Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40results about How to "Delicate and smooth feel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Multifunctional softener and preparation method for same

ActiveCN103321053AImprove biological activityPromote degradationFibre treatmentWater soluble chitosanAqueous solubility

The invention provides a multifunctional softener and a preparation method for the same. The multifunctional softener is composed of amino silicon oil, a compound emulsifier, water-soluble chitosan and water, wherein amino silicon oil is added in the compound emulsifier, and the mass ratio of the amino silicon oil to the compound emulsifier is 1:(0.2-0.8); then the water-soluble chitosan is added, and the added amount is 1-8% of the mass of the mixed solution of the amino silicon oil and the compound emulsifier; finally, water is added, and the mass of water is 10-50% of the total mass of the mixed solution aforementioned. The preparation method comprises the following steps of: preparation for the water-soluble chitosan, preparation for the compound emulsifier, and preparation for the multifunctional fabric softener. The multifunctional integrated softener obtained after compounding has all the excellent characteristics of modified chitosan on the basis of a soft function. Compared with the existing softener with an anti-bacterial function, the preparation process flow is simple, a complex configuration process is not required, and industrialized production is easy to realize.

Owner:JIANGSU GOLDSUN TEXTILE SCI & TECH

Velvet finishing agent for synthetic leather and preparation method thereof

The invention relates to a velvet finishing agent for synthetic leather and a preparation method thereof. The velvet finishing agent consists of the following raw materials in parts by weight: 80-120 parts of polyurethane resin, 3-10 parts of dry smooth wax powder, 2-8 parts of silicon dioxide extinction powder, 6-15 parts of glass microspheres with particle size of 5-60 microns, 1-6 parts of epoxidized soybean oil, 1-6 parts of phenmethyl silicon oil, 1-6 parts of plasticizer, 30-60 parts of dimethylformamide, 30-50 parts of butyl acetate, 20-40 parts of methylal and 20-40 parts of dimethylbenzene. The velvet finishing agent for synthetic leather provided by the invention has low cost and good velvet feel, can be used through multiple technologies such as roller painting, printing and the like, and is widely applicable. In the invention, a preparation technology of uniformly dispersing before grinding and filtering is adopted, and the prepared finishing agent can obtain more delicate velvet feel; and moreover, as the yangbuck powder requiring accurate temperature control and long-time foaming is not used, the preparation is easier.

Owner:SUZHOU DEERUN COMPOSITE MATERIALS

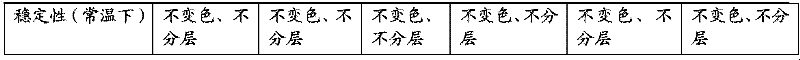

Preparation method of organic silicon modified polyether polyol

The invention provides a preparation method of organic silicon modified polyether polyol. The preparation method comprises following steps: step one, preparing terminal hydrogen containing silicone oil; step two, preparing allyl polyether; and step three, preparing organic silicon modified polyether polyol. The preparation method has the advantages that the structural characteristics of common polyether polyol are maximally preserved; the speed of reactions between modified polyether polyol and isocyanate is similar with that of reactions between common polyether polyol and isocyanate; modified polyether polyol can completely or partially replace common polyether polyol; modified polyether polyol can be used with polyester polyol to synthesize polyurethane, moreover, the reaction process is mild and easily controllable, the synthesized polyurethane is used to paint a material, the coated material is smooth and has a good wear resistant performance, and no surface migration happens.

Owner:江西三越新材料有限公司

Water-based multifunctional pearly coating

The invention public a kind of aquosity multiduty pearlescent coating. the complexity as follow: 10%-22% methacrylate adh, 0.3%-0.7% film buildup aux, 0.2%-0.4% dispersant, 5%-9% flow-changing modifier, 15%-21% colorant, 15.4%-19.4% water, 10.4%-14.4% excellent covering agent, 8%-12% pearl essence, 2%-4% bodying agent, 0.2%-0.6% anti blocking agent, 1%-3% anti microbial, 1%-3% anti plate out processing aid, 0.5%-0.9% propylene glycol, 3%-4% calcite, 2.5%-3.1% silicon dioxide.

