Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

54results about How to "Component raw materials are readily available" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lead-free low-melting sealing glass and preparation method thereof

InactiveCN101597136AScientific and reasonable componentsThe ratio is scientific and reasonableThermal expansionOperability

The invention discloses lead-free low-melting sealing glass and a preparation method thereof. The glass comprises the following raw materials in percentage by mol: 20 to 55 percent of P2O5, 5 to 30 percent of TeO2, 0 to 55 percent of ZnO and additives with the content not more than 30 percent of that of total compositions of the glass. The lead-free low-melting sealing glass has the advantages that the compositions and composition proportioning of the glass are scientific and reasonable, and the compositions do not contain lead which pollutes the environment or poisons human body; meanwhile, the glass is environment-friendly and low toxic and has wide softening temperature and thermal expansion coefficient ranges; therefore, the glass can be used in low-temperature packaging among different electronic components. Moreover, the simple and reasonable preparation method has strong operability and high qualified rate of finished products and is suitable for continuous large-scale industrialized production.

Owner:苏州恒仓红外光学材料研发中心有限责任公司

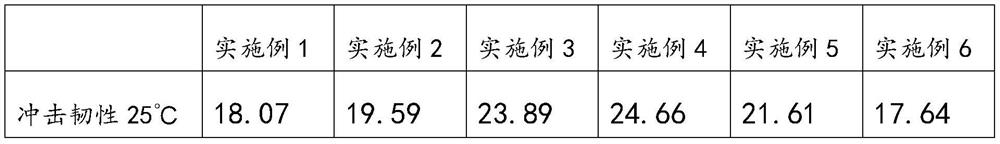

Compound toughening bisphenol-A epoxy resin inserted-bar glue high in adhesive capability in high-temperature environment and preparation method of bispheonl-A epoxy resin inserted-bar glue

ActiveCN104726048AAcid and alkali resistance is easy to getImprove corrosion resistanceEpoxy resin adhesivesRebarToughening

The invention discloses compound toughening bisphenol-A epoxy resin inserted-bar glue high in adhesive capability in the high-temperature environment and a preparation method of the bispheonl-A epoxy resin inserted-bar glue. The compound toughening bisphenol-A epoxy resin inserted-bar glue is characterized by being made of raw materials comprising a component A and a component B, wherein the component A includes, by weight, 40-60 parts of bisphenol-A epoxy resin, 30-40 parts of end carboxyl nitrile modified bisphenol-A epoxy resin, 20-30 parts of polyurethane modified bisphenol-A epoxy resin and 3-5 parts of silane coupling agents, and the component B includes, by weight, 20-30 parts of polyether amine and 10-20 parts of phenolic aldehyde modified amine, and the component A and the component B are subjected to mixture construction after being evenly mixed according to the weight ratio of 3 to 1. The outstanding characteristic of the glue is that steel-steel tensile shear strength can be up to 38Mpa, so that embedding length-to-diameter ratio can be reduced during bar inserting. A-grade adhesive bonding effect can be achieved when reinforcing steel bars are embedded shallowly, use in the high temperature environment of 120 DEG C can be achieved, and the glue is applicable to the occasion that the reinforcing steel bars limited in embedding depth are still kept high in bonding strength.

Owner:DALIAN UNIV OF TECH

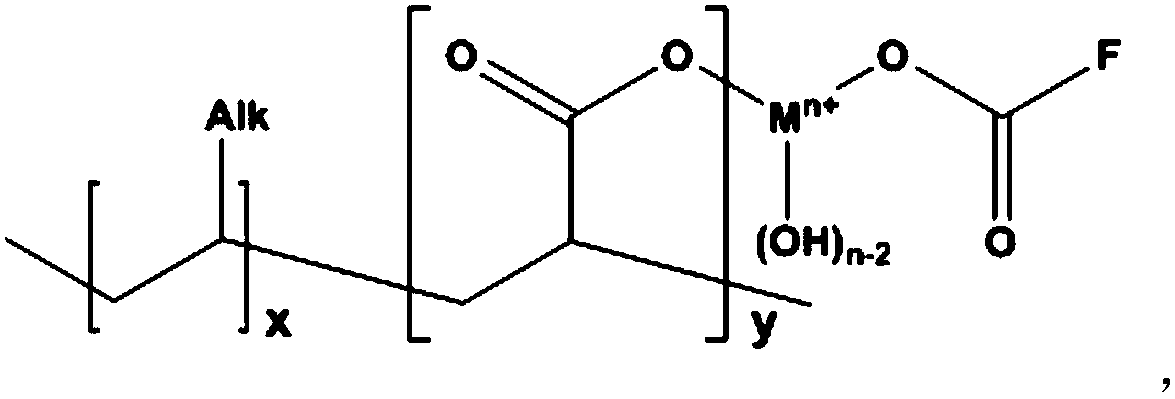

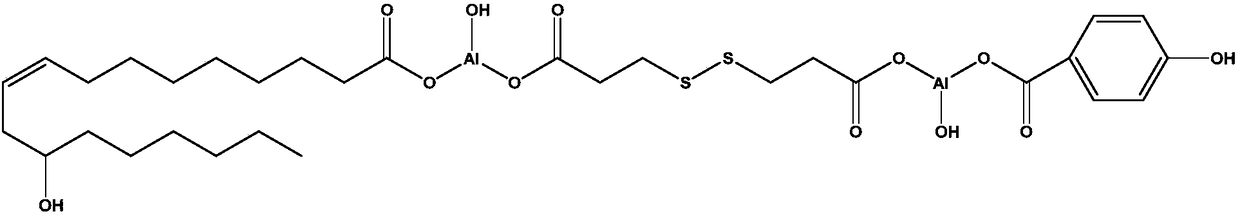

Rubber additive and preparation and application thereof

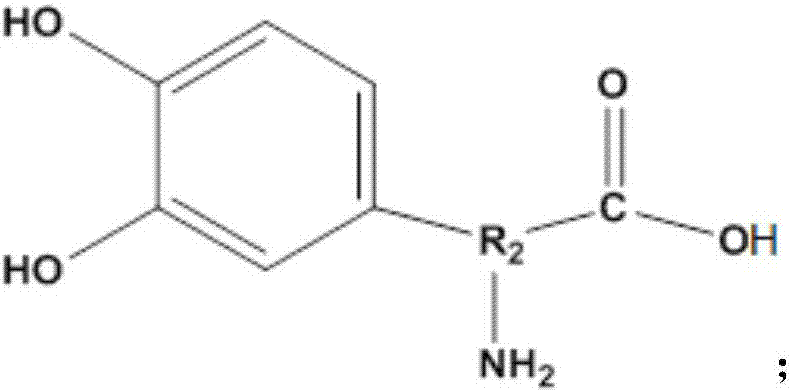

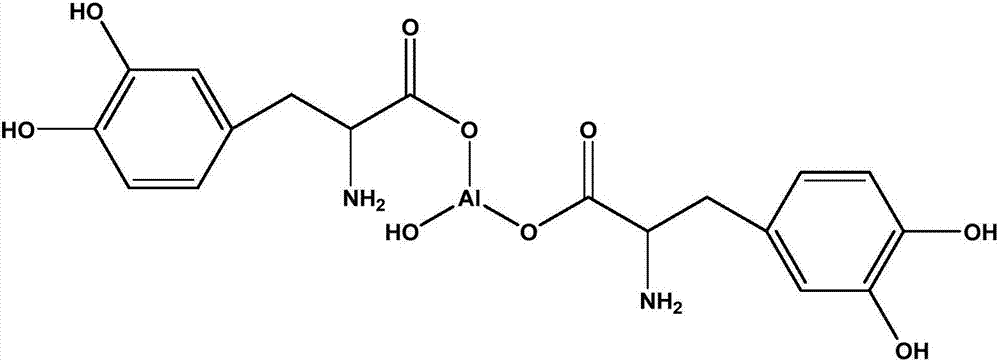

ActiveCN105418966ASimple preparation processComponent raw materials are readily availableIron group organic compounds without C-metal linkagesSpecial tyresPolymer scienceSimple aromatic ring

