Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Lower the burn-in temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A NiZnCu ferrite material and preparing method thereof

InactiveCN101552074AHigh sintering activityImprove permeabilityInorganic material magnetismMetallurgyInorganic oxide

The invention discloses a NiZnCu ferrite material, which is a ferrite material made by adding organic additives and inorganic oxide additives in the base raw material prescription of Fe[2] O [3], NiO, or Ni [2] O [3], CuO, ZnO. The reparing method includes: adding the raw material and the organic additives into the inorganic oxide additives, mixing with water, drying, sifting; presintering; joining the organic additives again, adding water for ball milling, mixing; drying and then sifting, to obtain the inventive NiZnCu ferrite material. Granulation, molding and sintering is required during manufacturing magnet ring. Compared with the existing technology, this invention adds organic additives twice to make the prescription and process simpler, reduce the cost and presintering temperature, improve the sintering activity of the presintering material so that the sintering temperature scope becomes wider, and obtain a NiZnCu ferrite material with a good consistency of production batches, suitability for industrial production, high magnetic permeability and Q value stability.

Owner:贵阳晶华电子材料有限公司

High-frequency nickel-copper-zinc ferrite and preparation thereof

The invention relates to a high frequency nickel-copper-zinc ferrite and a method for preparing the same, which belong to the technical field of nickel series soft magnetism ferrite. The main components of the ferrite are ferric oxide, nickel oxide, zinc oxide, and copper oxide, the accessory components comprise cobalt oxide, bismuth oxide, and silicon oxide, and the ferrite is prepared by an oxide method. The invention adopts an iron deficiency formulation, a low calcination temperature, and a low sintering temperature so that the prepared high frequency nickel-copper-zinc ferrite has good performances of low initial permeability, low relative dissipation factor between 50MHz and 200MHz, and high Curie temperature, and can better satisfy the use requirement of communication electronic parts and components; besides, the preparation process is stable, and the production process has low energy consumption.

Owner:TDG HLDG CO LTD

BCTZ-based perovskite system multi-component lead-free piezoelectric ceramic and preparation method thereof

InactiveCN102924078AStable piezoelectric performanceReduce sintering and pre-firing temperatureIonPerovskite

The invention discloses BCTZ-based perovskite system multi-component lead-free piezoelectric ceramic and a preparation method thereof. Raw material components in molar percent are represented by (1-y)[(1-x)Ba(Zr0.2Ti0.8)O3-x(Ca0.7Ca0.3)O3]-y[(Na0.52K0.44Li0.04)(Nb0.88-Sb0.08Ta0.04)O3], wherein x is 0.40 to 0.50; and y is 0.001 to 0.05. A principal crystalline phase of the material has a perovskite structure, the piezoelectric constant d33 is up to 464pC / N, the electromechanical coupling factor kp is up to 0.5, the performance of the traditional lead-containing piezoelectric ceramic is reached, and the preparation process is stable and repeatable; and the existence of Na, K and Li ions can reduce sintering and calcining temperature, and the piezoelectric ceramic has a good application prospect.

Owner:TIANJIN UNIV

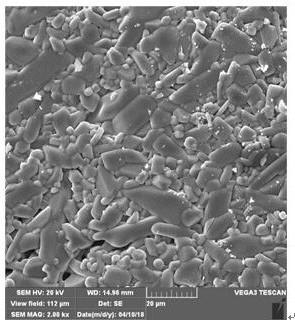

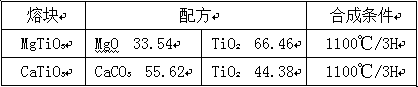

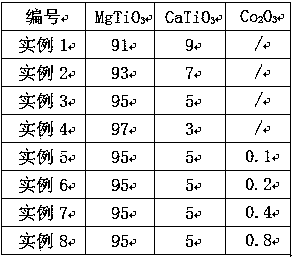

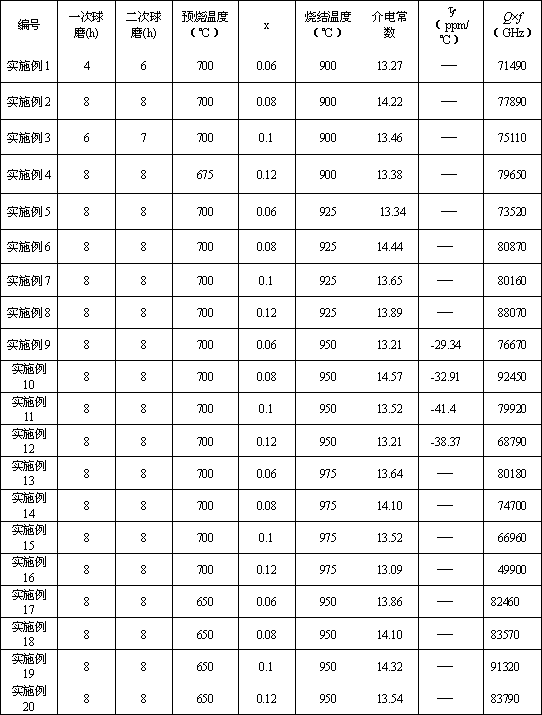

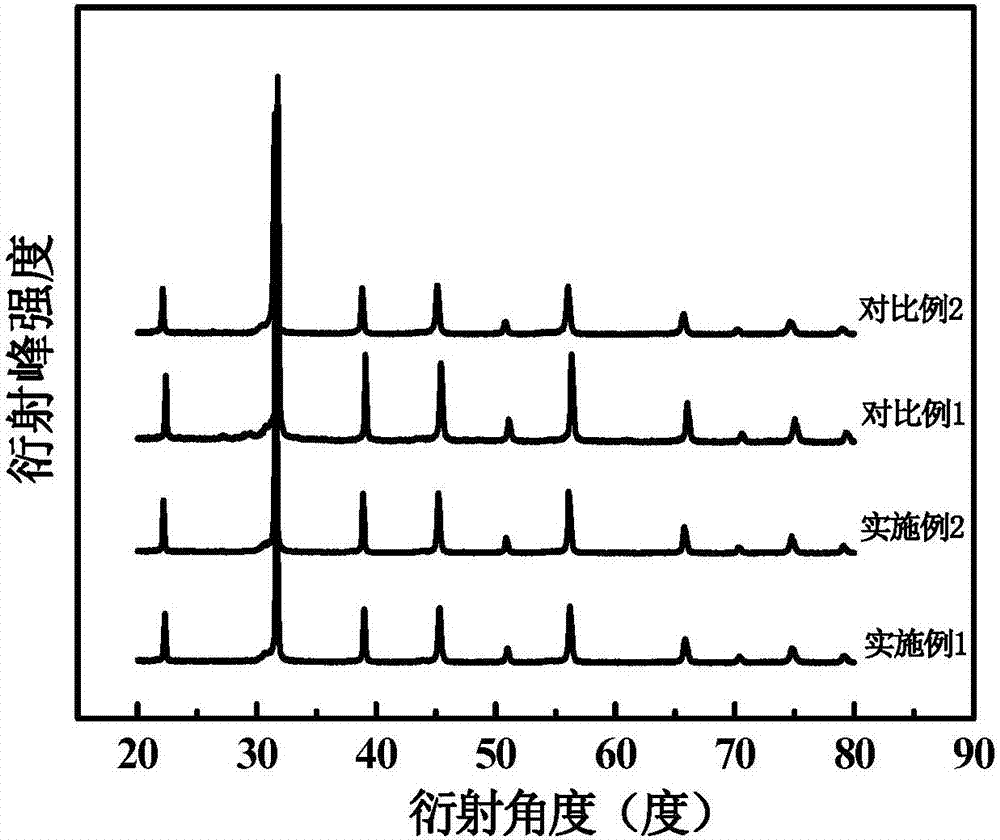

Microwave dielectric ceramic material and preparation method thereof

The invention particularly relates to a microwave dielectric ceramic material with a simple formula and a preparation method thereof. The chemical composition is (1-x)MgTiO3+xCaTiO3+ywt%Er2O3, wherein x is greater than or equal to 0.03 and smaller than or equal to 0.1, and y is greater than or equal to 0 and smaller than or equal to 1. The microwave dielectric ceramic is low in cost and simple in process, the production cost is greatly reduced, the production efficiency is improved, the microwave dielectric ceramic material has a medium and low dielectric constant, small loss and the temperature coefficient close to zero and is suitable for microwave devices such as dielectric resonators, filters and duplexers, the price of raw materials is low, and the process route is simple and easy to implement.

Owner:SHANDONG GREEN TEC MOTOR DRIVEN TECH

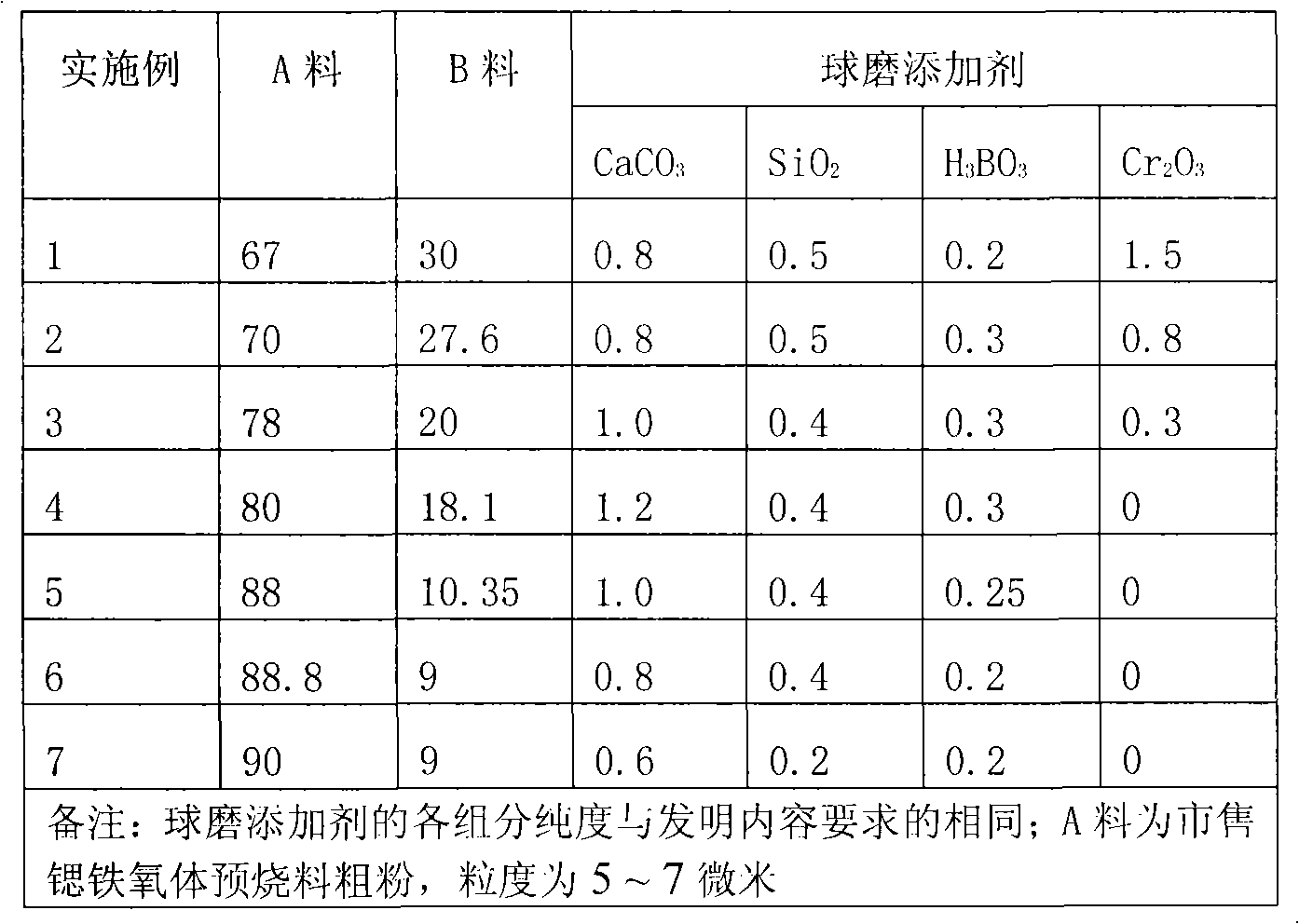

High-performance permanent ferrite and dyadic manufacturing method thereof

ActiveCN101409122AReduce dosageLow costInorganic material magnetismStrontium carbonateCobalt(II,III) oxide