Owner:SHUITIAN ZHENGYE SCI TRADE TIANJIN

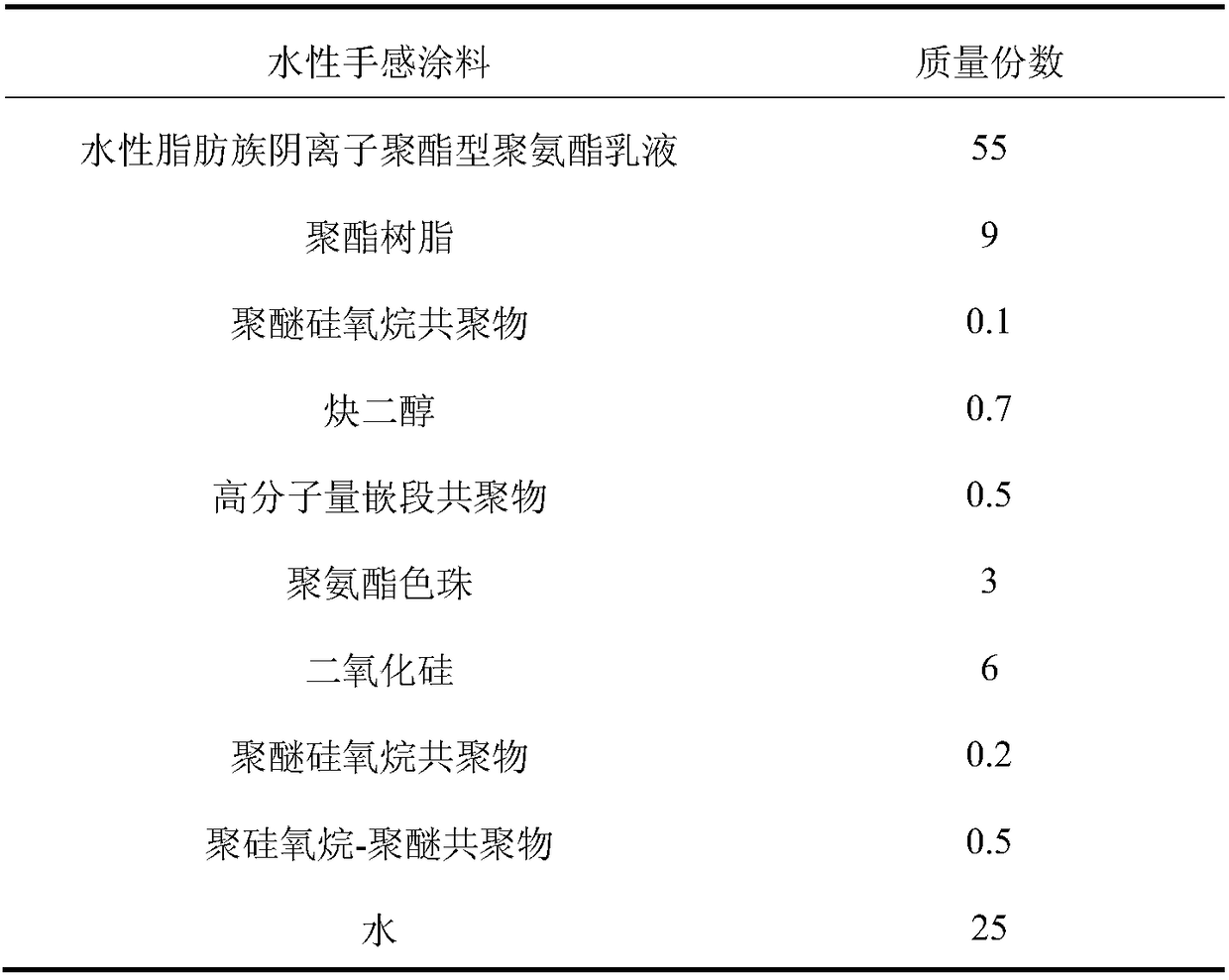

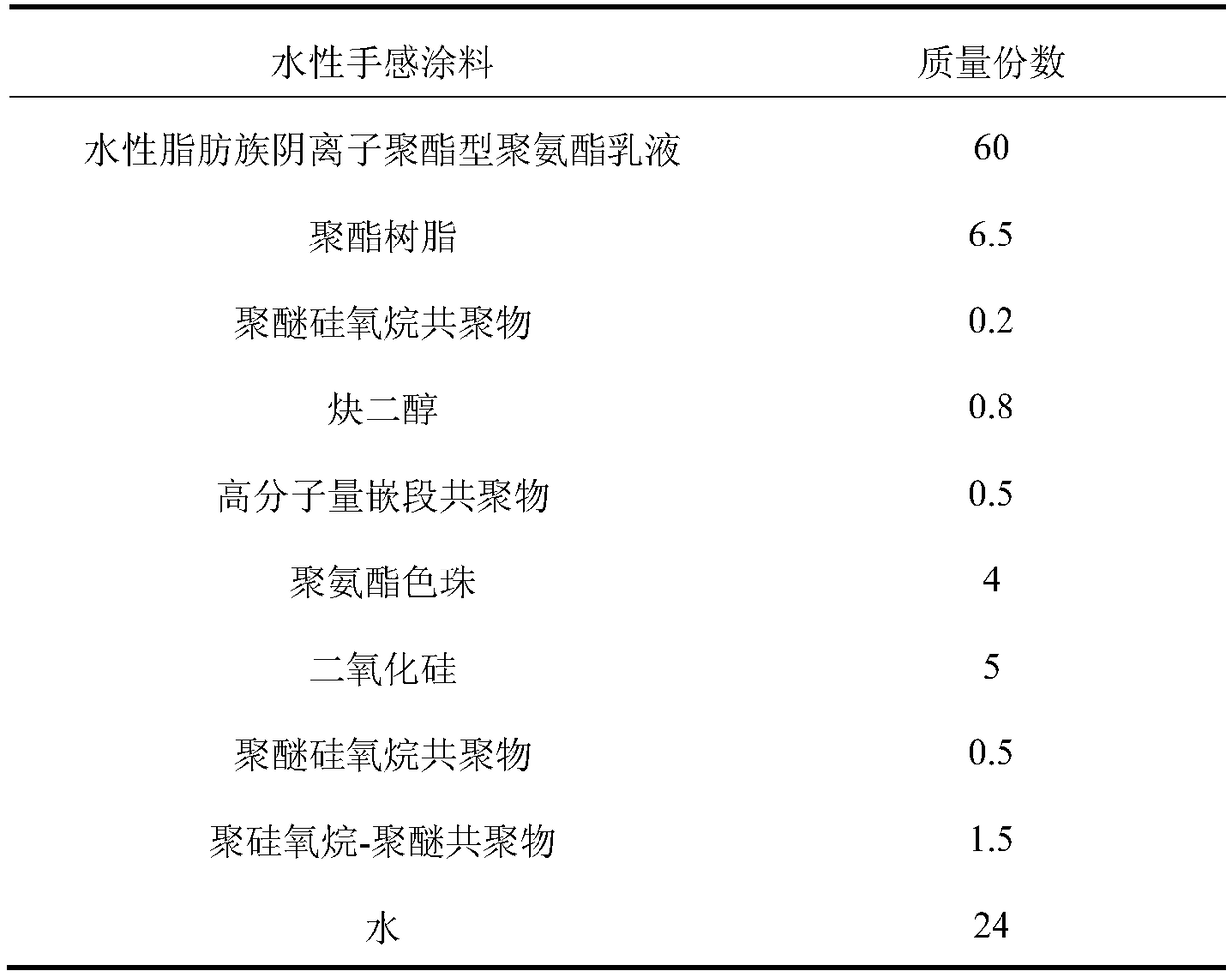

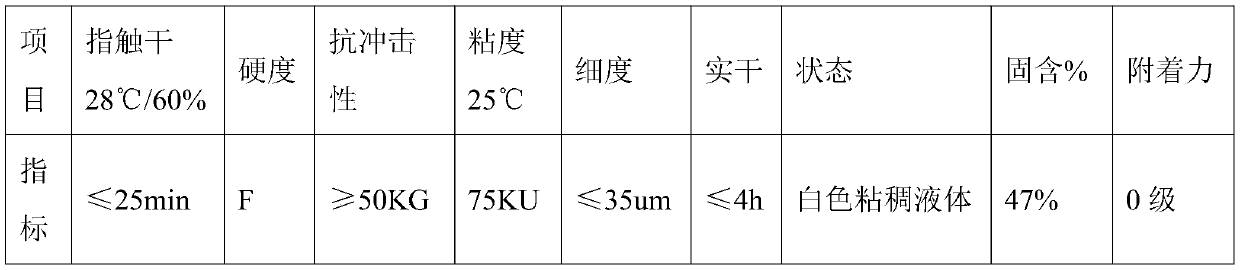

Aqueous hand-feeling coating and preparation method and use

InactiveCN109021804ADelicate and smooth feelSave materialPolyurea/polyurethane coatingsPolyester coatingsWater basedPolyester resin

The invention discloses an aqueous hand-feeling coating. The aqueous hand-feeling coating comprises, by weight, 40 to 60 parts of a polyester-modified water-based elastic resin, 5 to 10 parts of a polyester resin, 0.6 to 1.3 parts of a base wetting agent, 0.3 to 0.7 parts of a dispersing agent, 3 to 7 parts of elastic powder, 3 to 6 parts of matting powder, 0.7 to 2 parts of an aid and 23 to 32 parts of water. The aqueous hand-feeling coating has the characteristics of smooth paint, good adhesion and high hardness. A preparation method of the aqueous hand-feeling coating comprises two dispersion processes and physical mixing. Through the preparation method, the aqueous hand-feel coating has small particle sizes, is easy to disperse and is evenly distributed. The preparation method is simple and is suitable for large-scale use.

Owner:HUNAN SOKAN NEW MATERIAL

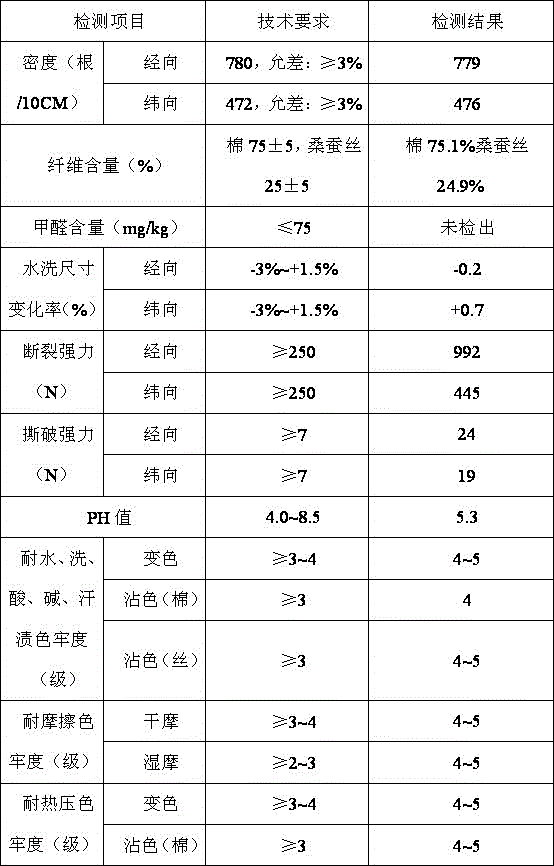

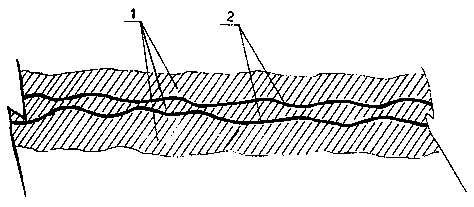

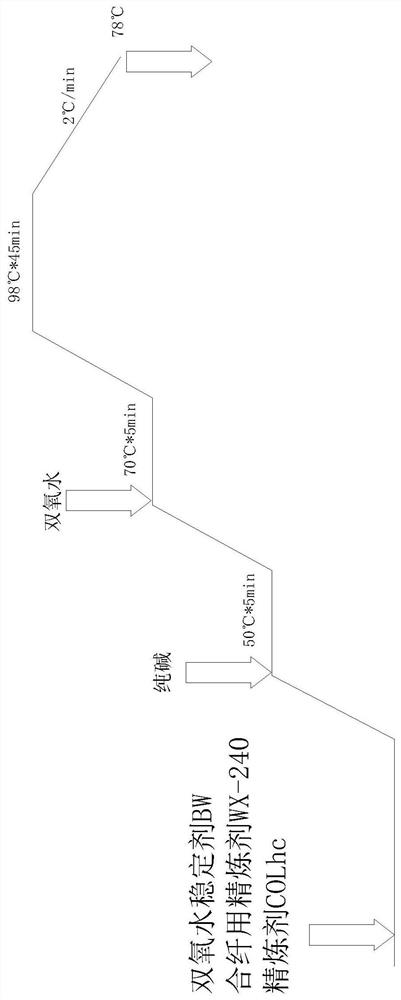

Low-carbon and environment-friendly superfine cotton silk woven fabric and production process thereof

InactiveCN103993406AHigh weaving efficiencyReduce speedSolvent-treatmentWoven fabricsFiberAfter treatment

The invention relates to a low-carbon and environment-friendly superfine cotton silk woven fabric. The fabric is characterized in that long-stapled cotton compactly-spun singed and mercerized threads are selected as warp of the fabric, mulberry silks are selected as weft of the fabric, and the fabric includes 75% of cotton and 25% of mulberry silks. A production process of the low-carbon and environment-friendly superfine cotton silk woven fabric includes the steps that cone dyeing, beam-warping and drafting are conducted on the warp; cone bleaching is conducted on the weft, and then weaving, body inspection and after treatment are conducted. The low-carbon and environment-friendly superfine cotton silk woven fabric is high in crease resistance and free of pollution; the production process of the low-carbon and environment-friendly superfine cotton silk woven fabric is easy to operate and low in energy consumption.

