Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

99results about How to "High bulkiness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

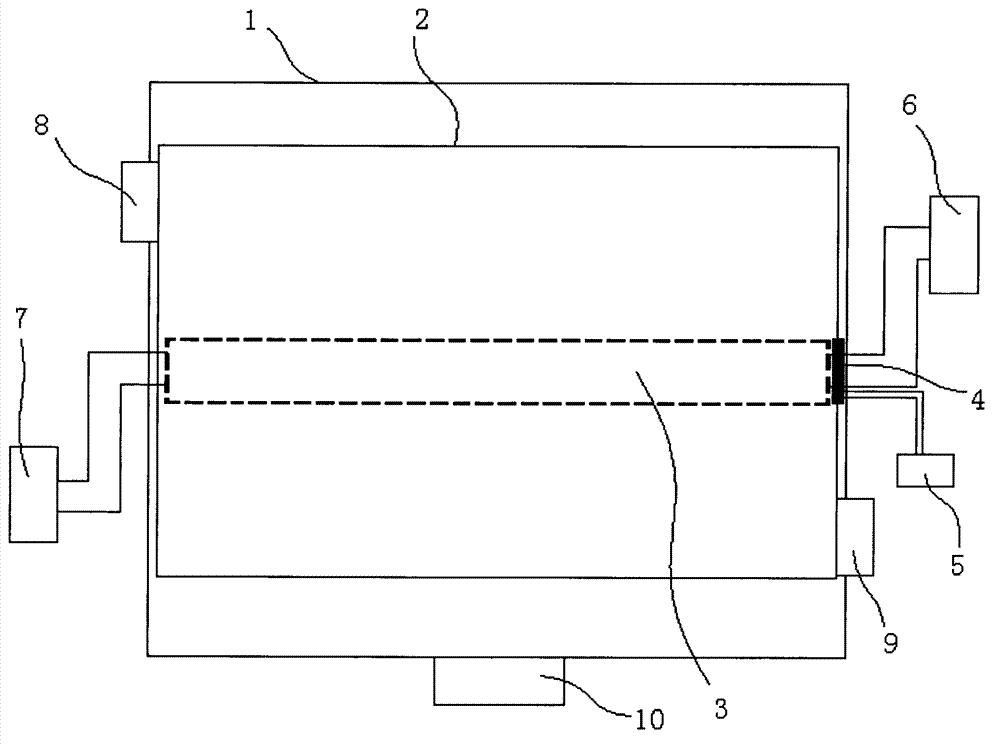

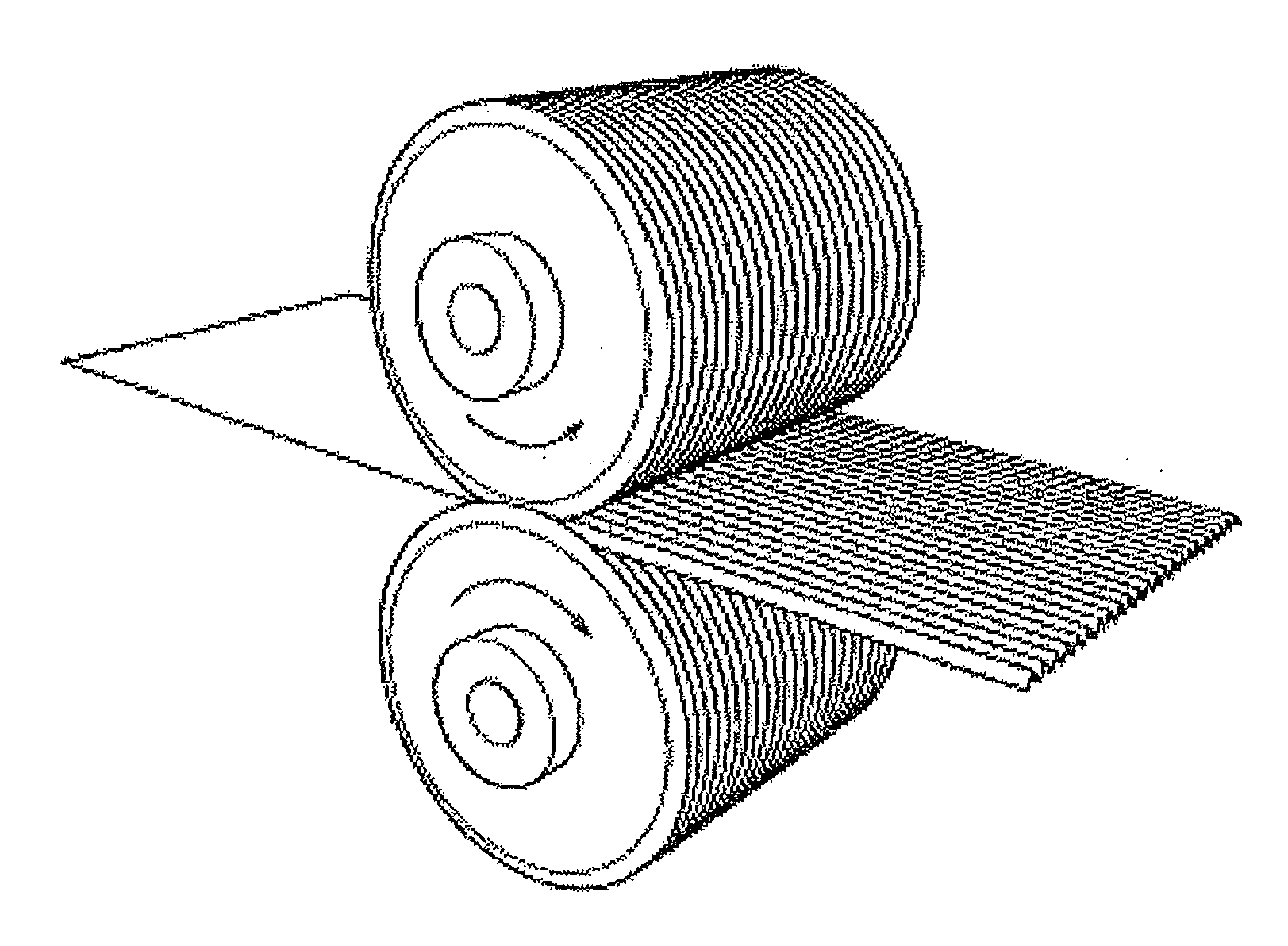

Bulking recovering method of non-woven fabric

A method for restoring bulkiness of nonwoven fabric which contains crimped thermoplastic fiber and is in a roll form is disclosed. The method comprises unwinding the nonwoven fabric from the stock roll, and blowing hot air to the unwound nonwoven fabric by a through-air technique to make the nonwoven fabric increase in bulkiness. The hot air is heated at a temperature lower than the melting point of the thermoplastic fiber and not lower than a temperature lower than that melting point by about 50 DEG C., and is blown for about 0.05 to 3 seconds.

