Preparation method of lithium ion battery positive plate

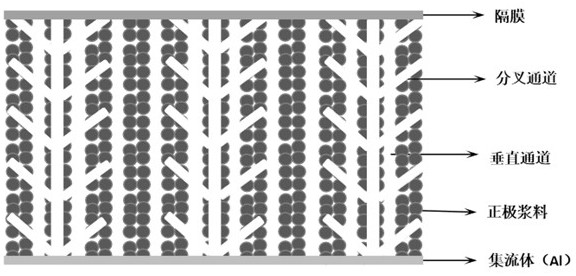

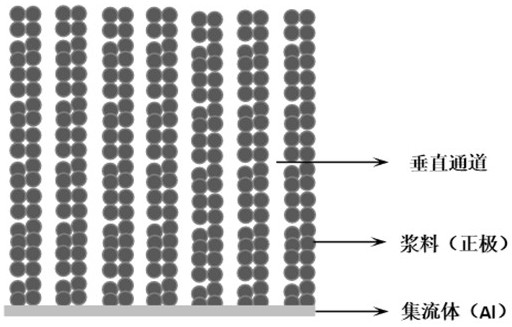

A technology for lithium-ion batteries and positive plates, which is applied in battery electrodes, inductance/transformer/magnet manufacturing, circuits, etc., and can solve problems such as easy shedding of active materials, reduction of ion and electron conductivity, and extension of electron and lithium ion transmission paths. , to achieve the effect of widening the forked channel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

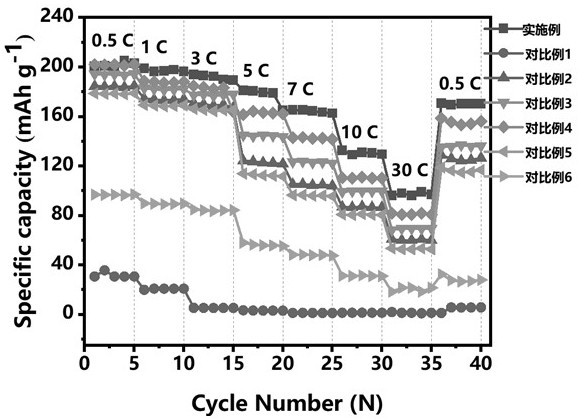

Examples

Embodiment

[0035] Step S1: 3mol Gd 2 O 3 and 5mol Ga 2 O 3 with a concentration of 5mol·L in 300mL −1 The mixed nitrate solution of gadolinium and gallium was obtained by condensing and refluxing for 6 hours under the condition of constant temperature and strong stirring at 250 °C. Then add 100mL with a concentration of 4mol·L −1 The pH of the mixed system is adjusted to 2.5-3.0 with concentrated ammonia water. Ammonium bicarbonate solution was used as the precipitant, the titration speed was controlled at 2 mL / min, and the pH of the mixed system was controlled at 7.5-8 during the process. After the titration was completed, stirring was continued for 1 h, and then left to stand for 12 h. The precipitate was filtered, washed with water, washed with alcohol, and dried at 60 °C for 10 h to obtain a loose precursor. After the precursor is ground and sieved in an agate mortar, it is calcined in a muffle furnace at 900° C. for 4 hours to obtain iron-doped gadolinium gallium garnet magne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com