Foam material for shoes and preparation method thereof

A foaming agent technology for shoes, which is applied in the field of foaming materials for shoes and its preparation, can solve the problems of poor dimensional stability, poor low-temperature toughness, high impact rebound rate, etc., and achieve a controllable thermal shrinkage rate, The effect of low cost and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0064] The present invention also provides a method for preparing the foaming composition for shoes according to the present invention, which includes the step of mixing the components of the foaming composition for shoes.

[0065] Specifically, the preparation method of the present invention comprises the following steps:

[0066] (1) Mix the base materials evenly with a high-speed mixer, and melt blend them in an internal mixer at 100-140°C for 3-5 minutes; add activators, foaming agents, cross-linking aids and fillers, and banbury for 3- 5min, finally add the cross-linking agent and mix for 2-3min before discharging;

[0067] (2) extruding the raw materials after mixing, and then processing and slicing them into primary embryo raw materials with a predetermined volume;

[0068] (3) Put the raw material of the embryo into the mold, carry out molding and foaming under the conditions of 10-15MPa and 160-175°C temperature, release and press after 5-15min to obtain a foam body,...

Embodiment 1-3

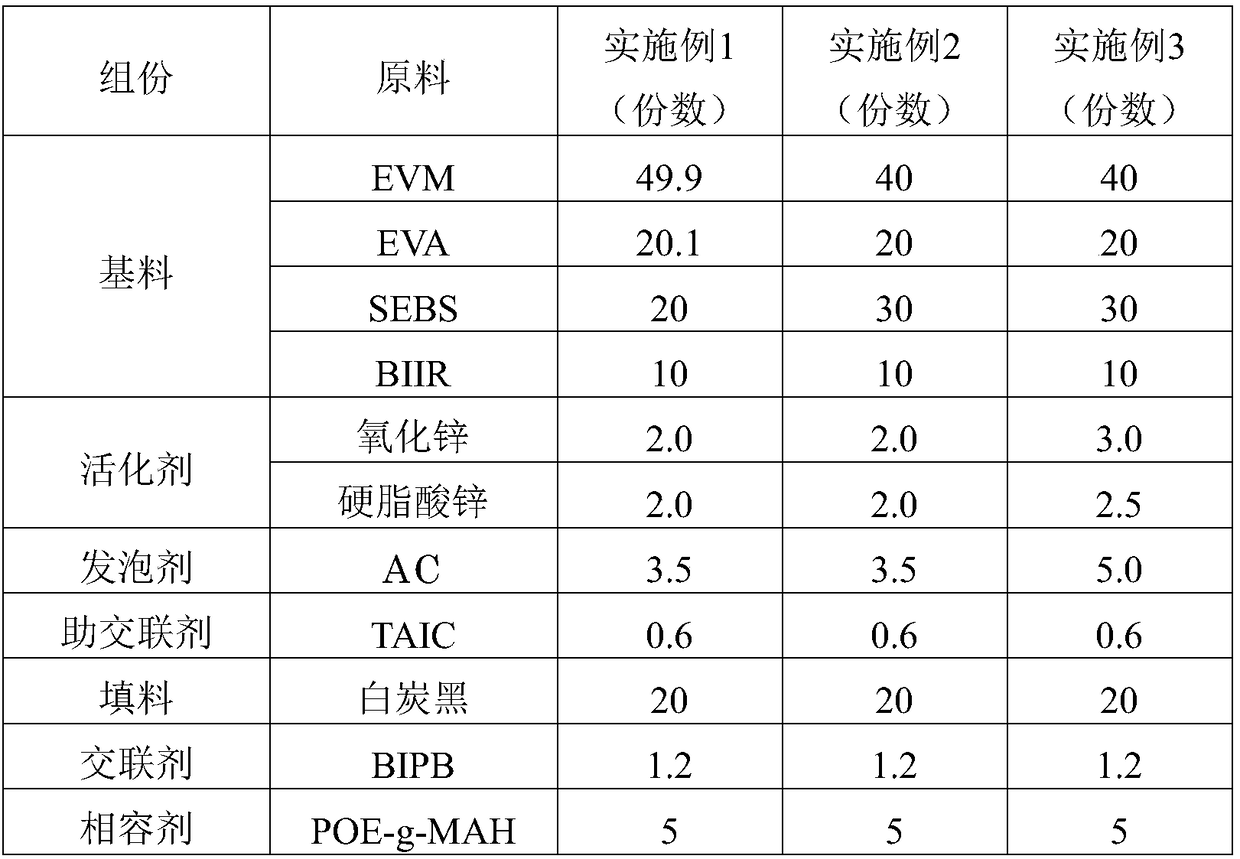

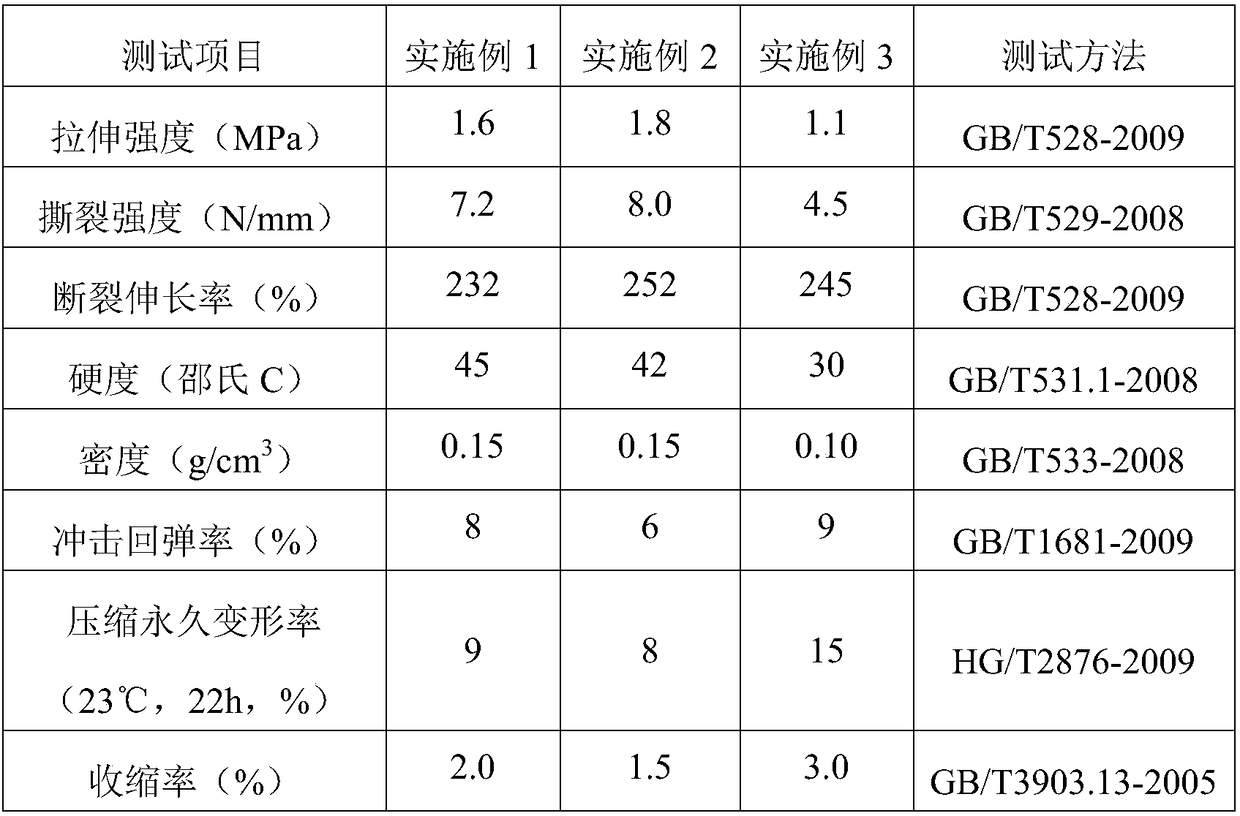

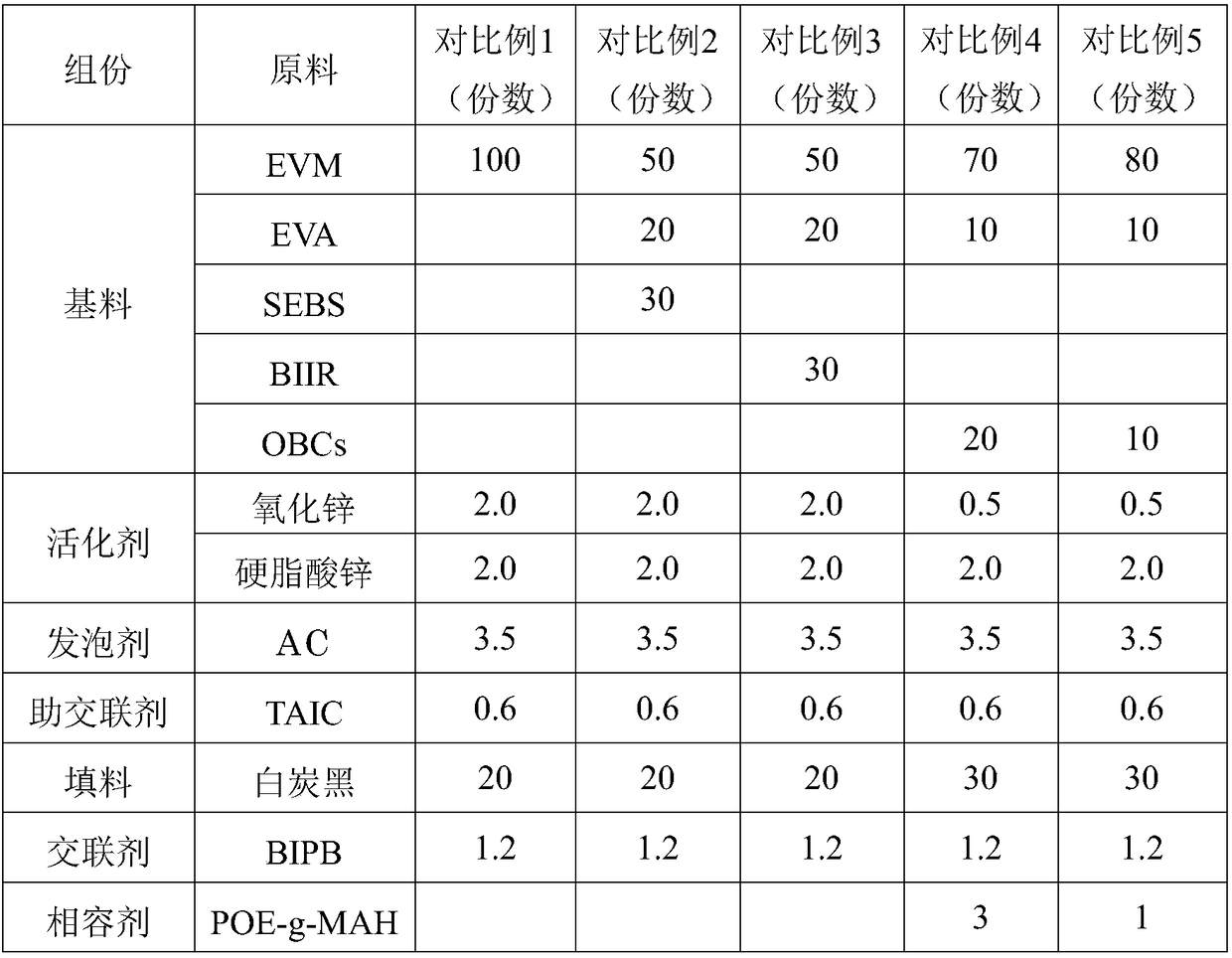

[0075] According to the mass parts of each component in the following Table 1, the foaming compositions for shoes of Examples 1-3 were prepared according to the following method.

[0076] The preparation method of embodiment 1-3 is:

[0077] (1) The base material (ethylene-vinyl acetate rubber (EVM), ethylene-vinyl acetate resin (EVA), styrene-ethylene-butylene-styrene block copolymer (SEBS) and brominated butyl rubber (BIIR)) and compatibilizer anhydride grafted ethylene-octene random copolymer (POE-g-MAH) were pre-mixed uniformly with a high-speed mixer, and then melt-blended in an internal mixer at 120±3°C 3min.

[0078] (2) Add foaming agent azodicarbonamide (AC), activator zinc stearate, activator zinc oxide, auxiliary crosslinking agent triallyl isocyanurate (TAIC) and filler silica , banburying for 5 minutes, and finally adding the cross-linking agent 1,4-bis-tert-butylperoxycumene (BIPB) and mixing for 2 minutes before discharging.

[0079] (3) Extruding the kneaded...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com