Owner:KAO CORP

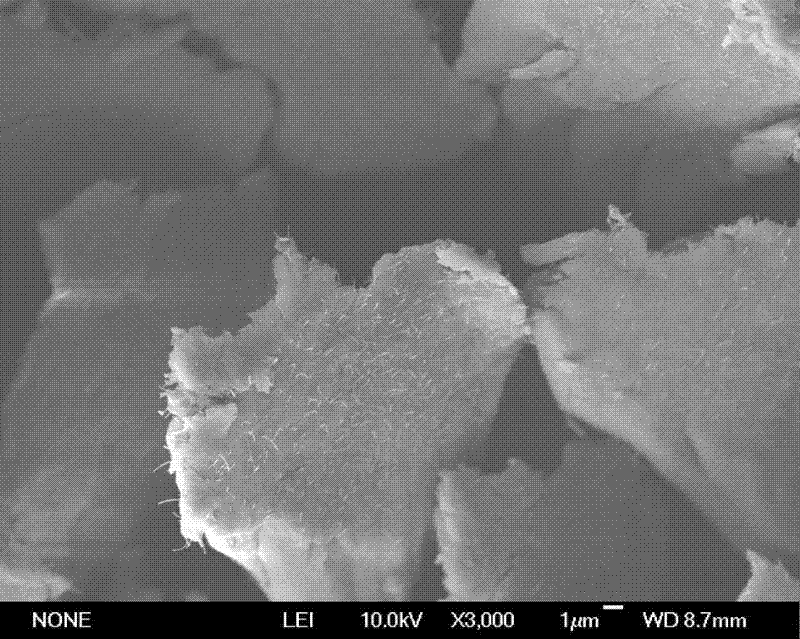

Crimped polyester fiber and fibrous structure comprising the same

InactiveCN1343271AHas curl numberHas curl rateFilament/thread formingNon-woven fabricsFiber structurePolyethylene terephtalate

A crimped polyester fiber which is made of a polytrimethylene terephthalate polyester, is three-dimensionally crimped so as to have a number of crimps of 9 to 30 per 25 mm and a percentage crimp of 20 to 50%, and has a crimp elasticity of 80% or higher; and a fibrous structure which comprises short fibers of the crimped polyester fiber and short heat-bondable composite fibers in a weight ratio of from 30 / 70 to 95 / 5 and in which at least part of the points where the two kinds of short fibers are in contact with each other and / or the points where the short heat-bondable composite fibers are in contact with each other have been thermally fixed.

Owner:TEIJIN FRONTIER CO LTD

Differential-shrinkage cotton-like composite filament and preparation method thereof

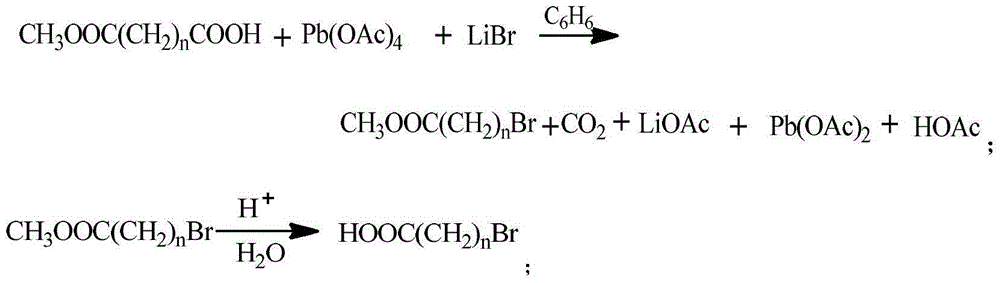

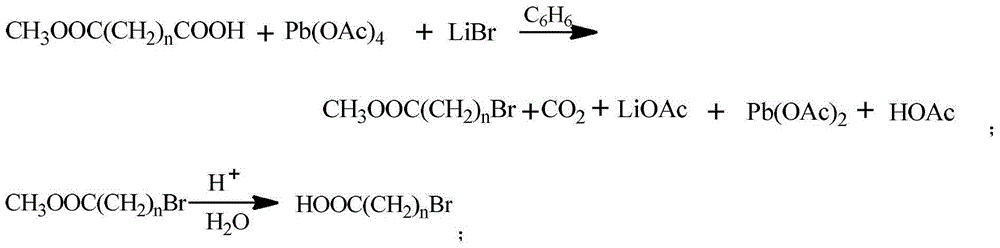

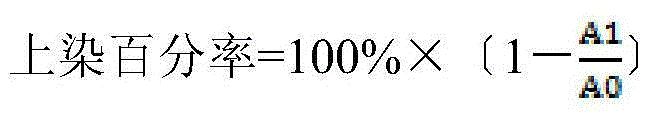

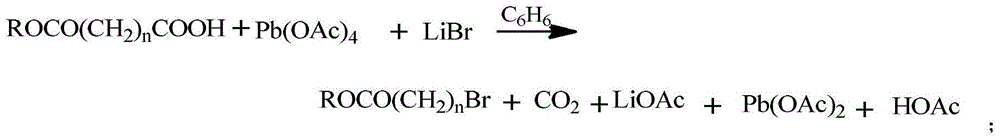

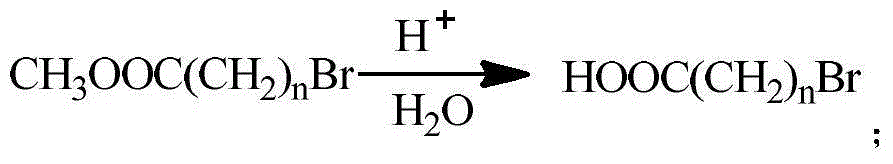

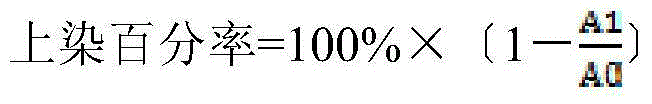

ActiveCN104562340AGood flexibilityGood compatibilityOrganic compound preparationAmino-carboxyl compound preparationPolyesterFatty acid ester

The invention relates to a differential-shrinkage cotton-like composite filament and preparation method thereof; the differential-shrinkage cotton-like composite filament is a composite filament blended by a modified polyester POY filament and a modified polyester FDY filament; the modified polyester consists of polyester and aminoadipic acid glycol ester; the aminoadipic acid glycol ester is dispersed among the molecular chains of the polyester; and the aminoadipic acid glycol ester takes effect of hydrogen bond among the molecular chains of the polyester, so as to stabilize the positions of the aminoadipic acid glycol ester with respect to the molecular chains of the polyester; in condition of the temperature is 90-130 degrees centigrade, the free volume spaces among the molecular chains inside the fiber of the differential-shrinkage cotton-like composite filament are increased by 20-30v / v%. The aliphatic ester increases the free volume of the polyester fiber in order to increase the diffusion degree of the dye, thereby increasing the dyeing performance of the polyester fiber. The differential-shrinkage cotton-like composite filament is applicable to clothes fabric, bedding article, decoration article, and the like.

Owner:JIANGSU HENGLI CHEM FIBER

Linen-like type differential shrinkage composite filament and preparation method thereof

ActiveCN104480568AGood flexibilityGood compatibilityNew-spun product collectionOrganic compound preparationFiberPolyester

The invention relates to a linen-like type differential shrinkage composite filament and a preparation method thereof. The linen-like type differential shrinkage composite filament is a composite filament prepared from modified polyester POY filaments and modified polyester FDY filaments which are subjected to fiber mixing processing; the breakage elongation of the linen-like type differential shrinkage composite filament is 40.0+ / -3.0%, the network degree of the linen-like type differential shrinkage composite filament is 95+ / -5 piece / m; the modified polyester consists of polyester and amino fatty acid gylcol ester; the amino fatty acid gylcol ester is dispersed among the molecular chains of the polyester and has a hydrogen bonding function with the molecular chains of the polyester, so that the relative positions of the amino fatty acid gylcol ester and the molecular chains of the polyester are fixed; under the condition that the temperature is 90-130 DEG C, the free volume space among the molecular chains of fiber of the linen-like type differential shrinkage composite filament is increased by 20-30v / v%. Due to adoption of the aliphatic ester, the free volume of the polyester fiber is increased, so that the diffusion degree of dye is increased, and the dyeing property of the polyester fiber is improved. The linen-like type differential shrinkage composite filament can be used in the industries such as high-class woof fabrics and clothes.