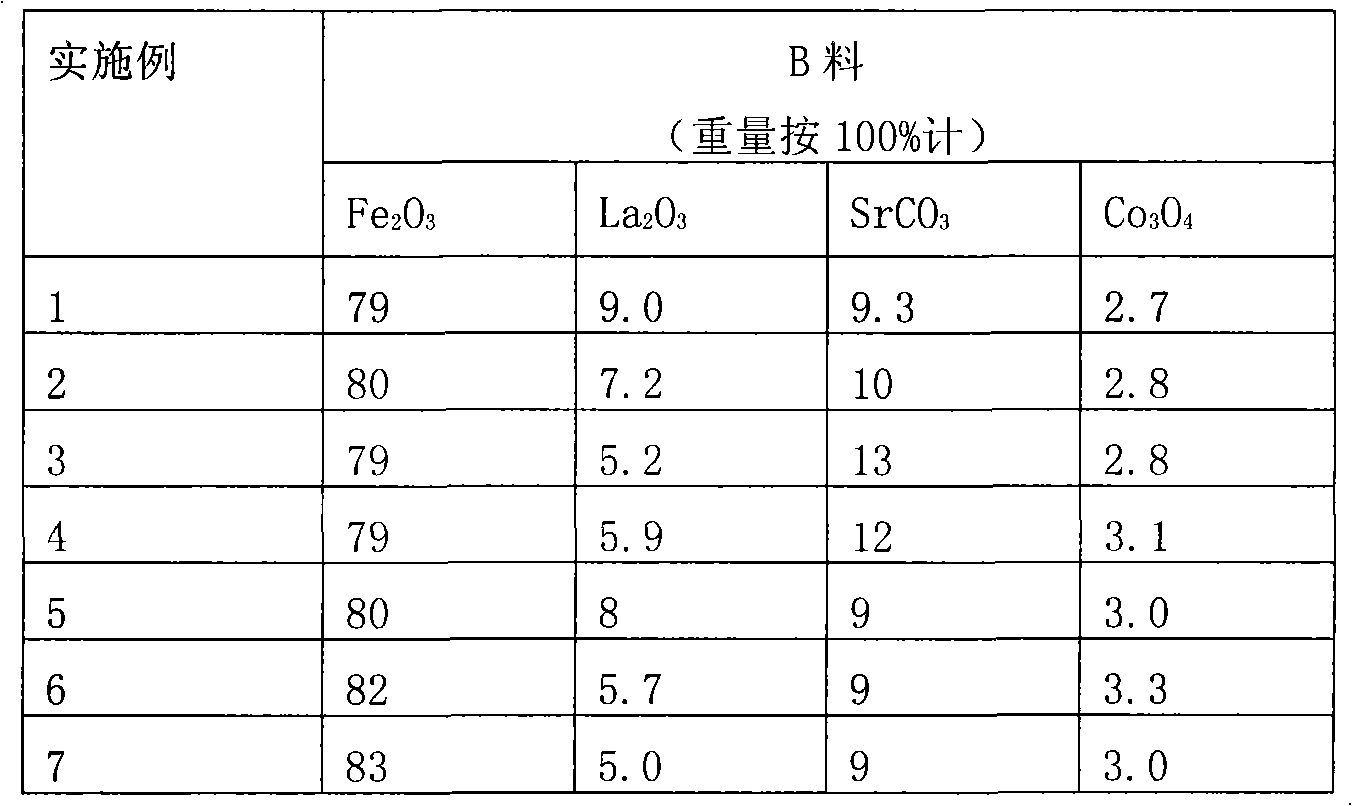

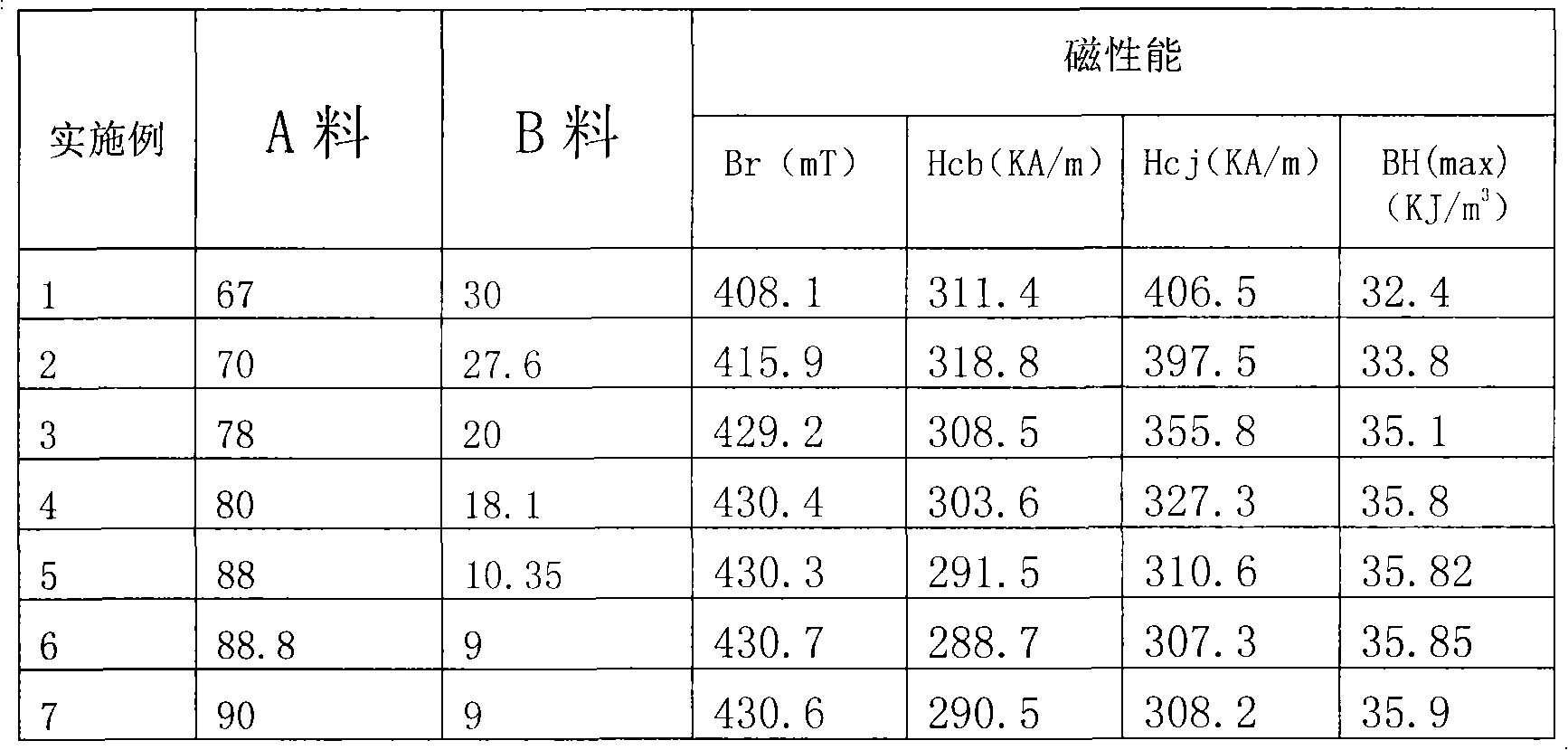

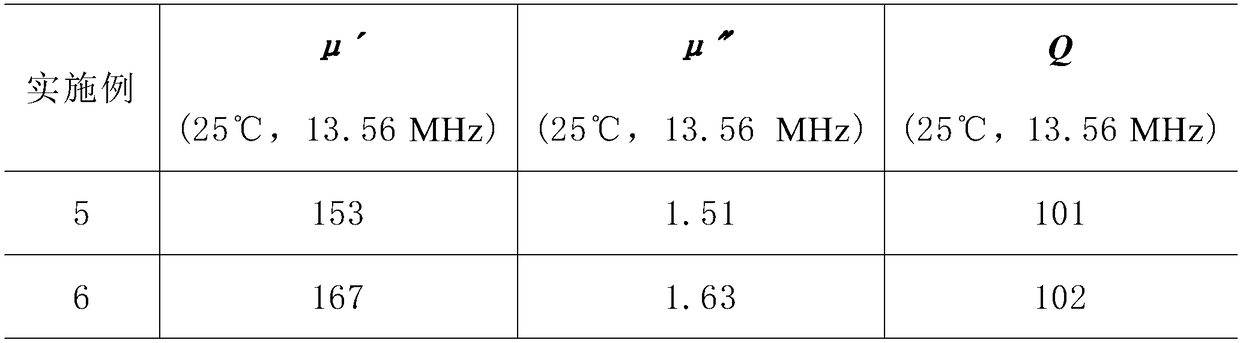

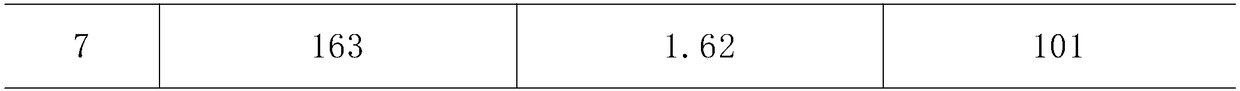

The invention discloses a high-performance permanent magnetic ferrite and a binary production method thereof. The permanent magnetic ferrite is prepared from a material A, a material B and a ball milling additive with accessories. The contents of the ingredients by weight are as follows: 67-90 percent of material A, 9-30 percent of material B and 1-3 percent of ball milling additive; the material A is the once preburning material of strontium ferrite purchased from the market; the material B comprises the following ingredients by weight (the total being 100 percent): 79.0-83.0 percent of ferric oxide with the purity of Fe2O3 of not less than 98.5 percent and the purity of SiO2 of not more than 0.05 percent, 5.0-9.0 percent of lanthana with the purity of La2O3 of not less than 98 percent, 9.0-13.0 percent of strontium carbonate with the purity of SrCO3 of not less than 97.5 percent and 2.7-3.3 percent of cobaltosic oxide with the purity of Co3O4 of not less than 98 percent. The material B is obtained through batching, mixing, drying, dispersing, preburning, grinding and sieving. The invention has the advantages of high magnetic performance of products, relatively low cost, strong market competitiveness, easy forming of magnetic pieces and the like and can be widely applied to the production process of high-performance permanent magnetic ferrite.

Owner:SINOSTEEL ANHUI TIANYUAN TECH

NiCuZn ferrite magnetic sheet for NFC and wireless charging

The invention discloses a NiCuZn ferrite magnetic sheet for NFC and wireless charging, and belongs to a method for manufacturing an electronic material. The method comprises the following steps of: carrying ball milling on 48-49 mol% of Fe2O3, 8-12 mol% of CuO, 15-18 mol% of NiO, the balance ZnO, doping 0.1-1wt% of Bi2O3, 0.01-0.1wt% of Co2O3, and 0.05-0.3% of SnO2, pre-sintering, carrying out curtain coating lamination and hydrostatic molding, discharging rubber, sintering, and the like to prepare the NiCuZn ferrite magnetic sheet. The ferrite magnetic sheet provided by the invention has highsaturation magnetic induction intensity, high residual magnetic induction intensity, high remanence ratio, low coercivity, low dielectric loss and low ferromagnetic resonance linewidth and can completely meet the applications of NFC and wireless charging.