Owner:江苏保丹服饰有限公司

Method for producing matte super-sensitive paper

ActiveCN101581059AGood printing reducibilityElegantly printed matte visual effectNatural cellulose pulp/paperPaper coatingCalcium carbonateAir knife

The invention relates to a method for producing matte super-sensitive paper. The base paper of the matte super-sensitive paper is made of 100 percent of wood pulp, which comprises 40 percent of needle pulp and 60 percent of kargeleaf pulp; the degree of beating is between 40 and 45 degrees of SR, the pulping concentration of the pulp is between 0.5 and 1.0 percent, and the quantitation of the base paper is between 80 and 200g / m; the base paper is subjected to double-sided coating processing and bundling treatment, wherein the double-sided coating processing adopts roller-type feeding and air knife coating forming for one time, a finished product is double coated paper, and the single coating quantity is between 10 and 15g / m; and the coating comprises main pigment and a matte additive, wherein the main pigment is prepared by mixing kaoline and calcium carbonate according to the ratio of 1:1, the matte additive is G-365 commonly sold on markets, and the dosage of the matte additive accounts for 5 to 10 percent of the coating. The coating paper surface and the printed coating paper surface have no bright luster, and the paper surface touches slippery and smooth like floss and has visual effect of elegant printing matte; and the method has easy production and low production cost, and reduces processing steps under the condition of ensuring the printing effect.

Owner:SHANDONG KAILI SPECIAL PAPER

Hydrophilic resin coating material for calendaring polyvinyl chloride (PVC) leather

InactiveCN102383308AStrong adhesionDelicate and smooth feelFibre treatmentPrepolymerDefoaming Agents

The invention discloses a hydrophilic resin coating material for calendaring polyvinyl chloride (PVC) leather, which is formed by the following steps of proportioning parts by weight of polyatomic alcohol compound, diisocyanate, chain extentor, hydrophilic chain extentor, salifying agent, hydrophilic flatting agent, hydrophilic thickening agent, hydrophilic defoaming agent and deionized water, being prepared by prepolymer, being chain extended by the prepolymer, being neutralized and emulsified by the polymer and the like. The hydrophilic resin coating material for calendaring the PVC leather can resolve the problem that the coating material on surface of the PVC leather is wet and extending. The hydrophilic resin coating material can be prepared with existing equipment, thereby saving production cost. Treating effects of the hydrophilic resin coating material for calendaring the PVC leather are identical with treating effects of corresponding solvent products. Furthermore, compared with traditional solvent products, the hydrophilic resin coating material for calendaring the PVC leather is more excellent in scraping resistance, full touch, fine texture and the like.

Owner:清远市美佳乐环保新材股份有限公司

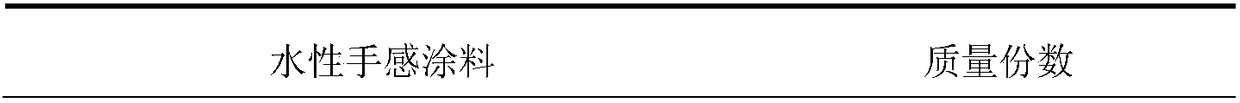

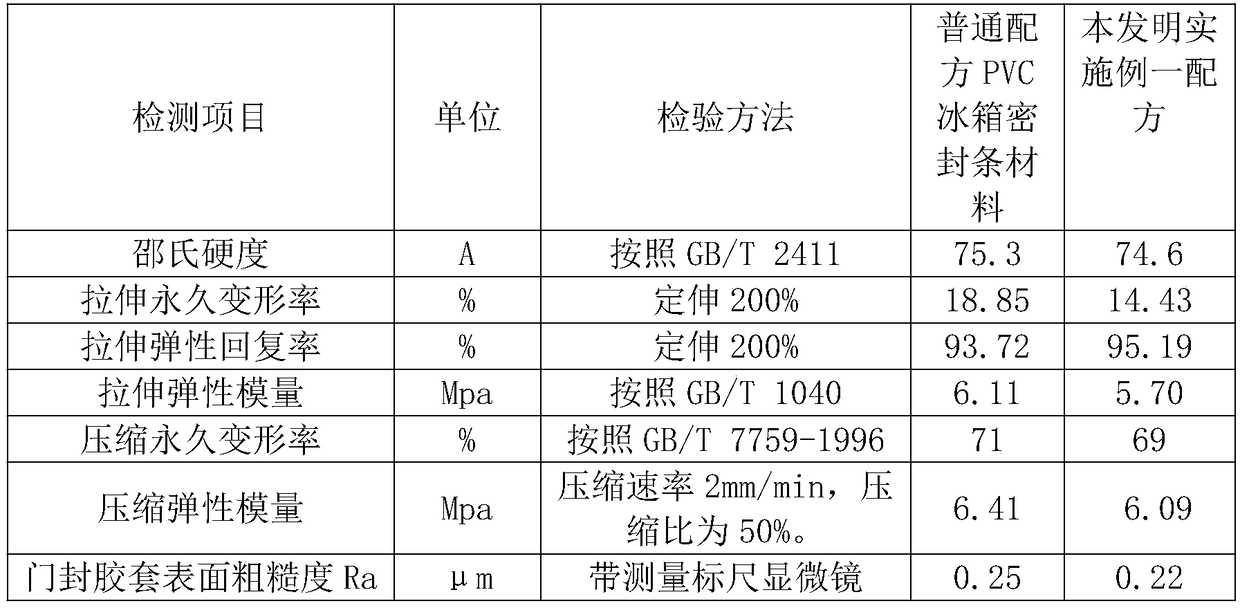

Smooth and delicate PVC door sealing material and preparation method thereof

The invention discloses a smooth and delicate PVC door sealing material and a preparation method thereof. The smooth and delicate PVC door sealing material is composed of PVC resin, plasticizer, filler, feeling agent, elastomer, stabilizer, lubricant and antibacterial mildew preventive. The preparation method for the smooth and delicate PVC door sealing material includes the steps of weighing; powder mixing; mixing; extrusion forming and hot cutting. According to the smooth and delicate PVC door sealing material and the preparation method thereof, the problem that an existing soft PVC materialincreasingly cannot meet the requirements of the market for the surface softness and fine texture of the product is solved. A polar group in the feeling agent and a PVC material system generate an attachment point by H bond bonding, a smooth main chain in the feeling agent is attached to the surface of the PVC material to form a smooth and continuous film, a convex-concave phenomenon of the product surface is improved, the surface roughness and surface defects are reduced, the smoothness and softness are improved, the smooth and delicate texture degree of the product surface can be improved lastingly, and the smooth and delicate PVC door sealing material is suitable as a low temperature flexible refrigerator door sealing material.

Owner:ANHUI BANGRUI NEW MATERIAL TECH CO LTD

Mosquito-repellent anti-mite silk stocking production process

InactiveCN105887475ALong-lasting effect of repelling mosquitoes and mitesIncrease elasticityBiochemical fibre treatmentHandkerchiefsEngineeringMite

The invention discloses a mosquito-repellent anti-mite silk stocking production process, which comprises the following steps of (1) weaving: putting core spun silk into an automatic air jet weaving machine for weaving, and preparing blank stockings; (2) dyeing: controlling the temperature to be 80 to 90 DEG C and the temperature rise speed to be 2 DEG C / 1min, and putting the blank stockings into weak acid dye containing dyeing auxiliary agents and color fixing agents for dyeing; (3) settling: performing alkaline washing on the blank stockings in the second step, then, controlling the temperature to be 85 to 100 DEG C; adding mosquito-repellent anti-mite settling agents to perform settling for 15 to 20 min; (4) shaping: performing drying and shaping on the blank stockings in the third step by steam being 160 DEG C to obtain finished product silk stockings. The silk stockings produced by the invention have the advantages that the mosquito-repellent anti-mite effect is permanent; the elasticity is high; the handfeel is fine, smooth and cool; meanwhile, the ventilation performance and the light and thin comfort of the silk stockings are also achieved.