Owner:JIANGSU HENGLI CHEM FIBER

Wool-like differential shrinkage composite filament and preparation method thereof

ActiveCN104480567AGood flexibilityGood compatibilityNew-spun product collectionOrganic compound preparationPolyesterFiber

The invention relates to a wool-like differential shrinkage composite filament and a preparation method thereof. The wool-like differential shrinkage composite filament is a composite filament prepared from modified polyester POY filaments and modified polyester FDY filaments which are subjected to fiber mixing processing; the amino fatty acid gylcol ester is dispersed among the molecular chains of the polyester and has a hydrogen bonding function with the molecular chains of the polyester, so that the relative positions of the amino fatty acid gylcol ester and the molecular chains of the polyester are fixed; under the condition that the temperature is 90-130 DEG C, the free volume space among the molecular chains of fiber of the wool-like differential shrinkage composite filament is increased by 20-30v / v%. Due to adoption of the aliphatic ester, the free volume of the polyester fiber is increased, so that the diffusion degree of dye is increased, and the dyeing property of the polyester fiber is improved. The wool-like differential shrinkage composite filament can be used in the industries such as clothes fabrics, bedding articles and decorative articles.

Owner:JIANGSU HENGLI CHEM FIBER

Production method of cotton polyester interwoven spandex core-spun elastic fabric

InactiveCN103556368ADrop high temperature damageLittle strengthBleaching apparatusDyeing processPolyesterYarn

The invention relates to a production method of textiles, in particular a production method of cotton polyester interwoven spandex core-spun elastic fabric. The cotton polyester interwoven spandex core-spun elastic fabric comprises cotton, polyester and spandex. Sixteen threads of cotton are woven in the warp direction, and 150D low-elasticity interlaced yarn and 70D spandex coated yarn are woven in the weft direction. The dyeing process of the cotton polyester interwoven spandex core-spun elastic fabric sequentially includes the steps of fabric turnover, scouring retreating, single-surface singeing, oxygen bleaching, shaping, mercerizing, double dyeing of pad dyeing and dyeing in the same color and finishing. A scouring and bleaching combined production line is adopted in the steps of scouring retreating and oxygen bleaching, the fabric is subjected to six-latticed countercurrent flattening washing prior to rolling pressure so as to control the moisture content to be 45-55% and subjected to padding in oxygen-bleaching liquid for fabric bleaching; the dyeing process further includes dipping flame-retardant treatment after the finishing process, namely putting the fabric into a vacuum pressure tank to be vacuumized and enabling vacuum degree of the vacuum pressure tank to be from -0.015MPa to -0.025Mpa, and adding a fire retardant into the tank and enabling the pressure to be increased to from 0.1MPa to 0.8Mpa. The fabric is stable in size after being washed, needless of ironing and energy saving in production, and flame-retardant safety is achieved.

Owner:ZHEJIANG DAGANG PRINTING & DYEING

Preparation method of antibacterial anti-flaming protein viscose fiber

InactiveCN102304783AImprove flame retardant performanceHigh strengthMonocomponent cellulose artificial filamentWet spinning methodsViscoseSlurry

The invention discloses a preparation method of an antibacterial anti-flaming protein viscose fiber. The preparation method comprises the following steps of preparing fire retardant slurry, a protein glue liquid and a chitosan solution, mixing uniformly the fire retardant slurry, the protein glue liquid and the chitosan solution with a viscose spinning solution before spinning, preparing the antibacterial anti-flaming protein viscose fiber through wet spinning, and carrying out soft arrangement on the prepared fiber. According to the preparation method of the antibacterial anti-flaming protein viscose fiber, disclosed by the invention, the antibacterial anti-flaming protein viscose fiber is prepared from hexaphenoxy cyclotriphosphazene as a fire retardant, alkyl polyglycoside as an emulsifier of the fire retardant, animal protein as a protein raw material, and chitosan as an antibacterial agent, has excellent flame retardant property and is up to the national textile anti-flaming standard; and meanwhile, the service performance and antibacterial property are excellent, the wet strength of the fiber is improved by more than 20%, the initial modulus is reduced by more than 30%, and the bulking intensity is improved by more than 8%.

Owner:TAIYUAN UNIV OF TECH

Production technology of the best down feather hanging down feather and hanging down feather screening device

The invention belongs to the technical field of down feather deep processing and particularly relates to a production technology of the best down feather hanging down feather and a hanging down feather screening device. The hanging down feather screening device is provided with a screening box body, a roller screen is arranged inside the screening box body, a blowing leakage tube is arranged in the middle of the roller screen, two ends of the roller screen are connected with a drive motor through a rolling shaft, at least one of two ends of the blowing leakage tube is connected with an air blower, screening holes are evenly formed in the surface of the roller screen, and air leakage holes are evenly formed in the surface of the blowing leakage tube. The feather and down feather row materials are sequentially processed by a preliminary classification process, a dust removing process, a water washing process, a drying process and a hanging down feather screening process. On the basis of the existing down feather processing technology, technological innovation is conducted to be combined with the hanging down feather screening technology, the down feather produced by white gooses in western Anhui is used as raw materials, and thereby down feather content of the screened hanging down feather is close to 100%, wherein the down feather has unique qualities such as big down feather flower, high bulkiness and extremely good quality.

Owner:六安皖智知识产权运营有限公司

Woody feed fermenting and enzymolyzing prepn process

InactiveCN1739373AImprove absorption rateGood flexibilityFood processingAnimal feeding stuffDigestionEnzyme

The present invention relates to feed preparing technology, and is especially woody feed fermenting and enzymolyzing preparation process. The present invention features that intermediate peashrub is crushed and mixed with concentrated material in 20-25 wt% of intermediate peashrub, activated compound enzyme in 3-4 wt% and Shengtaibao or EM bacterial preparation in 0.1-0.2 wt%, and the mixture is sealed and fermented to reach pH 4.0-5.0 to obtain the woody feed. The woody feed has the advantages of rich nutrients, easy digestion, feeding safety, low cost, etc.

Owner:SHENYANG INST OF APPL ECOLOGY CHINESE ACAD OF SCI

Instant jujube power and preparation method thereof

InactiveCN103431323AIncrease viscosityImprove stabilityFood shapingFood preparationSlurryHeat sensitive

The invention discloses instant jujube power and a preparation method thereof and belongs to the technical field of processing of foods. The instant jujube power comprises the following components in percentage by weight: 40-50 percent of concentrated jujube slurry solid, 30-40 percent of maltodextrin, 10-20 percent of white sugar power, 0.2-1.0 percent of sodium carboxymethylcellulose and 0.2-1.0 percent of cane sugar tallate, and the instant jujube power is formed by slurry homogenization, drying, crushing and filtering the components. The preparation method adopts vacuum and low-temperature drying, and is short in time, high in expansion ratio, less in the loss of nutritious substances in the instant jujube particles, and better in storage of heat sensitive components particularly Vc; in addition, small particles formed after crushing are not easy to cake and cluster, the instant dissolving performance is good, the instant jujube power can be infused into a thick solution without sediment, and the mouth feeling is spicy and sweet, natural and refreshing.