Owner:GUIZHOU ZHENHUA HONGYUN ELECTRONICS

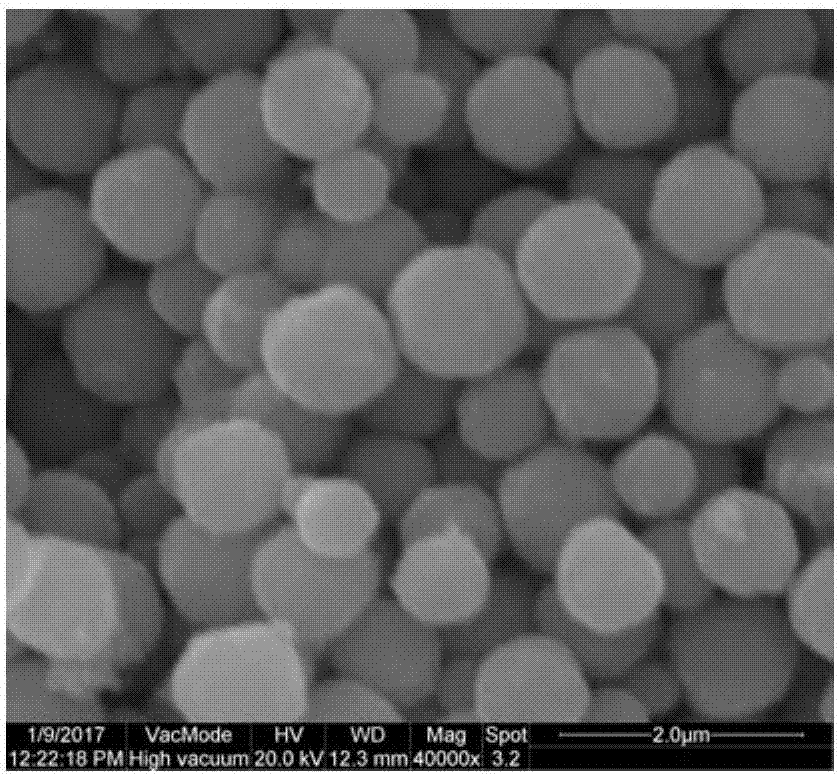

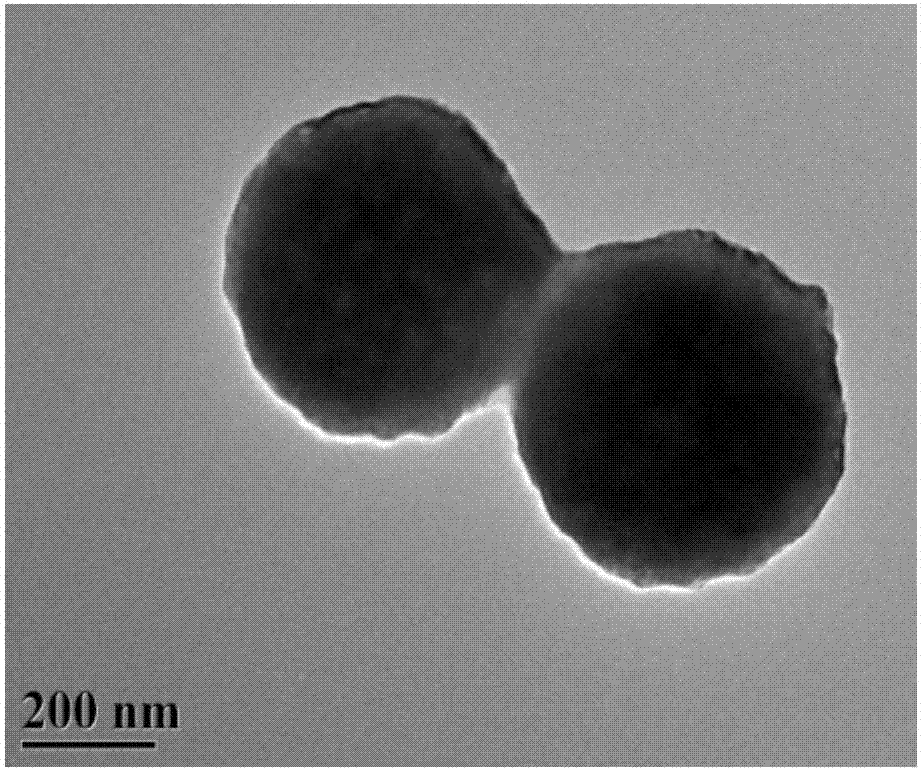

Method for preparing microwave dielectric ceramic material

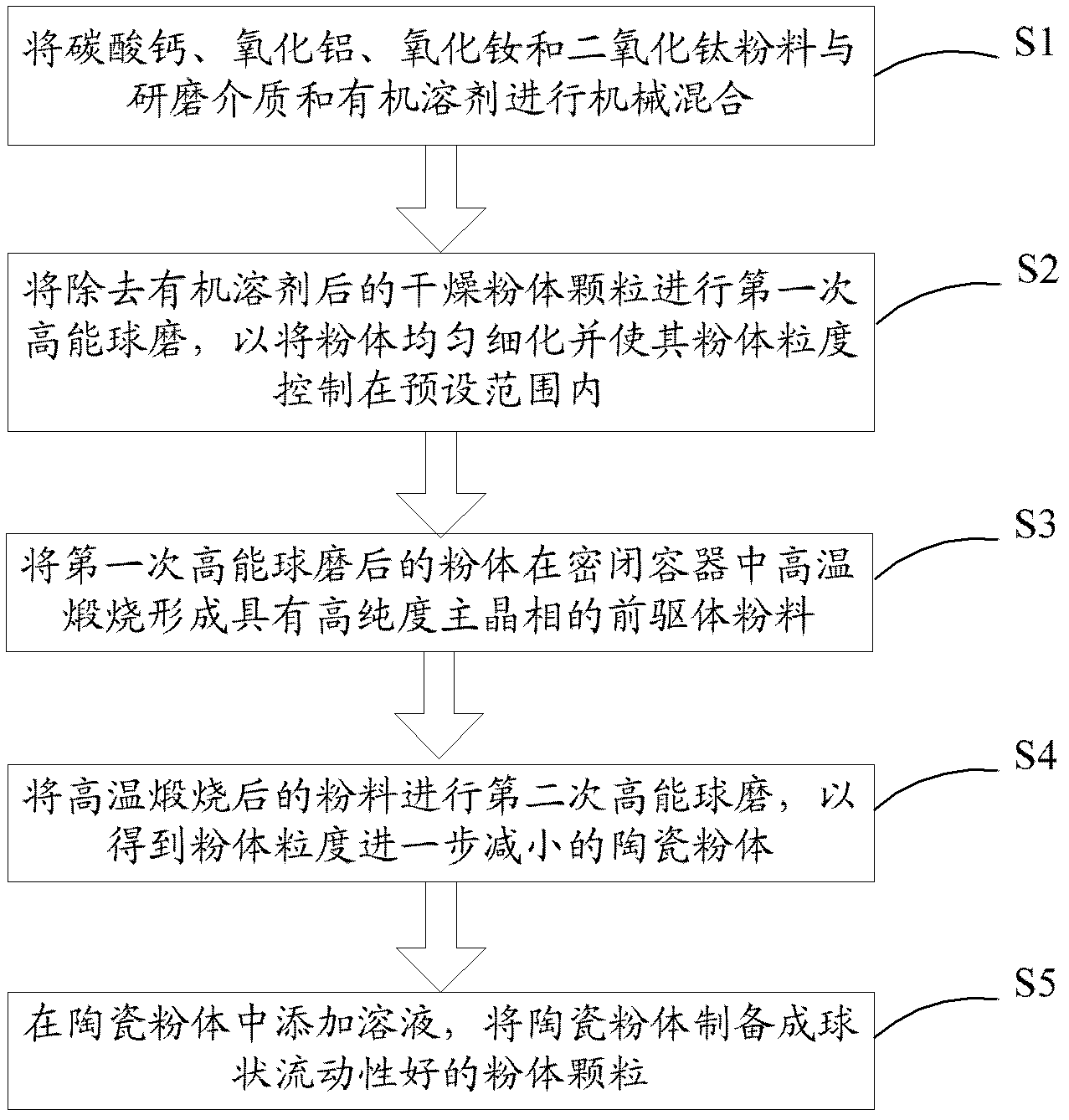

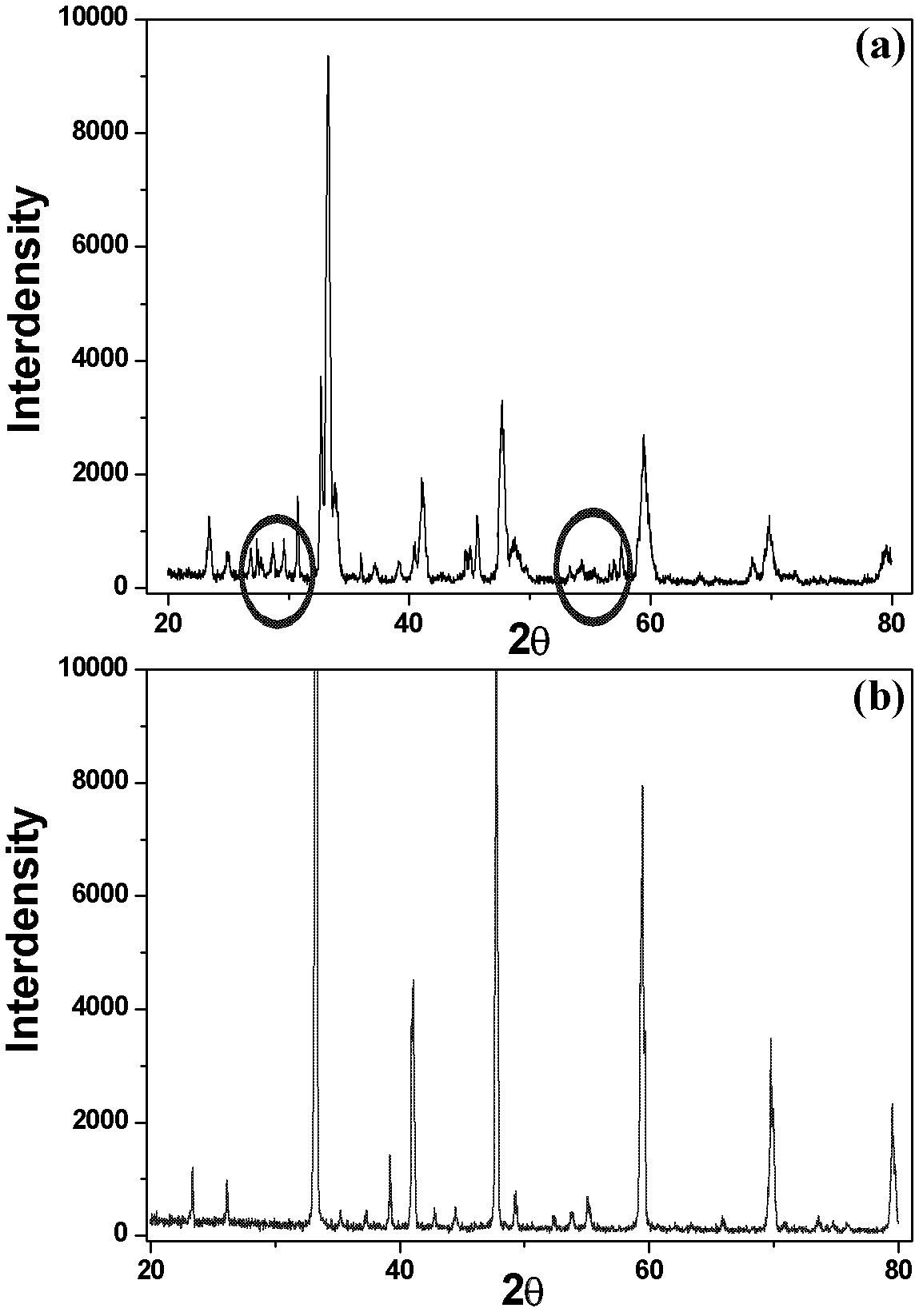

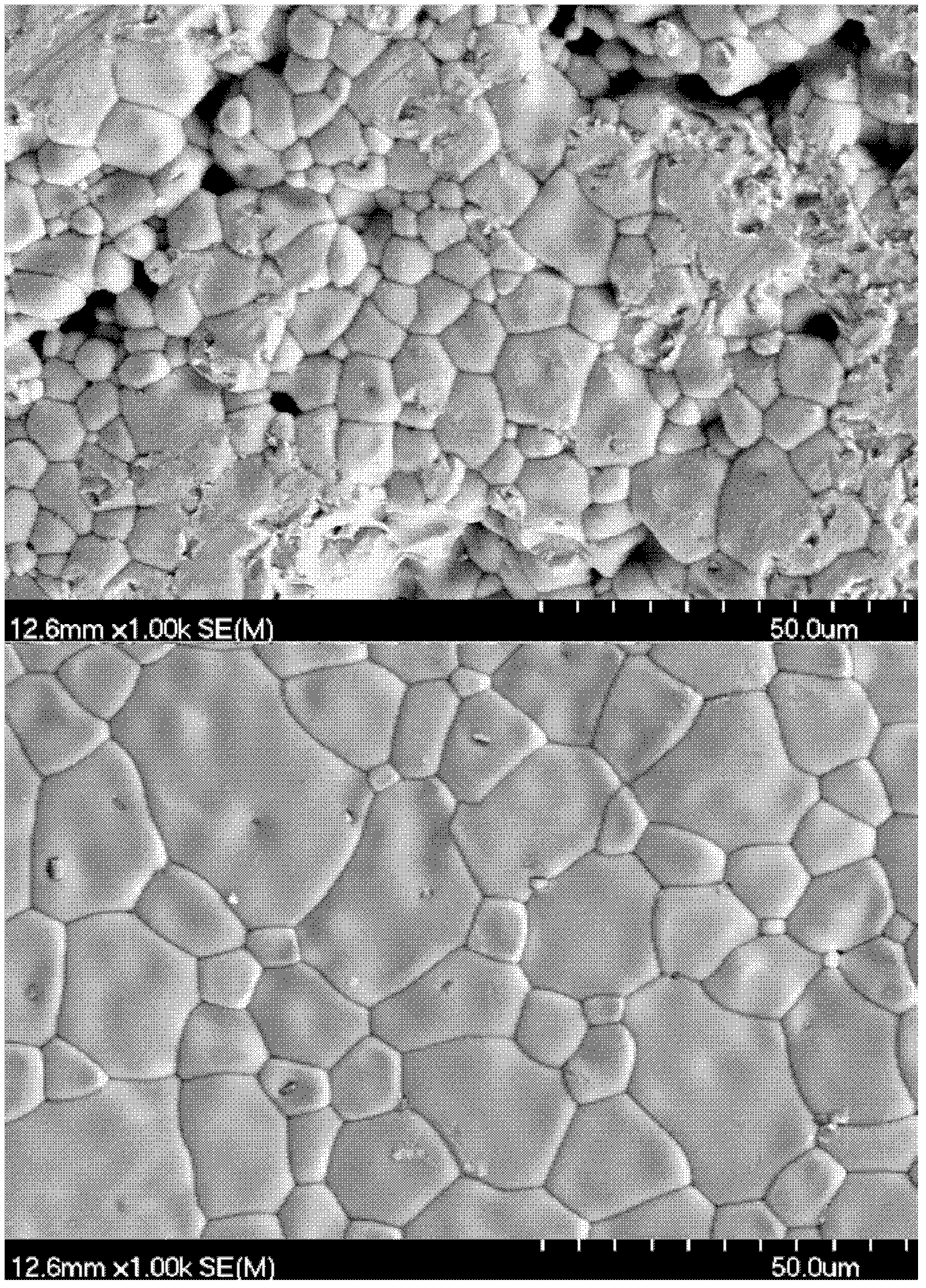

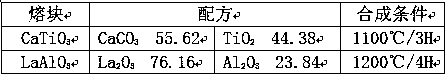

InactiveCN102875143ALower the burn-in temperatureLower sintering temperatureTitanium dioxideHigh energy

