High performant low consumption manganese zine ferrite material and preparation process thereof

A manganese-zinc ferrite and low power consumption technology, which is applied in the field of high-performance and low-power manganese-zinc ferrite materials and their preparation, can solve the problems of complex process, increased cost, etc., so as to reduce production cost and power consumption. , the effect of improving the performance of the sample

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

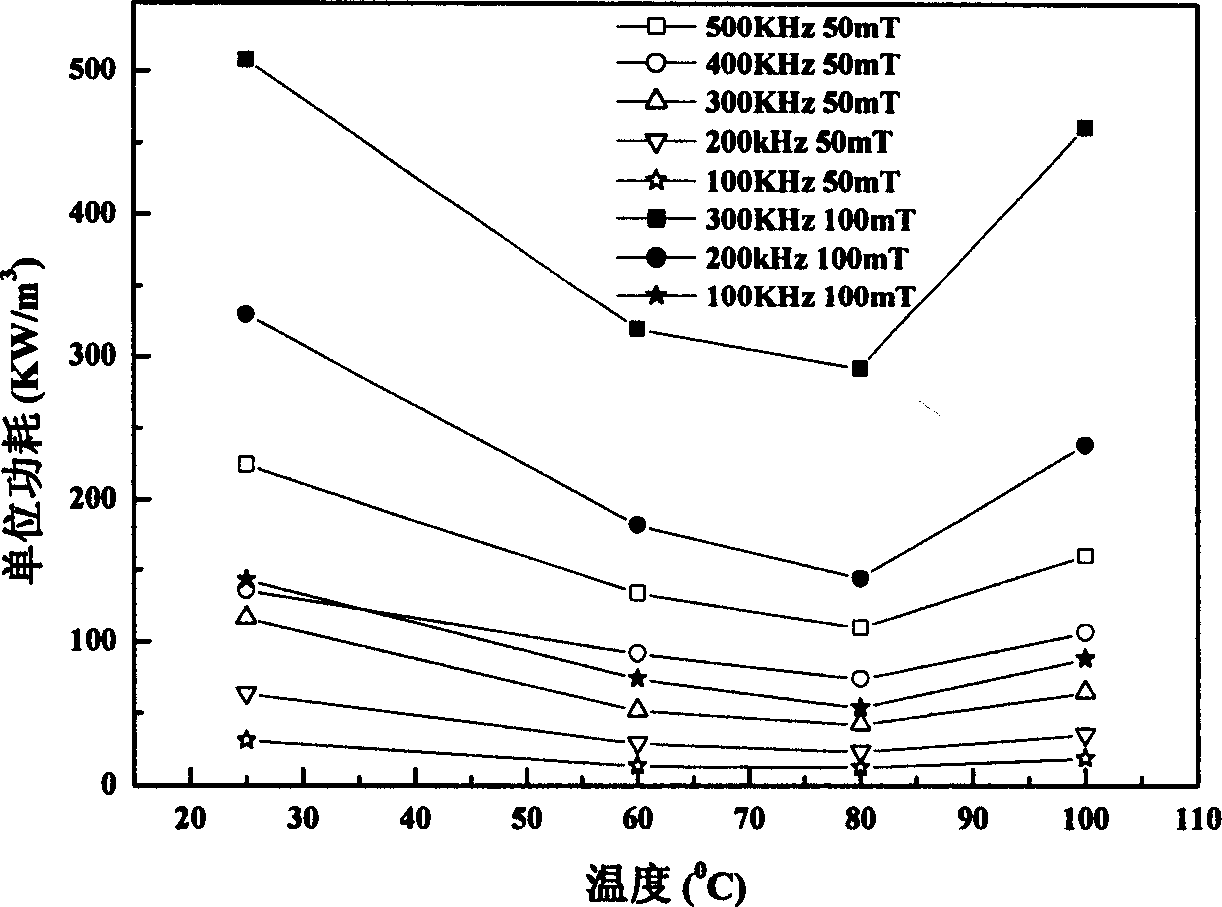

Embodiment 1

[0025] using Fe 2 O 3 69.1wt%, Mn 3 O 4 22wt%, ZnO 8.9wt% as the main components, put into a ball mill, mix ball mill for 2 hours according to the ratio of ball:material:water=6:1:1.4, and put it into a 120-degree oven for drying. Take out the dried material and put it into a box furnace for pre-sintering, the pre-sintering temperature is 900°C, and the temperature is kept for 1.5 hours. Weigh the doped oxide CaCO 3 0.08wt%, Nb 2 O 5 0.01wt%, Ta 2 O 5 0.01wt%, Co 2 O 3 0.1 wt% and pre-sintered material are put into a ball mill together with the ball: material: water = 8: 1: 1 and mixed for secondary ball milling, ball milling for 5 hours, and the average particle size after ball milling is 0.7-1.0 μm. After ball milling, oven drying is performed, and 12wt% polyvinyl alcohol solution with a concentration of 7% is added to the dried material for granulation, and sieved through a 60-80 mesh screen. Add 0.3wt% zinc stearate to the granulated material, press and fo...