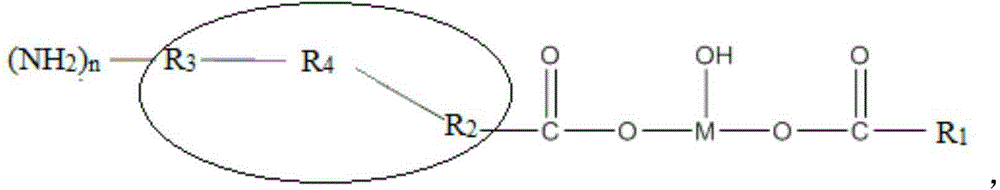

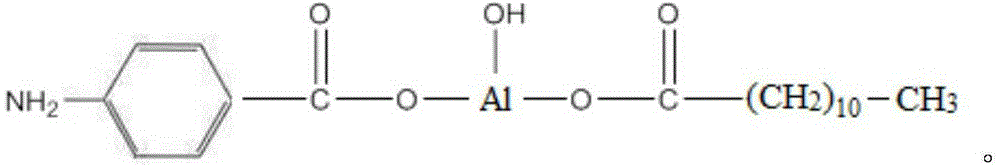

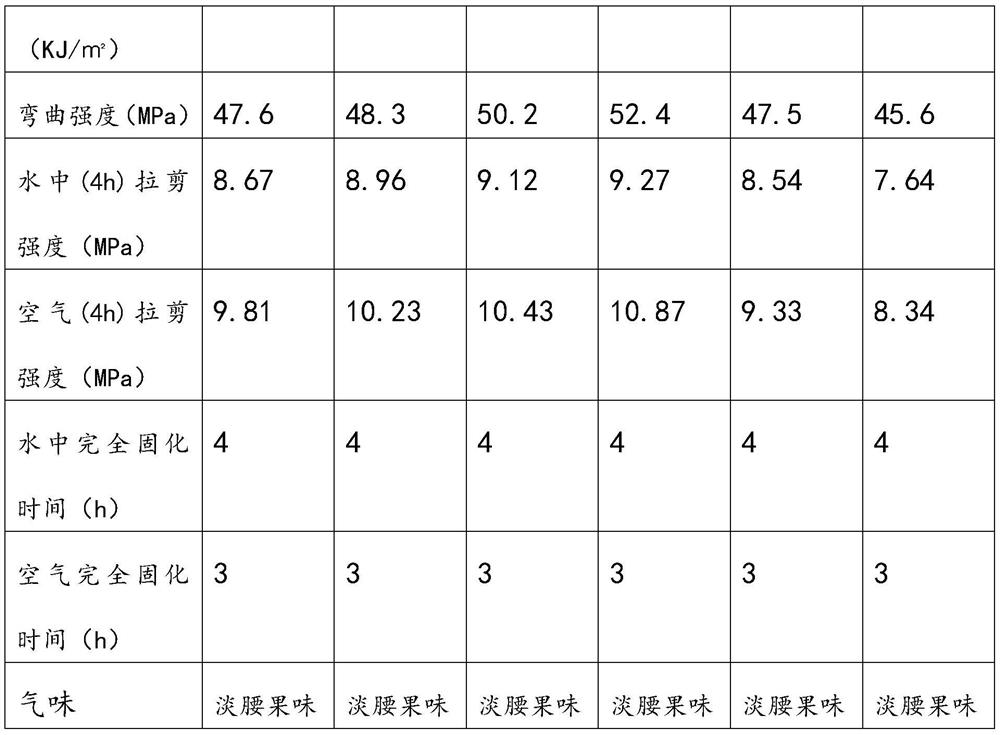

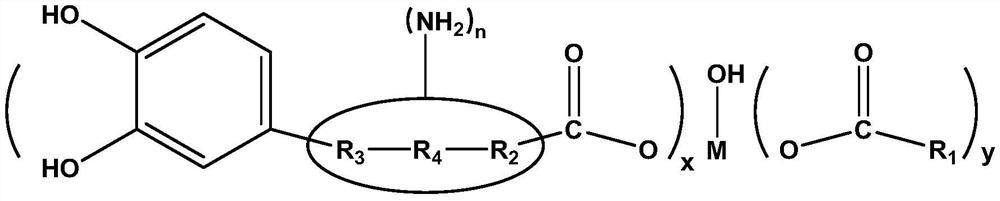

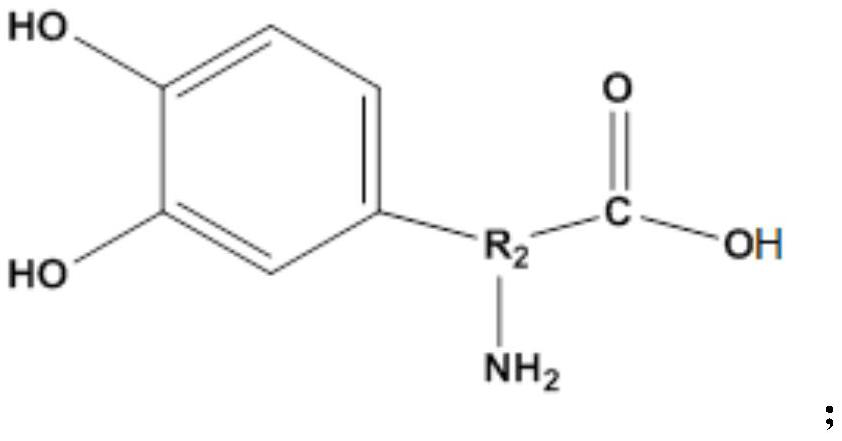

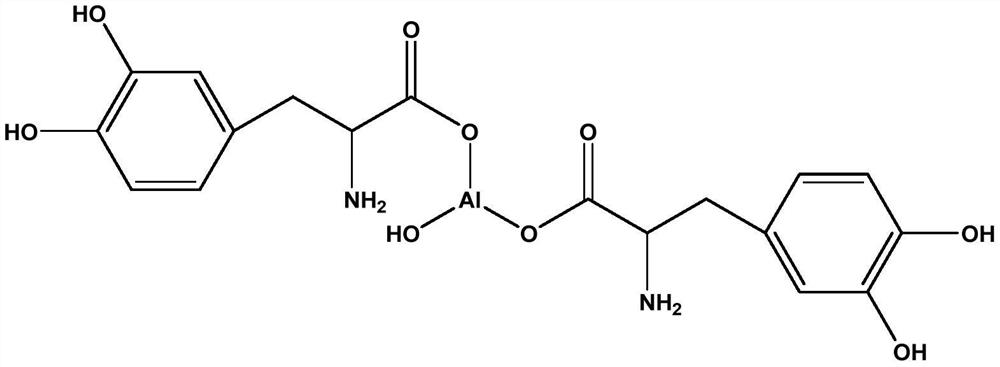

The invention relates to a rubber additive. A chemical structural formula of the rubber additive is as shown in the description, wherein M is metal of which the oxidation state is positive 3 or positive 4 valence, R1 is an aliphatic chain which contains 5 to 50 carbon atoms, R2 and R3 are aliphatic chains which contain 0 to 50 carbon atoms, R4 is an aromatic nucleus compound, and n is a positive integer which is larger than or equal to 1. Metallic soap is made through the following ways of respectively putting aromatic carboxylic acid with aromatic amine and alkali as well as fatty acid and the alkali in polar solvents, carrying out heating reactions, mixing products of the aromatic carboxylic acid and the fatty acid, adding a metallic M salt solution in the products, obtaining a white solid product through a reaction, and obtaining a target product after washing and drying, wherein the metallic soap is mainly used as the additive for preparing rubber. Compared with the prior art, the rubber additive disclosed by the invention has the advantages that the preparation of the metallic soap is simple, the raw materials are easily obtained, and the tensile strength, the tear strength and the wet / slip resistance can be obviously increased when the metallic soap is added in the rubber.

Owner:TONGJI UNIV +1

Water solution containing fine spray extinguishment additive agent and preparation and application

InactiveCN101214411AReduce the temperatureStrong penetrating powerFire rescueFire extinguisherSodium acetateCombustion

