Method for preparing hydrophilic porous membrane

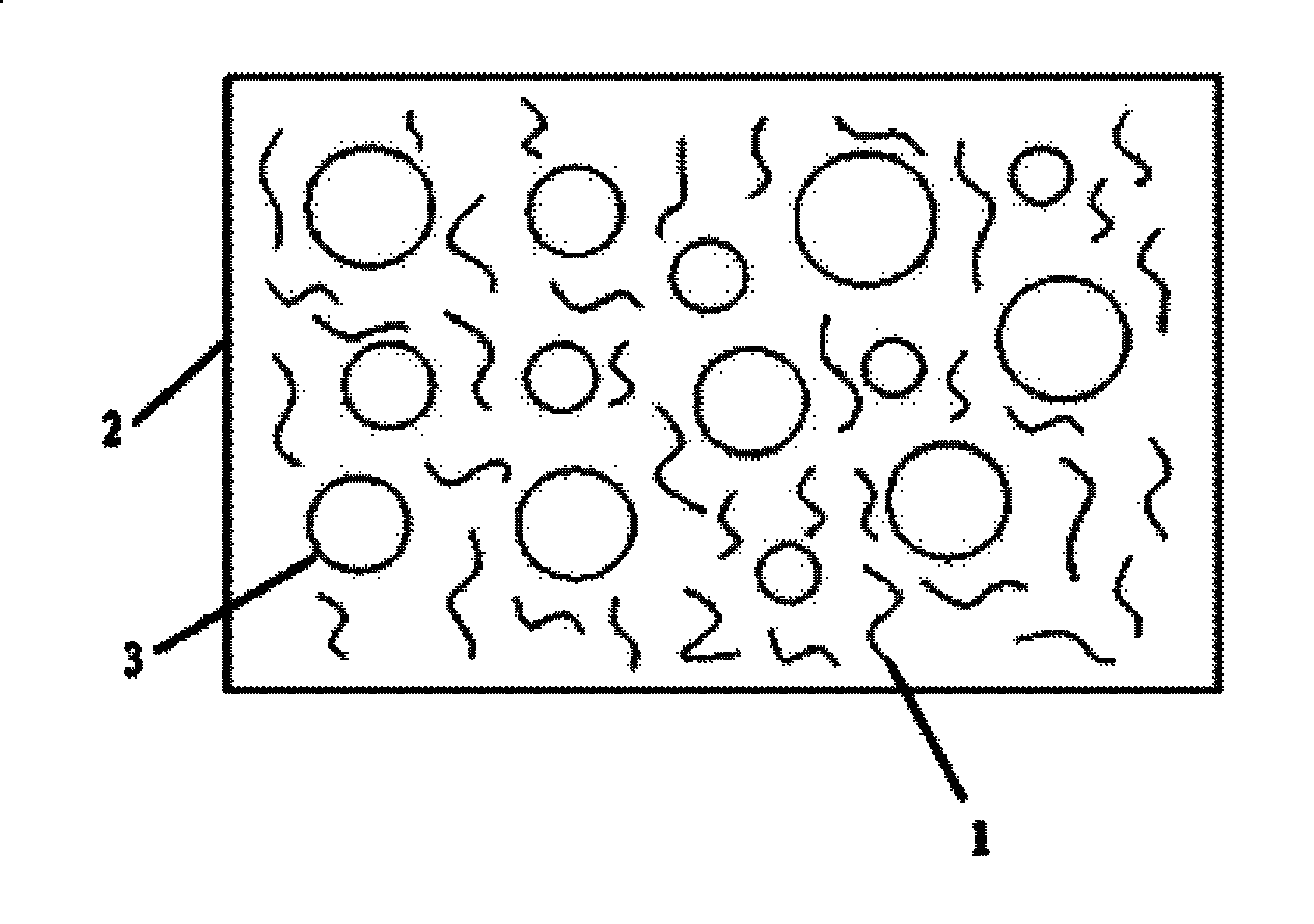

A porous membrane and hydrophilic technology, which is applied in the field of post-treatment of ultrafiltration and microfiltration membranes, can solve the problems of membrane pore enlargement, loss of filtration function, and deterioration of effluent water quality, and achieve uniform membrane pore size and uniform membrane pore size. The effect of structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

