Buffering energy-absorbing structure

A technology of energy-absorbing structure and wall structure, applied in the direction of bumpers, etc., can solve the problems of low energy, inefficient energy absorption of combined structure, waste of materials, etc., achieve stable impact force, stable deformation mode, and reduce casualties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

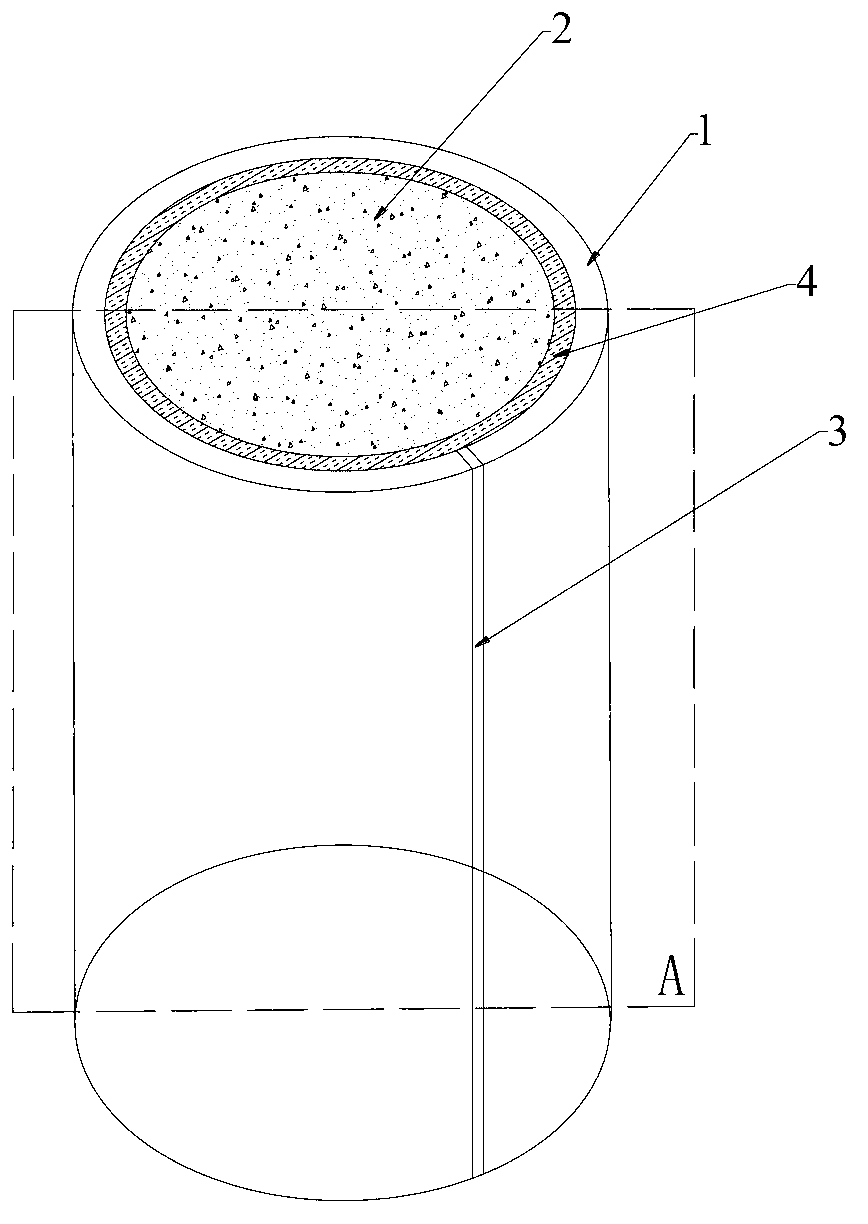

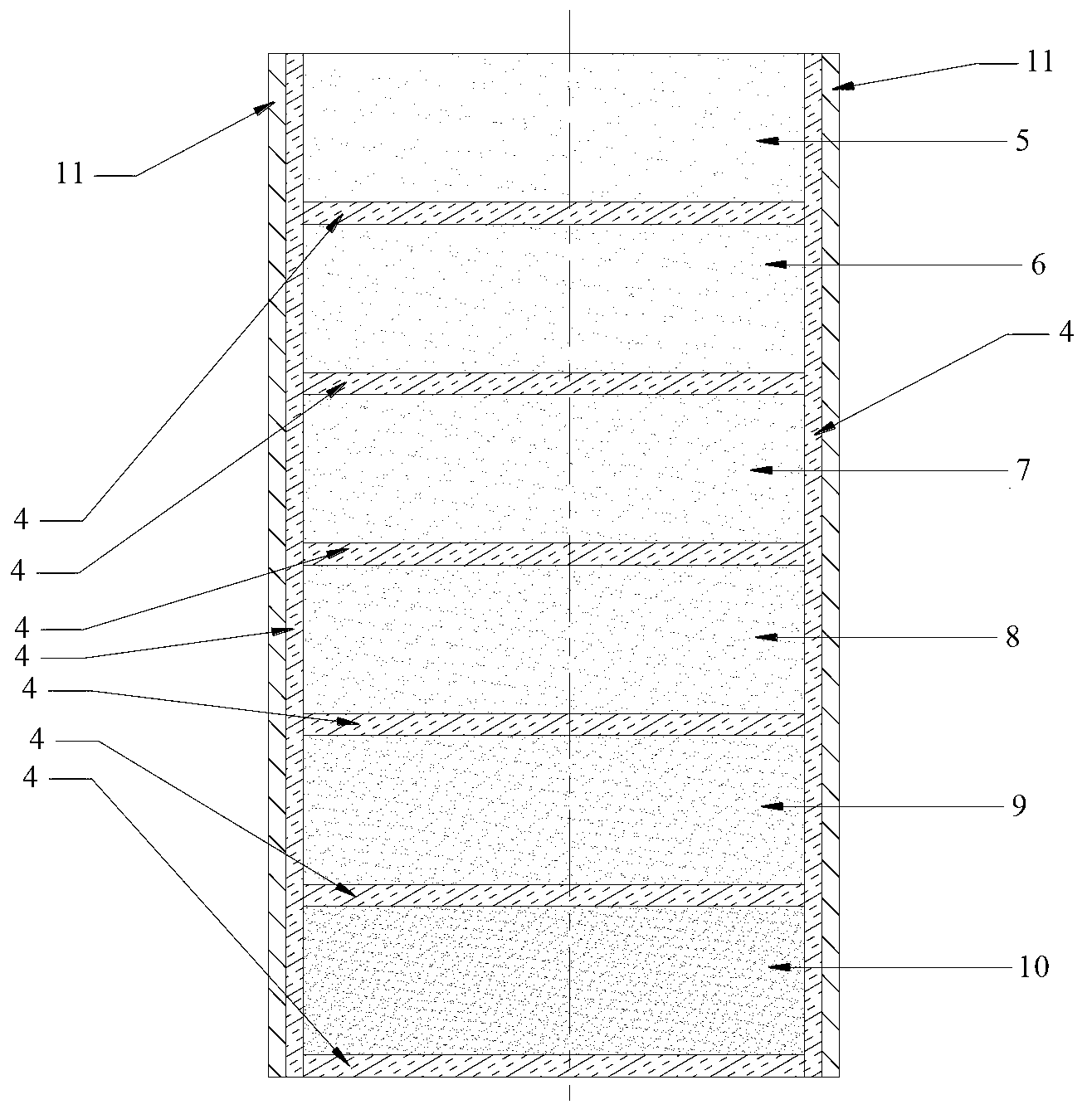

[0017] Specific Embodiment 1: The main external structure of this embodiment is a metal cylindrical hollow thin-walled structure, and the filling material is a foamed aluminum material with functional gradient changes. Due to the difficulty and high cost of manufacturing functionally graded foam materials in the existing technology, Therefore, the filled functionally graded foam material is subdivided into many layers along the length direction, and each layer is a uniform foam material. This technical change can not only enhance the deformation stability and improve the deformation mode of the hollow thin-walled structure, but also can The energy absorption capacity of the hollow thin-walled structure is improved, and at the same time, the collision force changes smoothly during the entire collision process, which can greatly improve the safety of the occupants.

[0018] For each layer of uniform foam, the stress-strain relationship can be described by the isotropic constituti...

