Continuous density gradient low-density porous carbon bonding composite material and preparing method thereof

A composite material and porous carbon technology, applied in the field of carbon bonding composite materials and their preparation, can solve the problems of poor anti-scour performance and poor mechanical strength, and achieve the effects of improving thermal insulation performance, optimizing performance and increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

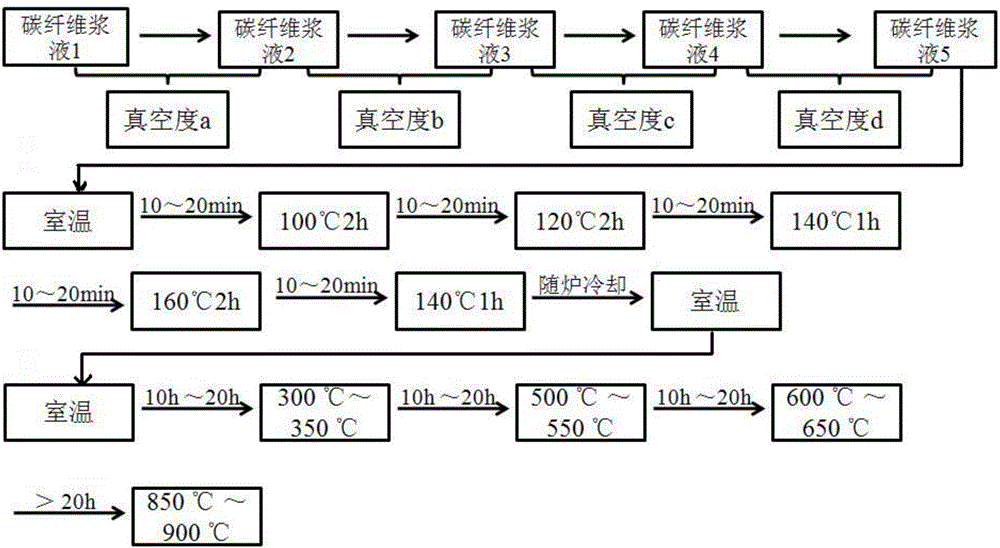

[0032] A method for preparing a continuous density gradient low-density porous carbon bonded composite material, comprising the steps of:

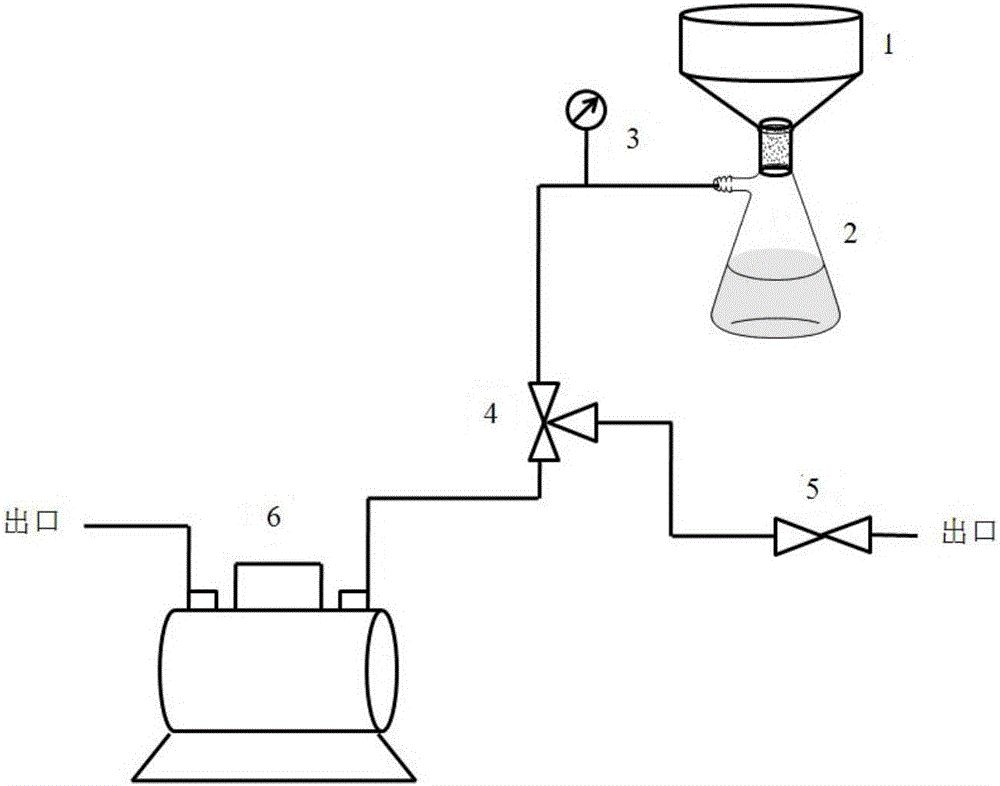

[0033] (1) Preparation of fiber slurry and vacuum filtration molding of fiber slurry. The chopped viscose-based carbon fibers of different lengths that have been mechanically cut are prepared into multiple fiber slurries to be formed by suction filtration according to the above-mentioned raw material mass ratio range, and the fiber slurries are stirred evenly with a mechanical stirrer. Add 50 to 100 parts by mass of deionized water, and use a glass rod to drain the fiber slurry into the molding mold slowly. Fill the molding mold with the fiber slurry and let the chopped viscose-based carbon fiber settle naturally for 5-10 minutes, then turn on the vacuum pump to vacuumize, so that the vacuum degree in the molding mold is first stabilized to 0.1MPa, and then adjusted during the suction filtration process The degree of vacuum is used to cha...

Embodiment 1

[0040] A method for preparing a continuous density gradient low-density porous carbon bonded composite material, the steps are as follows:

[0041] (1) Take out 4 pieces of chopped viscose-based carbon fibers whose mechanical cutting time is 8min, 12min, 16min and 20min, and the fiber length distribution is 1.5mm~2.5mm, 900μm~1.5mm, 600μm~900μm and 300μm respectively ~600μm. Each part of chopped viscose-based carbon fiber is prepared into chopped viscose according to the ratio of 12 parts by mass of chopped viscose-based carbon fiber, 12 parts by mass of phenolic resin, 3 parts by mass of polyacrylamide (PMA), and 1000 parts by mass of deionized water. Fiber slurry for gum-based carbon fibers. Stir the fiber slurry evenly with a mechanical stirrer and then add it in order of fiber length from short to long. During the vacuum filtration molding process, the vacuum degree changes within the range of 0.08MPa to 0.1MPa.

[0042] (2) After the vacuum filtration is completed, the ...

Embodiment 2

[0045] A method for preparing a continuous density gradient low-density porous carbon bonded composite material, the steps are as follows:

[0046] (1) Take out 5 parts of chopped viscose-based carbon fibers whose beating time is 5min, 10min, 15min, 20min and 30min, and the fiber length distribution is 2mm~3mm, 1mm~2mm, 600μm~1mm, 300μm~600μm and 100μm ~300μm. Each part of chopped viscose-based carbon fiber is formulated into chopped viscose-based carbon fiber according to the ratio of 12 parts by mass of chopped viscose-based carbon fiber, 30 parts by mass of resol resin, 5 parts by mass of polyacrylamide (PMA), and 1300 parts by mass of deionized water. A slurry of viscose-based carbon fibers. Stir the fiber slurry evenly with a mechanical stirrer and then add it in order of fiber length from short to long. During the vacuum filtration molding process, the vacuum degree changes within the range of 0.06MPa to 0.1MPa.

[0047] (2) After the vacuum filtration is completed, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com