Heat pipe

A technology for heat pipes and adiabatic sections, applied to heat pipes. In the field, it can solve the problems of high reflux resistance of condensed liquid, hindering the design of forming tools, and increasing the variability of heat transfer performance of heat pipes, etc., and achieve the effects of improving response speed, high capillary pressure, and high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

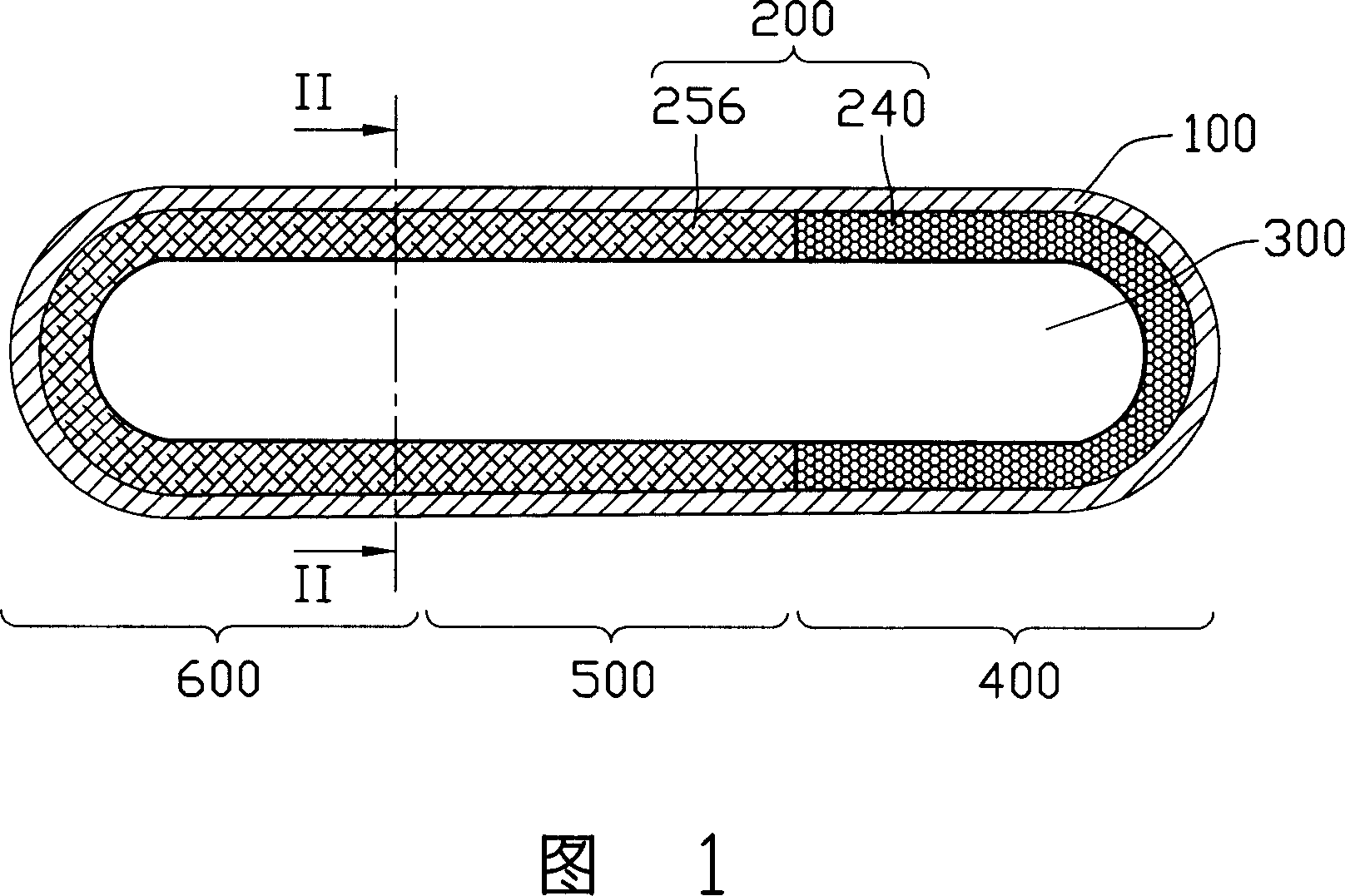

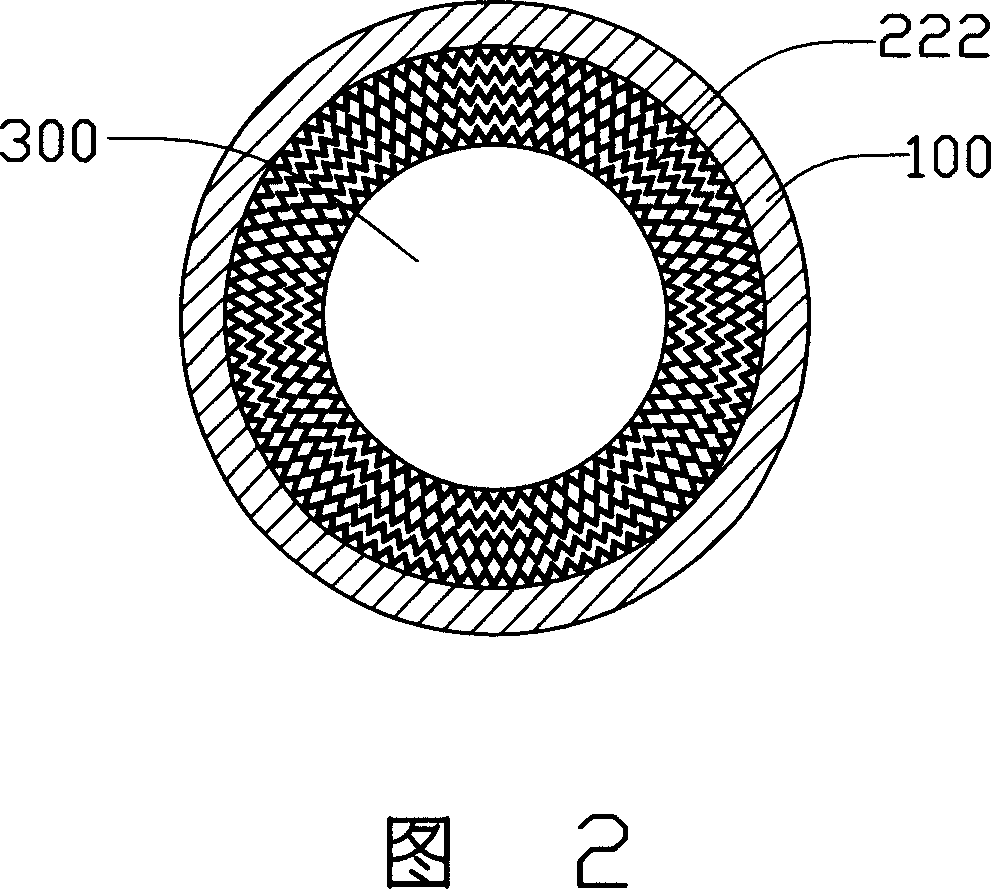