Owner:宜兴市艺蝶针织有限公司

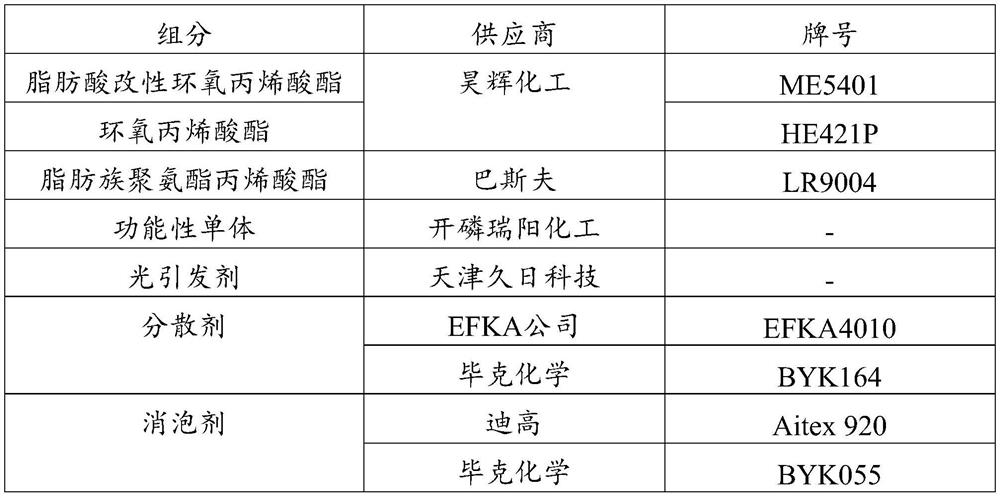

UV top-coat paint, preparation method and application thereof

InactiveCN112898879AHigh fullnessHigh transparencyPolyurea/polyurethane coatingsEpoxy resin coatingsPolymer scienceFunctional monomer

The invention provides a UV top-coat paint, a preparation method and application thereof, and relates to the technical field of paint. The UV top-coat paint provided by the invention is prepared from the following components by weight: 15-30 parts of fatty acid modified epoxy acrylate, 8-15 parts of aliphatic polyurethane acrylate, 5-10 parts of thermoplastic acrylate, 30-60 parts of a functional monomer, 4-6 parts of a photoinitiator, 0.5-2 parts of a dispersing agent, 0.1-0.5 part of a defoaming agent, 0.2-0.6 part of a flatting agent and 8-15 parts of matting powder. The UV top-coat paint product prepared by adopting the technical scheme is high in leveling speed and curing efficiency, and the solid content is close to 100%; when being applied to a reciprocating spraying process, the UV top-coat paint is convenient and fast to use, the product can be effectively recycled, the material loss and the emission of harmful substances are reduced, and the increasingly stringent environmental protection requirement can be met.

Owner:HUILON COATING IND

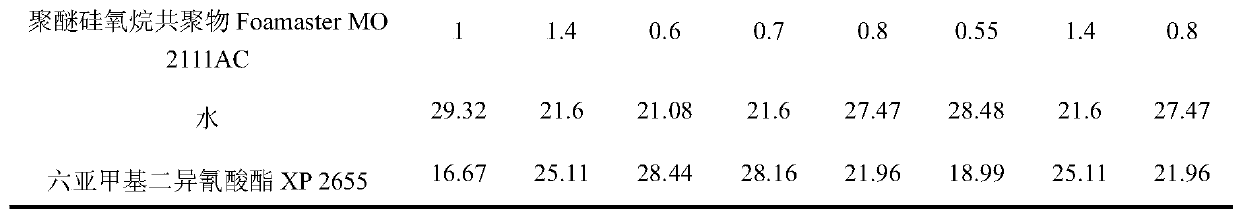

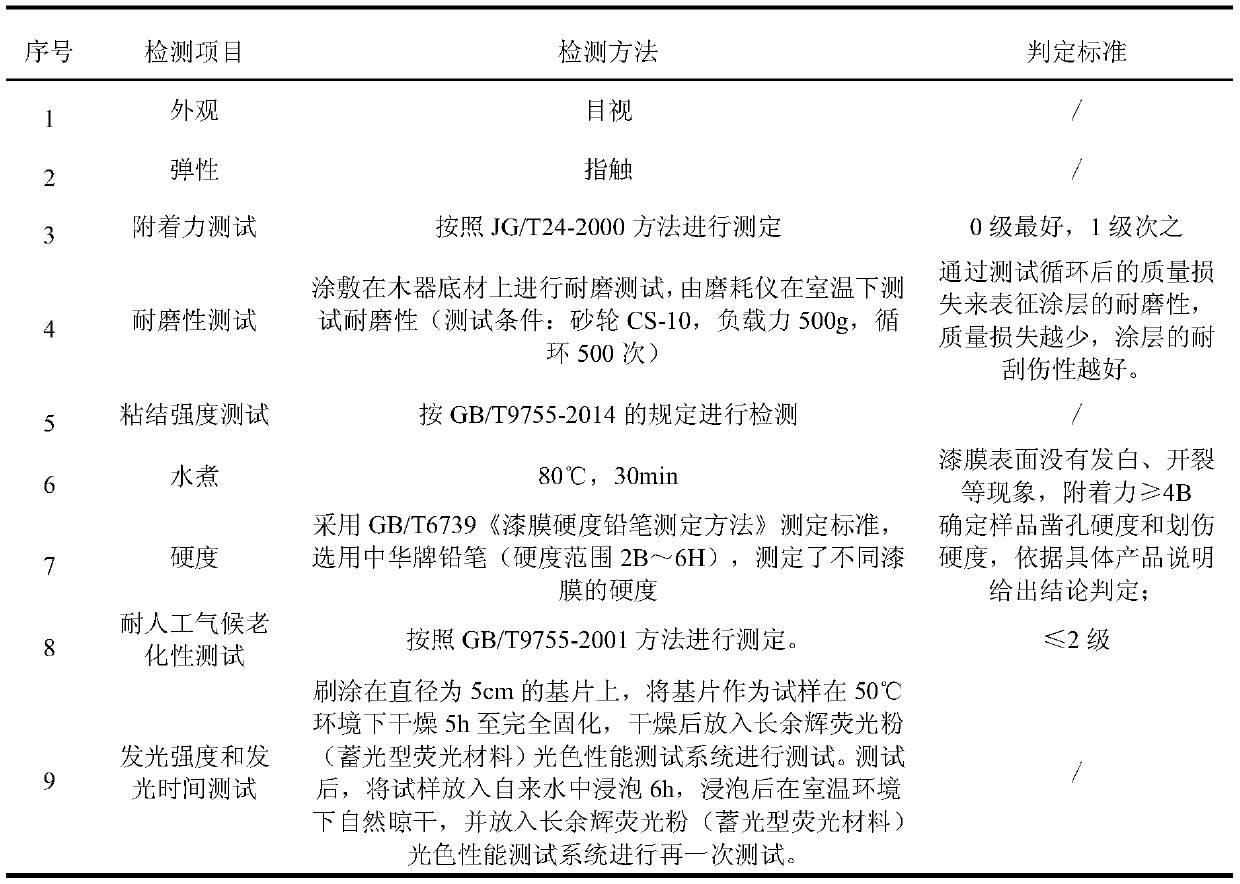

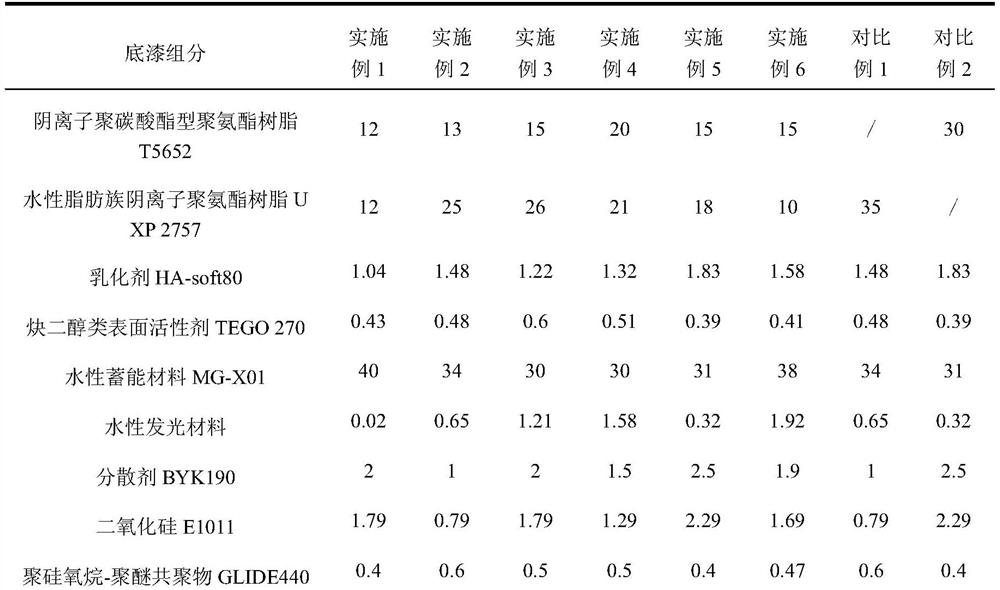

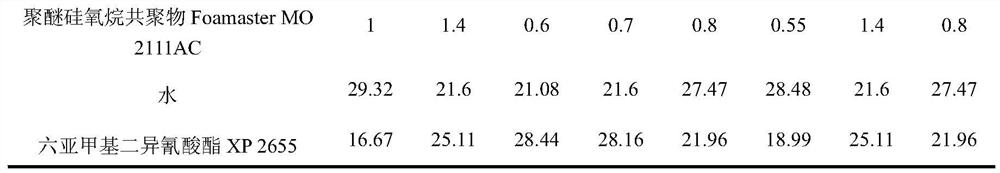

Water-based self-luminous elastic coating, and preparation method and application thereof

ActiveCN110791190AImprove toughnessIncrease elasticityLuminescent paintsPolyurea/polyurethane coatingsPolymer scienceWeather resistance

The invention discloses a water-based self-luminous elastic coating, and a preparation method and an application thereof. The water-based self-luminous elastic coating comprises a coating component and a curing agent component; the coating component comprises the components in parts by mass: 10-20 parts of modified oily elastic resin, 10-30 parts of water-based polyurethane elastic resin, 1-2 parts of an emulsifier, 0.3-0.6 part of a base material wetting agent, 30-40 parts of a water-based energy storage material, 0.01-2 parts of a water-based luminous material, 1-3 parts of a dispersing agent, 1-3 parts of extinction powder, 0.7-2 parts of an auxiliary agent and 20-40 parts of water. According to the water-based self-luminous elastic coating, modified oily elastic resin and water-based polyurethane elastic resin are used as main film-forming resin and are subjected to reaction with molecules of the curing agent component, and a compact net-shaped structure is formed, so that the hardness, boiling resistance and wear resistance of the coating are remarkably improved, a formed paint film is good in elasticity and fine and smooth in hand feeling, has the advantages of boiling resistance, weather resistance, wear resistance and the like, has the adhesive force of 5B, the hardness of H and high luminous intensity, and can emit light for 12 h or more after absorbing light for 10-20min.

