Smooth and delicate PVC door sealing material and preparation method thereof

A PVC resin and smooth technology, which is applied in the field of refrigerator door seal materials and preparation, can solve the problems of poor hand touch, scratches, and poor softness of airbags.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] Adopt above-mentioned a kind of preparation method that feels smooth and delicate PVC door seal material, its specific steps are:

[0018] Step 1: Weighing: Accurately weigh each component according to the range of parts in claim 1;

[0019] Step 2: Mix the powder: Use a high-speed mixing pot to fully mix the accurately weighed PVC resin, hand feeling agent, elastomer, stabilizer, lubricant and antibacterial and antifungal agent. After mixing slowly for 1 to 2 minutes, mix according to the right Requirements 1 The plasticizer after the weight ratio is accurately weighed is all put into the barrel of the high-speed mixing pot and slowly added into the high-speed mixing pot to increase the temperature of the high-speed mixing pot. When the temperature of the high-speed mixing pot rises When the temperature reaches 100°C, all the plasticizer in the high-speed mixing pot is added into the high-speed mixing pot. When the temperature of the high-speed mixing pot rises to 105°...

Embodiment 1

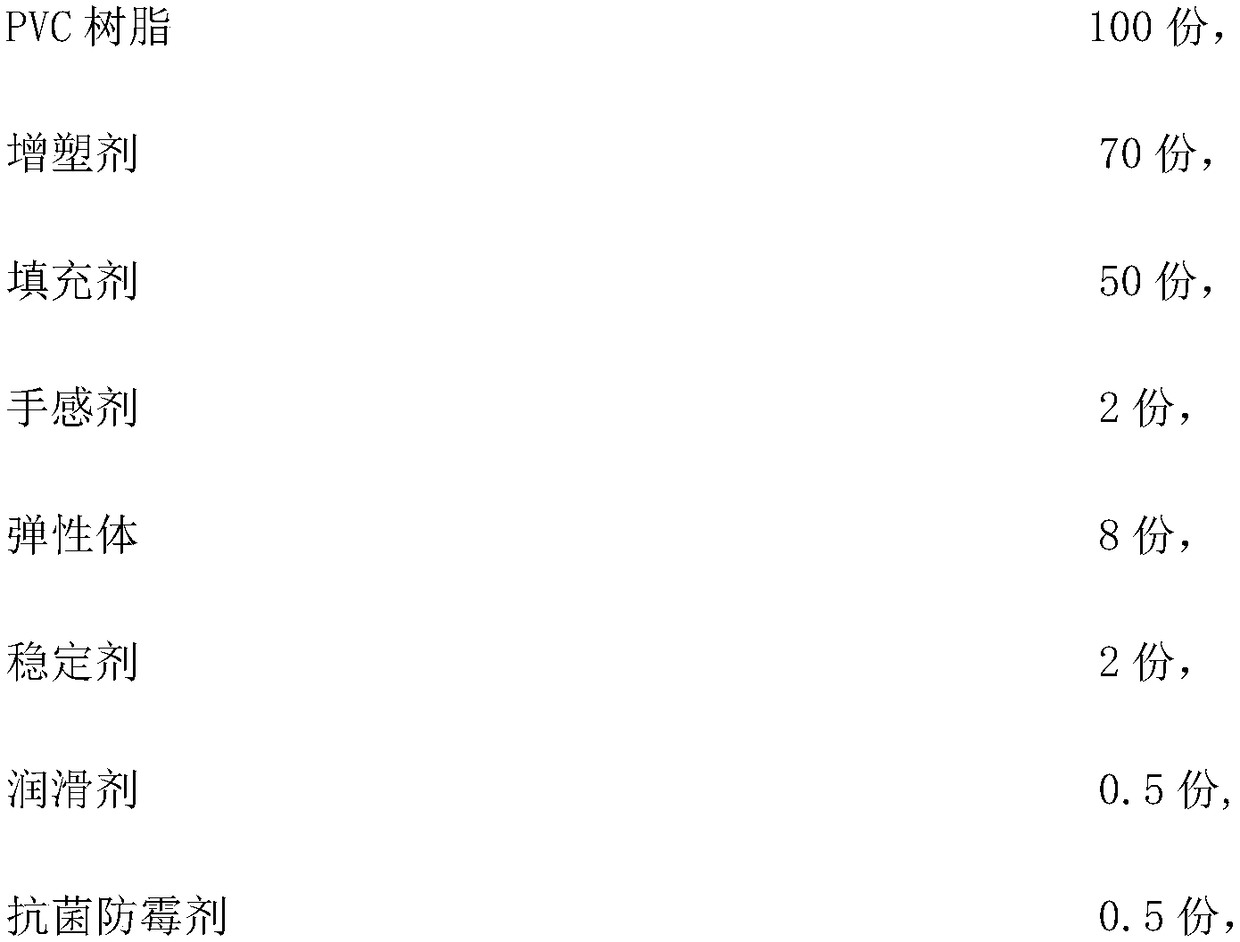

[0023] In the present invention, the refrigerator door seal material is accurately weighed according to the following material parts:

[0024] PVC resin is 100 parts, plasticizer is 50-75 parts, filler is 40-110 parts, hand feeling agent is 1-3 parts, elastomer is 5-20 parts, stabilizer is 1-5 parts, lubricant is 0.2 to 1 part, antibacterial and antifungal agent is 0.2 to 2 parts,

[0025]

[0026] Mix the accurately weighed PVC resin, hand feeling agent, elastomer, stabilizer, lubricant and antibacterial and antifungal agent in a high-speed mixing pot. After mixing slowly for 1 to 2 minutes, accurately weigh the Put all the plasticizers in the high-speed mixing pot into the high-speed mixing pot and slowly add the high-speed mixing pot to increase the temperature of the high-speed mixing pot. When the temperature of the high-speed mixing pot rises to 100 ° C, the high-speed mixing pot All the plasticizer in the barrel is added to the high-speed mixing pot. When the temper...

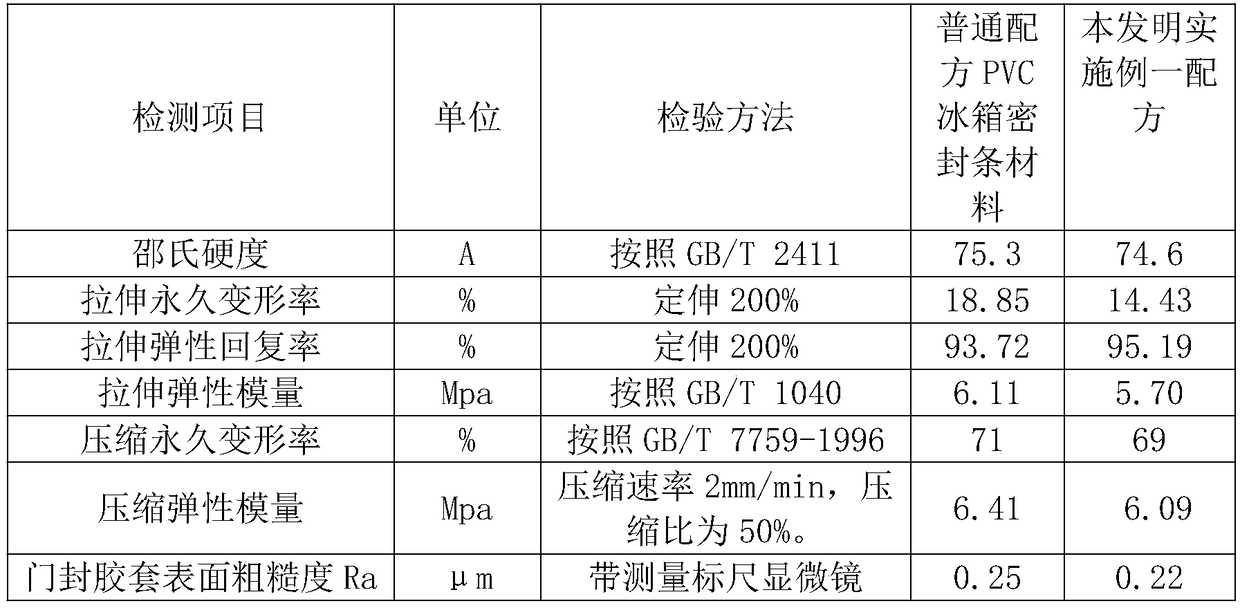

Embodiment 2

[0034] In the present invention, the refrigerator door seal material is accurately weighed according to the following material parts:

[0035]

[0036]

[0037] Mix the accurately weighed PVC resin, hand feeling agent, elastomer, stabilizer, lubricant and antibacterial and antifungal agent in a high-speed mixing pot for 1-3 minutes. Put the plasticizers accurately weighed in the above weight proportions into the barrel of the high-speed mixing pot and slowly add them into the high-speed mixing pot to increase the temperature of the high-speed mixing pot. When the temperature of the high-speed mixing pot rises to 100 At ℃, all the plasticizer in the high-speed mixing pot barrel is added into the high-speed mixing pot. When the temperature of the high-speed mixing pot rises to 105°C, the filler is added through the high-speed mixing pot barrel, and the high-speed mixing The pot continues to mix and the temperature continues to rise. When the temperature of the high-speed m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com