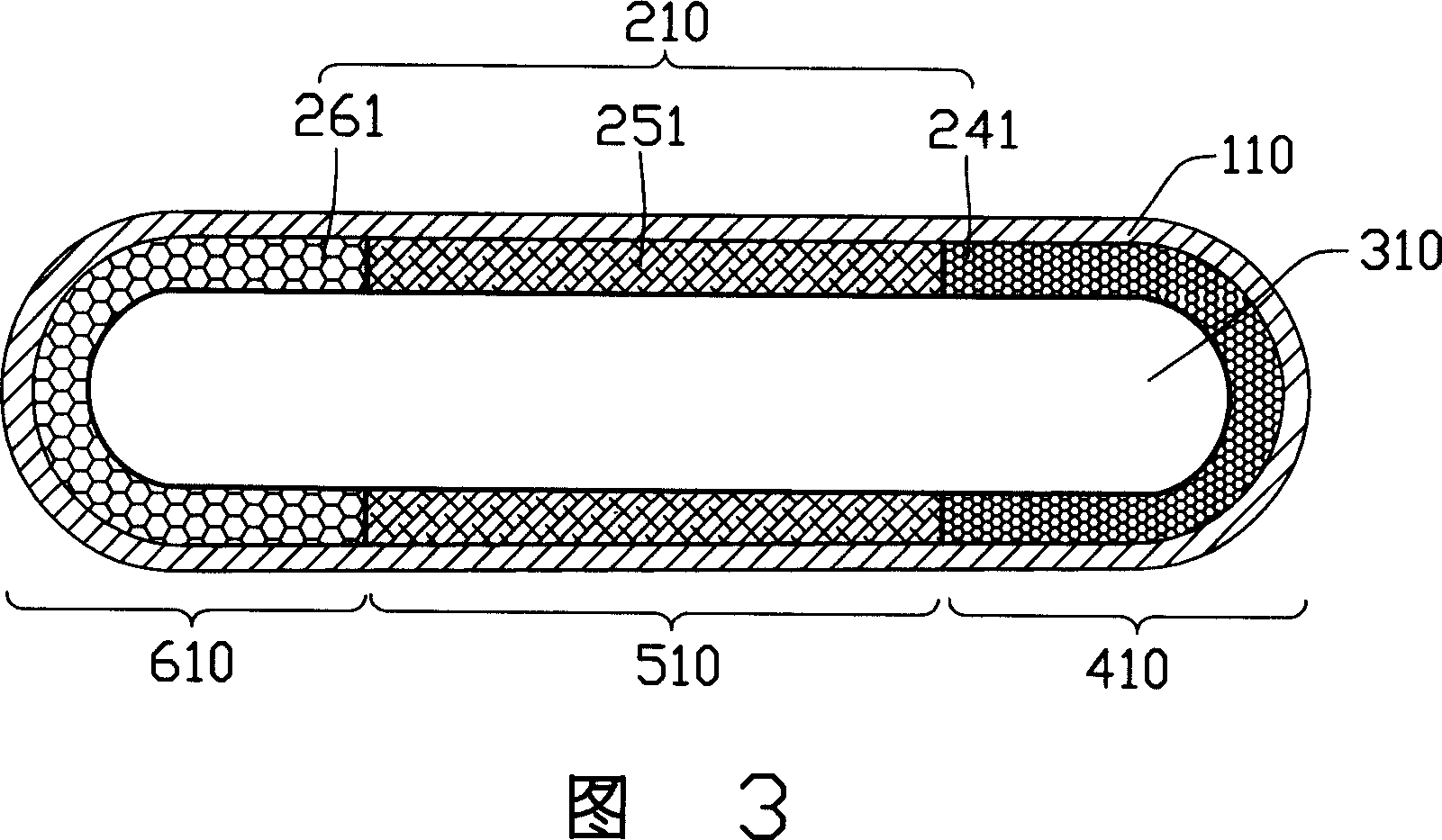

[0015] Please refer to Fig. 1, which is a longitudinal sectional view of the first embodiment of the heat pipe of the present invention; the shown heat pipe includes a metal pipe body 100 with a sealed cavity, and its inner wall is provided with a capillary structure 200, and inside the capillary structure 200 The central space is a steam channel 300, and a proper amount of working fluid (not shown) is sealed inside the metal pipe body 100 and can be moderately pumped to a certain degree of vacuum; The use function can be divided into an evaporation section 400, a condensation section 600 and an adiabatic section 500 between them. Wherein, the metal pipe body 100 is generally made of aluminum, copper or alloys thereof with good thermal conductivity, and its inner wall is smooth or may be provided with several micro-grooves.

[0016] The capillary structure 200 includes a honeycomb first capillary structure 256 and a sintered powder second capillary structure 240 . Please refe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com