Epoxy Adhesives for Concrete Wet Surfaces

A technology for epoxy resin glue and concrete, which is applied in the direction of epoxy resin glue, adhesive, adhesive additive, etc., can solve the problems of unimproved material brittleness, high price, and difficulty in mass production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

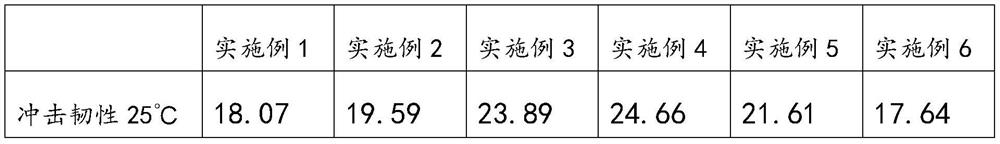

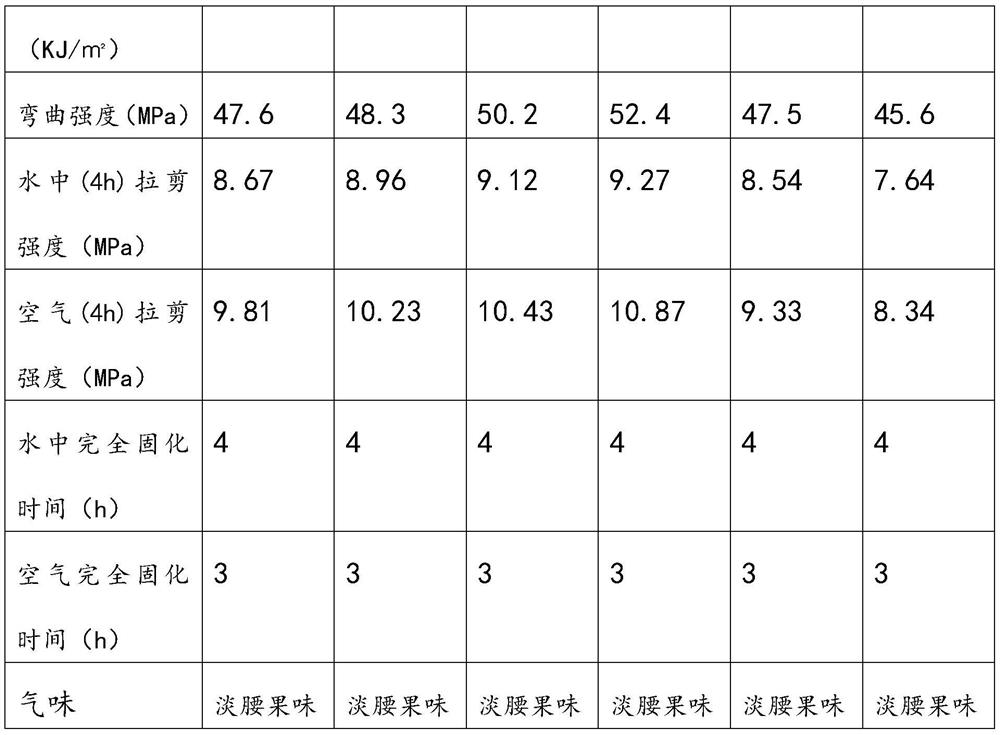

Examples

Embodiment 1

[0018] A kind of epoxy resin adhesive for wet concrete surface and preparation method thereof, its preparation method is as follows:

[0019] 1) Take 5 parts of palygorskite that has been wet-milled, centrifuged, ultrasonically dispersed, and dried, 15 parts of glass powder that has been dry-milled and wet-milled, and 100 parts of bisphenol A epoxy resin (E-51 ) are mixed and then fully stirred to obtain component A.

[0020] 2) Mix 116 parts of 1,6-hexamethylenediamine and 298 parts of cardanol, stir and heat to 35°C for 0.5h in turn, then raise the temperature to 70°C and slowly add 60 parts of formaldehyde solution with a mass fraction of 37% to 40%. After the dropwise addition of the formaldehyde solution is completed, raise the temperature to 90°C for 2 hours to fully react, vacuum filter to obtain the phenalkamine mixture, weigh 45 parts of the phenalkamine mixture, mix 10 parts of n-propylamine, 4 parts of white carbon black and the phenalkamine mixture , and stir even...

Embodiment 2

[0023] A kind of epoxy resin adhesive for wet concrete surface and preparation method thereof, its preparation method is as follows:

[0024] 1) Take 6.5 parts of palygorskite that has been wet-milled, centrifuged, ultrasonically dispersed, and dried, 17 parts of glass powder that has been dry-milled and wet-milled, and 100 parts of bisphenol A epoxy resin (E-51 ) are mixed and then fully stirred to obtain component A.

[0025] 2) Mix 130 parts of 1,6-hexamethylenediamine and 330 parts of cardanol, stir and heat in turn to 37°C for 0.7h, then slowly add 70 parts of formaldehyde solution with a mass fraction of 37% to 40% after heating up to 75°C. After the dropwise addition of the formaldehyde solution was completed, the temperature was raised to 95°C for 3 hours to fully react, and vacuum filtration was performed to obtain a phenalkamine mixture. Weighed 47 parts of the phenalkamine mixture, mixed 16 parts of n-propylamine, 5 parts of white carbon black and the phenalkamine m...

Embodiment 3

[0028] A kind of epoxy resin adhesive for wet concrete surface and preparation method thereof, its preparation method is as follows:

[0029] 1) Take 8 parts of palygorskite that has been wet-milled, centrifuged, ultrasonically dispersed, and dried, 20 parts of glass powder that has been dry-milled and wet-milled, and 100 parts of bisphenol A epoxy resin (E-51 ) are mixed and then fully stirred to obtain component A.

[0030] 2) Mix 141 parts of 1,6-hexamethylenediamine and 360 parts of cardanol, stir and heat to 40°C for 1 hour, then slowly add 75 parts of formaldehyde solution with a mass fraction of 37% to 40% when the temperature is raised to 80°C. After the dropwise addition of the solution, raise the temperature to 100°C for 4 hours to fully react, vacuum filter to obtain a mixture of phenalkamines, weigh 50 parts of the mixture of phenalkamines, mix 20 parts of n-propylamine, 6 parts of white carbon black and the mixture of phenalkamines at room temperature Stir evenly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com