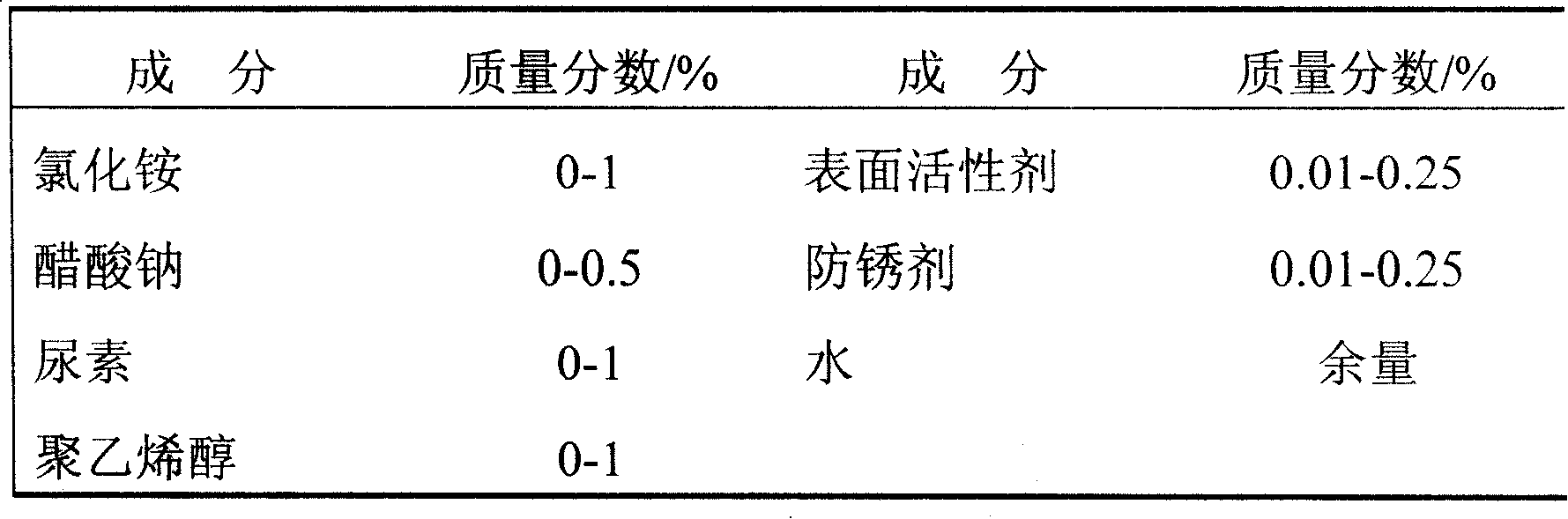

The invention relates to aqueous solution with fine water mist fire extinguishment additive, with the quality percentage of all components as below: ammonium chloride 0 percent to 1 percent, polyvinyl alcohol 0 percent to 1 percent, sodium acetate 0 percent to 0.5 percent, surface active agent 0.01 percent to 0.25 percent, urea 0 percent to 1 percent, rust preventive 0.01 percent to 0.25 percent, and the rest is water. The aqueous solution can improve the fire extinguishing efficiency of the fine water mist and effectively prevent after-combustion of inflamers; has little corrosion to equipments and instruments; basically has no pollution to fire scenes; is high-efficiency, stable and clean; the raw materials of all components are easy to be obtained; has stable performance; is basically nontoxic and low in cost; and has low consumption.

Owner:HENAN POLYTECHNIC UNIV

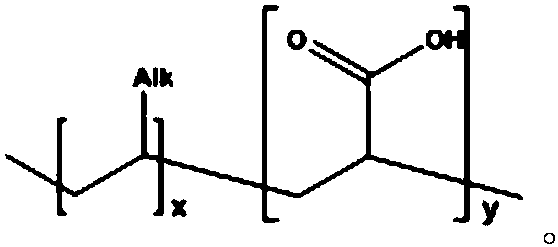

Rubber additive as well as preparation and application thereof

ActiveCN106866444ASimple preparation processComponent raw materials are readily availableOrganic compound preparationGroup 3/13 element organic compoundsPolymer scienceOxidation state

The invention relates to a rubber additive as well as preparation and application thereof. The chemical structural formula of the rubber additive is as shown in the specification, wherein M is a metal with the oxidation state of +3 or +4, R1 is a C5-C50 aliphatic chain, and R2, R3 and R4 are aliphatic chains with the carbon atomic number of 0 to 50; an amino is connected to the R2, the R3 and / or the R4 in the form of primary ammonia, secondary ammonia or tertiary ammonia; x is 1 to 2; y is 0 to 1; the sum of the x and the y is 2. The rubber additive provided by the invention is used when rubber is prepared; the obtained rubber additive can also enhance the tensile strength, the wet skid resistance and the like of the rubber remarkably.

Owner:TONGJI UNIV +1

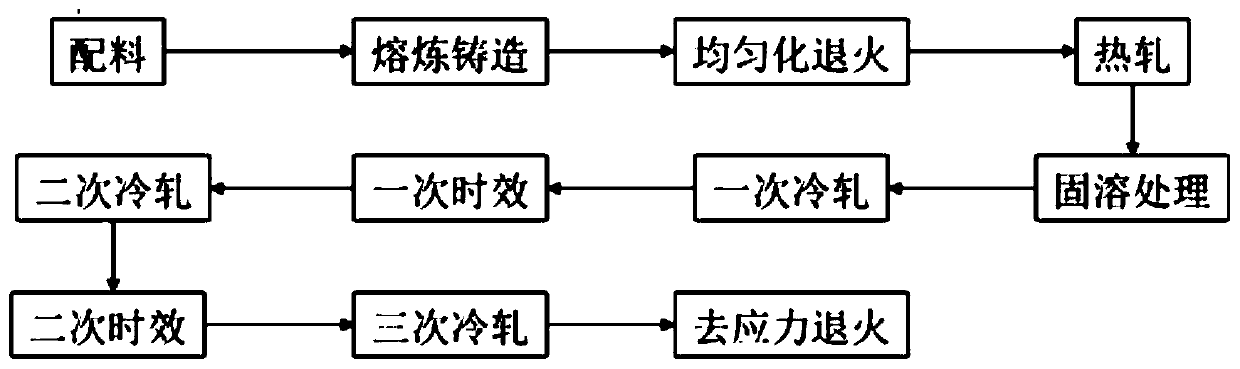

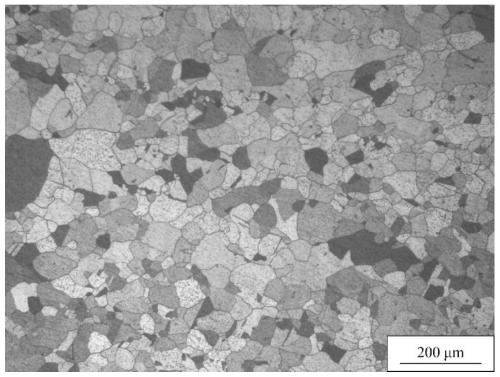

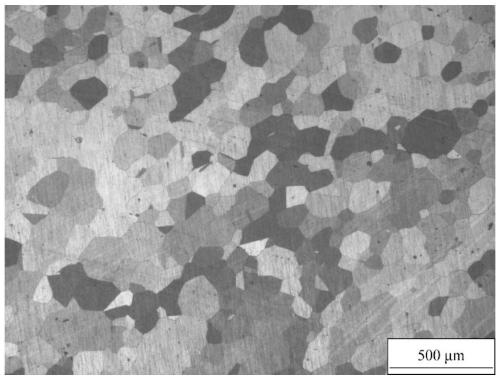

High-strength and high-conductivity heat-resistant copper-chromium alloy material and preparation process thereof

The embodiment of the invention provides a high-strength and high-conductivity heat-resistant copper-chromium alloy material and a preparation process thereof. The alloy material is reasonable in formula of components; the electric conductivity of the obtained copper-chromium alloy material can reach 82-98% IACS, the yield strength is 400-540 MPa, the strength of extension is 450-550 MPa, the ductility is 5-20%, and the material can resist heat greater than 550 DEG C; the problems of copper-chromium alloy materials in the prior art are solved; and raw materials of components are easy to obtain, no noble metal is included, and the cost is relatively low. The preparation process has no harsh preparation condition, is low in requirement for equipment, and is easy to industrially popularize.

Owner:CENT SOUTH UNIV

Nano additive as well as preparation method and application thereof

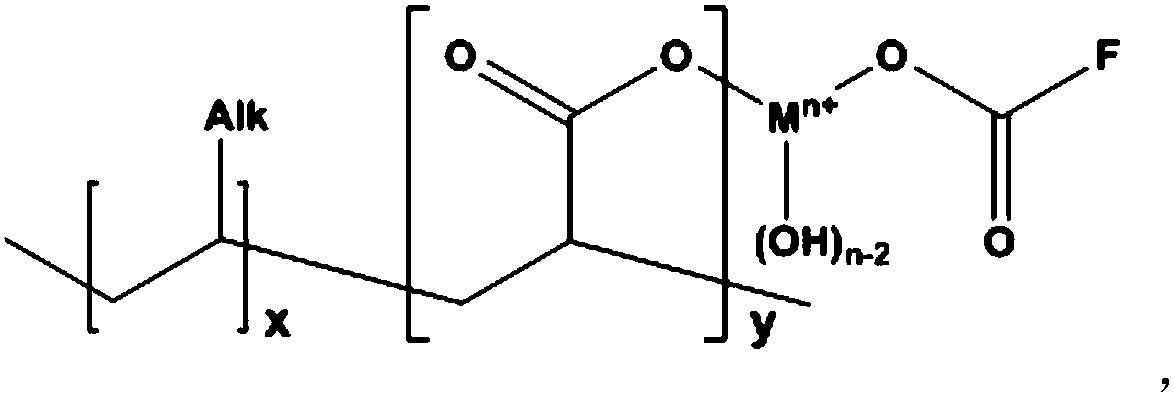

InactiveCN108059688ASimple preparation processComponent raw materials are readily availableSolesSpecial tyresChemical structureHydrogen atom

The invention relates to a nano additive as well as a preparation method and application thereof. The chemical structural formula of the nano additive is as shown in the specification, in the formula,n is an oxidation state of a metal element M; n is 2, 3 or 4; Alk is a hydrogen atom or a fat chain, alicyclic hydrocarbon or aromatic compound of which the carbon atom number is 1-18; x is greater than or equal to 0; y is greater than 0; an F-group is a short chain with functional groups, specifically a fat chain, alicyclic hydrocarbon or aromatic compound of which the carbon atom number is 2-50. Compared with the prior art, the nano additive provided by the invention is capable of increasing the elastic modus of a rubber composition when being used for preparing rubber, and in a part of demonstrative application schemes, rubber compositions with the nano additive are very high in slippery sliding resistance, and mostly have increased elastic modus and elongation at break.

