Water-based single-component white surface material as well as preparation method and application thereof

A single-component, white surface technology, applied in antifouling/underwater coatings, polyurea/polyurethane coatings, coatings, etc., can solve problems such as poor adhesion, poor water resistance, and low fullness, and achieve good compactness , good water resistance and excellent adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

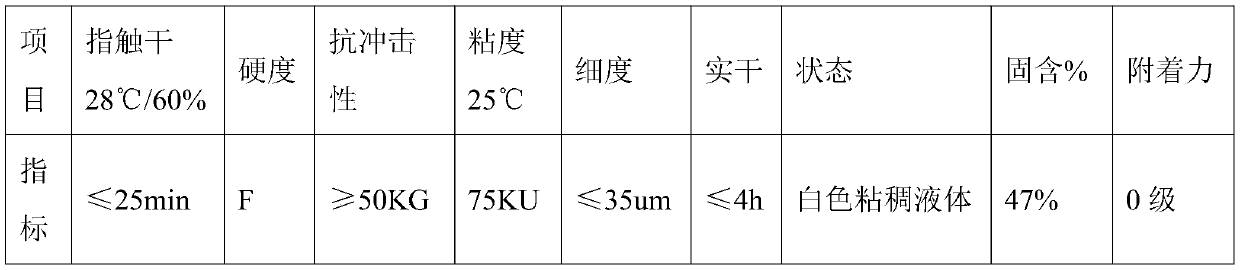

Image

Examples

Embodiment 1

[0031] (1) Preparation of 80% titanium dioxide slurry:

[0032] It is not easy to disperse when titanium white pulp is added directly to the wood lacquer system. Because the stable nano-alumina pulp is prepared in advance, it is added to the wood lacquer system during the let-down stage.

[0033] A. Titanium dioxide paste is prepared from the following raw materials in parts by weight:

[0034]

[0035] Mix and stir deionized water, defoamer, dispersant, and bactericide according to parts by weight, disperse at medium and low speed for 5-10 minutes, add titanium dioxide, disperse at high speed for 20-30 minutes, fineness ≤ 15um, and obtain titanium dioxide pulp.

[0036] The titanium dioxide content in the titanium dioxide slurry is 80%, and there is no delamination and coarsening phenomenon at 50°C / 7d.

[0037] Preparation of water-based one-component white flour material:

[0038]

[0039] Preparation:

[0040]Mix polyacrylic acid emulsion, polyurethane emulsion, d...

Embodiment 2

[0044] The preparation process is the same as in Example 1, except that the polyurethane emulsion in this example uses NEOREZ-986. Simultaneously present embodiment each component specific gravity is also different:

[0045]

[0046]

Embodiment 3

[0048] The preparation process is the same as in Example 1, except that the water-based single-component white flour material polyacrylic acid emulsion of this example uses AC2524 as follows:

[0049]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com