Owner:SHAANXI UNIV OF SCI & TECH

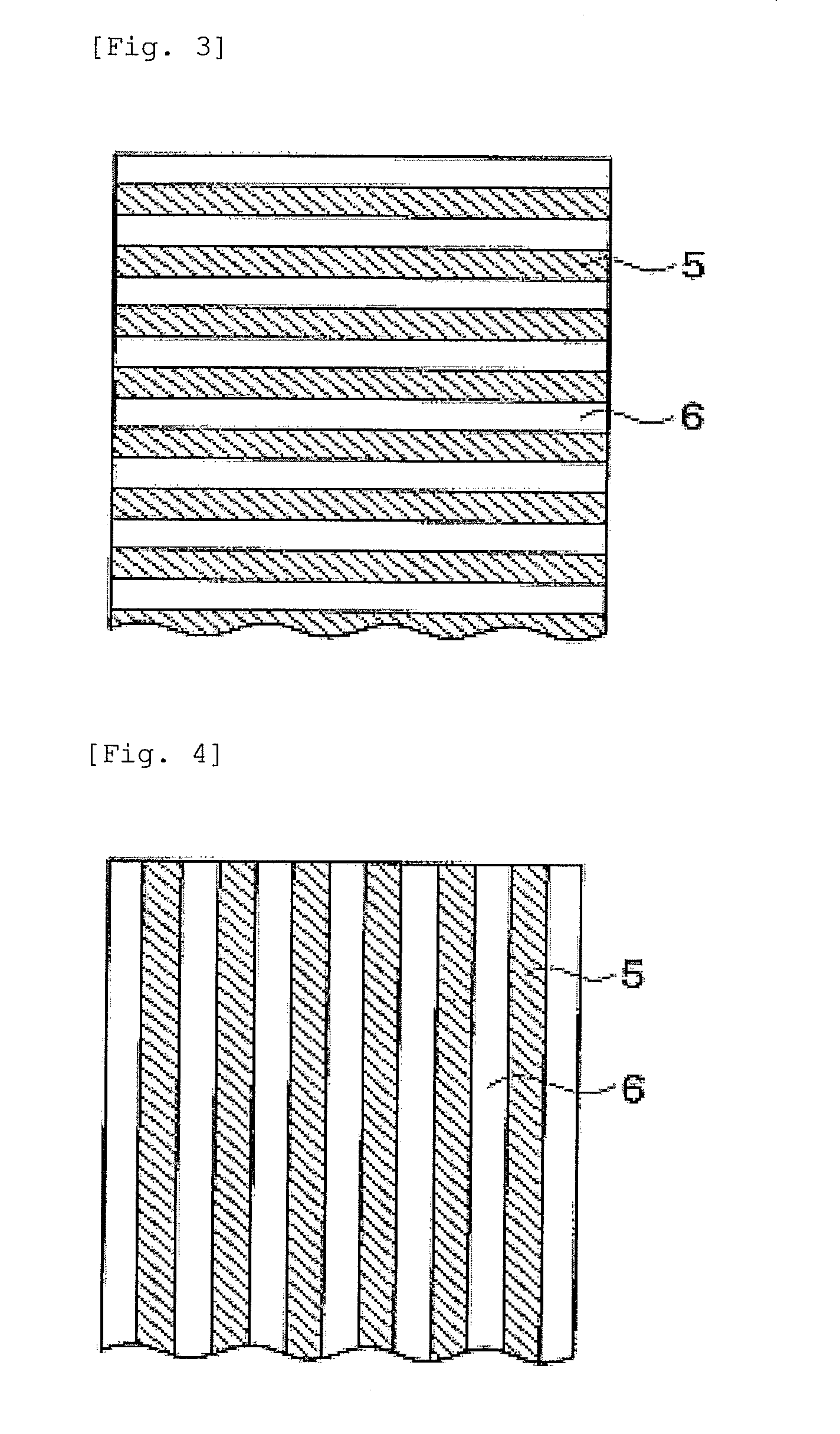

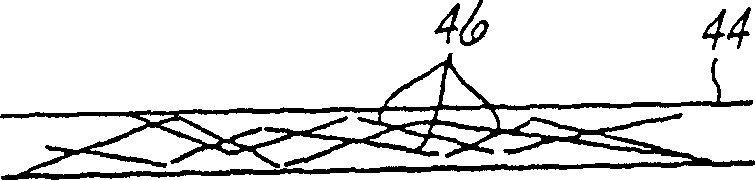

Mixed fiber spunbonded nonwoven fabric, and method for production and use thereof

InactiveUS20120164908A1Improve bulkImprove hydrophilicityFilament/thread formingWoven fabricsNonwoven fabricMaterials science

A mixed fiber spunbonded nonwoven fabric which comprises 90 to 10% by weight of a long fiber of thermoplastic resin (A) that has been hydrophilization-treated and 10 to 90% by weight of a long fiber of thermoplastic elastomer (B) and which has a strength ratio [the ratio of a strength at 20% of an elongation at a maximum strength (elongation at a maximum point) to the maximum strength] in at least one direction of not more than 40% and a bulk density of 0.10 to 0.40 g / cm3. The fabric can exhibit excellent initial hydrophilicity, long-lasting hydrophilicity, liquid dispersibility, liquid transpiration property, moisture permeability, breathability, softness, resistance to fluff, stretchability and touch, and low stickiness, and is suitable for sheets constituting absorbent articles such as sanitary napkins, panty liners, incontinence pads, and disposable diapers. A production method is also provided.

