Method for preparing coating microcapsule before microbial fermentation by utilizing common fermentation tank

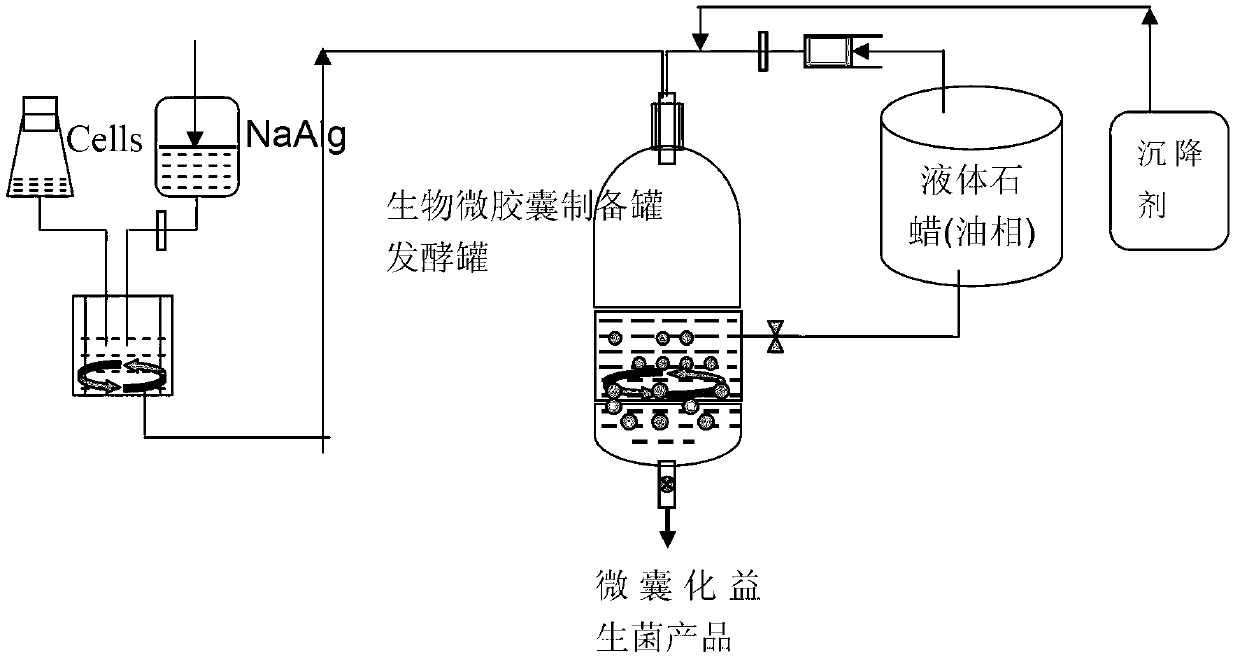

A technology of microbial fermentation and microcapsules, which is applied in the direction of being fixed on or in an inorganic carrier, or being fixed on or in an organic carrier, which can solve the problem that the degree of mechanization and automation cannot meet the requirements and affect the shape of the product (sphericity yield rate). , increase the complexity and cost of equipment, etc., to avoid low microencapsulation efficiency and yield, controllable cell density, and good shape and stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: 50 liters of fermentation tanks produce yeast microcapsules

[0026] 1. Preparation of seed solution: inoculate the preserved yeast strains in YPD medium, culture in shake flasks at 30±1°C for 8-10 hours, until the yeast grows to the end of logarithmic growth, stop the cultivation for later use.

[0027] 2. Preparation of capsule material solution: Add 3L of water into the feeding tank, weigh 45g of food-grade sodium alginate, add it to the feeding tank, stir until completely dissolved, and prepare a sodium alginate solution with a concentration of 15g / L , sterilized at 115°C for 15-20 minutes.

[0028] 3. Preparation of the aqueous phase mixture: weigh 45g of CaCO2 in a ratio of 1:1 to the mass ratio of the sodium alginate used. 3 , put into the feeding tank, mix evenly, steam sterilize at 115°C for 20 minutes, cool to about 35°C, add microbial seed liquid at the end of logarithmic growth, and cultivate to a density of 10 6 About cfu / ml, mix well again ...

Embodiment 2

[0034]Embodiment 2: the yeast microcapsule produced by 1000 liters of fermentation tanks

[0035] 1. Preparation of seeds: inoculate the preserved yeast strains in YPD medium, and culture in shake flasks at 30±1°C for 8-10 hours until the yeast grows to the end of logarithmic growth, stop the cultivation for later use.

[0036] 2. Preparation of capsule material solution: Add 60L of water into the feeding tank, weigh 1.2kg of food-grade sodium alginate, add it to the feeding tank, stir until completely dissolved, and prepare sodium alginate with a concentration of 20g / L Solution, sterilized at 115°C for 15-20 minutes.

[0037] 3. Preparation of the aqueous phase mixture: Weigh 1.8kg of CaCO2 at a ratio of 1:1.5 to the mass ratio of the sodium alginate used 3 , put it into the feeding tank, mix well, steam sterilize at 115°C for 25 minutes, cool to about 38°C, add microbial seed liquid at the end of logarithmic growth, and reach 10 6 The density is about cfu / ml, and fully mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com