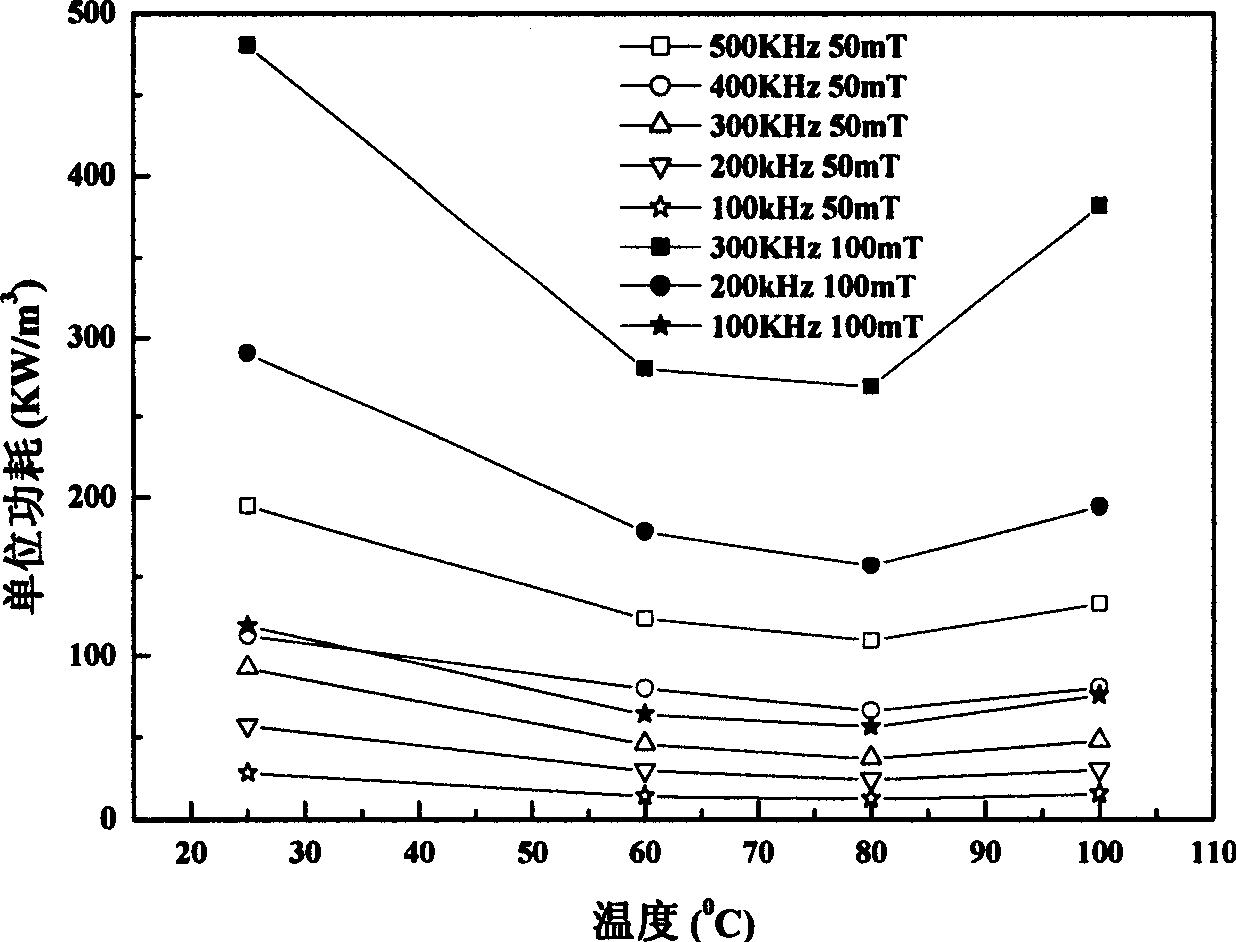

Embodiment 2

[0036] Using Fe 2 O 3 71wt%, Mn 3 O 4 23wt%, ZnO 6wt% as the main components, put into a ball mill, mix and ball mill for 2 hours according to the ratio of ball:material:water=6:1:1.4, and put it into a 120 degree oven for drying. Take out the drying material, put it into a box-type furnace for pre-burning, the pre-burning temperature is 870°C, and keep warm for 2 hours. Weigh doped oxide CaCO 3 0.08wt%, Nb 2 O 5 0.01wt%, Ta 2 O 5 0.01wt%, Gd 2 O 3 0.08wt% and calcined material are put into a ball mill together and mixed by ball: material: water = 8: 1: 1 and mixed by ball milling for 5 hours. After ball milling, the average particle size is 0.7-1.0 μm. After ball milling, dry in an oven, add 12 wt% polyvinyl alcohol solution with a concentration of 7% to the dried material to granulate, and sieve through a 60-80 mesh screen. Add 0.3wt% zinc stearate to the granulated material, press molding, and the green density is 3.4g / cm 3 , the size of the pressed sample...

