Method for preparing porous alumina ceramic material through combination of 3D printing and reactive sintering

A porous alumina, ceramic material technology, applied in ceramic products, applications, other household appliances, etc., can solve the problem of high shrinkage, achieve accurate realization, good uniformity and pore connectivity, and controllable pore size and porosity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The invention discloses a method for preparing a porous alumina ceramic material, which comprises the following steps: selecting a spherical metal aluminum powder prepared by an atomization method, preparing a porous aluminum body through a rapid prototyping process of a 3D printer, and oxidizing in an air atmosphere and Sintering obtains a porous alumina ceramic material. The invention provides a method with simple process and low cost to prepare porous alumina ceramics with complex shape and excellent performance, and has the advantages of forming and sintering in close size.

[0026] The invention provides a method for preparing a porous alumina ceramic material, which specifically includes the following steps:

[0027] (a) adding aluminum powder to a commercial three-dimensional printer feeding box;

[0028] (b) Load the three-dimensional image that needs to be printed in the computer, and start printing after adjusting the printing parameters;

[0029] (c) The pr...

Embodiment 1

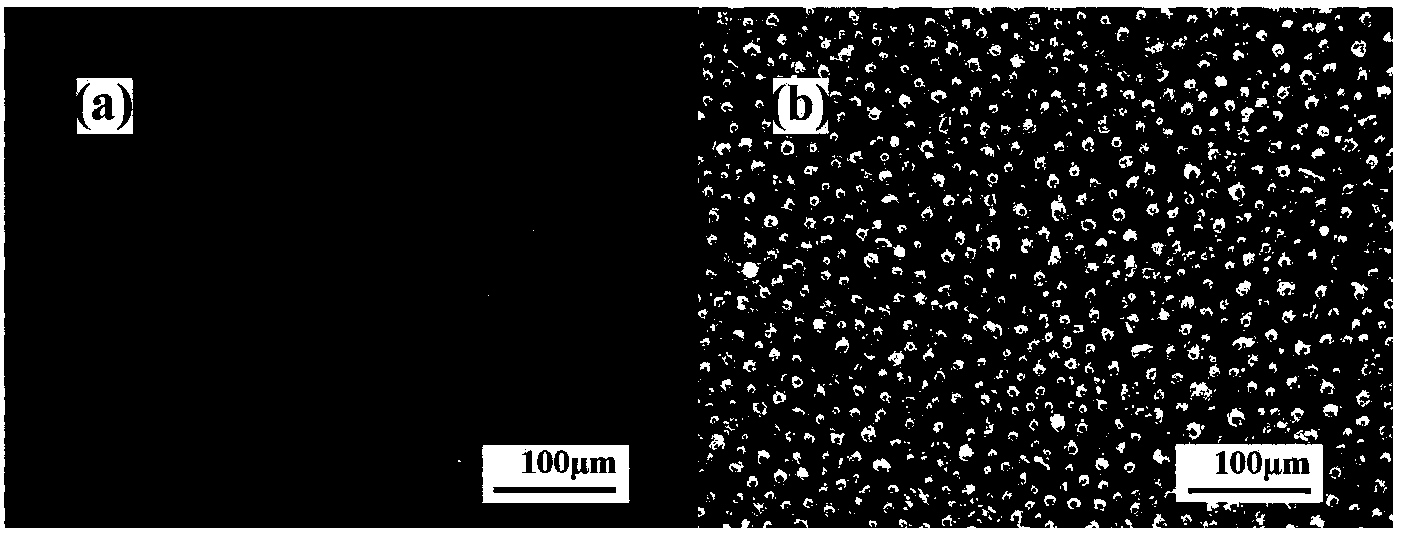

[0041] (1) 10 ~ 25μm Al powder (such as figure 1 Shown in middle a) add in commercial three-dimensional printer feeding box;

[0042] (2) The printing parameters are adopted as layer thickness 50 μm, binder saturation is 80%, binder is a mixture of 15% ethylene glycol and 85% ethylene glycol monobutyl ether, and the drying time is 60 s;

[0043] (3) The printed porous body is cured in an oven at 120°C for 24 hours;

[0044] (4) Put the cured sample into a muffle furnace for 2°C / min to 600°C to remove the binder (hold for 2 hours), 1°C / min to 1400°C for oxidation (hold for 6 hours), 5°C / min increased to 1600°C for sintering (4 hours of heat preservation), and finally obtained porous alumina ceramics with a bending strength of 74.8Mpa, a porosity of 45%, and a sample size increase of 0.6%;

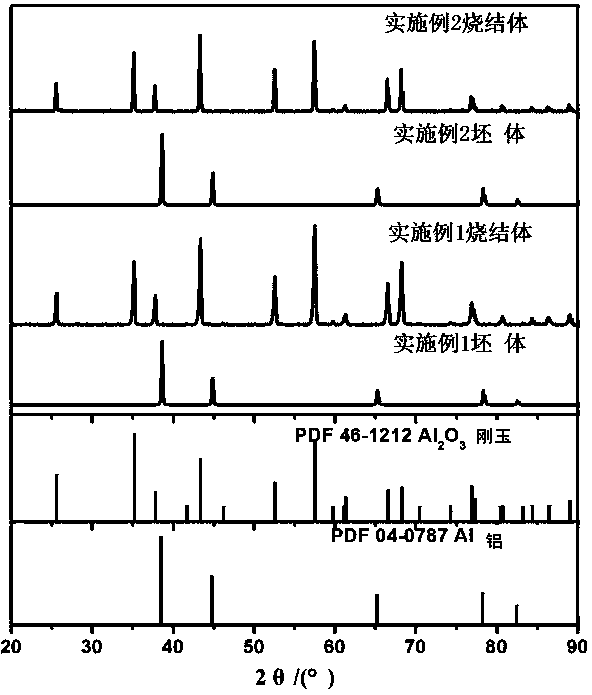

[0045] From figure 2 It can be seen that the aluminum powder is completely oxidized, and the final product is an alumina ceramic material; from Figure 4 It can also be seen from the p...

Embodiment 2

[0047] (1) Add 10-25 μm Al powder into a commercial 3D printer feeding box;

[0048](2) The printing parameters are adopted as layer thickness 100 μm, binder saturation is 120%, binder is a mixture of 15% ethylene glycol and 85% ethylene glycol monobutyl ether, and the drying time is 90s;

[0049] (3) The printed porous body is cured in an oven at 120°C for 24 hours;

[0050] (4) Put the cured sample into a muffle furnace for 1°C / min to 600°C to remove the binder (hold for 2 hours), 1°C / min to 1400°C for oxidation (hold for 12 hours), 5°C / min increased to 1600°C for sintering (holding temperature for 2 hours), and finally obtained porous alumina ceramics with a bending strength of 71.3Mpa, a porosity of 44%, and a sample size increase of 0.8%;

[0051] From figure 2 It can be seen that the aluminum powder is completely oxidized, and the final product is an alumina ceramic material; from image 3 It can be seen that the green body particles are densely packed, and there is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com