The embodiment of the invention discloses a method for preparing a microwave dielectric ceramic material. The method comprises the following steps of: mechanically mixing calcium carbonate, aluminum oxide, neodymium oxide and titanium dioxide powder, grinding media and organic solvents; performing primary high-energy ball milling on dry powder particles in which the organic solvents are removed, so that the powder is uniformly refined, and the particle size of the powder is controlled in a preset range; calcinating the powder subjected to primary high-energy ball milling in a closed container at high temperature to form precursor powder with a high-purity principal crystalline phase; performing secondary high-energy ball milling on the calcinated powder so as to obtain ceramic powder of which the particle size is further reduced; and adding a solution into the ceramic powder, and making the ceramic powder into a spherical powder particle which has high flowability. By the method, the microwave dielectric ceramic material which is calcinated at low temperature and highly densified and has an intermediate dielectric constant and a high quality factor is prepared.

Owner:ANHUI TATFOOK TECH CO LTD

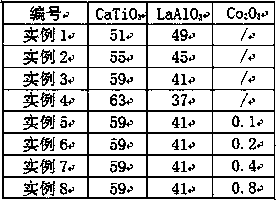

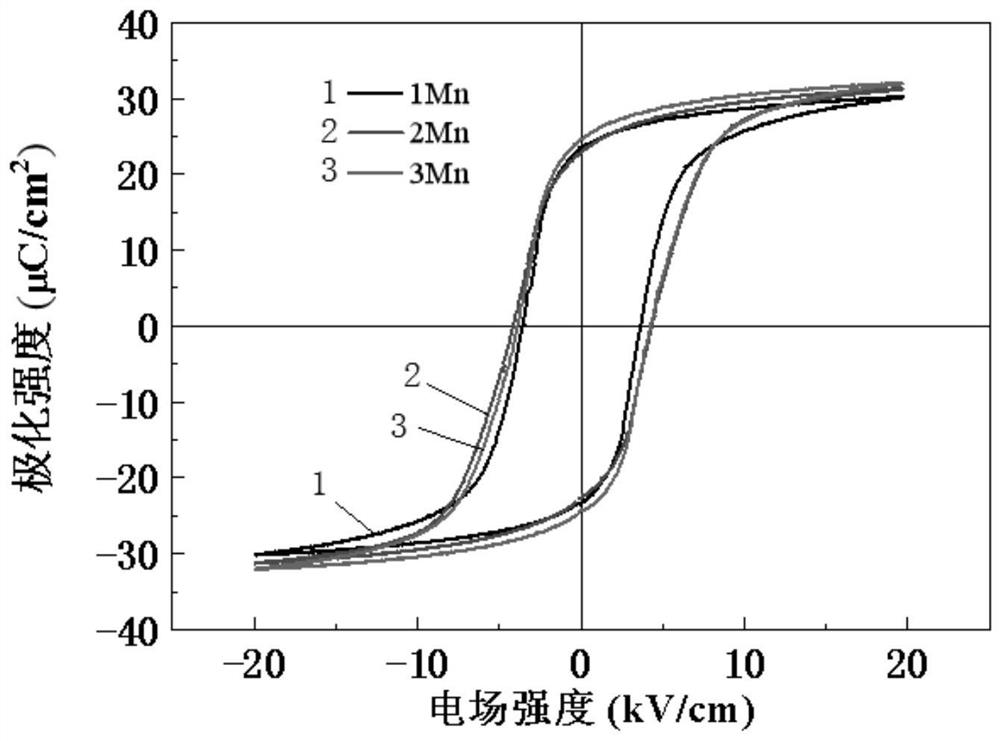

Low-cost microwave dielectric ceramic material and preparation method thereof

The invention particularly relates to a low-cost microwave dielectric ceramic material and a preparation method thereof, wherein the chemical composition is xCaTiO3+(1-x)LaAlO3+ywt%Co2O3, x is more than or equal to 0.35 and is less than or equal to 0.65, and y is more than or equal to 0 and is less than equal to 1. According to the present invention, the product is a low-cost CaTiO3-LaAlO3-based microwave dielectric ceramic capable of replacing CaTiO3-NdAlO3-based ceramics, has the greatly-reduced production cost, has characteristics of low cost and medium dielectric constant, is suitable fordielectric resonators, wave filters, duplexes and other microwave devices, and further has characteristics of adjustable dielectric constant, high Q.f and excellent resonance frequency temperature coefficient [tau]f. The invention further provides a preparation method of the low-cost microwave dielectric ceramic material, wherein the preparation method has characteristics of low raw material priceand simple and easy-performing process route.

Owner:SHANDONG GREEN TEC MOTOR DRIVEN TECH

Method for preparing high-performance magnet by using reclaimed material of wet-pressing permanent magnet ferrite

InactiveCN109400144AIncrease profitCost-effectiveInorganic material magnetismMetallurgyPre treatment

The invention discloses a method for preparing a high-performance magnet by using a reclaimed material of wet-pressing permanent magnet ferrite. The method comprises the following operation steps: (1)pretreating the reclaimed material by smashing; (2) weighting ingredients; (3) firstly grinding; (4) pre-burning; (5) secondarily grinding; (6) sintering. According to the invention, the reclaimed material is finely processed and a pre-burning process is added, so that the use ratio of reclaimed material is greatly increased; the technical problems of low use value of reclaimed material of permanent magnet ferrite and difficulty in producing high-performance permanent magnet ferrite by fully utilizing the reclaimed material of permanent magnet ferrite in the prior art are solved; the recycling of the reclaimed material of permanent magnet ferrite is realized; waste is turned into wealth; the use ratio of reclaimed material is increased; the material cost is lowered; the cost performance of material is increased.

Owner:ANHUI SINOMAG TECH

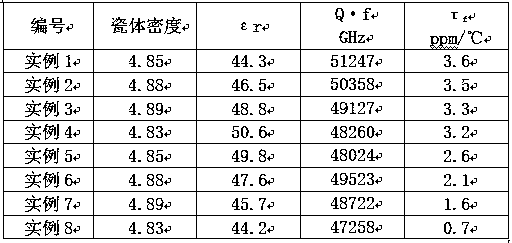

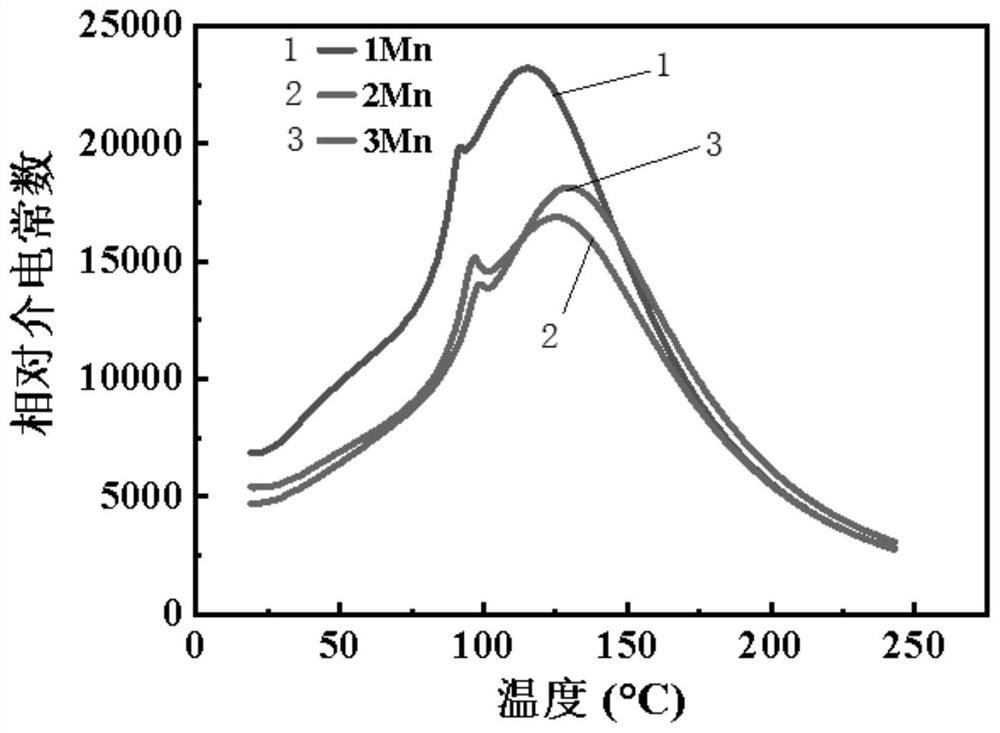

Lead manganate niobate-lead nickelate niobate-lead zirconate titanate high-voltage ferroelectric ceramic with ultralow dielectric loss and preparation method thereof

The invention relates to lead manganate niobate-lead nickelate niobate-lead zirconate titanate high-voltage ferroelectric ceramic with ultralow dielectric loss and a preparation method thereof. The invention belongs to the field of ferroelectric materials. The invention aims to solve the technical problem of high dielectric loss of an existing soft ceramic. The chemical general formula of the lead manganate niobate-lead nickel niobate-lead zirconate titanate high-voltage electric ferroelectric ceramic with ultralow dielectric loss is x Pb (Mn1 / 3Nb2 / 3) O3-(0.55-x) Pb (Ni1 / 3Nb 2 / 3) O3-0.135 PbZrO3-0.315 PbTiO3, wherein x is equal to 0.01-0.03. The preparation method comprises the following steps of: proportioning components according to the proportion of the ceramic components; sequentially carrying out pre-sintering, tabletting, glue discharging and sintering; carrying out silver sintering and polarization to obtain the lead manganate niobate-lead nickelate niobate-lead zirconate titanate high-voltage ferroelectric ceramic with ultralow dielectric loss. According to the method, the pre-sintering temperature is low, the lead manganate niobate-lead nickelate niobate-lead zirconate titanate relaxor ferroelectric ceramic is sintered through optimization of a formula and a process, the piezoelectric constant of the ceramic, measured by a quasi-static d33 tester reaches 760 pC / N, meanwhile, the dielectric loss of the ceramic is lower than 0.5%, and the performance of the ceramic is excellent.

Owner:HARBIN INST OF TECH

Aluminum oxide powder, aluminum oxide ceramic and preparation method of aluminum oxide ceramic

The invention relates to aluminum oxide powder, and an aluminum oxide ceramic and a preparation method thereof, and provides aluminum oxide ceramic powder, which comprises the following components inparts by weight: 100-115 parts of aluminum oxide, 23-28 parts of aluminum hydroxide, 5-6 parts of magnesium oxide, 6-7 parts of titanium dioxide powder, 1-5 parts of magnesium silicon nitride powder,10-15 parts of a silane coupling agent, 3-4 parts of a binder, 15-20 parts of zirconium oxide, 2-6 parts of aluminum nitride powder, 1-2 parts of a defoaming agent and 5-8 parts of AlF3. According tothe invention, the raw material components of the aluminum oxide ceramic are reasonably matched, so that the use quality of the aluminum oxide ceramic powder is optimized; and the green body is kept in a certain shape and has high density and compactness by virtue of the interaction force among aluminum nitride, aluminum oxide, zirconium oxide and magnesium oxide, so that ceramic sintering is facilitated, the sintering temperature can be reduced, and the ceramic density is improved.