Owner:TONGJI UNIV

Phase-change energy-storage three-dimensional fabric concrete canvas and preparation method thereof

The invention discloses phase-change energy-storage three-dimensional fabric concrete canvas which has properties of heat preservation, rapid curing and hardening, flame retardancy, water resistance,wind resistance and the like, and is capable of meeting requirements that a temporary tent is rapidly constructed as a refuge. The phase-change energy-storage three-dimensional fabric concrete canvasdisclosed by the invention is composed of a three-dimensional partitioned fabric and a cement grouting sizing agent, wherein the three-dimensional partitioned fabric is a glass fiber knitted three-dimensional partitioned fabric of which the thickness is 20-30mm; the cement grouting sizing agent is composed of rapidly hardened cement, quartz sand and a phase-change material; by 100 parts of the cement grouting sizing agent, the amount of the rapidly hardened cement in the cement grouting sizing agent is 35-45 parts, the amount of the quartz sand is 45-60 parts, and the amount of the phase-change material is 2-10 parts; the rapidly hardened cement, the quartz sand and the phase-change material can be uniformly mixed and used later when the canvas is used.

Owner:ARMY ENG UNIV OF PLA

Antifreezing automobile windshield washing liquid and preparation method thereof

InactiveCN104651073APrevent oxidationLowering the freezing pointNon-ionic surface-active compoundsOther chemical processesEthylene oxideDodecyldimethylamine oxide

Owner:王沛强

Automobile glass antifogging agent and preparation method thereof

The invention relates to an antifogging agent and especially relates to an automobile glass antifogging agent and a preparation method thereof. The automobile glass antifogging agent comprises, by weight, 15-18% of polyglycerol monostearate, 16-20% of sorbitan monstearate (S-60), 14-18% of sorbitan monopalmitate (S-40), 14-18% of fatty alcohol-oxirane condensate, 14-20% of dimethicone, 2-6% of haw seed oil and 2-8% of alum. The preparation method adopts easily available raw materials, has simple production processes and is convenient for adjustment. The automobile glass antifogging agent has 100% of antifogging effects on toughened glass, optical lens and plastic lens and can prevent mirror surface aging and oxidation. The automobile glass antifogging agent can substantially reduce a liquid ice point thereby producing antifreezing effects and can fast dissolve ice and frost.

Owner:王沛强

Insulating paint used for overhead high voltage line and preparation method thereof

InactiveCN101781498BGuaranteed super weather resistanceGuaranteed self-cleaningPlastic/resin/waxes insulatorsCoatingsInsulative paintPhysical chemistry

The invention discloses insulating paint used for an overhead high voltage line, which has the excellent properties of self cleaning, snow accumulation prevention and high voltage prevention, and the property thereof can reach the insulating requirement of resisting 35 KV voltage. The insulating paint used for the overhead high voltage line of the invention comprises a component A and a componentB, wherein the component A is formed by mixing the following components in parts by weight: 100 parts of teflon resin, 20-40 parts of inorganic pigment, 20-30 parts of diluent, 0.3-0.7 part of defoamer and 1.2-1.8 parts of anti-settling agent; the component B is a curing agent. When in use, the component A and the component B are evenly mixed to be used, and the amount of the component B is equalto 6-8 parts by taking 100 parts of the teflon resin in the component A as the reference.

Owner:ENG COLLEGE OF ENG CORPS PLA UNIV OF SCI & TECH

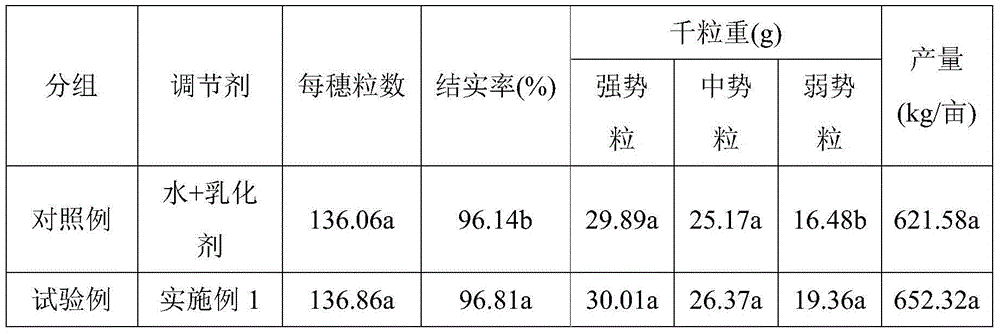

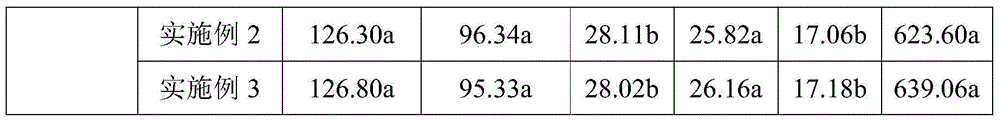

Chemical regulator for improving grain filling plumpness of rice, and preparation method and use method thereof

ActiveCN104824029AIncrease thousand kernel weightIncrease speedBiocidePlant growth regulatorsVitamin CSide effect

The invention discloses a chemical regulator for improving the grain filling plumpness of rice, and a preparation method and a use method thereof, and belongs to the technical field of plant growth regulators. The chemical regulator is prepared by mainly compounding salicylic acid, vitamin C, zinc sulfate, potassium dihydrogen phosphate, boric acid and an emulsifier, can improve the thousand seed weight of rice grains, increase the initial power of grain filling, the maximum filling rate and the average filling rate and shorten the time required by reaching of the maximum filing rate to improve the polished rice rate and the entire polished rice rate of grains and reduce the unsound grain rate and the chalky grain rate of the grains, and has a substantial regulation effect on rice weak power grains. The regulator has the advantages of easily available raw materials, low cost and no toxic side effects. The use method is simple and is easy to realize. The preparation method of the chemical regulator for improving the grain filling plumpness of rice has the advantages of simple process, simple operation, and easy industrial popularization application.

Owner:HENAN AGRICULTURAL UNIVERSITY

Cleaning factor-rich lubricating oil composition for vehicles

InactiveCN104651023AReduce failureExtended service lifeLubricant compositionPhysical chemistryViscosity index

The invention relates to lubricating oil and especially relates to a cleaning factor-rich lubricating oil composition for vehicles. The cleaning factor-rich lubricating oil composition comprises, by weight, 60-75% of hydrogenated base oil, 5-8% of metalized sodium, 2-3% of a calcium-phenol compound, 2-3% of a magnesium-phenol compound, 5-8% of an ash-free extreme pressure antioxidant, 6-11% of a viscosity index improver, 6-8% of a dispersant and 0.5-1% of a pour-point depressant. The cleaning factor-rich lubricating oil composition adopts easily available raw materials, can be produced by simple processes, is convenient for preparation, has wear resistance, prevents deposition on the surface, maximally reduces engine fault caused by lubrication and prolongs an engine service life.