Owner:MITSUI CHEM INC

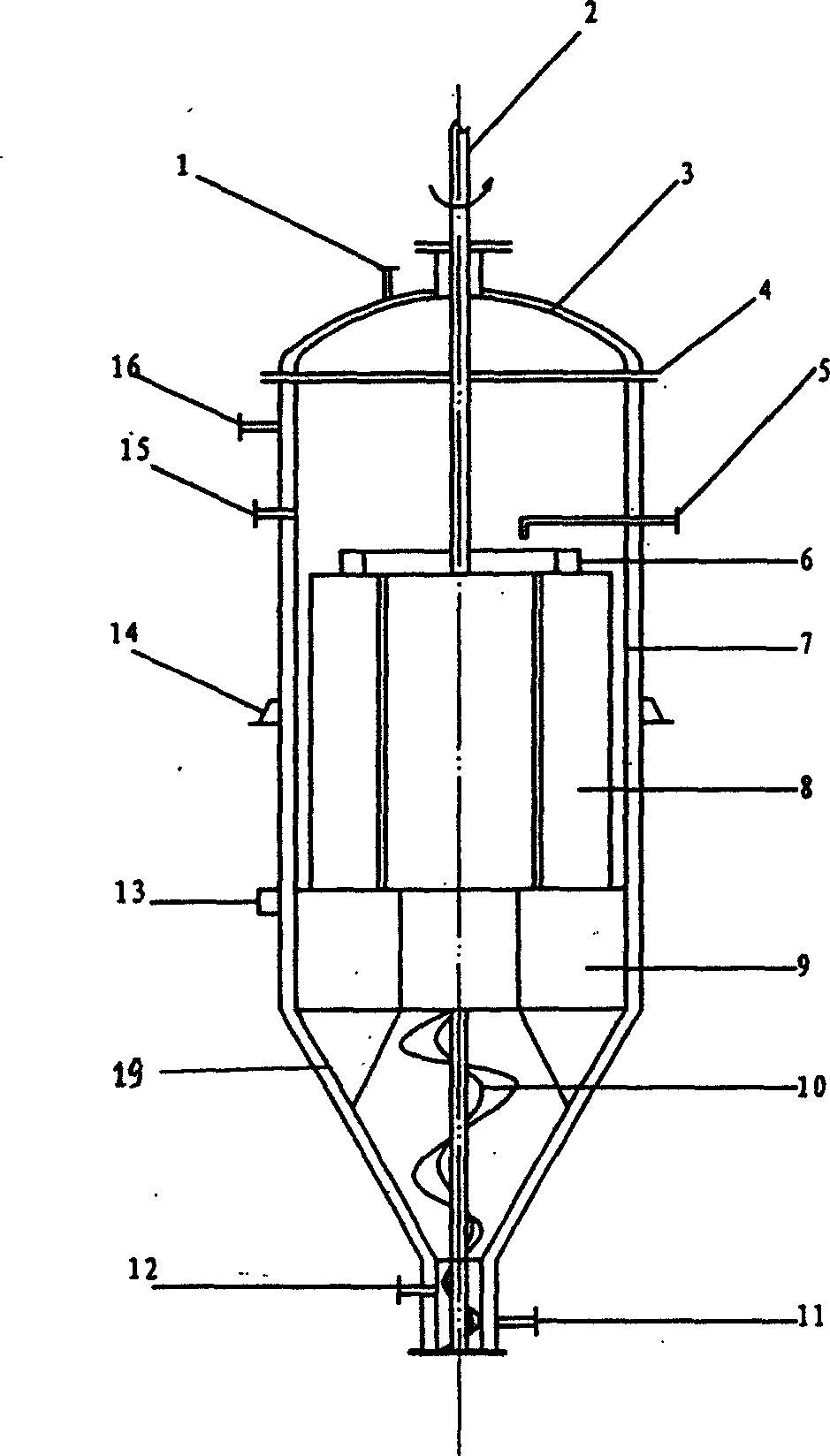

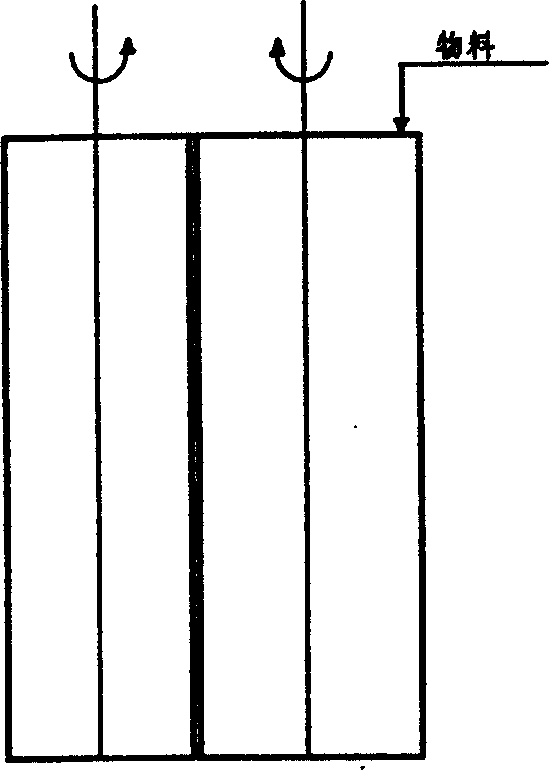

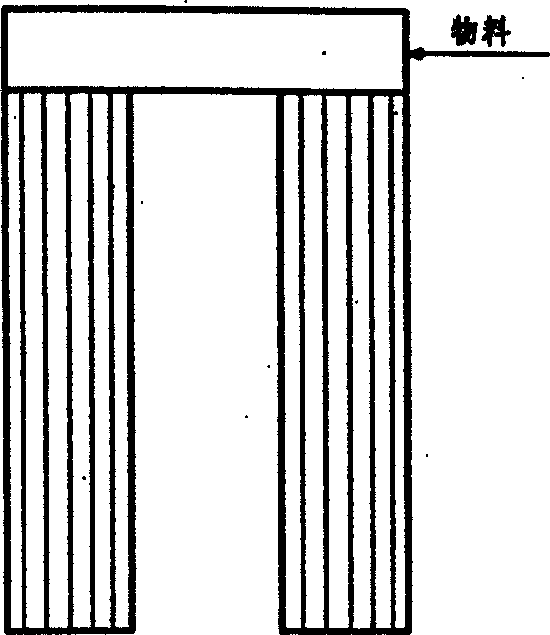

Liquid-phase continuous condensation polymerization apparatus of high-viscosity polyester (PET)

InactiveCN1470546AMeet the special requirements of mixing systemsReduce manufacturing costChemical/physical/physico-chemical stationary reactorsPolyesterVacuum pumping

The present invention discloses a high-viscosity polyester (PET) liquid phase continuous polycondensation production equipment, which utilizes the motor mounted in the top of reactor to drive the rotating shaft fixed in bottom of reactor and top of reactor by bearings, and in the reactor a self-cleaning stirring system formed from planetary gear and helicoid, a devolatilization system and vacuum-pumping pipeline are mounted, and the exterior of the reactor is closed to a homogenization viscosity-increasing reactor which is heated by biphenyl steam. Said reactors can be individually operated, also can be series-connected or parallelly-connected together for operation, and the material can be fed into and discharged out between all the reactors by means of metering pump.

Owner:王泽新

Production method of spandex core-spun elastic fabric

InactiveCN103541182AClothing with superior performanceDimensionally stableSingeingHeating/cooling textile fabricsYarnPolyester

The invention relates to a textile and in particular relates to a production method of a spandex core-spun elastic fabric. The spandex core-spun elastic fabric comprises cotton, polyester and spandex, blended yarns formed by sixteen cotton fibers and bamboo fibers are arranged in warp direction, the content of the cotton fibers is 50%-70%, the content of the bamboo fibers is 30%-50%, and 150D low-elasticity network yarns and 70D covered spandex are arranged in weft direction. A dyeing process comprises the steps of turning cloth, singeing of a single side, scouring and bleaching, sizing, mercerizing, disperse hot melting dyeing and after finishing; the singeing of the single side is concretely singeing by a gas, singeing is carried out twice on the front of two fire holes, and a processing speed is 80-85 m / min; the blended yarns formed by the cotton fibers and the bamboo fibers are subjected to bamboo vinegar treatment, and the bamboo vinegar treatment comprises primary bamboo vinegar treatment and secondary bamboo vinegar treatment, wherein the primary bamboo vinegar treatment comprises the step that the blended yarns are immersed in a first bamboo vinegar treating fluid at the temperature of 60-70 DEG C for 10-15 minutes, and the secondary bamboo vinegar treatment comprises the step that the blended yarns are immersed in a secondary bamboo vinegar treating fluid at the temperature of 85-90 DEG C for 3-8 minutes. The spandex core-spun elastic fabric product is stable in dimension after being washed, does not need to be ironed and is high in antibacterial rate.

