Method for preparing pore diameter controllable porous capillary core

A capillary core and pore size technology, applied in ceramic products, household appliances, other household appliances, etc., can solve the problems of uneven pore size distribution, difficult to control the pore-making process, and large pore-forming pore size, and achieve controllable pore size distribution and preparation. Simple process and controllable porosity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: adopt the uniform pure nickel powder of particle size, evenly mix in soluble salt powder NaCl, its mass ratio is NaCl: Ni is 40: 60, the particle size of NaCl remains on 400 order, cold press molding, cold press molding pressure is 20Mpa. Sinter in an argon-protected sintering furnace at 650°C for 60 minutes, wash in clean water to remove soluble salts, and dry at last.

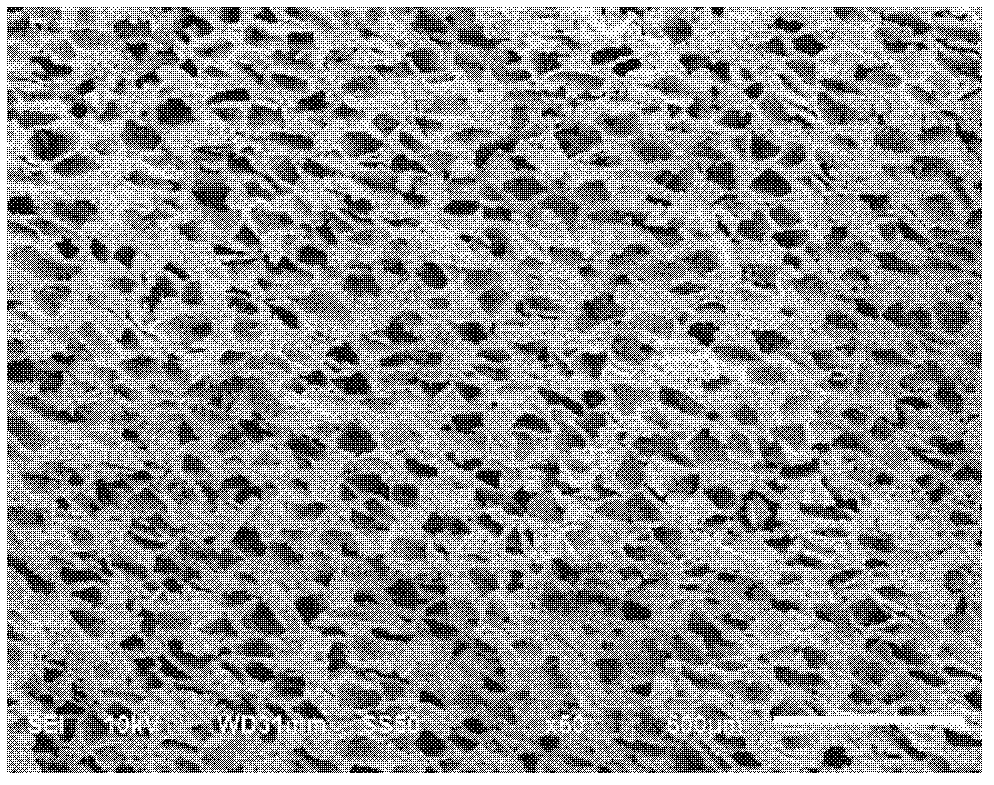

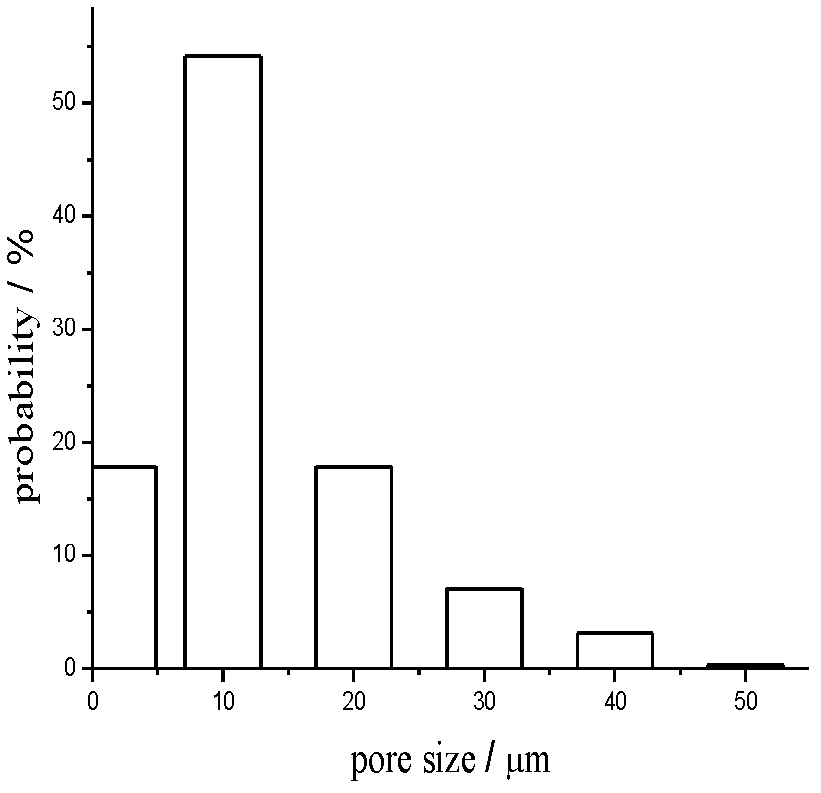

[0022] The morphology of the obtained capillary core is as follows figure 1 shown. Its final porosity is 73%. The pore size distribution is shown in figure 2 . It can be seen from this figure that the capillary core obtained by the dissolved salt pore-forming method is not only small but also has a concentrated pore size distribution and uniform pore size.

