Method for preparing silicon dioxide aerogel by using acidic silica sol

A technology of acidic silica sol and silicon dioxide, which is applied in the production of silicon dioxide, silicon oxide, bulk chemicals, etc., can solve problems such as increasing airtightness, explosion-proof anti-static, increasing risk, cumbersome process, etc., to achieve effective Conducive to the control of wet gel structure, improving work efficiency and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

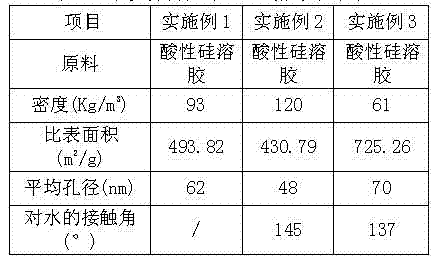

Embodiment 1

[0034] Take 100ml of acidic silica sol with a silica content of 30% (wt) and put it in a 1000ml beaker, measure 300ml of water and add it to the beaker to dilute the acidic silica sol. into the prepared silica sol aqueous solution, and stir while adding dropwise until the pH value of the silica sol aqueous solution reaches 11.0, and then with 2mol / L H 2 SO 4 Solution titration of silica sol aqueous solution, stirring while adding dropwise, until the pH value reaches 7.0, put the dropwise added solution in a 70°C water bath, after 3.5h, the solution forms a hydrogel, continue to age in a 60°C water bath atmosphere for 2h, put The gel was taken out and replaced in 95% (wt) ethanol. The volume ratio of ethanol to hydrogel was 5:1, the replacement temperature was 60°C, and the replacement time was 3 hours. A total of 3 replacements were performed to obtain the alcohol gel. Supercritical drying of carbon dioxide to obtain hydrophilic SiO 2 airgel.

Embodiment 2

[0036] Take 100ml of acidic silica sol with a silica content of 30% (wt) in a 1000ml beaker, measure 200ml of water and add it to the beaker to dilute the acidic silica sol. Slowly drop the sodium solution into the prepared silica sol aqueous solution, and stir while adding, until the pH value of the silica sol aqueous solution reaches 10.8, then titrate the silica sol aqueous solution with 2mol / L HCl solution, and stir while dropping, until the pH value When it reaches 7.05, put the dropwise solution in a 60°C water bath. After 1min, the solution forms a hydrogel, and continues to age in a 60°C water bath for 2 hours. Take out the gel and replace it with 95% (wt) ethanol. The volume ratio to the hydrogel is 5:1, the replacement temperature is 60°C, the replacement time is 3h, and the replacement is 2 times. The gel is taken out and placed in a trimethylchlorosilane solution for surface methylation treatment, soaked at 60°C for 3h , by supercritical drying of ethanol to obtain...

Embodiment 3

[0038] Take 50ml of acidic silica sol with a silica content of 30% (wt) in a 1000ml beaker, measure 200ml of water and add it to the beaker to dilute the acidic silica sol. The sodium solution was slowly dropped into the prepared aqueous silica sol solution, and stirred while adding dropwise until the pH value of the aqueous silica sol solution reached 9.7, and then added with 3mol / L H 2 SO 4 Solution titration of silica sol aqueous solution, stirring while adding dropwise, until the pH value reaches 6.15, put the dropwise added solution in a 60°C water bath, after 12 minutes, the solution forms a hydrogel, continue to age in a 60°C water bath atmosphere for 2.5h, put The gel was taken out and replaced in 95% (wt) ethanol. The volume ratio of ethanol to hydrogel was 5:1, the replacement temperature was 60°C, and the replacement time was 3 hours. Methyl chlorosilane solution was subjected to surface methylation treatment, soaked at 60°C for 3h, and then dried under normal pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com