Owner:ZHEJIANG DAGANG PRINTING & DYEING

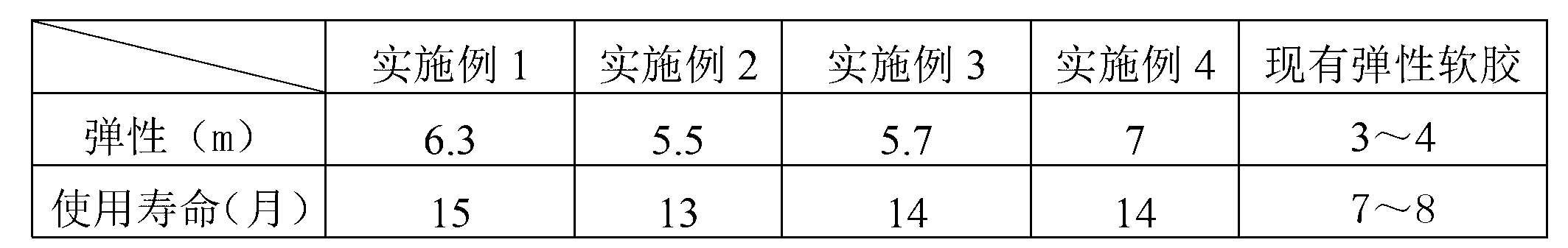

Elastic flexible glue and preparation method thereof

The invention relates to elastic material for preparing elastic and flexible toys, and particularly relates to elastic flexible glue. The elastic flexible glue comprises the following components by weight percentage: simethicone, super fine calcium carbonate, boric acid, TPR (thermal plastic rubber), zinc stearate, silicon resin, bentonite, barium carbonate, linseed oil and erucyl amide. The elastic flexible glue provided by the invention has good elasticity and proper bulking intensity; the surface of the elastic flexible glue is smooth, good in hand feel, adhesive, and tough, and has good aging resistance, high stability and long service life that is from 13 to 15 months; and the elastic and flexible toys made of the elastic flexible glue have high quality, and are playable and durable.

Owner:杜京财

Calcium sulfate composite oxidant for fireworks and crackers and preparation method thereof

The invention relates to a calcium sulfate composite oxidant for fireworks and crackers and a preparation method thereof, belonging to the technical field of chemical raw materials of the industry of the fireworks and crackers. The oxidant takes calcium sulfate and iron oxide as a main body assisted by barium nitrate, takes potassium permanganate and potassium perchlorate as initiators, and is added a small amount of an active agent. The preparation method comprises the following steps: roasting gypsum (calcium sulfate dihydrate), smashing, adding a mixed powder body of potassium permanganate and potassium perchlorate, grinding, smashing iron oxide, adding the active agent into the iron oxide powder, and then adding barium nitrate and grinding; and uniformly mixing the two types of ground powder. One of main raw materials of the invention is calcium sulfate which is non-toxic and has low price, and after being roasted the calcium sulfate, the calcium sulfate is not only an oxidant but also a moisture-proof agent and a leavening agent and also is a mechanical sensitivity buffer which is fine and smooth and slippery. Since the composite oxidant of the invention is prepared into the fireworks and crackers according to the traditional method, the fireworks and crackers has the advantages that the burning property is good, the safety is strong, the friction sensitivity and impact sensitivity are zero, and the production cost is greatly reduced.

Owner:谢新佑

Cotton polyester interwoven spandex core-spun elastic fabric

InactiveCN103556366AHigh elastic modulusHigh bulkinessSingeingHeating/cooling textile fabricsPolyesterYarn

The invention relates to textiles, in particular to cotton polyester interwoven spandex core-spun elastic fabric. The cotton polyester interwoven spandex core-spun elastic fabric comprises cotton, polyester and spandex. Sixteen threads of cotton are woven in the warp direction, and 150D low-elasticity interlaced yarn and 70D spandex coated yarn are woven in the weft direction. The dyeing process includes the steps of fabric turnover, desizing, single-face singeing, oxygen bleaching, shaping, mercerizing, double dyeing of pad dyeing and dyeing in the same color and finishing, wherein a scouring and bleaching combined production line is adopted in the steps of scouring retreating and oxygen bleaching. The fabric is subjected to six-latticed countercurrent flattening washing prior to rolling pressure so as to control moisture content to be 45-55% and subjected to padding in oxygen-bleaching liquid for fabric bleaching; a scouring retreating and bleaching combined machine arranged in the scouring and bleaching combined production line comprises a desizing machine and an oxygen-bleaching machine, the desizing machine comprises a first desizing-machine washing section, a desizing-machine steaming box and a second desizing-machine washing section, the oxygen-bleaching machine comprises an oxygen-blenching-machine washing section, an oxygen-blenching-machine steaming box, a drying cylinder, a heat exchanger, a desizing-machine filter box, a desizing-machine return water pump, an oxygen-bleaching-machine filter box and an oxygen-bleaching-machine return water pump. The fabric is stable in size after being washed, needless of ironing and energy saving in production.

Owner:ZHEJIANG DAGANG PRINTING & DYEING

Thermochromic bio-magnetic skin-care mask base material and making method thereof

InactiveCN108578254APromote blood circulationImprove microcirculationCosmetic preparationsElectrotherapyEngineeringColor changes

The invention discloses a thermochromic bio-magnetic skin-care mask base material, which comprises a piece of base cloth, as well as a thermochromic layer and bio-magnetic particles which are arrangedon the base cloth. According to the thermochromic bio-magnetic skin-care mask base material provided by the invention, reversible color change can be presented, so that an acting effect of the skin-care base material facial mask on skin can be directly indicated, and a utilization rate on nutritive substances in the facial mask can be improved; and in addition, a user can be scientifically guidedin using the facial mask at proper temperature, so that skin injury is prevented.

Owner:雅弗生物实验室有限公司

Yarn spinning method of heat-accumulation and heating fiber blended and bulked double-layered-structure yarns

The invention discloses a yarn spinning method of heat-accumulation and heating fiber blended and bulked double-layered-structure yarns. The yarn spinning method comprises the following steps: selection of raw materials and a blending ratio; a blended yarn spinning process; a yarn spinning process; a vinylon dissolving process. The formation of hollow parts of the double-layered-structure yarns actually comprises two aspects that in one aspect, the hollow parts are formed through dissolving water-soluble vinylon with hot water; in the other aspect, in a hot water treatment process, an irreversible heat shrinkage rate generated by high shrinkage acrylic fibers is more than a heat shrinkage rate generated by outer wrapping short fibers, so that the bulkiness and the hollow degree are also increased on the basis of previous hollow parts.

Owner:徐州银宇纺织有限公司

Instant donkey-hide glue powder and preparation method thereof

InactiveCN101912419ABeautiful colorHigh bulkinessPowder deliveryUnknown materialsEconomic benefitsProduct property

The invention relates to instant donkey-hide glue powder and a preparation method thereof. The preparation method for the instant donkey-hide glue powder comprises the following steps: heating and dissolving finished donkey-hide glue in water, adding a proper amount of tween-20, glycerin monostearate and a proper amount of sweetener according to a proportion, drying under the conditions of low temperature and vacuum, and smashing to obtain a finish product. The finished product instant donkey-hide glue powder retains original active constituents and color of the donkey-hide glue and dispersibility thereof is reduced from 154s to 15s, thereby obviously improving the instant of the donkey-hide glue powder in water and effectively removing the original fishy smell of the donkey-hide glue. The method has less equipment investment, simple and practicable technology, stable product property, convenient eating and high economic benefit, and is an ideal method for producing the instant donkey-hide glue powder.