Owner:ZHENGZHOU HICER HIGH TECH CERAMICS

Anion substituted low-temperature sintered lithium magnesium and titanium series microwave dielectric ceramic

InactiveCN109437887ALower sintering temperatureLower the burn-in temperatureSolid phasesMicrowave dielectric properties

The invention belongs to the technical field of ceramic materials, and discloses an anion substituted low-temperature sintered lithium magnesium and titanium series microwave dielectric ceramic and apreparation method thereof. The chemical formula of the anion substituted low-temperature sintered lithium magnesium and titanium series microwave dielectric ceramic is Li2Mg3Ti (O1-x / 2Fx)6, and 0.06< / =x< / =0.12. The preparation method comprises the steps of blending Li2CO3, MgO, TiO2 and LiF in proportion; drying and sieving after primary ball-milling, and calcining at a certain temperature to obtain pre-calcined powder; after secondarily ball-milling the pre-calcined powder, drying and sieving the pre-calcined powder, granulating the pre-calcined powder, sieving, and then compressing to obtain a blank; and sintering the blank at a certain temperature, and after insulating, cooling the product to the room temperature to obtain the final product. A traditional solid-phase method is adopted,by substitution of F-ions to O2-ions, the pre-calcining temperature and sintering temperature of the lithium magnesium and titanium ceramic are reduced effectively, the low-temperature sintered Li2Mg3TiO6 series microwave dielectric ceramic is prepared, meanwhile, an excellent microwave dielectric property is maintained, and application of the ceramic in an LTCC technology can be met.

Owner:TIANJIN UNIV

Tech of sintering Nb2O5-TiO2 system deelectric ceramic

A sintering process for dielectric Nb2O5-TiO2 ceramic includes such steps as proportionally mixing Nb2O5 powder with TiO2 powder, heating at 1250 deg. C for 18 hr, proportionally adding PVC powder, granulating, die pressing, sintering at 1350-1380 deg. C for 2-15 hr and cooling. It has high dielectric coefficient.

Owner:BEIJING UNIV OF TECH

Coprecipitation preparation method for calcium barium zirconate titanate leadless piezoelectric ceramic material

The invention discloses a coprecipitation preparation method for a calcium barium zirconate titanate leadless piezoelectric ceramic material. The method comprises the following steps: using barium acetate, calcium acetate, zirconium nitrate and titanium tetrachloride as raw materials, using sodium hydroxide or potassium hydroxide as a precipitator, firstly preparing calcium barium zirconate titanate precursor powder with high purity, uniform particles and relatively high activity, and then carrying out presintering, pelleting, tabletting, glue arrangement and sintering on the precursor to obtain the calcium barium zirconate titanate leadless piezoelectric ceramic material. Presintered powder of the ceramic material is prepared by adopting a coprecipitation method, the technology is simple and low in cost, no impurity is unlikely to introduce in the whole process, the prepared presintered powder is high in purity, uniform in dispersion, uniform in shape and relatively high in activity, the sintering temperature is reduced, and meanwhile the sintering temperature of the ceramic material can also be reduced, so that the problem that a traditional solid-phase method is non-uniform in mechanical mixing, unlikely to introduce impurities and high in synthesis temperature is solved.

Owner:SHAANXI NORMAL UNIV

Nine-layer-structure titanium iron bismuth cobalt oxide multiferroic ceramic material and preparation method thereof

The invention discloses a nine-layer-structure titanium iron bismuth cobalt oxide ceramic material with multiferroic performance and a preparation method thereof. The preparation method is characterized in that dissolving titanate, bismuth nitrate, ferric nitrate and cobalt nitrate in an aqueous nitric acid solution according to a mol ratio of 3: 10: (6-x): x and adding a complexing agent composed of ethylene diamine tetraacetic acid and citric acid, wherein a mol ratio of ethylene diamine tetraacetic acid to citric acid to metal ions in the solution is 0.5-1: 1: 1; and pre-burning powder obtained after full evaporation of the solution at a temperature of 700 to 800 DEG C to remove an organic matter and carrying out sintering at a temperature of 800 to 1100 DEG C for 5 to 10 h after tablet compressing and molding so as to obtain a nine-layer-structure Aurivillius-type multiferroic ceramic with a chemical formula of Bi10Fe6-xCoxTi3O30. The structure of the ceramic is that three titanium-oxygen (Ti-O) octahedrons and six iron-oxygen (Fe-O) octahedrons are sandwiched between two bismuth-oxygen layers ((Bi2O2)<2+>) and a part of Fe is substituted by Co; and the ceramic has ferroelectricity and ferromagnetism at the same time at a temperature higher than room temperature.