Owner:HUNAN SOKAN NEW MATERIAL

Processing method of colorful brocade fabric

The invention discloses a processing method of a colorful brocade fabric. The processing method of the colorful brocade fabric is characterized by comprising the following process steps: a, warping, b, beam dyeing, c, steaming color fixing, d, soaping, e, drying, f, shuttle weaving and g, after finishing. The processing method is characterized in that warping treatment is firstly performed on yarns and then beam dyeing is carried out to obtain beam-dyed yarns with consistent circulation law and circulation length; next, weaving is performed according to a designed style; after finishing is performed on the fabric so that the unique-style shuttle weaved fabric like colorful brocade can be obtained. The colorful brocade fabric has a multiple-color cycle, and is bright in color, smooth and fine in hand feeling, soft, slip and glutinous, and also strong in drapability; simultaneously, the colorful brocade fabric has special bright and smooth luster, moisture absorption and hand feeling that the high-grade fabric has, and also has the unique characteristic of affinity to skin.

Owner:WUXI NATURAL GREEN FIBER TECH

Method for preparing powder fluff for electrostatic flocking from waste Cr-containing leather debris

ActiveCN106245253ADelicate and smooth feelExcellent imitation leather effectSucessive textile treatmentsTwo or more solvent application treatmentSodium bicarbonateOrganic solvent

The invention relates to a method for preparing powder fluff for electrostatic flocking from waste Cr-containing leather debris, and belongs to the technical field of leather. The method comprises steps as follows: the waste Cr-containing leather debris is ground into particles and dried; the particles are dried, left to stand for 95-105 days and screened; the particles are immersed in an organic solvent, a feeling agent is added in terms of the mass of a screened material, the mixture is stirred for 30-40 min, and a liquid is drained; the product is placed in a cylinder, and a degreasant is added for operation in terms of mass of the screened material, a penetrate is added for operation, sodium bicarbonate, sodium formate and sodium citrate are added for operation, dye is added, a color fixing agent is added for operation, sodium chloride is added for operation, a slipping agent is added for operation, the product is taken out of the cylinder, dehydrated and dried continuously, and the powder fluff for electrostatic flocking is obtained. The powder fluff for electrostatic flocking, prepared with the method, feels smooth and fluffy, and an electrostatic flock product is endowed with good leather feel.

Owner:滨州市科创孵化器有限公司

Ultrathin silk-like cotton

InactiveCN103614862AHigh bulkinessHigh compression resilienceNon-woven fabricsTextile shapingFiberPolyester

The invention discloses ultrathin silk-like cotton which is made by bonding polyacrylonitrile fiber and polyester staple fiber through ES fiber. The front and back of the silk-like cotton are lustered by a natural luster finishing machine. The polyacrylonitrile fiber is 35-38% in mass percent, the polyester staple fiber is 48-52% in mass percent, and the ES fiber is 12-15% in mass percent. Lustering is performed at the temperature of 120-125DEG C. Therefore, the surface flatness of the ultrathin silk-like cotton can be improved, no hair sticks to the ultrathin silk-like cotton, the ultrathin silk-like cotton feels fine and smooth, the thickness of the ultrathin silk-like cotton is reduced, the weight of the ultrathin silk-like cotton is reduced, and the ultrathin silk-like cotton is improved in terms of bulkiness, compressive resilience, insulation, strength and washability.

Owner:CHANGSHU JINYU FIBER PROD

Single-layer double-sided heat transfer printing process for polyester blankets

InactiveCN110117915ABroaden the field of printing and dyeingPlay a protective effectTransfer printing processDyeing processWater usePolyester

The invention discloses a single-layer double-sided heat transfer printing process for polyester blankets. The printing process includes the steps of 1), pretreatment; 2), double-sided printing; 3), over-hydrolyzed untwisting ; 4), drying; 5), brushing; 6), aftertreatment; 7), production of finished products. In the printing process, the single-layer double-sided magnetic rod printing technology of traditional polyester blankets is innovated, good permeability of blanket fiber in the printing process with a heat transfer printing machine is achieved, and the printing process is simple, clear and time saving and labor saving; continuous washing and fixing of high-temperature evaporated flowers using over-hydrolyzed untwisting instead of traditional magnetic bar printing machines greatly reduces the amount of water used and can guarantee the untwisting degree of the blanket fiber, functions in energy saving and no sewage treatment are imperceptibly achieved, and the concept of green environmental protection production is met; most importantly, the effect of printing is quite realistic and can be matched with digital printing heat transfer printing paper, traditional heat transfer printing paper can be used as well, and a wide market prospect is achieved.

Owner:江苏康尼纺织品有限公司

Mildewproof latex paint for inner wall and use method thereof

InactiveCN102453414AImprove adhesionLow costAntifouling/underwater paintsPaints with biocidesAdhesion forceCellulose

The invention relates to a mildewproof latex paint for an inner wall and a use method thereof. The mildewproof latex paint consists of the following components by weight percent: 10-35% of deionized water, 1.5-2% of cellulose, 0.5-1.5% of dispersing agent, 0.5-3% of lithopone, 10-25% of kaolin, 15-20% of calcium carbonate, 1-3% of talcum powder, 0.1-1% of mildew preventive, 1-3% of zinc oxide, 15-30% of acrylic emulsion and 10-25% of film-forming auxiliary agent. The product provided by the invention has the advantages of good mildewproof and antibacterial effects, long service life, low production cost and soft smell; and the mildewproof latex paint takes the acrylic emulsion as a base material, provides extremely good adhesion force for various wall surfaces and reduces the water-absorption capacity of a base layer to be coated, thereby being beneficial to the uniformity of color of finish paint, reducing the consumption of the finish paint, improving the gloss and reducing the whole coating cost, so that a wall surface is good in painting effect. The method is simple to operate and convenient in use; and a paint film is pliable and tough, has the advantages of fine and smooth hand feel, strong adhesion force and good scrubbing resisting property, and is not easy to fall.