Owner:SHAANXI UNIV OF SCI & TECH

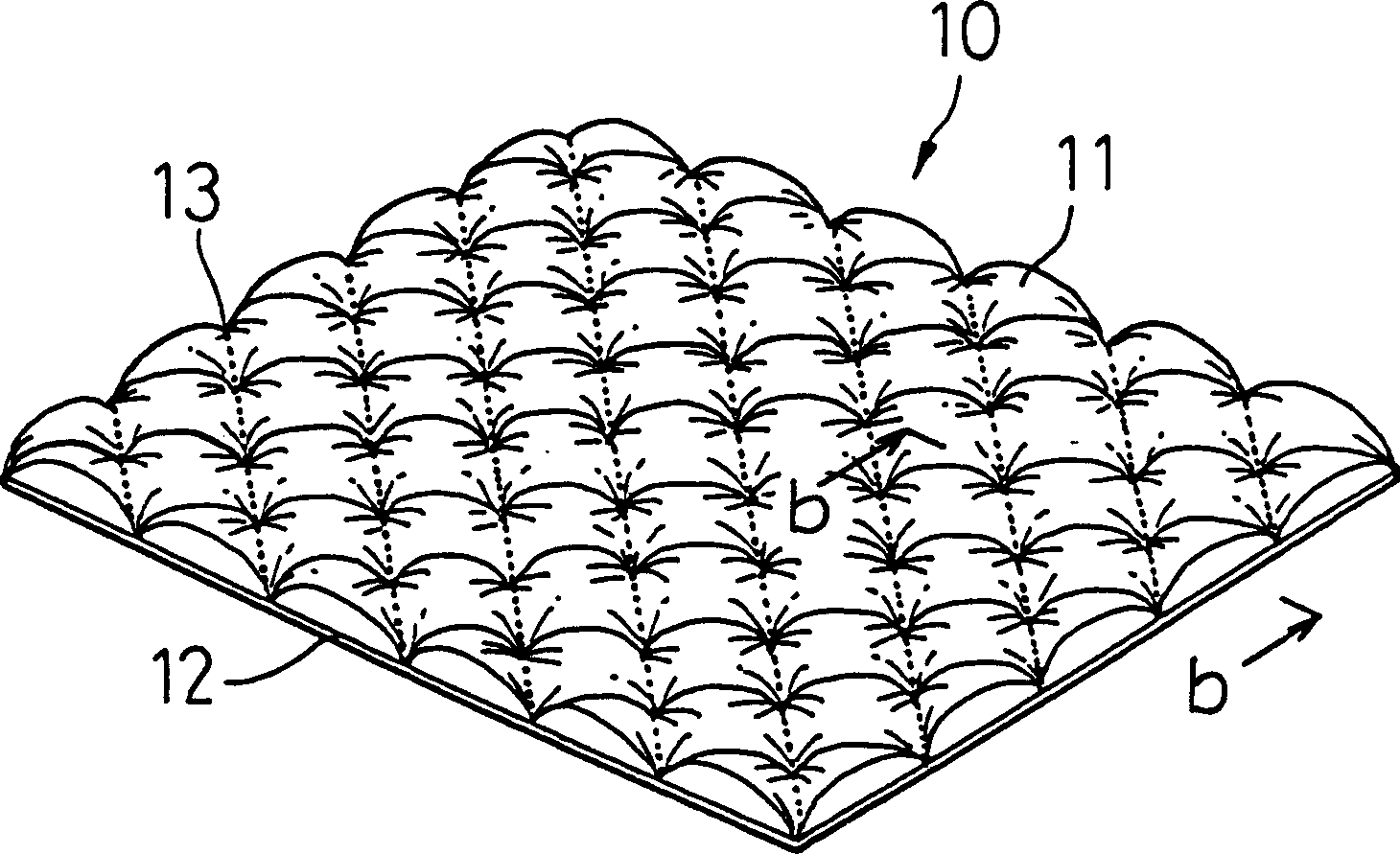

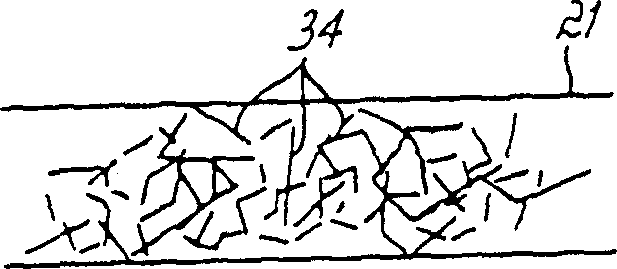

Method of forming high-loft spunbond non-woven webs and product formed thereby

InactiveCN1550603AImprove performanceReduce basis weightHeating/cooling textile fabricsWoven fabricsEngineeringPolymer

A method of forming a plurality of substantially-continuous and uninterrupted multi-component filaments for use as a high-loft non-woven web. The multi-component filaments include at least two polymers of different melt flow rates, which imparts latent crimp in each filament. After collection, the latent crimp of the filaments is activated either thermally or by applying tension to the non-woven web.

