Manufacture method of high porosity and high strength yttrium-silicon-oxygen porous ceramics

A technology of porous ceramics and high porosity is applied in the field of porous ceramic materials to achieve the effects of convenient operation, reduced thermal conductivity and easy mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

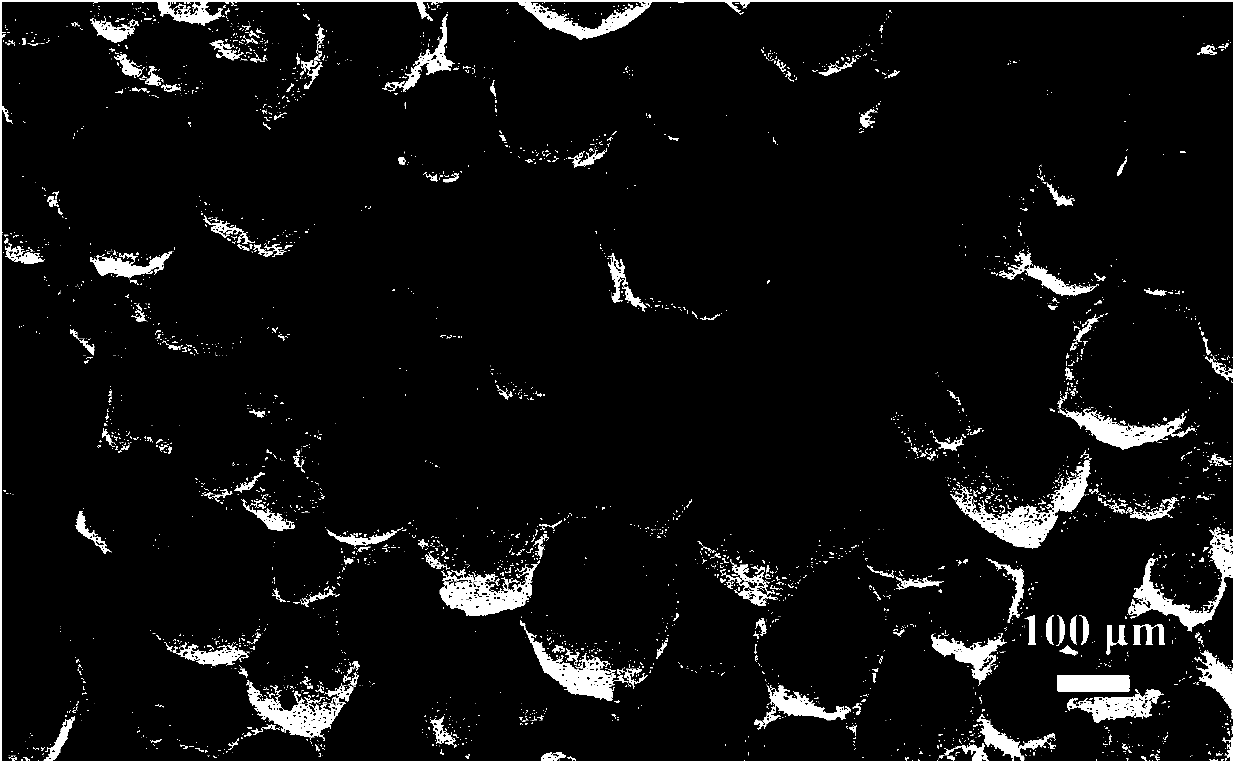

[0024] The present invention has high porosity and high strength yttrium silicon oxide (γ-Y 2 Si 2 o 7 ) The preparation method of porous ceramic material, concrete steps are as follows:

[0025] 1) Preparation of slurry: by mass parts, Y 2 o 3 and SiO 2 80-120 parts of mixed powder with a molar ratio of 1:2, 30-50 parts of deionized water, 4-8 parts of organic monomer, 0.5-1.5 parts of dispersant, cross-linking agent N,N'-methylenebisacrylamide 0.3-0.9 parts are used as raw materials, mixed, and then stirred for 1-4 hours to form a slurry;

[0026] 2) Add 0.5-1.5 parts of foaming agent sodium lauryl sulfate and stir quickly (the speed range of the mixer is 1000-2000rpm) for foaming for 15-30 minutes, then add 0.5-1.5 parts of peeling inhibitor, catalyst N, N , 2-6 parts of N',N'-tetramethylethylenediamine and 1-5 parts of initiator ammonium persulfate, after stirring for 20-60 seconds, injection molding is performed immediately, and a green body is formed after demouldi...