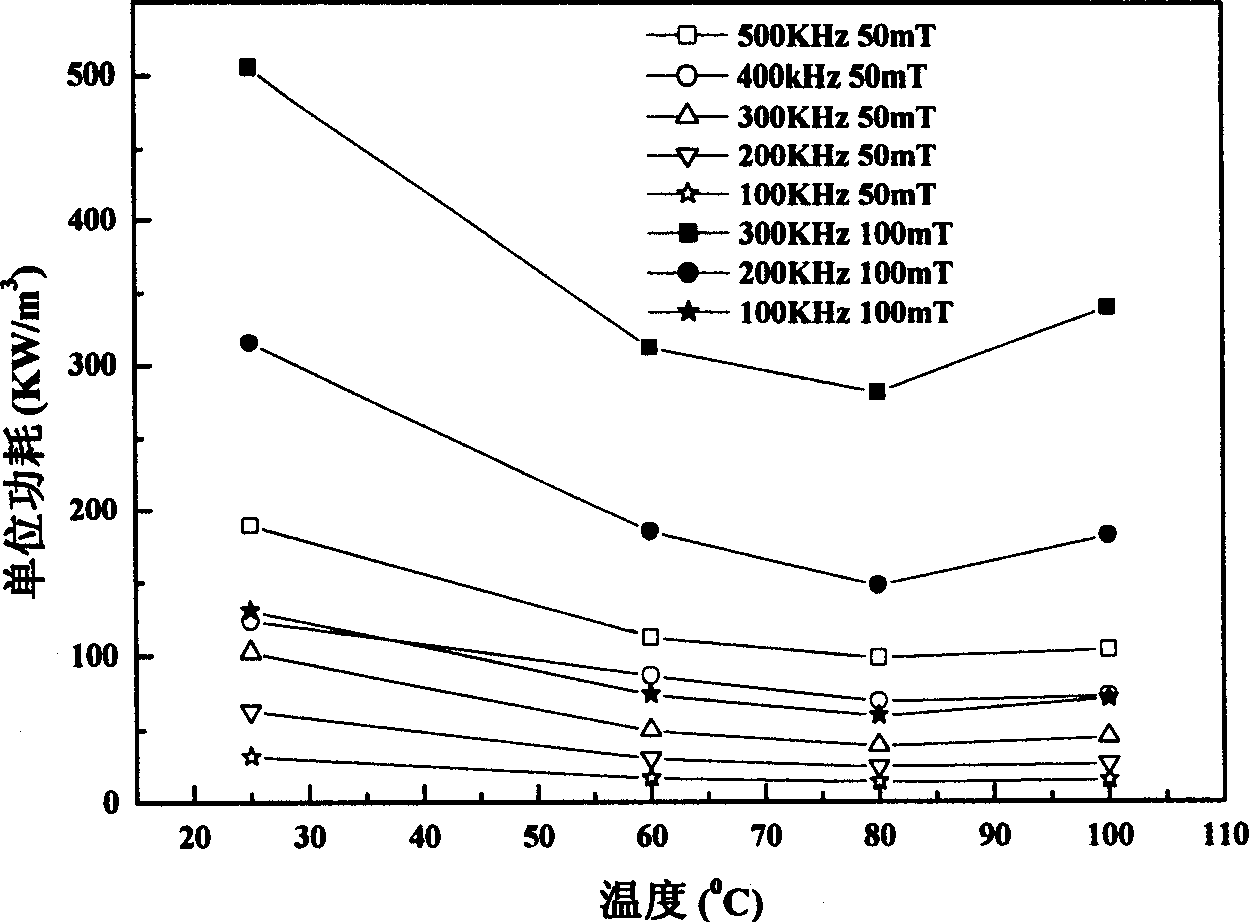

Embodiment 3

[0040] Using Fe 2 O 3 72wt%, Mn 3 O 4 23.5wt%, ZnO 4.5wt% as the main components, put into a ball mill, mix and ball mill for 2 hours according to the ratio of ball:material:water=6:1:1.4, and put it into a 120 degree oven for drying. Take out the drying material, put it into a box-type furnace for pre-burning, the pre-burning temperature is 850°C, and keep warm for 3.5 hours. Weigh doped oxide CaCO 3 0.06wt%, Nb 2 O 5 0.008wt%, Ta 2 O 5 0.0085wt%, SnO 2 0.2wt%, Gd 2 O 3 0.08wt% and calcined material are put into a ball mill together and mixed by ball: material: water = 8: 1: 1 and mixed by ball milling for 5 hours. After ball milling, the average particle size is 0.7-1.0 μm. After ball milling, dry in an oven, add 12 wt% polyvinyl alcohol solution with a concentration of 7% to the dried material to granulate, and sieve through a 60-80 mesh screen. Add 0.3wt% zinc stearate to the granulated material, press molding, and the green density is 3.2g / cm 3 , the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com