specific Embodiment approach 2

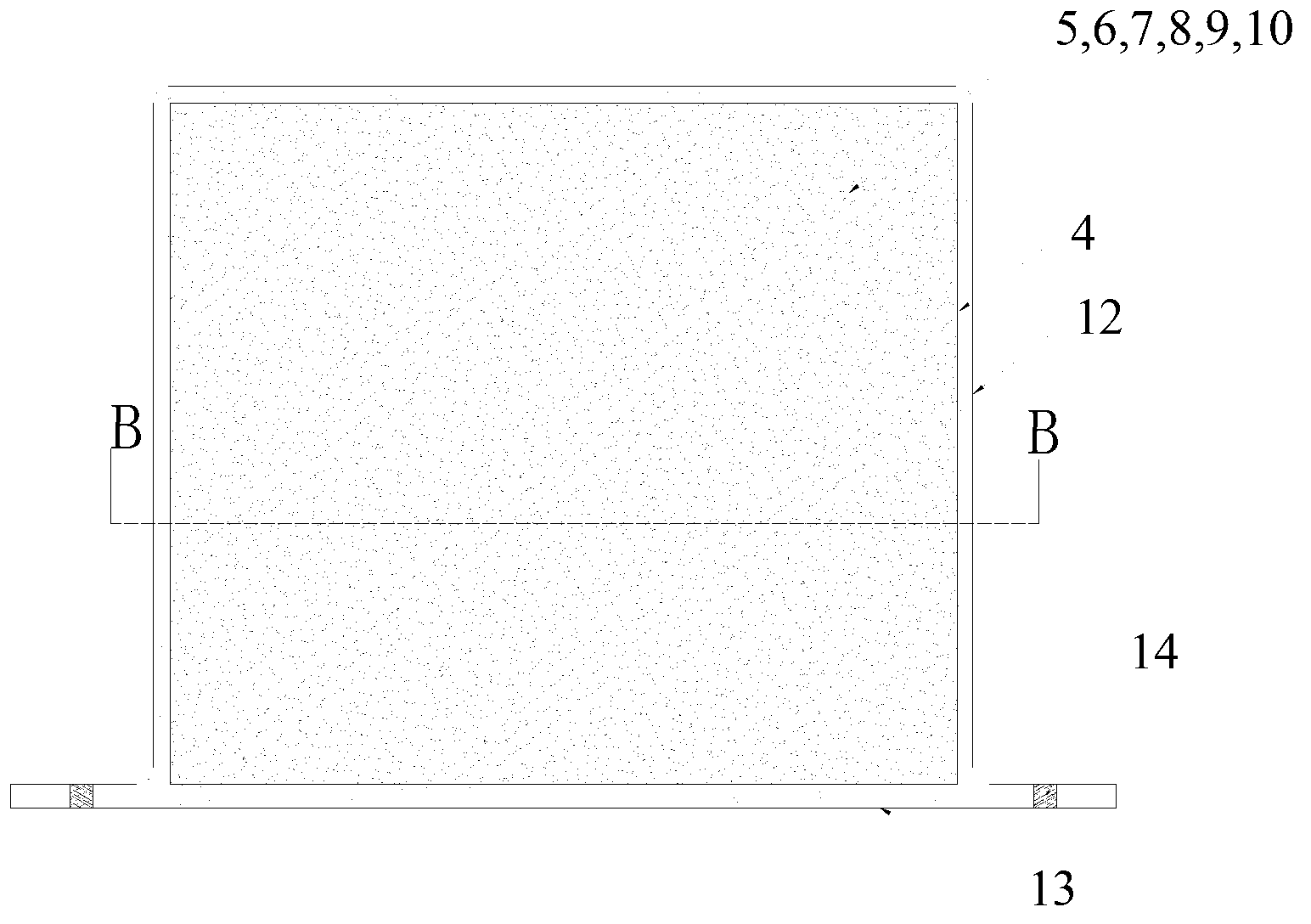

[0033] Specific implementation mode two: (see image 3 ) The external structure of this embodiment includes a metal cap-shaped thin-walled structure, image 3 As the cross section of the structure, it consists of a U-shaped structure 12 and a web 13 which are fixedly connected by a welding structure 14 to form a closed cavity. Other implementation processes are the same as the specific implementation mode 1, along the image 3 The structure of the cross-section B-B in the figure 2 The structure in is similar.

specific Embodiment approach 3

[0034] Embodiment 3: The main difference between this embodiment and Embodiment 1 is that the internal structure is a honeycomb structure, and the sandwich layer of this structure is a series of hexagonal cells made of metal materials. The upper and lower sides of the sandwich layer are then glued (or brazed) to a thinner surface plate. The honeycomb structure has higher strength and rigidity than other sandwich structures, and compared with the riveted structure, the structural efficiency can be increased by 15% to 30%. The size and height of the honeycomb cells in the interlayer and the thickness of the thin slices that make up the lattice determine the critical stress of the local buckling of the surface plate and the buckling of the cell wall plate. Metal honeycomb structure materials have a wide range of sources and low cost. The combined structure is conducive to absorbing impact energy in stages, and can improve the energy absorption capacity of the hollow thin-walled s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com