Owner:王沛强

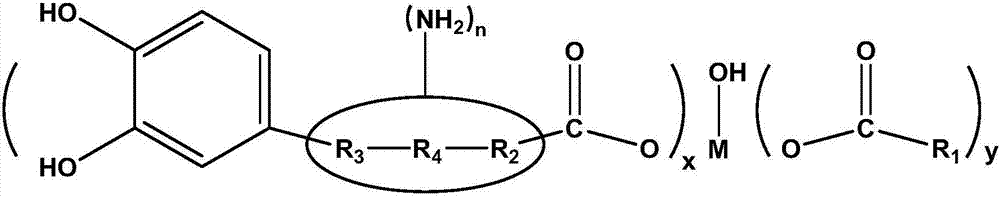

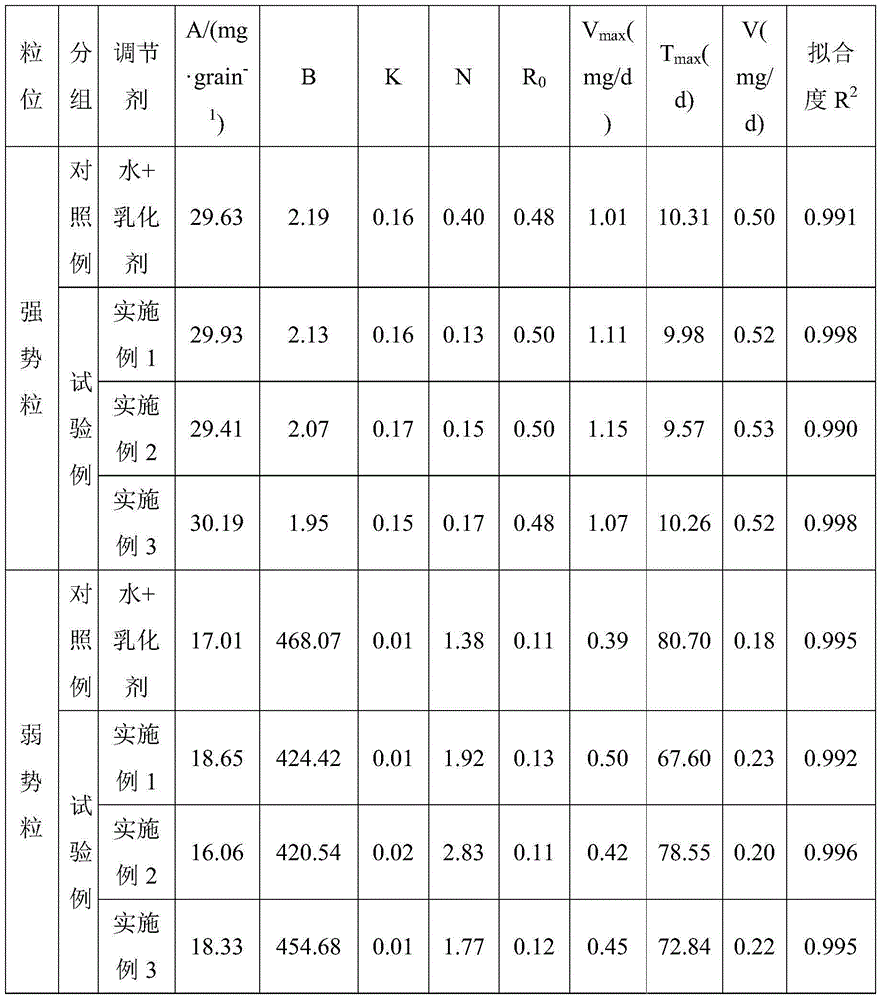

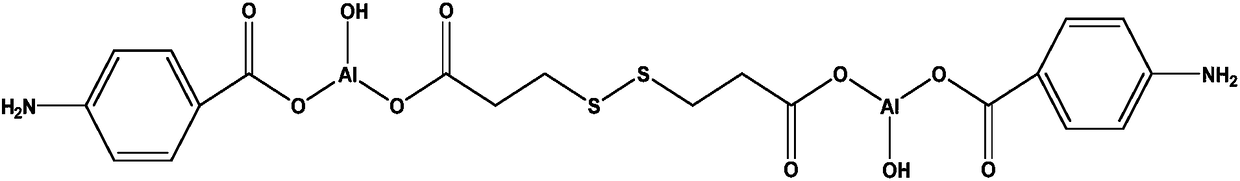

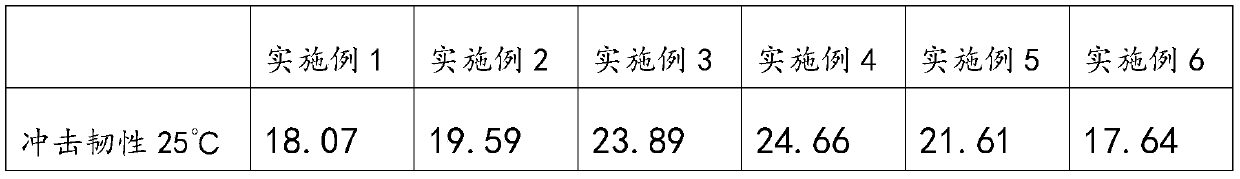

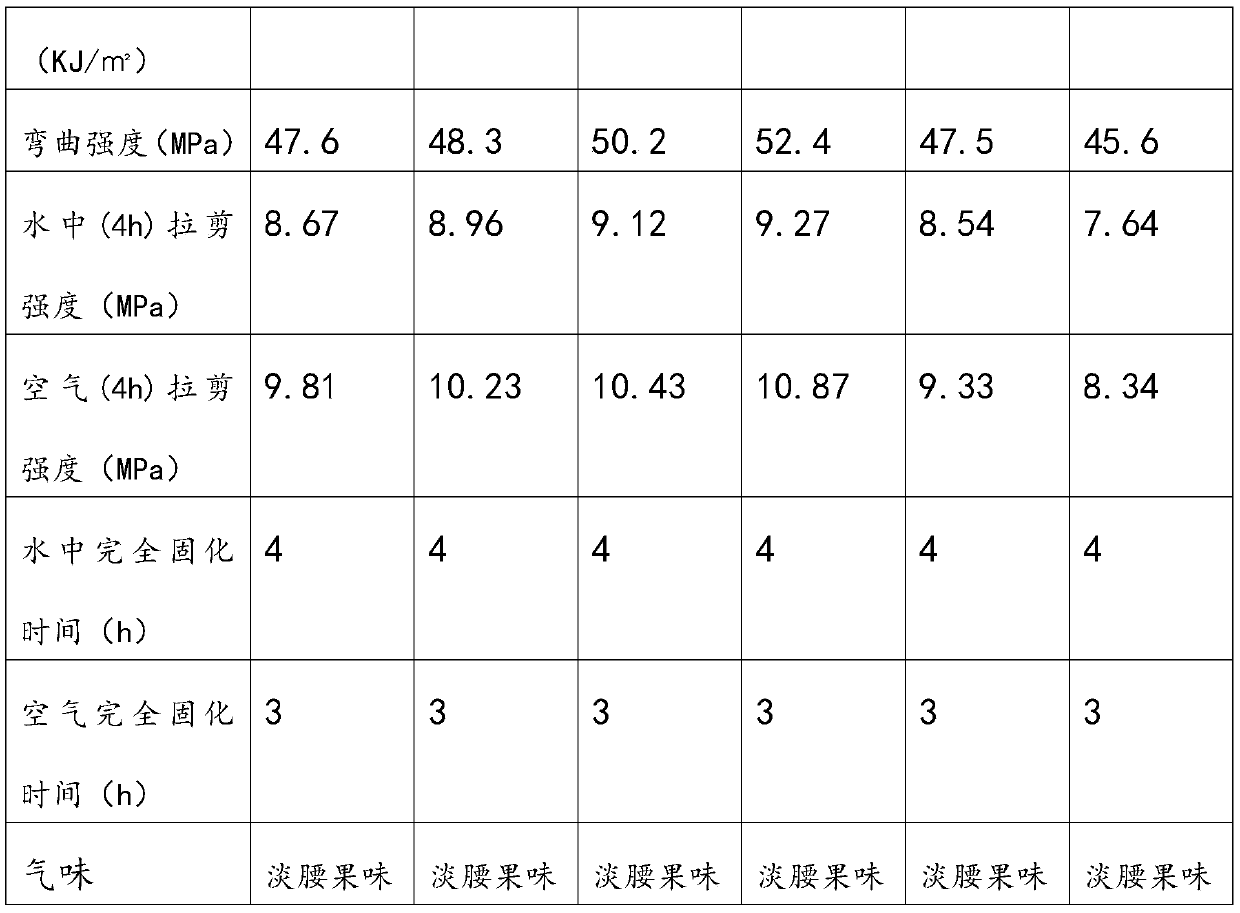

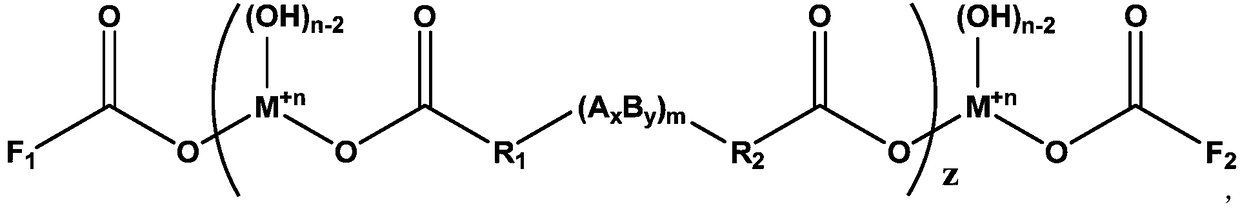

Amino compound rubber additive as well as preparation and application thereof

ActiveCN108218905ASimple preparation processComponent raw materials are readily availableOrganic compound preparationGroup 3/13 element organic compoundsChemical LinkageAlicyclic Hydrocarbons