Owner:徐贵才

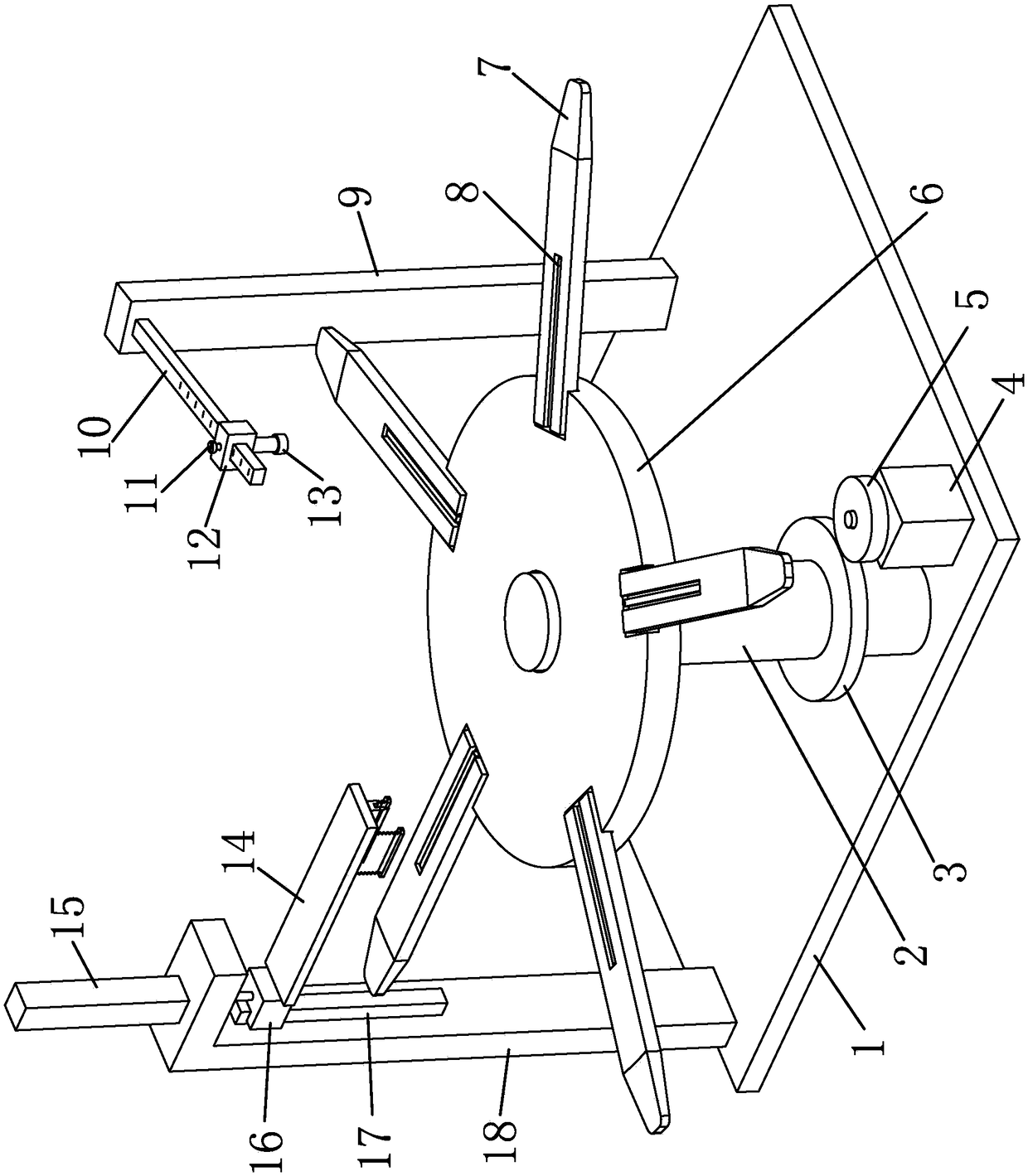

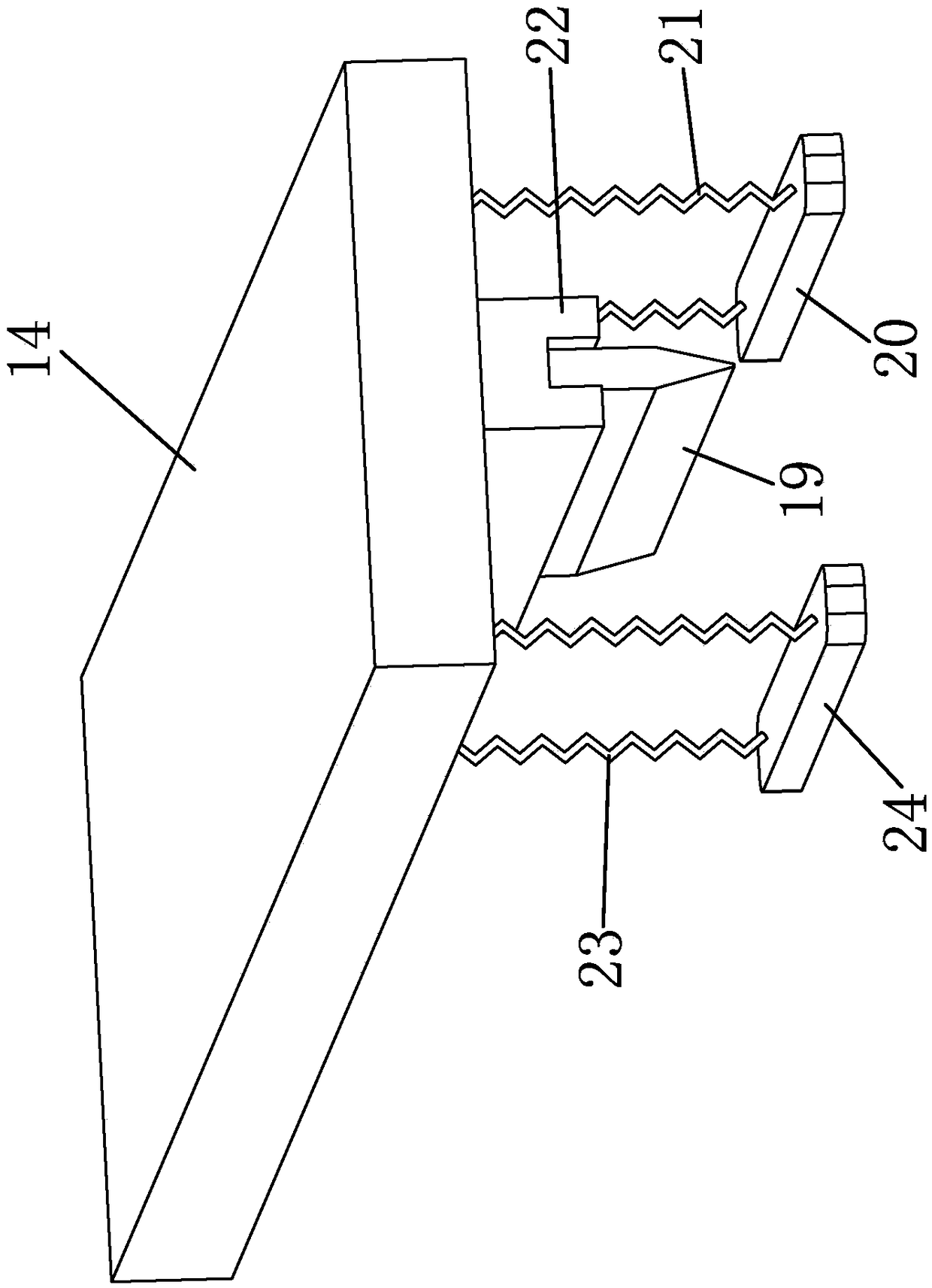

Panty-hose production method and device

The invention provides a panty-hose production method and device. The technical problem is solved that there is no corresponding panty-hose production method at present and accordingly large-batch production cannot be achieved and the production speed is low. The panty-hose production method comprises the following specific steps that (a) knitting is executed, wherein legs and crotches of panty-hoses are knitted through a silk stocking knitting machine, and waist parts are knitted through a seamless underwear knitting machine; (b) cutting is executed, wherein the legs of the panty-hoses are opened through an efficient cutting device to form spiced parts of the panty-hoses; (c) sewing is executed, wherein sewing is achieved through a sewing device, the legs and crotches of panty-hoses are firstly sewed, and then the waist parts are sewed with the legs and crotches of panty-hoses to obtain panty-hose bodies; (d) dyeing is executed, wherein dyes and panty-hose bodies are put in an energy-saving dyeing machine for dyeing; (e) dyeing and setting are executed, wherein the panty-hose bodies are dried and set through a drying and setting integrated machine, namely finished products panty-hoses can be obtained; (f) packaging is executed, wherein quality inspection is conducted on the finished products panty-hoses, and packaging and warehousing are executed after qualified inspection. The panty-hose production method has the advantage of quick production.

Owner:海宁亚润袜业有限公司

Blended comfort fiber fabric

InactiveCN103799588AImprove wear resistanceIncrease elasticityProtective garmentSpecial outerwear garmentsUltimate tensile strengthWear resistance

The invention discloses a blended comfort fiber fabric which is blended and woven from five fibers of a real silk fiber, an organic lifting wire cotton fiber, a superfine polyamide fiber, a superfine polyester fiber and a high count cotton fiber, wherein the real silk fiber accounts for 33%-36%, the organic lifting wire cotton fiber accounts for 14%-17%, the superfine polyamide fiber accounts for 19%-22%, the superfine polyester fiber accounts for 11%-14%, and the high count cotton fiber accounts for 11%-23% among the five components of the blended comfort fiber fabric according to weight percentages. The blended comfort fiber fabric is blended and woven from five fibers of the real silk fiber, the organic lifting wire cotton fiber, the superfine polyamide fiber, the superfine polyester fiber and the high count cotton fiber, and the woven fabric has the characteristics of softness, good wear resistance, high elastic recovery rate, high strength, fine and smooth hand feel, comfort and air permeability.

Owner:TAICANG SIXIN TEXTILE

Water-based single-component white surface material as well as preparation method and application thereof

InactiveCN111286236AImprove fullnessImprove compactnessAntifouling/underwater paintsPaints with biocidesWaxSlurry

The invention discloses a water-based single-component white surface material as well as a preparation method and application thereof. The water-based single-component white surface material is prepared from 30-40 parts of polyacrylic emulsion, 10-20 parts of polyurethane emulsion, 0.1-0.5 parts of an antifoaming agent, 1-5 parts of a wetting dispersant, 0.5-1.5 parts of a thickening agent, 25-30parts of titanium dioxide slurry, 1-3 parts of organic extinction powder, 3-5 parts of Fischer-Tropsch wax, 5-10 parts of a coalescing agent, 0.1-0.2 parts of a pH regulator, 0.1-0.2 part of a bactericide and 5-10 parts of water. The water-based single-component white surface material is high in paint film compactness, excellent in water resistance, high in fullness, good in construction performance and high in adhesive force, overcomes the defect that an existing water-based single-component white surface material is low in fullness, poor in compactness, poor in adhesive force, common in water resistance and the like, has a certain yellowing resistance effect and is a novel composite water-based environment-friendly product.