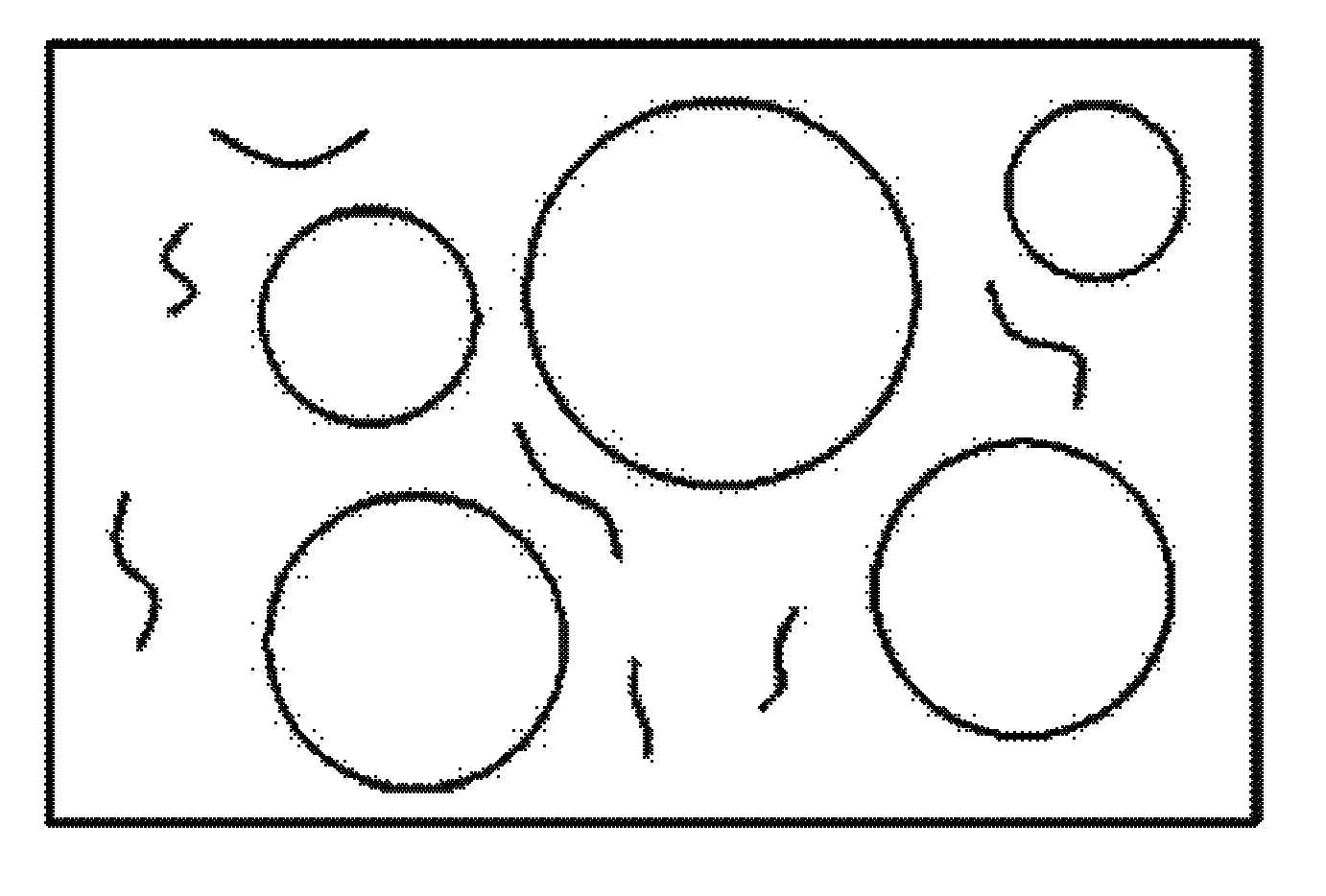

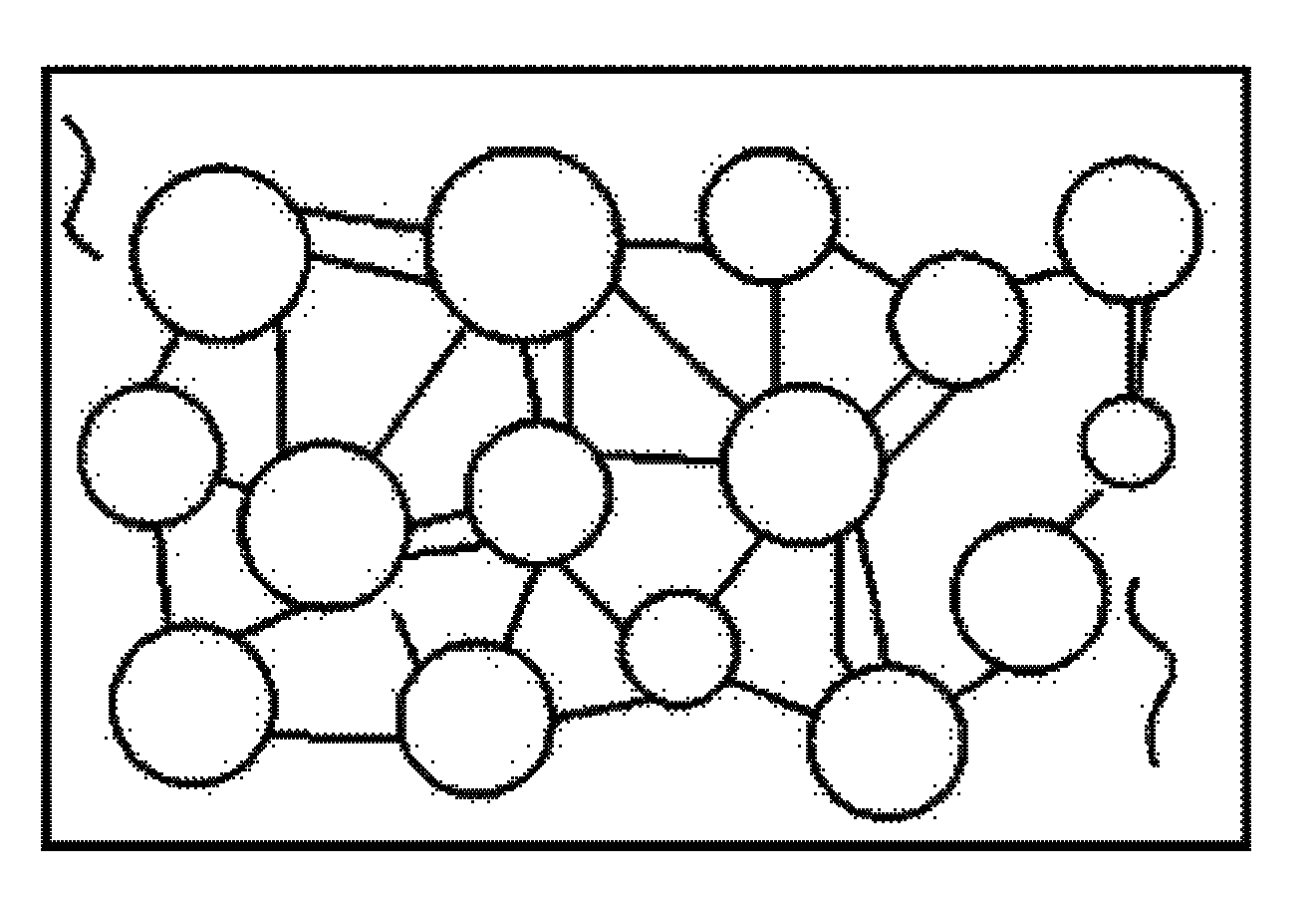

[0026] Embodiment 1: prepare polymer film by known blending modification method, film-forming polymer is polyethersulfone (English abbreviation is PES), modification additive is polyvinylpyrrolidone (English abbreviation is PVP), PES concentration is 18%, the PVP concentration is 3%, stirring and dissolving at 90°C for 6h, standing for defoaming for 24h, scraping the membrane, and then chemically crosslinking the polymer membrane to obtain a hydrophilic porous membrane. The chemical crosslinking treatment is Soak the polymer film in ammonium persulfate solution at a temperature of 80°C, then take it out and put it into a glycerol solution with a concentration of 30% by weight, soak it for about 1 hour, and then dry it at room temperature. and soaking time are tested, then the membrane flux of the prepared porous membrane is detected, and the data in table 1 are obtained:

[0027] Table 1

[0028] sample number

[0029] The known polymer membrane has a membrane flux ...

Embodiment 2

[0030] Example 2: In the post-processing process of the water filtration membrane, it is often necessary to wet the membrane pores with glycerin to prevent the membrane pores from collapsing during the drying process. The porous membrane treated by cross-linking in Example 1 can be directly dried at room temperature without wetting with glycerin, and the dried porous membrane still maintains a high membrane flux. Table 2 shows the test results of polymer membranes made of polysulfone (abbreviated as PSF) and polyvinylpyrrolidone / vinyl acetate copolymer (PVP / VA) without glycerol treatment, and the polymer membranes were soaked in The cross-linking agent solution was used for half an hour, the temperature was controlled at 90 °C, and then the film was dried at room temperature.

[0031] Table 2

[0032] sample number

[0033]Based on the above results, it can be seen that glycerol has a great influence on the membrane flux without cross-linking treatment, but has litt...

Embodiment 3

[0034] Example 3: A polymer film is produced by a known blending modification method, wherein the film-forming polymer is polyvinylidene fluoride (English name abbreviated as PVDF), and the modification additive is polyvinylpyrrolidone (English abbreviated as PVP), Soak the prepared polymer membrane in ammonium persulfate aqueous solution with a concentration of 10% by weight at room temperature for different periods of time, then take it out and heat it to 100°C with steam for half an hour to test its membrane flux. The results are shown in Table 3 .

[0035] table 3

[0036] sample number

[0037] The test results show that sufficient soaking time is very necessary to improve the membrane flux.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com