Owner:UNIV OF SCI & TECH OF CHINA

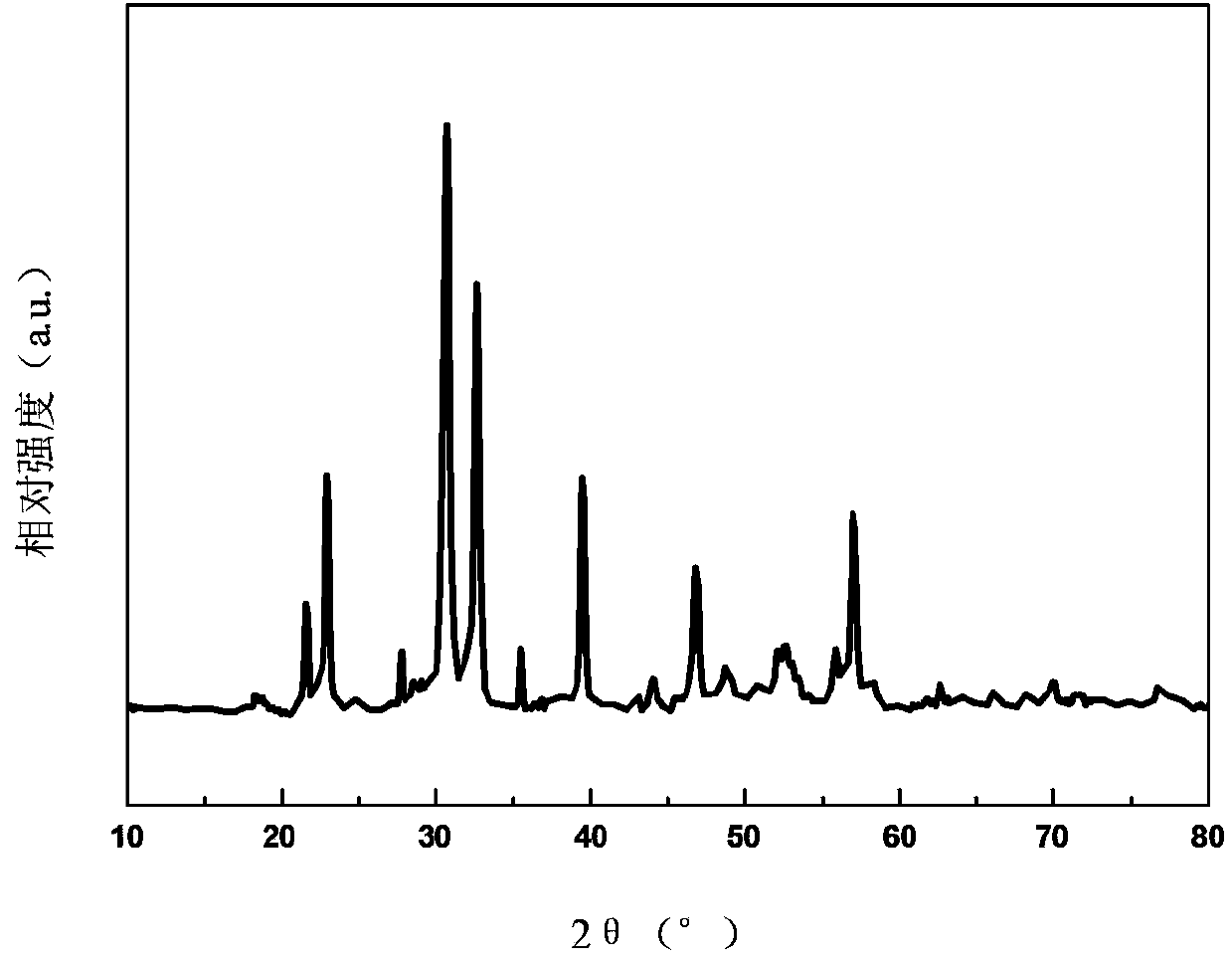

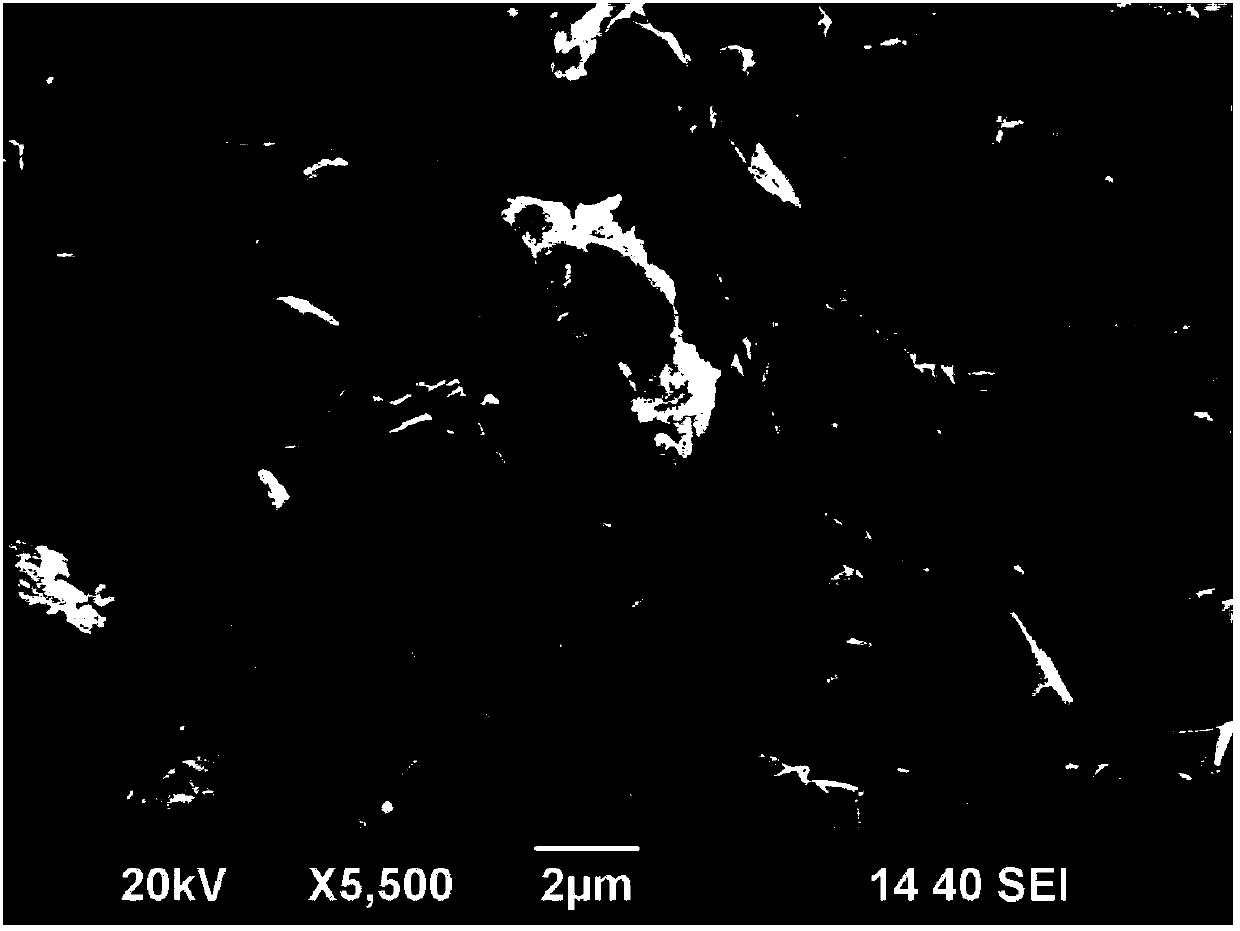

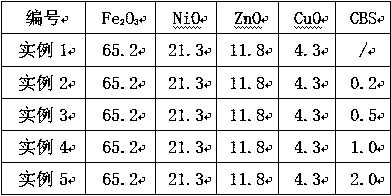

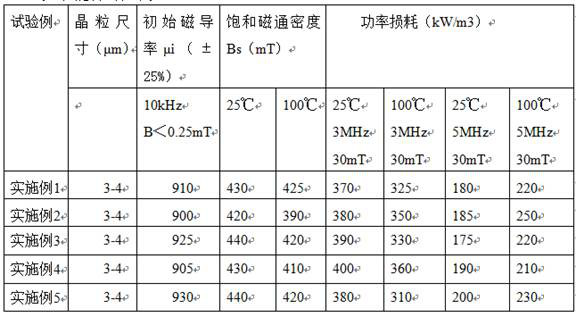

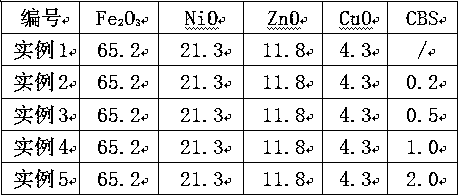

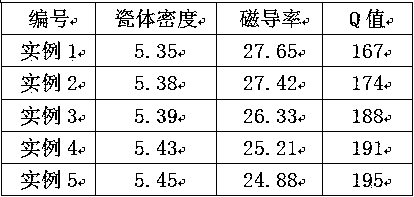

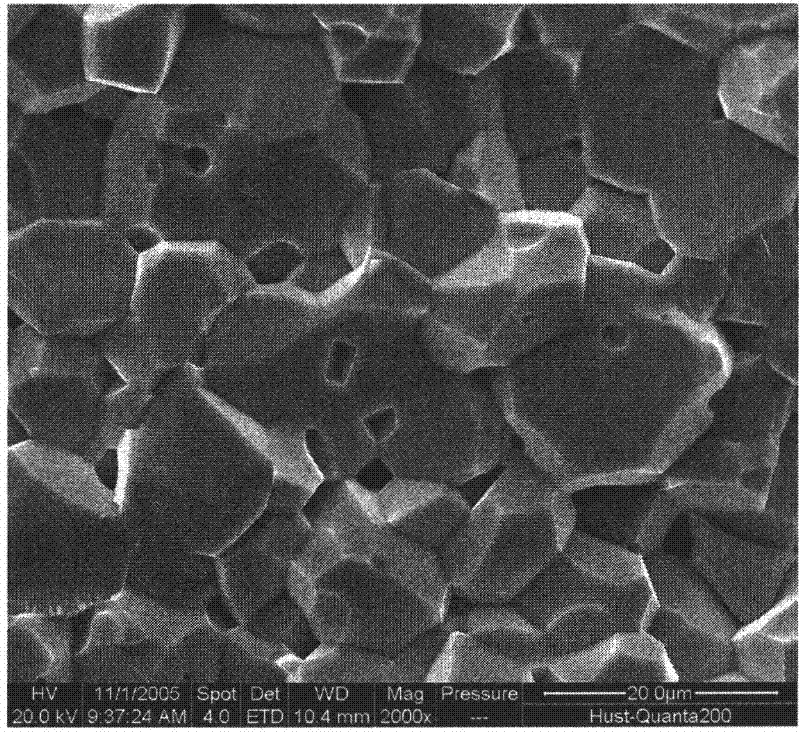

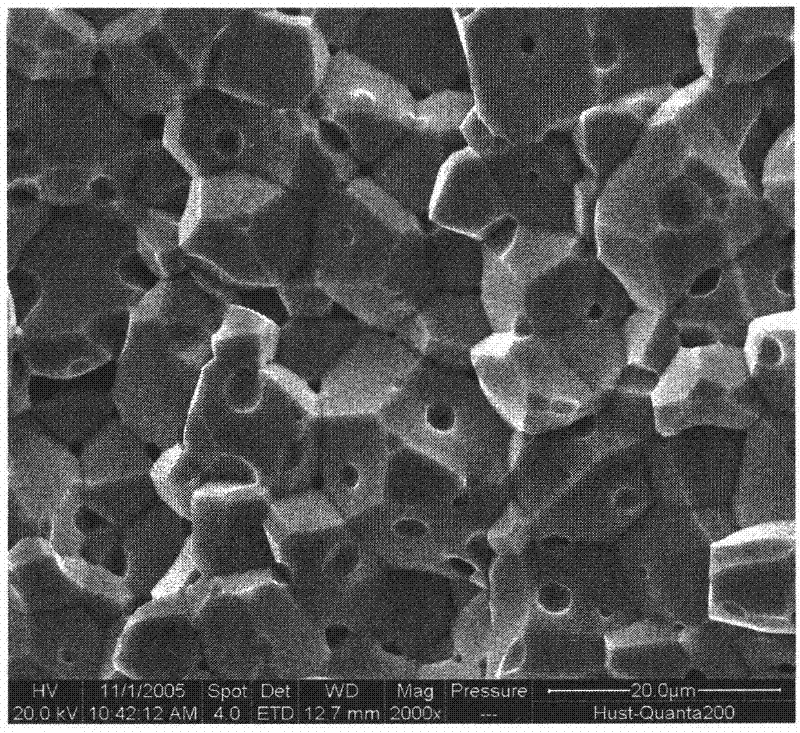

Low-temperature sintering soft magnetic ferrite material and preparation method thereof

InactiveCN110372363ASimple ingredientsLower firing temperatureInorganic material magnetismMagnetic beadCopper oxide

The invention discloses a low-temperature sintering soft magnetic ferrite material and a preparation method thereof, and belongs to the technical field of electronic information functional materials and devices. Iron-nickel-zinc-copper oxide is used as a main component composition, CBS glass is used as a sintering aid, and the low-temperature sintering soft magnetic ferrite material is prepared bya solid-phase reaction method and prepared by ball milling, drying, pre-sintering, secondary ball milling, drying and pulverization and sieving and the other processes. The low-temperature sinteringsoft magnetic ferrite material has the characteristics of low sintering temperature, high self-resonance frequency, high quality factor and high impedance and can be used for manufacturing peak magnetic beads and chip inductors, and the problem that a magnetic body and a silver electrode cannot co-sinter well is solved.

Owner:SHANDONG GREEN TEC MOTOR DRIVEN TECH

Ultra-high frequency soft ferrite material and preparation method of magnetic core

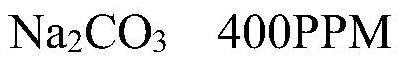

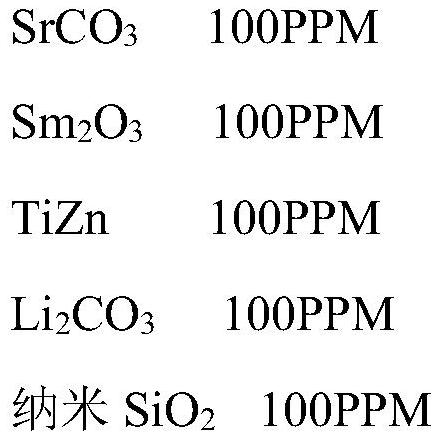

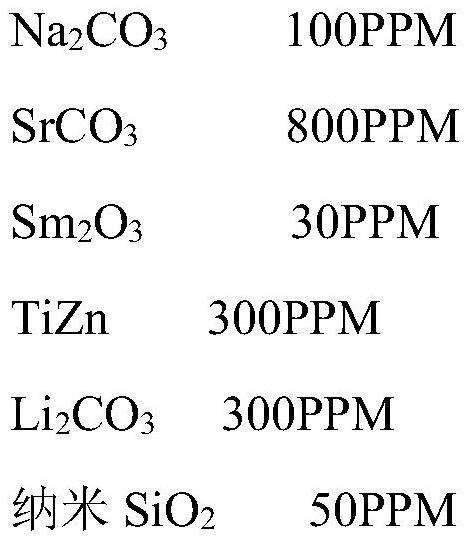

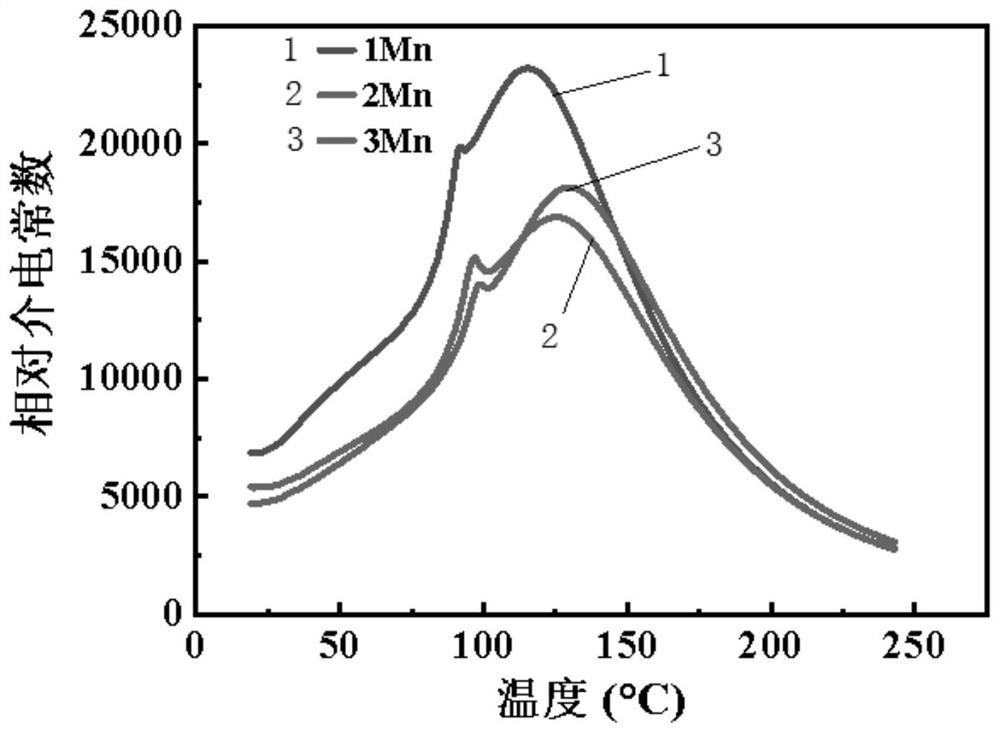

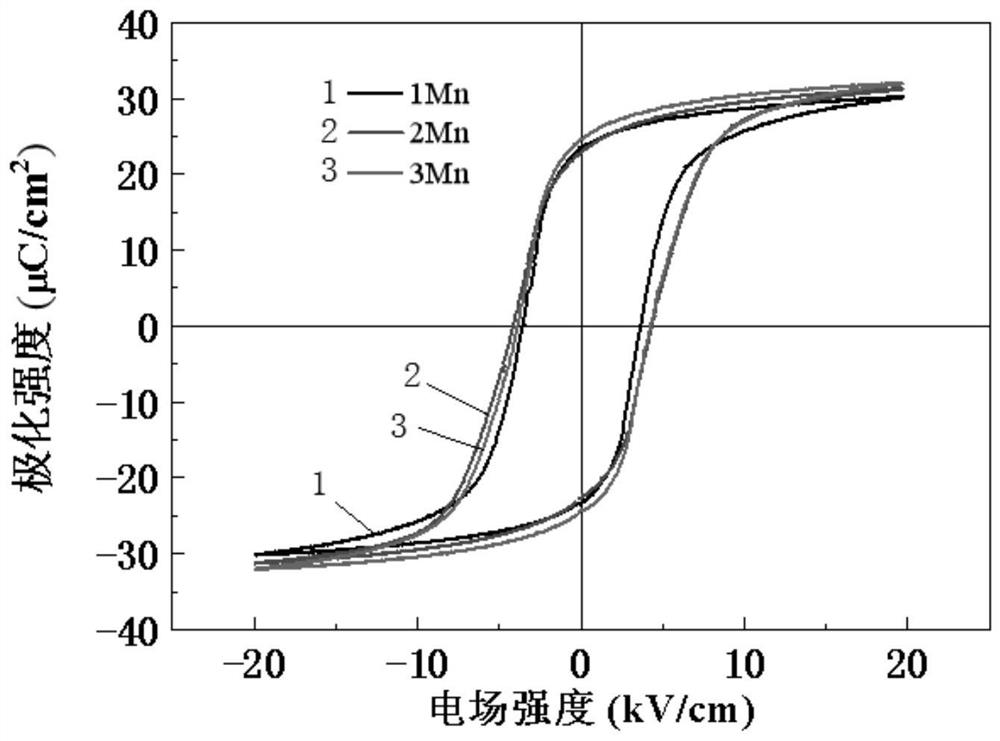

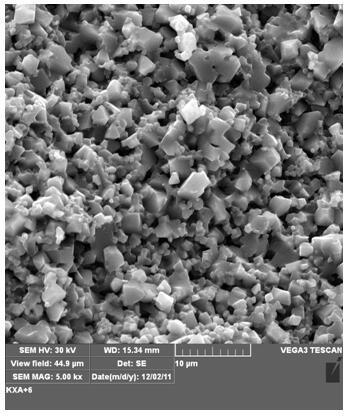

The invention relates to the technical field of soft magnetic ferrite, and discloses a method for preparing an ultra-high frequency soft magnetic ferrite material and a magnetic core. The main components include: Fe 2 o 3 67~69mol; BaCO 3 23~25mol; flaky Co 3 o 4 7~9mol; Relative to the total amount of main components, the weight percentages of each additive component are respectively: Na 2 CO 3 100~400PPM; SrCO 3 100~800PPM; Sm 2 o 3 30~100PPM; TiZn 100~300PPM; Li 2 CO 3 100-300PPM, the present invention has the advantages of high magnetic permeability, low loss and high frequency.

