Wear-resistant high-strength shoe material and preparation method thereof

A high-strength, shoe material technology, applied in footwear, applications, clothing, etc., can solve the problems of low strength, short service life, poor wear resistance, etc., achieve high tensile strength, improve tensile strength, and improve durability The effect of grinding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

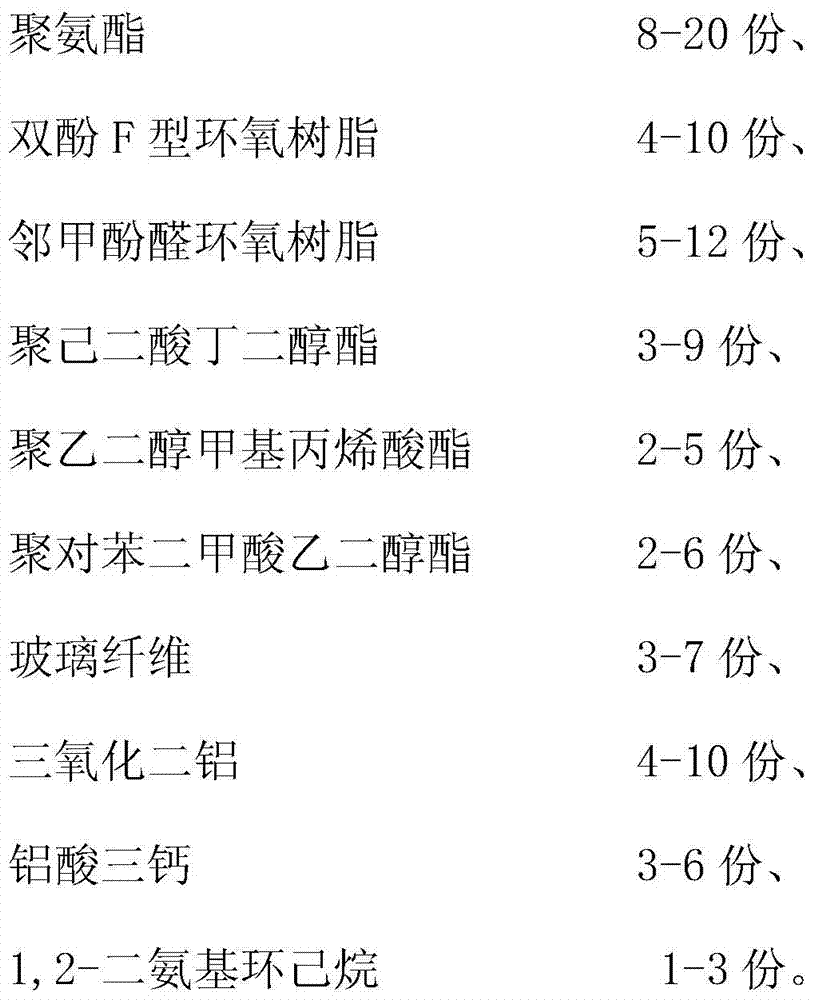

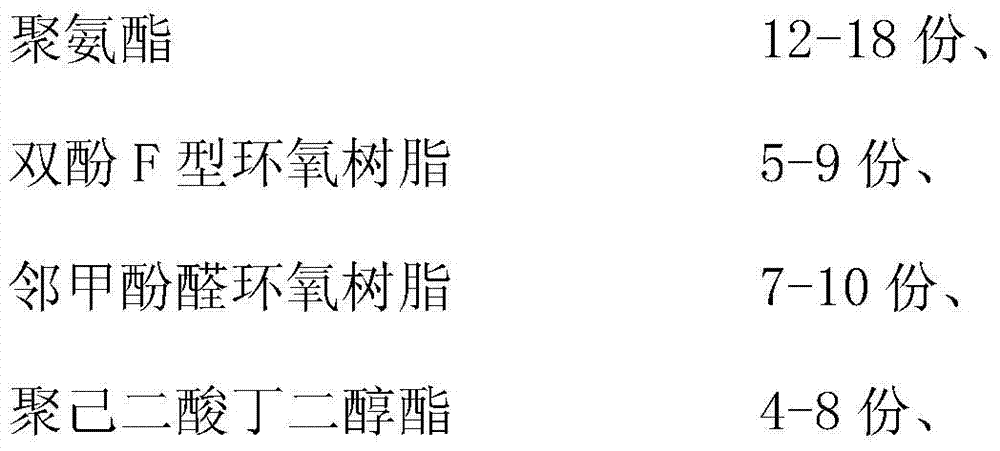

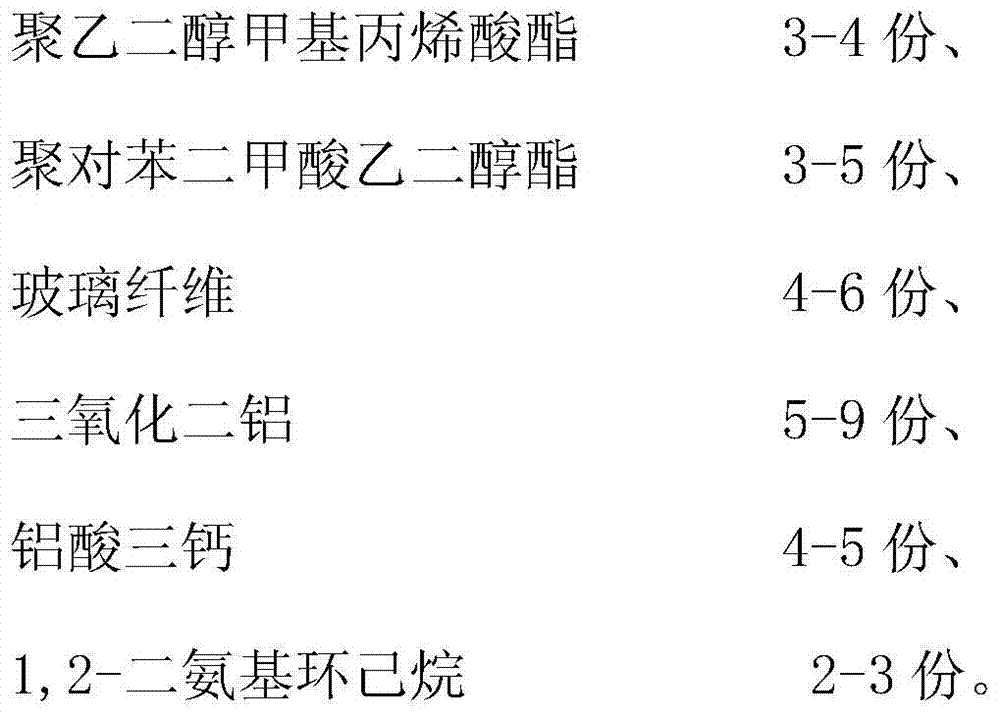

Method used

Image

Examples

Embodiment 1

[0021] (1) Aluminum oxide and tricalcium silicate are pulverized with an ultrafine pulverizer until the mesh number of aluminum oxide and tricalcium silicate is more than 150 mesh;

[0022] (2) Open the reactor, and add 20 parts of polyurethane, 4 parts of bisphenol F epoxy resin, 5 parts of o-cresol novolac epoxy resin, 9 parts of polybutylene adipate, polyethylene glycol by weight into the reactor. 5 parts of diol methacrylate, 6 parts of polyethylene terephthalate, and 3 parts of glass fiber, the temperature is raised to 70°C, and the ingredients in the reactor are stirred for 40 minutes;

[0023] (3) Slowly add 10 parts of aluminum oxide and 3 parts of tricalcium aluminate into the reaction kettle by weight, and stir for 10 minutes;

[0024] (4) Raise the temperature to 120°C, and finally add 3 parts of 1,2-diaminocyclohexane into the reaction kettle, then stir the reaction kettle for 10 minutes, and then press the shoe material into tablets to make it wear-resistant and h...

Embodiment 2

[0026] (1) Aluminum oxide and tricalcium silicate are pulverized with an ultrafine pulverizer until the mesh number of aluminum oxide and tricalcium silicate is more than 150 mesh;