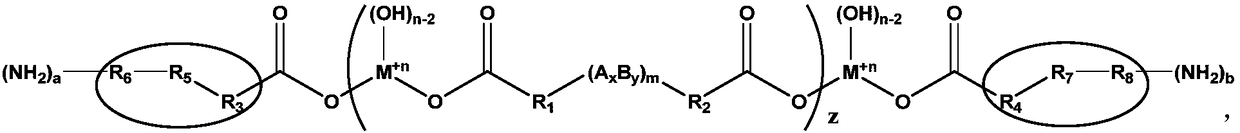

The invention relates to an amino compound rubber additive as well as preparation and application thereof. The chemical structural formula of the additive is shown in the description, wherein n is anoxidation state of a metal element M; n=2, 3 or 4; A is one of oxygen, sulfur, carbon, nitrogen, phosphorus or silicon; x is more than or equal to 0 and less than or equal to 10; B is one of oxygen, sulfur, carbon, nitrogen, phosphorus or silicon; y is more than or equal to 0 and less than or equal to 10; (AxBy)m indicates that atoms are connected by chemical bonds; x and y are not 0 at the same time; m is more than or equal to 0 and less than or equal to 10; z is less than or equal to 50; R1 and R2 are fatty chains, alicyclic hydrocarbons or aromatic compounds with 0 to 50 carbon atoms; R3, R4, R6 and R8 are saturated or unsaturated fatty chains or alicyclic hydrocarbons with 0 to 50 carbon atoms; R5 and R7 are aromatic ring compounds; a and b are positive integers. The prepared additivecan be applied to rubber, and improves the hardness, wet skid resistance, dynamic-mechanical properties and tensile property of the rubber; a part of rubber compositions containing the additive have higher Shore hardness, elongation at break, wet skid resistance and dynamic elastic modulus.

Owner:TONGJI UNIV

Cement-based high-strength geomechanic model test similar material and preparation method thereof

InactiveCN108439914AHigh bulk densityStable mechanical propertiesPreparing sample for investigationSilica fumeCement mortar

The invention discloses a cement-based high-strength geomechanic model test similar material. The cement-based high-strength geomechanic model test similar material has the advantages of easiness in molding, stable mechanical performances and low price. The cement-based high-strength geomechanic model test similar material comprises a component A and a component B, the component A is prepared by mixing, by weight, 2-6 parts of cement, 5 parts of silica fume, 57-65 parts of barite sands and 22-30 parts of barite powder, the component B is composed of water, and a ratio of the use amount of cement mortar in the component A to the use amount of the water in the component B is 100:(8-12). The similar material can be used by uniformly mixing the component A with the component B.

Owner:ARMY ENG UNIV OF PLA

Automobile glass antifogging agent

InactiveCN104650810AImprove sexual functionImprove stain resistanceOther chemical processesPalmitatesStearic acid

The invention relates to an antifogging agent and especially relates to an automobile glass antifogging agent. The automobile glass antifogging agent comprises, by weight, 16-20% of sorbitan monstearate (S-60), 2-5% of methyltrifluoropropyl silicone oil, 14-18% of sorbitan monopalmitate (S-40), 2-5% of volatile perfluoro-oil, 2-5% of 1, 5-pentanediol, 0.5-2.5% of sodium benzoate, and 45-65% of deionized water. The automobile glass antifogging agent has excellent hydrophobicity and antifogging function, can prevent a high temperature, can improve dirt resistance, can prolong antifogging time, can improve antifogging effects, and has a wide use range, a low cost and no side effects on the human body. Through coating automobile outer glass and rearview mirrors, the automobile glass antifogging agent has effects of preventing rain, cleaning glass and protecting a wiper. The automobile glass antifogging agent can be dissolved in water, has no easy combustion and blast risk and is portable.

Owner:王沛强

Epoxy resin adhesive for concrete wet surfaces

ActiveCN110922925AGood flexibilityImprove hydrophobicityNon-macromolecular adhesive additivesEpoxy resin adhesivesPolymer scienceFirming agent

The invention relates to an epoxy resin adhesive for concrete wet surfaces, and solves the problems that an existing epoxy resin adhesive is high in cost, high in brittleness and low in toughness, andvarious properties need to be further improved. The epoxy resin adhesive is prepared by mixing a component A and a component B in a ratio of (2-4):1, wherein the component A comprises the following raw materials in parts by weight: 100 parts of bisphenol A epoxy resin, 5-10 parts of palygorskite powder and 15-25 parts of waste glass powder; the component B comprises the following components in parts by weight: 45-65 parts of a modified amine curing agent, 10-20 parts of monoamine and 4-6 parts of a thixotropic agent. The epoxy resin adhesive is simple in raw material, low in cost, good in flexibility, excellent in hydrophobicity, low in permeability, low in toxicity, excellent in self-drying property and excellent in adhesive property, and is particularly suitable for the concrete wet surfaces.

Owner:HUBEI UNIV OF TECH

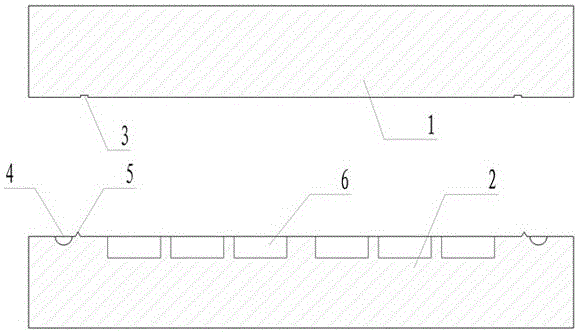

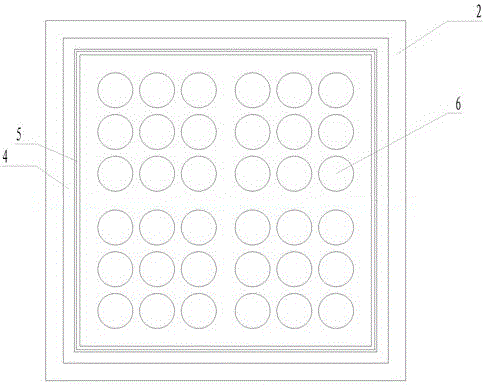

Transparent rubber pad of heparin cap for remaining needle and production method of transparent rubber pad

ActiveCN104387626ALow transparencyTo solve the chemical cleanliness needs to be improvedPolymer scienceThermoplastic elastomer

The invention discloses a transparent rubber pad of a heparin cap for a remaining needle. The transparent rubber pad mainly comprises 100 parts of polyisoprene rubber, 3-10 parts of a thermoplastic elastomer, 1-10 parts of alkali white carbon black and 0.3-1.5 parts of peroxide. The invention also discloses a production method of the transparent rubber pad of the heparin cap for the remaining needle. By using the production method, the problems that the existing transparent rubber pad of the heparin cap for the remaining needle is not high in transparency, the chemical cleanliness of the existing transparent rubber pad needs to be improved, and particularly, the pH change value and the ultraviolet absorbance of the transparent rubber pad easily exceed the standard are solved, the size of each curing burr are controlled within 0.03-0.10mm, and the cured transparent rubber pad of the heparin cap can be directly frozen and deburred; and meanwhile, the surface of a curing mould is treated by using a mirror polishing process, so that the transparent rubber pad of the heparin cap, which is provided with relatively thin curing burrs, is conveniently cured and demoulded. The transparent rubber pad of the heparin cap for the remaining needle, disclosed by the invention, is resistant to multiple punctures, excellent in cleaning performance and compatibility with tube sealing fluid of the heparin cap and low in extractable substance content.

