepared powders in a muffle furnace into BCZT oxide powders; grinding and granulating the BCZT oxide powders, and then sintering the BCZT oxide powders in the muffle furnace; finally, coating the sintered ceramic material with silver paste on both sides, and sintering and solidifying the ceramic material at a certain temperature to form a metal silver electrode. The method, by using the Ba0.85Ca0.15Zr0.1Ti0.9O3 ceramic material prepared by a sol-gel method, effectively regulates the Curie temperature of the BCZT ferroelectric ceramic material to the vicinity of room temperature, and is simple in process, low in cost, andhigh in energy storage density and efficiency.

Owner:HENAN NORMAL UNIV

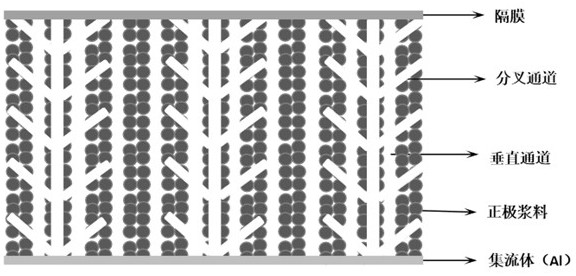

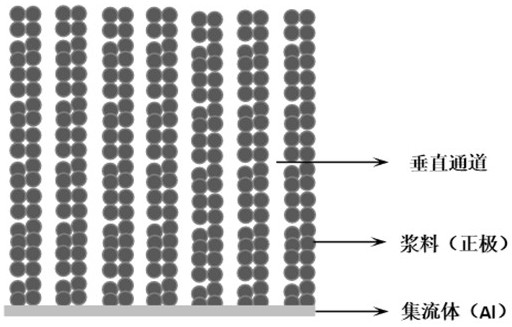

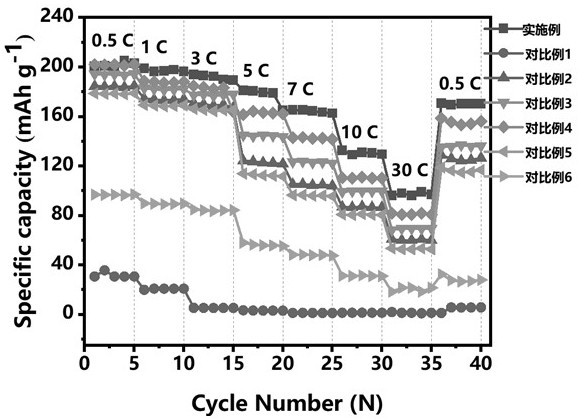

Preparation method of lithium ion battery positive plate

ActiveCN114744160AChange surface propertiesLiquidFinal product manufacturePositive electrodesGadolinium gallium garnetMagnetite Nanoparticles

The invention discloses a preparation method of a positive plate of a lithium ion battery, which comprises the following specific steps: uniformly mixing a high-nickel positive electrode material and a magnetic material through mechanical stirring to obtain high-nickel positive electrode slurry, coating the surface of a current collector with the high-nickel positive electrode slurry, and drying to obtain the positive plate of the lithium ion battery. The magnetic material is directionally arranged in the high-nickel positive electrode slurry by alternately loading and removing a magnetic field, meanwhile, a thick polar plate with a graded multi-dimensional through channel is prepared by utilizing an ice crystal effect, and then the magnetic material in the thick polar plate is recovered by adopting a magnetic recovery device to prepare the positive plate of the lithium ion battery, and the content of Ni in the high-nickel positive electrode material is greater than or equal to 80wt%. The magnetic material is iron-doped gadolinium gallium garnet magnetic nanoparticles. The constructed thick electrode with the hierarchical multi-dimensional through channel is applied to the lithium ion battery, and the rapid charging and discharging capability of the lithium ion battery is realized on the premise of not sacrificing the utilization rate and the capacity of an active material.

Owner:新乡市中天新能源科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com