Owner:CHENGDU ZHANCHEN PAINT +2

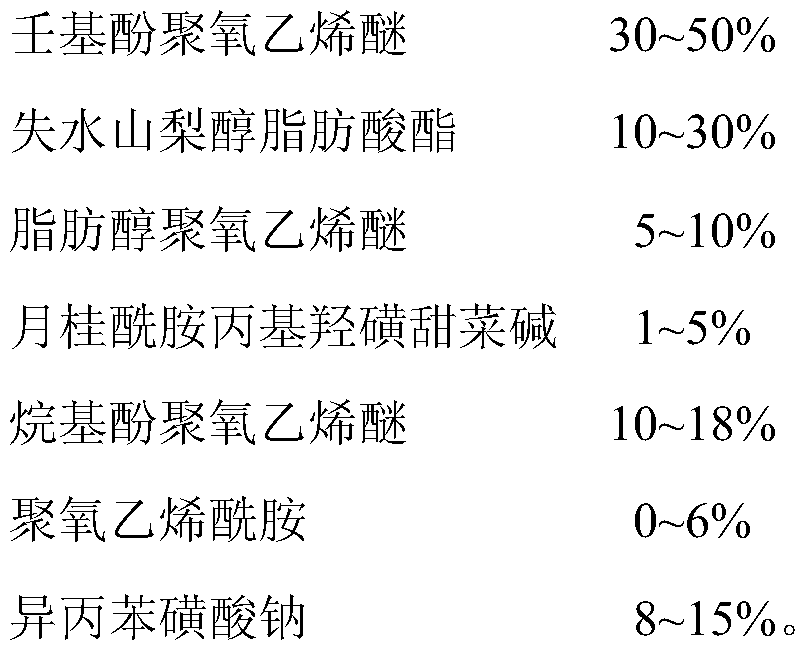

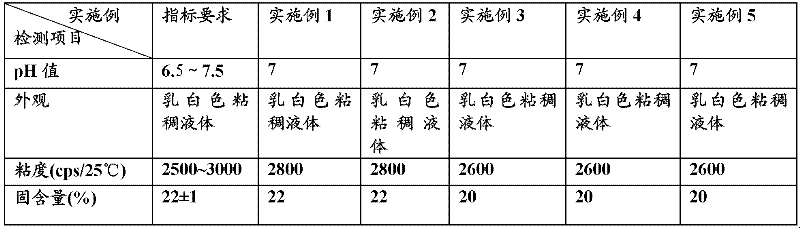

Multifunctional softener and preparation method for same

ActiveCN103321053BImprove biological activityPromote degradationFibre treatmentWater soluble chitosanAqueous solubility

The invention provides a multifunctional softener and a preparation method for the same. The multifunctional softener is composed of amino silicon oil, a compound emulsifier, water-soluble chitosan and water, wherein amino silicon oil is added in the compound emulsifier, and the mass ratio of the amino silicon oil to the compound emulsifier is 1:(0.2-0.8); then the water-soluble chitosan is added, and the added amount is 1-8% of the mass of the mixed solution of the amino silicon oil and the compound emulsifier; finally, water is added, and the mass of water is 10-50% of the total mass of the mixed solution aforementioned. The preparation method comprises the following steps of: preparation for the water-soluble chitosan, preparation for the compound emulsifier, and preparation for the multifunctional fabric softener. The multifunctional integrated softener obtained after compounding has all the excellent characteristics of modified chitosan on the basis of a soft function. Compared with the existing softener with an anti-bacterial function, the preparation process flow is simple, a complex configuration process is not required, and industrialized production is easy to realize.

Owner:JIANGSU GOLDSUN TEXTILE SCI & TECH

Vortex spun electromagnetic shielding fabric and textile method

PendingCN111074400AGood skin affinityDelicate and smooth feelContinuous wound-up machinesMulti-ply fabricsFiberPolymer science

The invention discloses a vortex spun electromagnetic shielding fabric and a textile method. The vortex spinning electromagnetic shielding fabric comprises a fabric body; the double-layer fabric comprises an inner layer fabric and a surface layer fabric which are laminated; the fabric body is of a double-layer plain stitch structure; the lining fabric uses vortex spun conductive yarns as inner warps and inner wefts; the surface layer fabric uses vortex spun elastic yarns as surface warps and surface wefts; an arrangement ratio of the surface warps to the inner wefts is 2:1; a surface and innerweft input ratio is 1:2, and binding is carried out in a mode that the lower part is connected with the upper part so as to form a warp rib binding point stitch; the vertex spun conductive yarns usecopper filaments with silvered layers on the surfaces as the conductive filaments and use combed cotton fibers as outer wrapping fibers; the vertex spun elastic yarns comprise elastic yarns and skin layers wrapped outside the elastic yarns; and the outer surface of the surface layer fabric is subjected to sanding treatment to form a fuzz layer. The vortex spun electromagnetic shielding fabric is soft and fluffy in hand feeling and comfortable to wear, has excellent durability and air permeability, and has a good electromagnetic shielding effect.

Owner:SUZHOU SHIXIANG BIOLOGICAL FIBER CO LTD

Comfortable and breathable blend fiber fabric

InactiveCN105077781ADelicate and smooth feelGood elastic recovery rateProtective garmentSpecial outerwear garmentsSilk fiberMaterials science

The invention discloses comfortable and breathable blend fiber fabric. The comfortable and breathable blend fiber fabric is formed by weaving four types of fibers, namely real silk fibers, sateen fibers, alginate fibers and hemp single fibers in a blending mode, wherein the blend fiber fabric comprises, by weight, 32%-37% of the real silk fibers, 27%-30% of the sateen fibers, 17-21% of the alginate fibers and 11%-23% of the hemp single fibers. According to the fabric, the fabric is formed by weaving the four types of fibers, namely the real silk fibers, the sateen fibers, the alginate fibers and the hemp single fibers in a blending mode, the fabric obtained through the weaving has the advantages of being fine, smooth and cool in hand feeling, high in elasticity recovery rate and strength, comfortable and breathable.

Owner:安徽创星实业有限公司

Low-carbon environmental protection ultra-fine special cotton silk interwoven fabric and its production process

InactiveCN103993406BThe production process is simple to operateDelicate and smooth feelSolvent-treatmentWoven fabricsPolymer scienceSpinning

The invention relates to a low-carbon and environment-friendly superfine extra-fine cotton silk interwoven fabric, which is characterized in that: the warp yarn of the fabric is made of long-staple cotton compact spinning singeing silk, the weft yarn is made of mulberry silk, and the fiber content is 75% cotton and 25% mulberry silk. Its production process is that the warp yarn is dyed, warped, and heald-drawn through the package, and the weft yarn is bleached through the package, and then weaving, blank inspection and finishing. The low-carbon and environment-friendly superfine special cotton silk interwoven fabric of the present invention has good wrinkle resistance and no pollution, and the production process is simple in operation and low in energy consumption.

Owner:江苏保丹服饰有限公司

Modal fiber and silkworm pupa protein viscose compact siro spinning blended yarn technology

ActiveCN114753031APerformance is fully reflectedLow costDrafting machinesFibre cleaning/opening machinesPolymer scienceCarding

The invention discloses a modal fiber and silkworm pupa protein viscose compact siro spinning blended yarn technology, and the prepared blended yarn comprises the following components in percentage by weight: 55-60% of modal fiber and the balance of silkworm pupa protein fiber; the method specifically comprises the steps of raw material preparation, opening picking, cotton carding, drawing, roving and spinning. By blending the two fibers with different properties, the manufactured compact siro yarn has the advantages of high single yarn strength, uniform evenness, compact structure, good wear resistance, less hairiness, bright and clean yarn and the like, not only has the plied yarn style, but also has the single yarn property, combines the respective performance characteristics of the two fibers, and has a good application prospect. The performance advantages of the silkworm pupa protein fiber and the Lenzing modal fiber are fully reflected. The processed fabric has the characteristics of soft hand feeling, bright luster and good hygroscopicity, has a certain silk health care function, and overcomes the defects of low strength and large shrinkage rate of common viscose fibers.

Owner:山东超越纺织有限公司

Waterborne self-luminous elastic coating and its preparation method and application

ActiveCN110791190BImprove toughnessIncrease elasticityLuminescent paintsPolyurea/polyurethane coatingsPolymer scienceWeather resistance

The invention discloses a water-based self-luminous elastic coating, and a preparation method and an application thereof. The water-based self-luminous elastic coating comprises a coating component and a curing agent component; the coating component comprises the components in parts by mass: 10-20 parts of modified oily elastic resin, 10-30 parts of water-based polyurethane elastic resin, 1-2 parts of an emulsifier, 0.3-0.6 part of a base material wetting agent, 30-40 parts of a water-based energy storage material, 0.01-2 parts of a water-based luminous material, 1-3 parts of a dispersing agent, 1-3 parts of extinction powder, 0.7-2 parts of an auxiliary agent and 20-40 parts of water. According to the water-based self-luminous elastic coating, modified oily elastic resin and water-based polyurethane elastic resin are used as main film-forming resin and are subjected to reaction with molecules of the curing agent component, and a compact net-shaped structure is formed, so that the hardness, boiling resistance and wear resistance of the coating are remarkably improved, a formed paint film is good in elasticity and fine and smooth in hand feeling, has the advantages of boiling resistance, weather resistance, wear resistance and the like, has the adhesive force of 5B, the hardness of H and high luminous intensity, and can emit light for 12 h or more after absorbing light for 10-20min.