Owner:湖北华磁电子科技有限公司

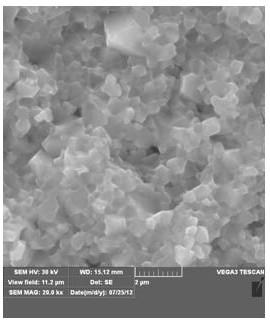

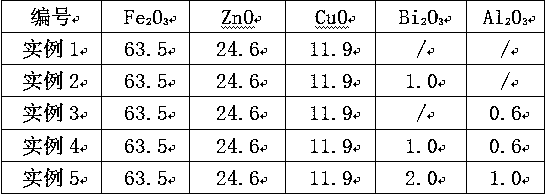

Soft magnetic ferrite material and preparation method thereof

PendingCN110317052ASimple ingredientsAdjustable quality factorInorganic material magnetismInductances/transformers/magnets manufactureMagnetic beadInductor

The invention discloses a soft magnetic ferrite material and a preparation method thereof, belongs to the technical field of electronic information function materials and devices. The soft magnetic ferrite material is prepared by using oxides of iron, zinc and copper as main components, using bismuth and aluminum as doping elements, and using a solid-phase reaction method, and prepared through working procedures of ball-milling, drying, pre-sintering, secondary-ball-milling, drying, smashing and sieving and the like. The soft magnetic ferrite material has the characteristics of low cost, higher self-resonant frequency, good current resistance and a low temperature change rate and the like, can be used for preparing a large-current magnetic bead, and reducing silver consumption, used for apower inductor interlayer, and capable of solving a problem caused by using ceramic powder that co-firing cannot be performed well.

Owner:SHANDONG GREEN TEC MOTOR DRIVEN TECH

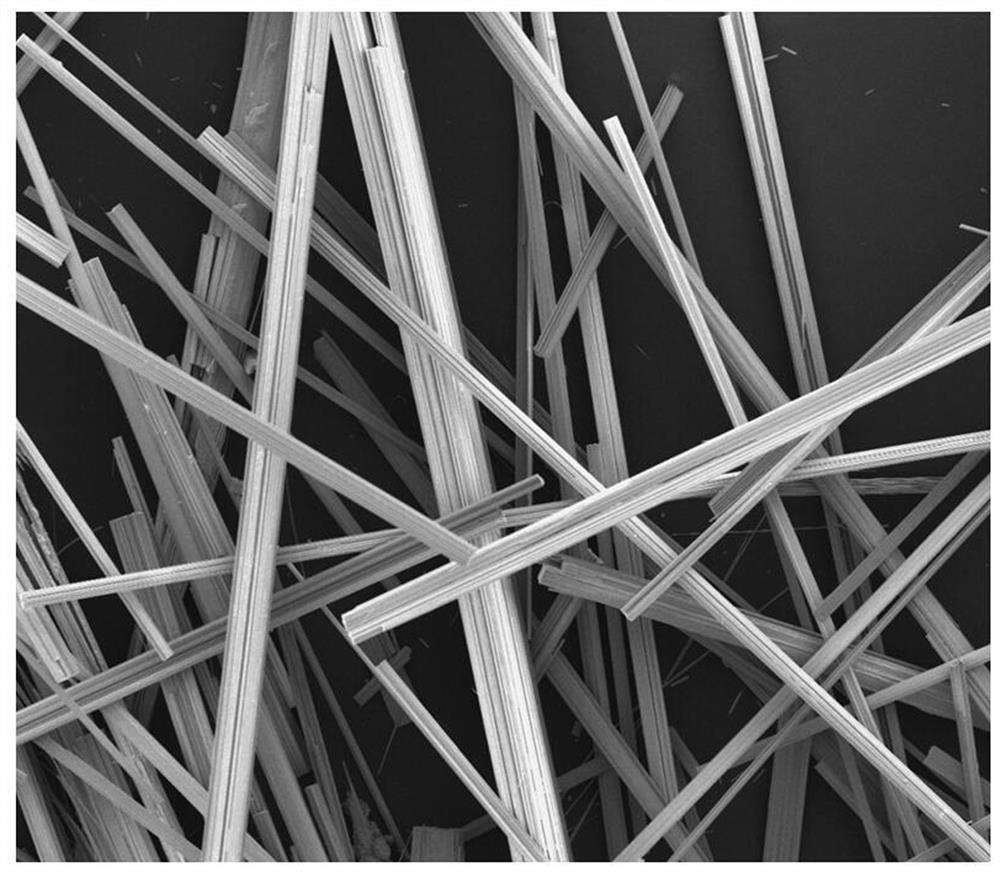

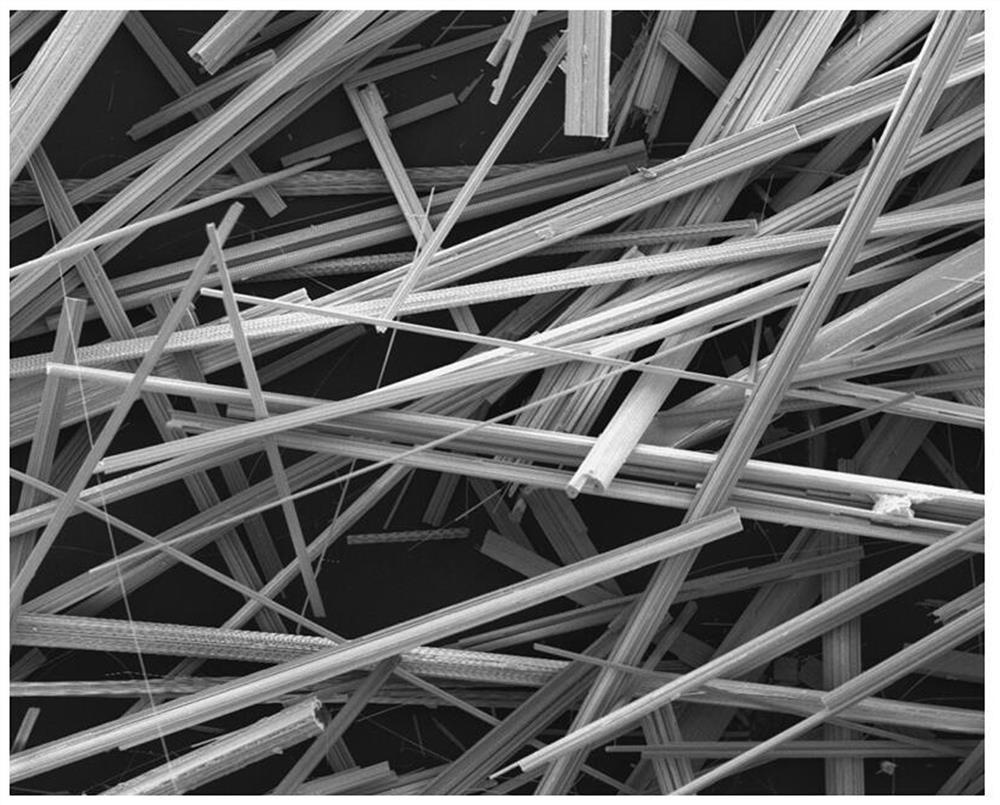

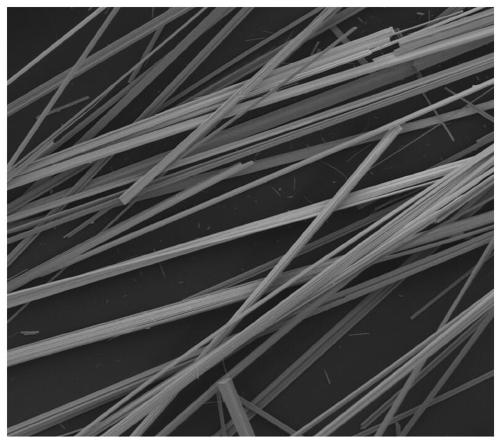

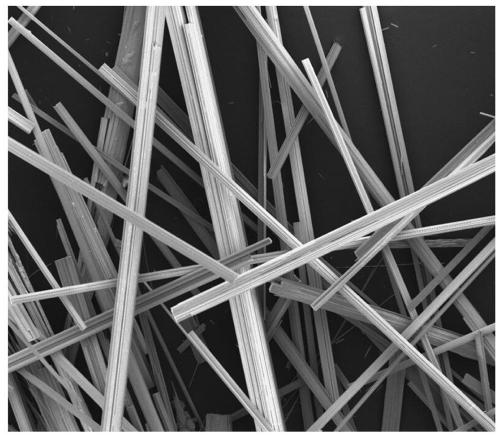

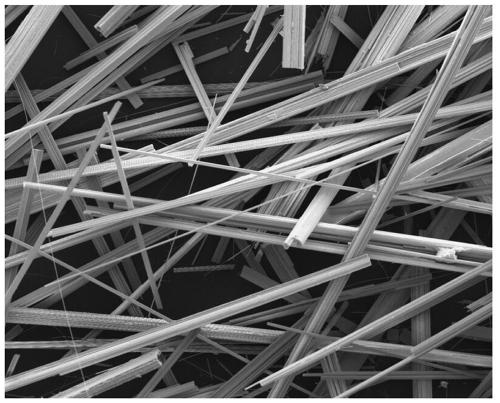

A kind of double niobium source alkali metal niobate micro-nanowire material and preparation method thereof

Owner:GUILIN UNIV OF ELECTRONIC TECH

Technique for quick sintering ceramics in (Ta2O5)1-x(TiO2)x system

The present invention relates to a process for quickly sintering (Ta2O5)1-x(TiO2)x system ceramic, belonging to the field of Ta2O5)1-x(TiO2)x system dielectric ceramic preparation technology. Said process includes the following steps: preparing Ta2O5 and TiO2 powder material according to a certain ratio, ball-grinding and mixing them and drying, precalcining for 12 hr at 1200 deg.C, ball-grinding precalcined powder material and drying, adding polyvinyl alcohol (PVA) adhesive, pressing the above-mentioned powder material into flake blank body, heating to 1550 deg.C, heat-insulating for 1 hr, cooling to room temperature, sintering so as to obtain compact flake ceramic body.

Owner:BEIJING UNIV OF TECH

Tech of sintering Nb2O5-TiO2 system deelectric ceramic

Owner:BEIJING UNIV OF TECH

Ultrahigh-frequency soft magnetic ferrite material and preparation method of magnetic core

The invention relates to the technical field of soft magnetic ferrites, and discloses an ultrahigh-frequency soft magnetic ferrite material and a preparation method of a magnetic core, and the ultrahigh-frequency soft magnetic ferrite material comprises the following main components in parts by mole: 67-69mol of Fe2O3; 23-25 mol of BaCO3; and 7-9 mol of sheet-shaped Co3O4 (cobalt oxide). Relative to the total amount of the main components, the weight percentages of additive components are as follows: 100-400PPM of Na2CO3; 100-800 PPM of SrCO3 (strontium carbonate); 30-100 PPM of Sm2O3; 100-300 PPM of TiZn; and 100-300 PPM of Li2CO3. According to the invention, the material has the advantages of relatively high magnetic conductivity, low loss and high frequency.

Owner:湖北华磁电子科技有限公司

Technique for quick sintering ceramics in (Ta2O5)1-x(TiO2)x system

The present invention relates to a process for quickly sintering (Ta2O5)1-x(TiO2)x system ceramic, belonging to the field of Ta2O5)1-x(TiO2)x system dielectric ceramic preparation technology. Said process includes the following steps: preparing Ta2O5 and TiO2 powder material according to a certain ratio, ball-grinding and mixing them and drying, precalcining for 12 hr at 1200 deg.C, ball-grinding precalcined powder material and drying, adding polyvinyl alcohol (PVA) adhesive, pressing the above-mentioned powder material into flake blank body, heating to 1550 deg.C, heat-insulating for 1 hr, cooling to room temperature, sintering so as to obtain compact flake ceramic body.

Owner:BEIJING UNIV OF TECH

An ultra-low dielectric loss lead niobate manganate-lead niobate nickelate-lead zirconate titanate high piezoelectric ferroelectric ceramic and its preparation method

An ultra-low dielectric loss lead niobate-lead niobate-nickelate-lead zirconate titanate high-voltage ferroelectric ceramic and a preparation method thereof. The invention belongs to the field of piezoelectric ferroelectric materials. The invention aims to solve the technical problem of high dielectric loss of existing soft ceramics. The general chemical formula of a kind of lead niobate manganate-lead niobate-nickelate-lead zirconate titanate high piezoelectric ferroelectric ceramic of the present invention is x Pb(Mn 1 / 3 Nb 2 / 3 )O 3 ‑(0.55‑x)Pb(Ni 1 / 3 Nb 2 / 3 )O 3 ‑0.135PbZrO 3 ‑0.315PbTiO 3 , where x=0.01‑0.03. Preparation method: according to the proportion of ceramic ingredients, then pre-fired, pressed, deglued, sintered, and then silver-fired and polarized to obtain lead niobate-manganate-lead niobate-zirconate with ultra-low dielectric loss Lead titanate piezoelectric ferroelectric ceramics. The method of the present invention has a low pre-firing temperature, and the lead niobate-manganese-niobate-lead-niobinickelate-lead zirconate-titanate relaxor ferroelectric ceramics are obtained by optimizing the formula and process, and the quasi-static d 33 While the piezoelectric constant measured by the tester reaches 760pC / N, the dielectric loss is lower than 0.5%, and the performance is excellent.