Owner:郑州翱翔医药科技股份有限公司

Composition capable of reducing aflatoxin (AFT) B1 in solid material as well as preparation method and use method of composition

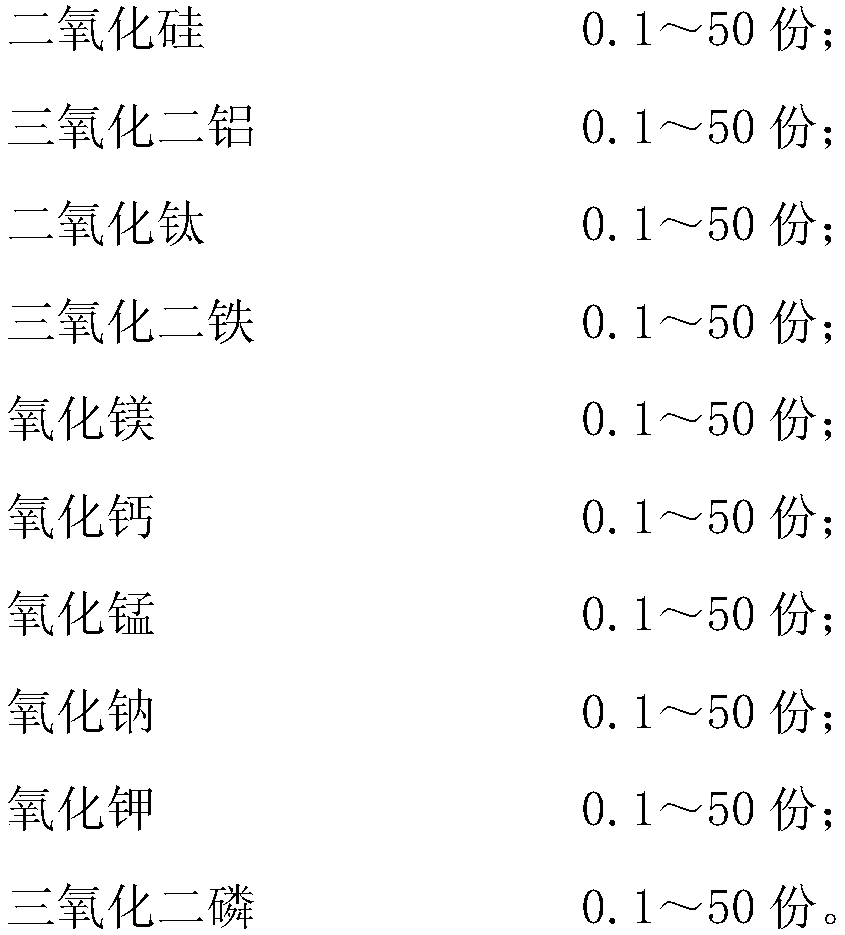

InactiveCN108576574AReduce contentComponent raw materials are readily availableConiferophyta medical ingredientsFood scienceManganese oxideSilicon dioxide

The invention discloses a composition capable of reducing aflatoxin (AFT) B1 in a solid material. The composition comprises silicon dioxide, aluminum oxide, titanium dioxide, ferric oxide, magnesium oxide, calcium oxide, manganese oxide, sodium oxide, potassium oxide and phosphorus trioxide. Besides, the invention further provides a preparation method and a use method of the composition capable ofreducing the AFT B1 in the solid material. The content of the AFT B1 can be effectively decreased by use of the composition capable of reducing the AFT B1 in the solid material, prepared by the method provided by the invention. In addition, the composition is non-toxic, harmless and pollution-free, raw materials are easy to obtain and low in price, and the production process is simple and prone to industrial mass production.

Owner:赵万友

Insulating paint used for overhead high voltage line and preparation method thereof

InactiveCN101781498AGuaranteed super weather resistanceGuaranteed self-cleaningPlastic/resin/waxes insulatorsCoatingsDiluentEngineering

The invention discloses insulating paint used for an overhead high voltage line, which has the excellent properties of self cleaning, snow accumulation prevention and high voltage prevention, and the property thereof can reach the insulating requirement of resisting 35 KV voltage. The insulating paint used for the overhead high voltage line of the invention comprises a component A and a component B, wherein the component A is formed by mixing the following components in parts by weight: 100 parts of teflon resin, 20-40 parts of inorganic pigment, 20-30 parts of diluent, 0.3-0.7 part of defoamer and 1.2-1.8 parts of anti-settling agent; the component B is a curing agent. When in use, the component A and the component B are evenly mixed to be used, and the amount of the component B is equal to 6-8 parts by taking 100 parts of the teflon resin in the component A as the reference.

Owner:ENG COLLEGE OF ENG CORPS PLA UNIV OF SCI & TECH

Automotive glass antifogging agent

InactiveCN104194724AImprove sexual functionImprove stain resistanceOther chemical processesSorbitan monostearateSide effect

The invention relates to an antifogging agent and in particular relates to an automotive glass antifogging agent. The automotive glass antifogging agent comprises the following components in percentage by weight: 16-20 percent of sorbitan monostearate (S-60), 2-5 percent of methyl trifluoropropyl silicone oil, 14-18 percent of sorbitan monopalmitate (S-40), 2-5 percent of volatile perfluorinated oil, 2-5 percent of 1,5-pentanediol, 0.5-2.5 percent of sodium benzoate and 45-65 percent of deionized water. The automotive glass antifogging agent disclosed by the invention has excellent hydrophobicity and antifogging function and has high-temperature resistance and enhanced stain resistance; the antifogging time can be prolonged and the antifogging effect is improved; the automotive glass antifogging agent is wide in application range and low in cost and does not have a side effect on the human body; the antifogging effect has the effects of protecting glass from rain, cleaning the glass and protecting the windscreen wiper after applied to the automobile outside glass and a rearview mirror; and the antifogging agent takes water as a solvent, eliminates inflammable and explosive hazards and is convenient to carry.

Owner:QINGDAO RUNXIN WEIYE TECH & TRADE

Wear-resistant lubricating oil composition for vehicles

InactiveCN104651024AReduce failureExtended service lifeLubricant compositionPhosphateZinc dithiophosphate

The invention relates to lubricating oil and especially relates to a wear-resistant lubricating oil composition for vehicles. The wear-resistant lubricating oil composition comprises, by weight, 60-75% of hydrogenated base oil, 5-8% of zinc dithiophosphate, 6-12% of phosphate, 4-6% of acid phosphate, 8-10% of a polymer ashless dispersant and 0.5-1% of a pour-point depressant. The wear-resistant lubricating oil composition adopts easily available raw materials, can be produced by simple processes, is convenient for adjustment, has wear resistance, maximally reduces engine fault caused by lubrication and prolongs an engine service life.

Owner:王沛强

Antifoggant for automobile glass and preparation method thereof

InactiveCN104194723ASimple production processSimple modulationOther chemical processesFrostSorbitan monostearate

The invention relates to an antifoggant and particularly relates to an antifoggant for automobile glass and a preparation method thereof. The antifoggant comprises the following components in percentage by weight: 15%-18% of polyglycerol stearate, 16%-20% of sorbitan monostearate (S-60), 14%-18% of sorbitan palmitate (S-40), 14%-18% of fatty alcohol and ethylene oxide condensation compound, 14%-20% of simethicone, 2%-6% of hawthorn seed oil and 2%-8% of alums. The antifoggant provided by the invention is easily available in raw materials of components, simple in production process and convenient to modulate. The antifoggant provided by the invention not only has a 100% antifogging effect to tempered glass, optical glasses and plastic glasses, but also further can be used for preventing the mirror side from being aged and oxidized. The ice point of a liquid can be remarkably reduced so as to have the anti-freezing effect, so that rime frost can be quickly dissolved.