Owner:HUNAN SOKAN NEW MATERIAL

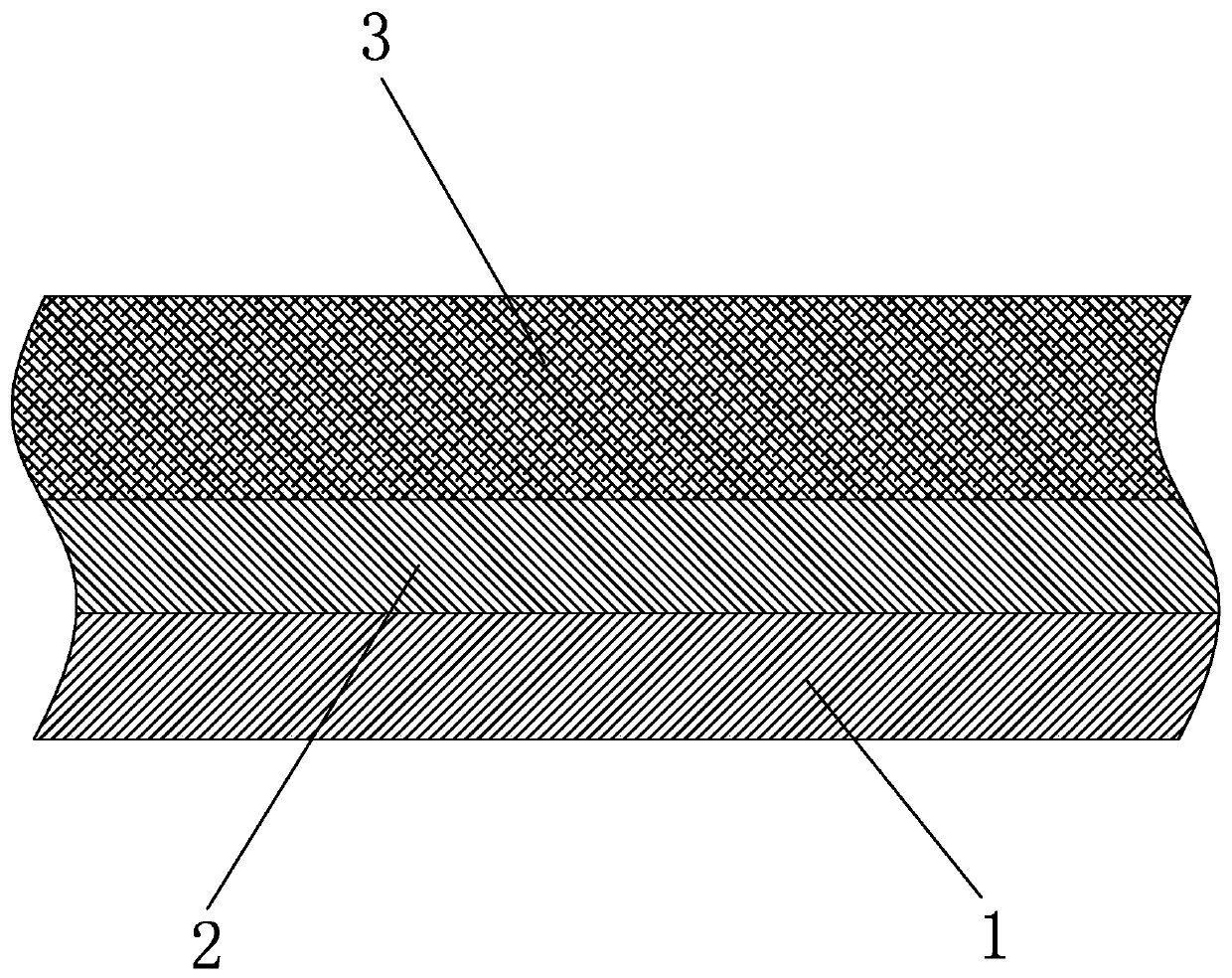

Novel warmth retention textile material for lining

InactiveCN105563982AUniform textureDelicate and smooth feelSynthetic resin layered productsTextile fiberEngineering

The invention provides a novel warmth retention textile material for a lining, which comprises a plurality of layers of textile fiber meshes. Polyethylene films with a specification of 60 to 100mu are laid between the fiber meshes; the fiber meshes and the films are mutually fixed by a needling method, so that the plurality of layers of formed fiber meshes and the interval films are combined into one whole body. The product is light, thin and soft, is uniform in texture, is fine and smooth in hand feeling, has good wind resistance, excellent warmth retention performance and high strength, is rich in elasticity, and has washing resistance; warmth retention performance and air permeability are improved in a direct proportional manner; the novel warmth retention textile material has good hygroscopicity, is comfortable to wear, and is convenient to cut, sew and process. A production process of the product is matured, simple and convenient, and is low in cost and high in efficiency.

Owner:SHANDONG VOCATIONAL COLLEGE OF SCI & TECH

Method for producing matte super-sensitive paper

ActiveCN101581059BImprove smoothnessDelicate and smooth feelNatural cellulose pulp/paperPaper coatingPulp and paper industryAir knife

The invention relates to a method for producing matte super-sensitive paper. The base paper of the matte super-sensitive paper is made of 100 percent of wood pulp, which comprises 40 percent of needlepulp and 60 percent of kargeleaf pulp; the degree of beating is between 40 and 45 degrees of SR, the pulping concentration of the pulp is between 0.5 and 1.0 percent, and the quantitation of the basepaper is between 80 and 200g / m<2>; the base paper is subjected to double-sided coating processing and bundling treatment, wherein the double-sided coating processing adopts roller-type feeding and air knife coating forming for one time, a finished product is double coated paper, and the single coating quantity is between 10 and 15g / m<2>; and the coating comprises main pigment and a matte additive, wherein the main pigment is prepared by mixing kaoline and calcium carbonate according to the ratio of 1:1, the matte additive is G-365 commonly sold on markets, and the dosage of the matte additiveaccounts for 5 to 10 percent of the coating. The coating paper surface and the printed coating paper surface have no bright luster, and the paper surface touches slippery and smooth like floss and has visual effect of elegant printing matte; and the method has easy production and low production cost, and reduces processing steps under the condition of ensuring the printing effect.

Owner:SHANDONG KAILI SPECIAL PAPER

Solid Beverage Containing Barley Leaves And Preparation Method Thereof

InactiveUS20220095650A1Reduce roughnessImprove intestinal environmentDispersion deliveryInorganic non-active ingredientsBiotechnologySucrose

The present invention provides a solid beverage containing barley leaves, comprising the following components: 15-60 wt. % of a barley leaf micro-powder, 10-50 wt. % of xylitol granules, 5-20 wt. % of a matcha powder, 1-10 wt. % of inulin, 0.5-4.0 wt. % of a konjac powder, 0.2-3.0 wt. % of silicon dioxide, and 0.1-3.0 wt. % of sucralose. The present invention also relates to a method for preparing the solid beverage, comprising the following steps: mixing a barley leaf micro-powder, inulin, a konjac powder and matcha powder, and then performing wet granulation on same to obtain granulated powders; passing the granulated powders through a 20-mesh sieve after drying same to obtain whole granules; and uniformly mixing the whole granules with xylitol granules, sucralose and silicon dioxide, and then sub-packaging same, so as to obtain the solid beverage. The solid beverage is easy and fast to dissolve, does not separate, and tastes refined and smooth.

Owner:ZHEJIANG MEDICINE CO LTD XINCHANG PHAMACEUTICAL FACTORY

Preparation method of mercerized-like all-cotton knitted fabric

The invention provides a preparation method of mercerized-like all-cotton knitted fabric, and belongs to the technical field of textiles. Fine cotton fiber yarn is selected, and a double-rib interwoven structure is adopted; an enzyme washing process is added during dyeing processing to reduce hairiness on the cloth surface and make the cloth surface smooth and clean; a pre-shrinking process is added, so that the washing stability of the fabric is improved while the mercerized-like effect is achieved; and the pre-shrinking process comprises the steps that the fabric passes through a rubber blanket and then passes through a wool blanket. The mercerized-like all-cotton knitted fabric has the advantages of being bright in color, fine and smooth in hand feeling, flat in cloth surface and good in smoothness, and meanwhile compared with common cotton knitted fabric, the mercerized-like all-cotton knitted fabric has the advantages of being stable in physical performance, good in drapability and the like.

Owner:湖北嘉麟杰纺织品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com