[0027] (2) Open the reactor, and add 8 parts of polyurethane, 10 parts of bisphenol F epoxy resin, 12 parts of o-cresol novolac epoxy resin, 3 parts of polybutylene adipate, polyethylene glycol by weight into the reactor. 2 parts of diol methacrylate, 2 parts of polyethylene terephthalate, and 7 parts of glass fiber, the temperature is raised to 80°C, and the ingredients in the reactor are stirred for 20 minutes;

[0028] (3) Slowly add 4 parts of aluminum oxide and 6 parts of tricalcium aluminate into the reaction kettle by weight, and stir for 30 minutes;

[0029] (4) Raise the temperature to 150°C, and finally add 1 part of 1,2-diaminocyclohexane into the reaction kettle, then stir the reaction kettle for 20 minutes, and then press the shoe material into tablets to make it wear-resistant and hi...

Embodiment 3

[0031] (1) Aluminum oxide and tricalcium silicate are pulverized with an ultrafine pulverizer until the mesh number of aluminum oxide and tricalcium silicate is more than 150 mesh;

[0032] (2) Open the reactor, and add 18 parts of polyurethane, 5 parts of bisphenol F epoxy resin, 10 parts of o-cresol novolac epoxy resin, 4 parts of polybutylene adipate, polyethylene glycol by weight into the reactor. 4 parts of diol methacrylate, 3 parts of polyethylene terephthalate, and 4 parts of glass fiber, the temperature is raised to 70°C, and the ingredients in the reactor are stirred for 40 minutes;

[0033] (3) Slowly add 9 parts of aluminum oxide and 4 parts of tricalcium aluminate into the reaction kettle by weight, and stir for 10 minutes;

[0034] (4) Raise the temperature to 120°C, and finally add 3 parts of 1,2-diaminocyclohexane into the reaction kettle, then stir the reaction kettle for 10 minutes, and then press the shoe material into tablets to make it wear-resistant and h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com