Owner:QINGDAO YONGTONG ELEVATOR ENG

A kind of gamimycin injection and preparation method thereof

ActiveCN103462884BExpand the scope of clinical applicationStable in natureAntibacterial agentsOrganic active ingredientsGamithromycin Injectable SolutionAntioxidant

Owner:TIANJIN ZHONGSHENG TIAOZHAN BIOTECH

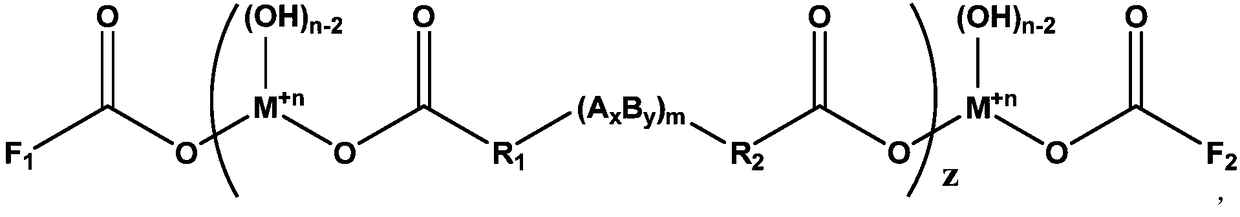

Additive with functional group double-terminated structure as well as preparation and application of additive

ActiveCN108250484ASimple preparation processComponent raw materials are readily availableCosmetic preparationsNon-macromolecular adhesive additivesChemical structureAlicyclic Hydrocarbons

The invention relates to an additive with a functional group double-terminated structure as well as a preparation and application of the additive. The additive has a chemical structural formula as shown in the specification, wherein n is an oxidation state of metal M and is equal to 2, 3 or 4; A is one of oxygen, sulfur, carbon, nitrogen, phosphorus and silicon, and x is larger than or equal to 0and is smaller than or equal to 10; B is one of oxygen, sulfur, carbon, nitrogen, phosphorus and silicon, and y is larger than or equal to 0 and is smaller than or equal to 10; (AxBy)m shows that atoms are connected by chemical bonds, and x and y are not zero at the same time; m is larger than or equal to 0 and is smaller than or equal to 10; z is smaller than or equal to 50; R1 and R2 are aliphatic chains, alicyclic hydrocarbons or aromatic compounds of which the carbon atom numbers do not exceed 50; and F1 and F2 are organic groups with functional groups and have different structures. The additive prepared by using the preparation method can be introduced to rubber compositions so as to comprehensively improve the hardness, wet skid resistance, dynamic mechanical property and tensile property of rubber, and even, in parts of exemplary embodiments, the rubber compositions containing the additive with the functional group double-terminated structure have improved Shore hardness, elongation at break and wet skid resistance.

Owner:TONGJI UNIV

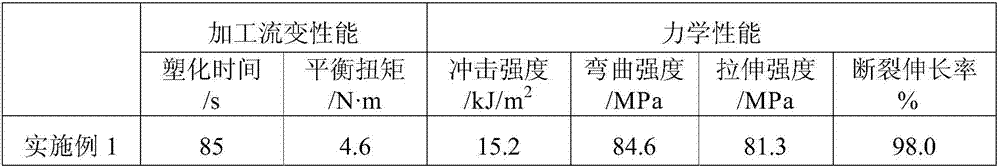

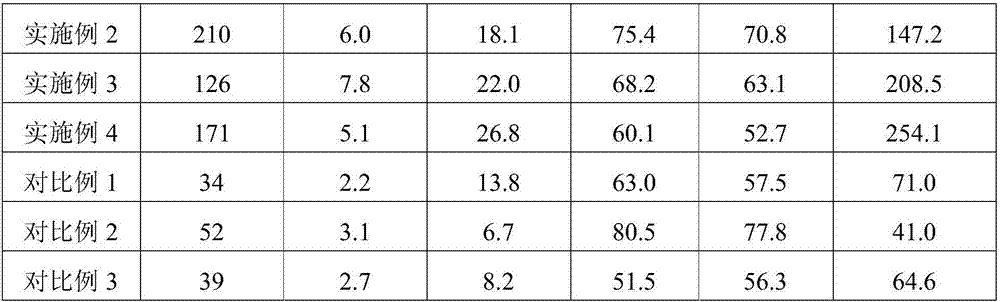

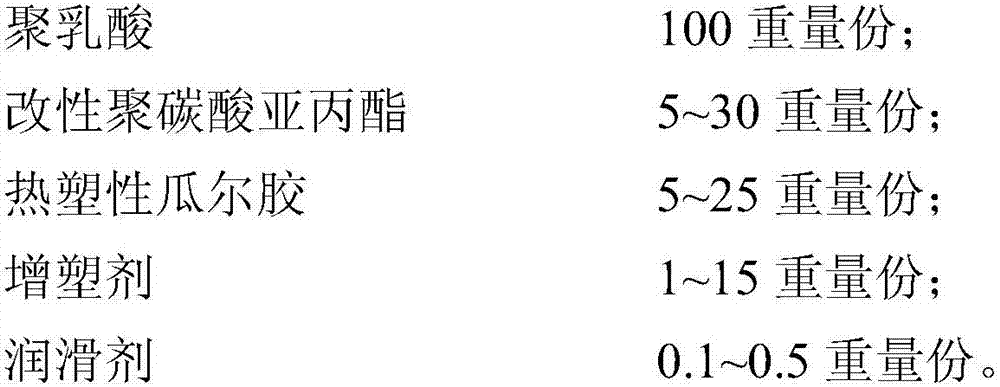

Polylactic acid/modified polypropylene carbonate/thermoplastic guar gum composite material and preparation method thereof

The invention provides a polylactic acid / modified polypropylene carbonate / thermoplastic guar gum composite material and a preparation method thereof. The polylactic acid / modified polypropylene carbonate / thermoplastic guar gum composite material comprises the following materials in parts by weight: 100 parts of polylactic acid; 5 to 30 parts of modified polypropylene carbonate; 5 to 25 parts of thermoplastic guar gum; 1 to 5 parts of a plasticizer; 0.1 to 0.5 part of a lubricant. The olylactic acid / modified polypropylene carbonate / thermoplastic guar gum composite material is available in all components, low in cost, nontoxic, green and environmentally friendly, has the characteristics of excellent processing rheological property and mechanical property, low cost and capability of being biodegradable, and is applicable to the manufacture of plastic products, such as disposable tableware, packing materials and films, through various forming technoliges.

Owner:广东超远生物科技有限公司

A kind of heparin cap transparent rubber pad for indwelling needle and preparation method thereof

ActiveCN104387626BAvoid yellowingSolve the problem of not easy punching positioningUv absorbanceVulcanization

Owner:郑州翱翔医药科技股份有限公司

Epoxy Adhesives for Concrete Wet Surfaces

ActiveCN110922925BGood flexibilityImprove hydrophobicityNon-macromolecular adhesive additivesEpoxy resin adhesivesPolymer sciencePalygorskite

The invention relates to an epoxy resin adhesive used for concrete wet surfaces, which solves the problems of high cost, high brittleness, low toughness and various performances of the existing epoxy resin adhesives. The present invention is prepared by mixing component A and component B at a ratio of 2 to 4:1, wherein the component A includes the following raw materials in parts by weight: 100 parts of bisphenol A epoxy resin, 5 to 10 parts of palygorskite powder 15-25 parts of waste glass powder; the composition and parts by weight of the B component are: 45-65 parts of modified amine curing agent, 10-20 parts of monoamine, and 4-6 parts of thixotropic agent. The invention has simple raw materials, low cost, good flexibility, excellent hydrophobicity, low permeability, low toxicity, self-drying property and excellent bonding performance, and is especially suitable for concrete wet surfaces.

Owner:HUBEI UNIV OF TECH

A kind of rubber additive and its preparation and application

ActiveCN106866444BSimple preparation processComponent raw materials are readily availableOrganic compound preparationGroup 3/13 element organic compoundsPolymer scienceOxidation state

The present invention relates to a rubber additive and its preparation and application. The chemical structural formula of the rubber additive is: wherein, M is a metal whose oxidation state is +3 or +4, and R 1 is the aliphatic chain of C5‑C50, R 2 , R 3 and R 4 It is an aliphatic chain with 0 to 50 carbon atoms, and the amino group can be connected to R in the form of primary, secondary or tertiary ammonia. 2 , R 3 and / or R 4 Above, x is 1 or 2, y is 0 or 1, and the sum of x and y is 2. When the rubber additive of the present invention is used for rubber preparation, the obtained rubber additive can also significantly enhance the tensile strength and wet skid resistance of the rubber.

Owner:TONGJI UNIV +1

Antioxidant anticorrosion lubricating oil composition

The invention relates to a lubricating oil and especially relates to an antioxidant anticorrosion lubricating oil composition. The antioxidant anticorrosion lubricating oil composition comprises, by weight, 65-70% of mineral base oil, 5-8% of zinc dialkyl dithiophosphate-T202, 2-3% of zinc dialkyl dithiophosphate-T203, 2-3% of zinc dialkyl dithiophosphate-T204, 5-8% of thiadiazole derivative, 6-11% of polyvinyl-N-butylether, 6-8% of dialkenyl succinimide, and 0.5-1% of a pour point depressant. The antioxidant anticorrosion lubricating oil composition adopts easily available raw materials, can be produced by simple processes, is convenient for preparation, has wear, oxidation and corrosion resistance, can prevent metal oxidation and catalysis aging, delays an oil product oxidation speed, prevents contact between an acidic object and metal, produces a protection film, has wear resistance, maximally reduces engine fault caused by lubrication and prolongs an engine service life.

Owner:王沛强

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com