Owner:江苏省声学产业技术创新中心

Low-temperature sintering iron, nickel, zinc and copper-based soft magnetic ferrite material and preparation method thereof

InactiveCN110372364ASimple ingredientsLower firing temperatureInorganic material magnetismHigh resistanceMagnetic bead

The invention discloses a low-temperature sintering iron, nickel, zinc and copper-based soft magnetic ferrite material and a preparation method thereof, and belongs to the technical field of electronic information functional materials and devices. According to the low-temperature sintering iron, nickel, zinc and copper-based soft magnetic ferrite material and the preparation method thereof, an oxide of iron, nickel, zinc and copper is used as a main component, CBS glass is used as sintering aids, and a solid-phase reaction method is adopted and the preparation method of the low-temperature sintering iron, nickel, zinc and copper-based soft magnetic ferrite material comprises the steps of ball-milling, drying, presintering, secondary ball-milling, drying, smashing and sieving and the like.The low-temperature sintering iron, nickel, zinc and copper-based soft magnetic ferrite material has the characteristics of low sintering temperature, higher self-resonance frequency, high quality factor, high resistance and the like, can be used for manufacturing peal magnetic beads and chip inductor, and solves the problem that a magnetic body and a silver electrode cannot be cofired well.

Owner:SHANDONG GREEN TEC MOTOR DRIVEN TECH

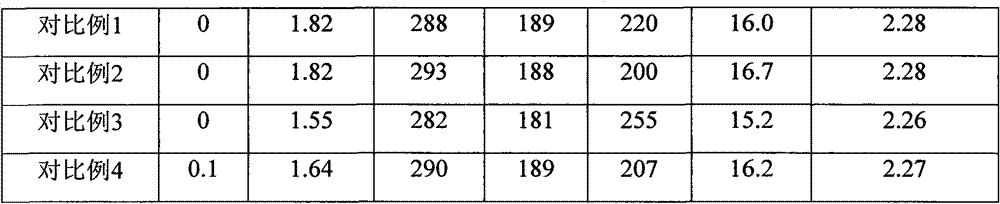

A method of manufacturing an intermediate frequency low loss mnzn ferrite core

ActiveCN101859622BLower the burn-in temperatureFacilitate solid phase reactionInorganic material magnetismInductances/transformers/magnets manufactureAdditive ingredientIntermediate frequency

The invention provides a method for manufacturing an intermediate frequency low-loss MnZn ferrite core, the method is composed of the following steps: A, batching; B, grinding and mixing; C, pre-burning; D, secondary grinding; E, granulation ; F, molding; G, sintering. The invention promotes the solid-phase reaction by adding low-temperature flux, thereby reducing the pre-burning temperature, and can greatly save energy on the basis of achieving the same solid-phase reaction effect. In addition, because the pre-calcination temperature is low, the activity of the powder is better, so the reaction can occur at a lower temperature, thereby reducing the sintering temperature of the present invention and saving energy. At the same time, the MnZn ferrite core manufactured by the invention has lower loss and higher saturation magnetic flux density.

Owner:江门江益磁材有限公司

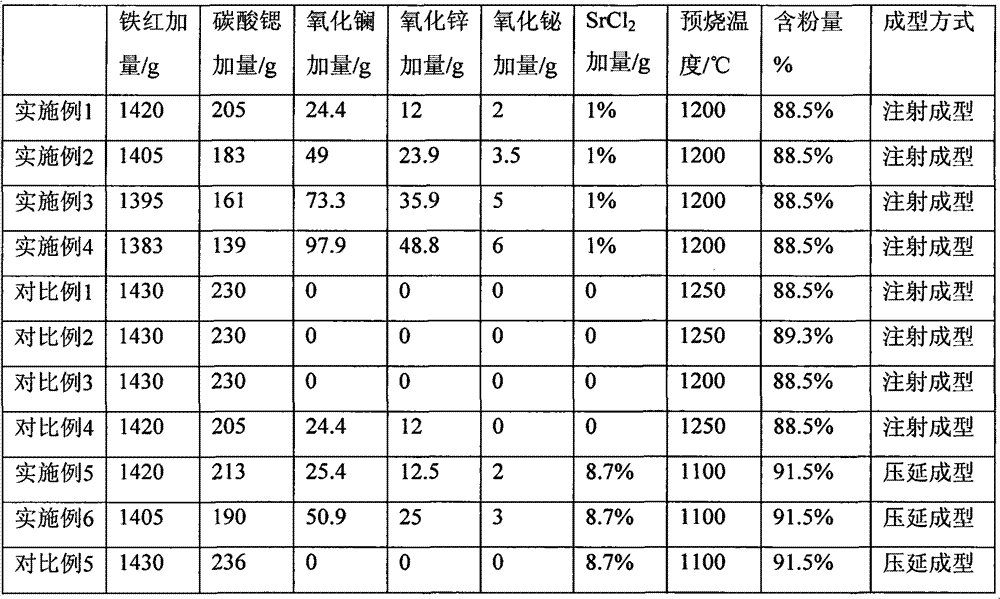

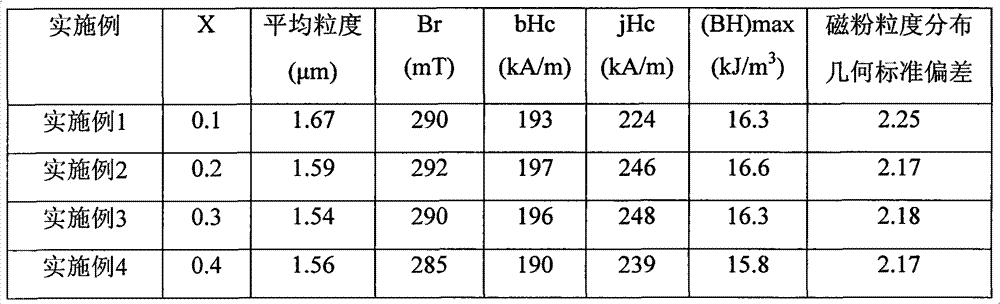

Bonded ferrite magnetic powder, preparation method thereof and bonded permanent magnet

ActiveCN101894648BControl growthControl particle size distributionInductances/transformers/magnets manufactureMagnetic materialsStrontiumChloride

Owner:BEIKUANG MAGNETS FUYANG CO LTD

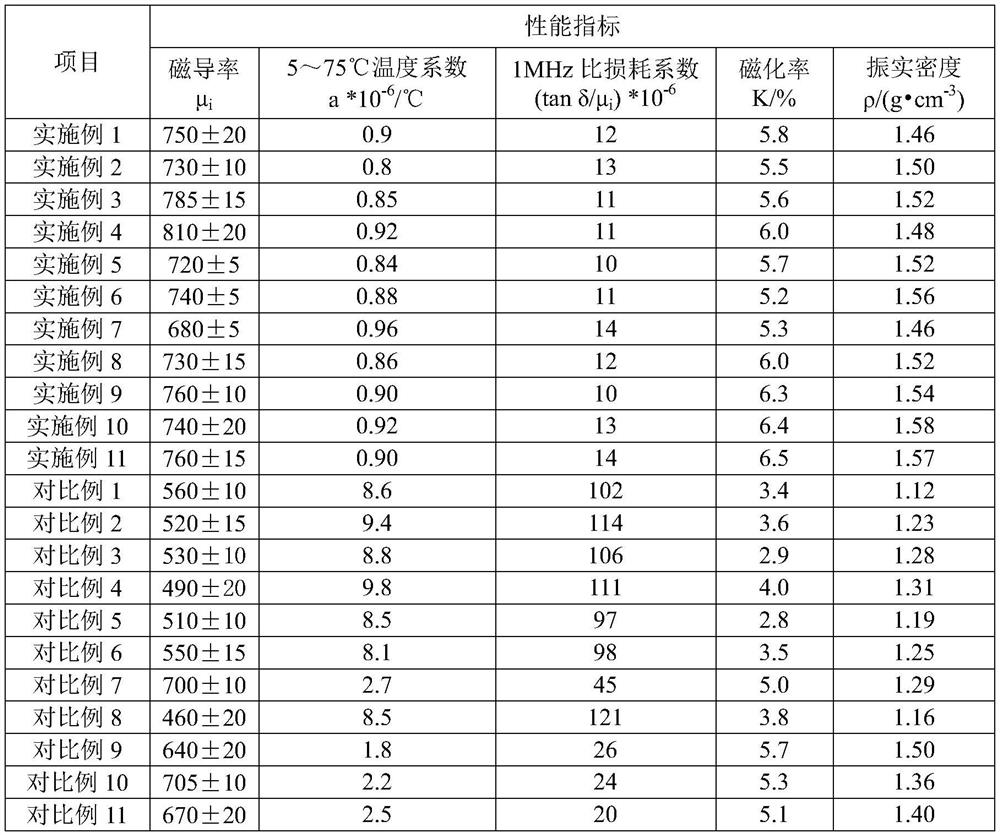

MnZn ferrite material with low temperature coefficient and low loss at high frequency and preparation method thereof

ActiveCN112479697AThorough responseAppropriate and uniform grain sizeInorganic material magnetismComposite materialHigh frequency

The invention relates to the technical field of MnZn ferrite materials, and discloses a MnZn ferrite material with low temperature coefficient and low loss at high frequency in order to realize high frequency and low loss of the MnZn ferrite material. The MnZn ferrite material comprises a main component, a first auxiliary component and a second auxiliary component, wherein the main component comprises Fe2O3, ZnO and MnO; the first auxiliary component comprises CaO, Nb2O5, ZrO2, V2O5 and Bi2O3; and the second auxiliary component is one or more selected from the group consisting of MoO3, Co2O3 and TiO2. A presintering temperature is controlled to be 650-800 DEG C during preparation; a sanding particle size before sintering is 0.8-1.2 [mu]m; and a secondary sintering temperature is 1055-1100DEG C. The prepared MnZn ferrite material has a relatively low temperature coefficient and a relatively low loss coefficient at high frequency.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

A kind of mnzn ferrite material with low temperature coefficient and low loss at high frequency and its preparation method

ActiveCN112479697BThorough responseAppropriate and uniform grain sizeInorganic material magnetismTemperature coefficientMaterials science

The invention relates to the technical field of MnZn ferrite materials. In order to realize the high frequency and low loss of MnZn ferrite materials, a MnZn ferrite material with low temperature coefficient and low loss at high frequencies is disclosed, including main components, second An auxiliary component and a second auxiliary component; the main component is Fe 2 o 3 , ZnO, MnO; the first auxiliary component includes CaO, Nb 2 o 5 , ZrO 2 , V 2 o 5 、 Bi 2 o 3 ; The second auxiliary component is MoO 3 、Co 2 o 3 and TiO 2 One or more of them, during preparation, the pre-firing temperature is controlled to be 650-800°C, the sand mill particle size before sintering is 0.8-1.2 um, and the secondary sintering temperature is 1055-1100°C. The prepared MnZn ferrite material has lower temperature coefficient and lower loss coefficient at high frequency.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

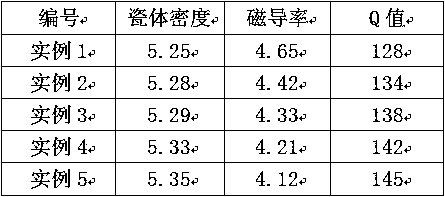

Dual-niobium-source alkali metal niobate micro-nano wire material and preparation method thereof

The invention discloses a dual-niobium-source alkali metal niobate micro-nano wire material. The micro-nano wire material is synthesized through a traditional ceramic solid-phase sintering process byusing K2CO3, Na2CO3, Nb2O5, C10H5NbO20, BaCO3 and Bi2O3 as raw materials which are blended according to a chemical formula of (1-y)K<z>Na<1-z>Nb<(C)x>Nb<(N)1-x>O<3-y>BaBiO<3>, wherein Nb<(C)> is an element Nb from a niobium source C<10>H<5>NbO<20>, Nb<(N)> is an element Nb from a niobium source Nb<2>O<5>, x is greater than 0 and less than or equal to 0.1, y is greater than 0 and less than 0.1, andz is greater than or equal to 0.4 and less than or equal to 0.6. A preparation method of the dual-niobium-source alkali metal niobate micro-nano wire material comprises the following steps of (1) rawmaterial drying; (2) raw material weighing and ball-milling; (3) pre-sintering of powder obtained after ball-milling; (4) secondary ball-milling of pre-sintered powder; (5) pressing of powder obtained after secondary ball-milling into a round billet; (6) heat preservation treatment of the round billet. The dual-niobium-source alkali metal niobate micro-nano wire material and the preparation method thereof have the advantages that after the double niobium sources are adopted, the crystallinity of pressed billet powder and the growth speed of micro-nano wires can be effectively increased; meanwhile, purified water can be used as a ball-milling medium, no absolute ethyl alcohol is needed, and thus the cost is greatly saved and environment pollution and potential safety hazards in the dryingprocess are reduced; the pre-sintering temperature is lowered by 150-425 DEG C, and heat preservation time is shortened.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com