Embodiment 1

[0031] First weigh 50g of deionized water, then add polyethyleneimine 1.5g, acrylamide 6g, N,N′-methylenebisacrylamide 0.9g, and Y 2 o 3 and SiO 2 Mix 120g of mixed powder with a molar ratio of 1:2, and then stir for 4 hours to form a slurry;

[0032] Then add 1.5 g of sodium lauryl sulfate to the slurry, stir rapidly (the speed of the mixer is 1500 rpm) to foam for 30 minutes, then add 1.5 g of polyethylene oxide, N, N, N', N'-tetramethyl Ethylenediamine mass fraction is 15% aqueous solution 6g and ammonium persulfate mass fraction is 25% aqueous solution 5g, after stirring for 20 seconds, injection molding solidifies immediately, forms green body after demoulding;

[0033] The green body was dried at room temperature for 48 hours, then dried in an oven at 90°C for 24 hours, and finally heated to 1525°C in air at a rate of 6°C / min for high-temperature reaction sintering and kept for 2 hours to obtain γ-Y 2 Si 2 o 7 porous ceramics. In this embodiment, the porosity of th...

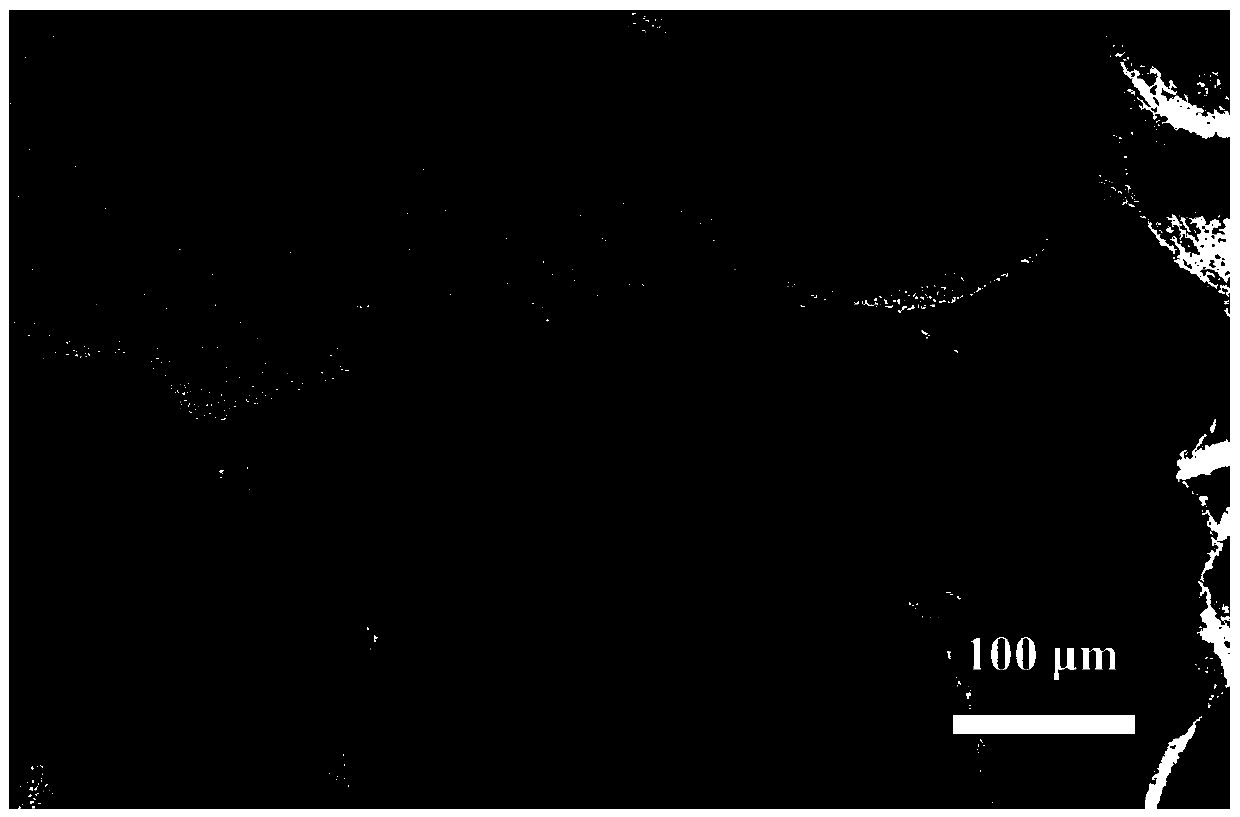

Embodiment 2

[0035] First weigh 30g of deionized water, add 0.5g of ammonium citrate, 4g of acrylamide, 0.3g of N,N′-methylenebisacrylamide, and Y 2 o 3 and SiO 2 Mix 80g of mixed powder with a molar ratio of 1:2, and then stir for 1 hour to form a slurry;

[0036] Then add 0.5g of sodium lauryl sulfate to the slurry, stir rapidly (the speed of the mixer is 1800rpm) to foam for 15 minutes, then add 0.5g of polyethylene glycol, N,N,N',N'-tetramethyl Ethylenediamine massfraction is 25% aqueous solution 2g and ammonium persulfate massfraction is 20% aqueous solution 4g, after stirring for 60 seconds, injection molding is solidified immediately, forms green body after demoulding;

[0037] The green body was dried at room temperature for 24 hours, then dried in an oven at 60°C for 36 hours, and finally heated to 1500°C in air at a rate of 4°C / min for high-temperature reaction sintering and kept for 2.5 hours to obtain Y 2 Si 2 o 7 porous ceramics. In this embodiment, the porosity of the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com