Embodiment 2

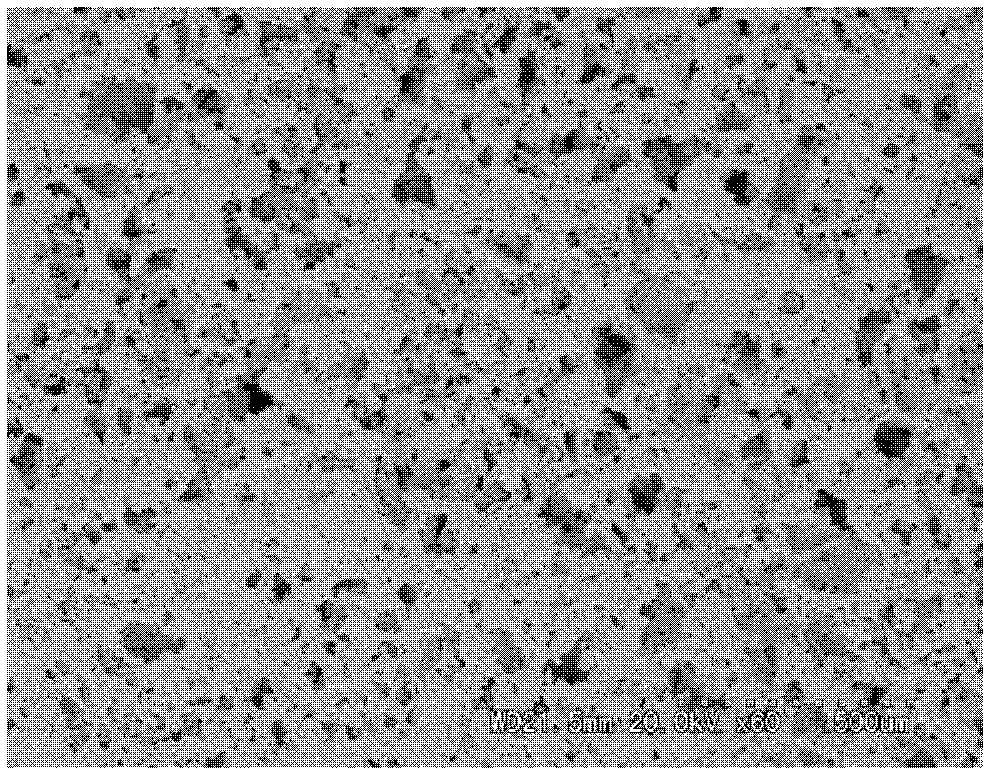

[0024] The mixed powder of nickel powder and titanium powder with uniform particle size is used, wherein the titanium powder accounts for 10% of the weight of the metal powder, and then mixed with NaCl with a particle size of 400 mesh, the weight ratio of NaCl and metal mixed powder is 20:80, and cold pressed. , The cold forming pressure is 50Mpa. Sinter in an argon-protected sintering furnace at 650°C for 60 minutes, wash in clean water to remove soluble salts, and dry at last. Its final porosity is 65%.

Embodiment 3

[0026] Use Cr13 stainless steel powder with uniform particle size of 300 mesh, mixed with particle size of 400 mesh K 3 PO 4 , K 3 PO 4 The weight ratio to stainless steel is 20:80. The mixed powder is placed in a graphite mold and then sintered in a vacuum hot-press furnace. The heating rate is 10 degrees per minute. degree, the holding time is one hour. After sintering and cooling, cleaning and desalination can finally obtain a stainless steel capillary core with a porosity of about 67%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com