Owner:NORDSON CORP

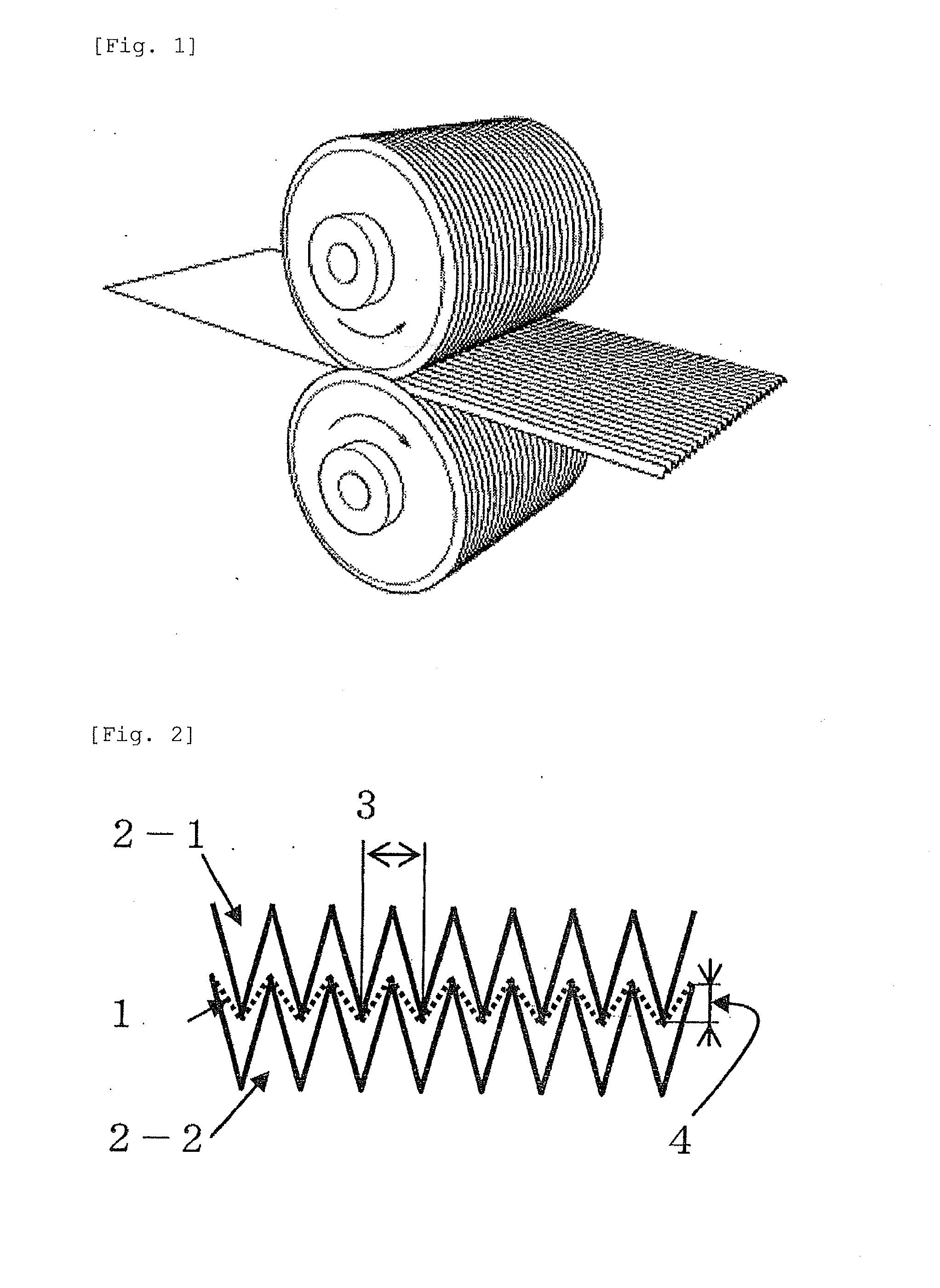

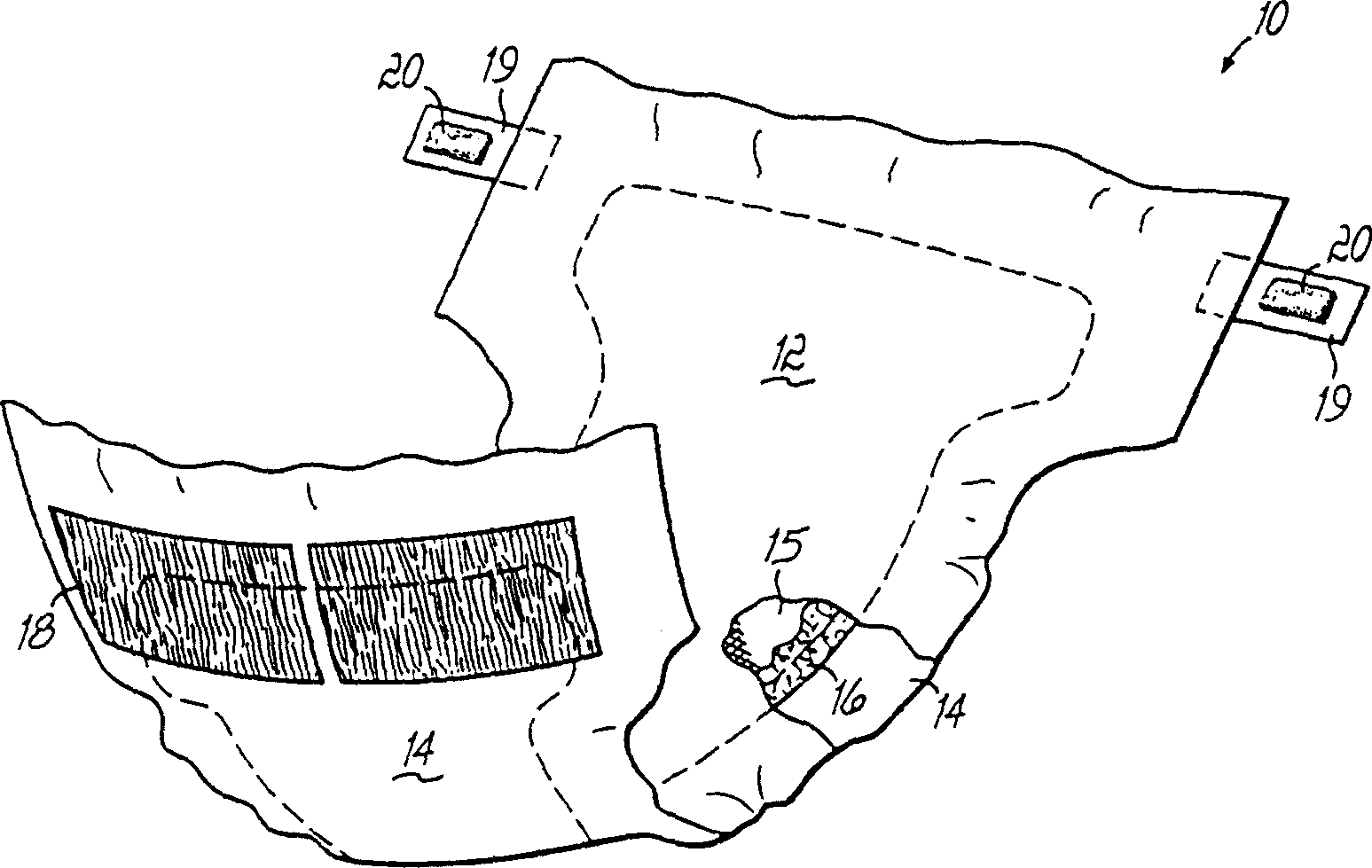

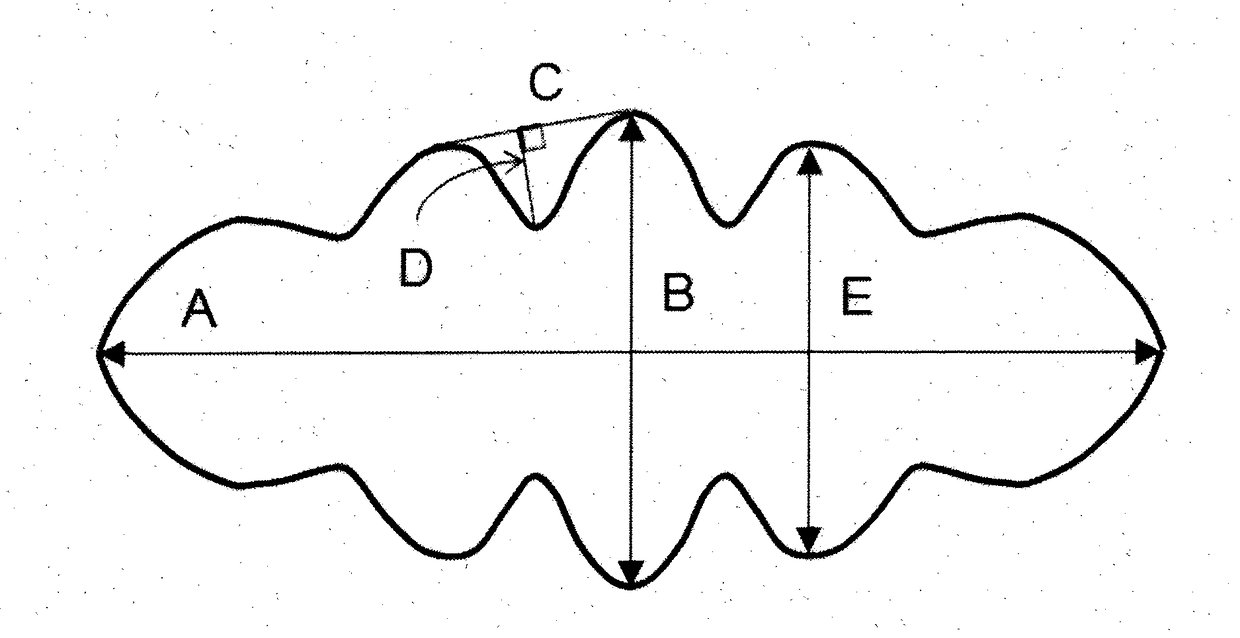

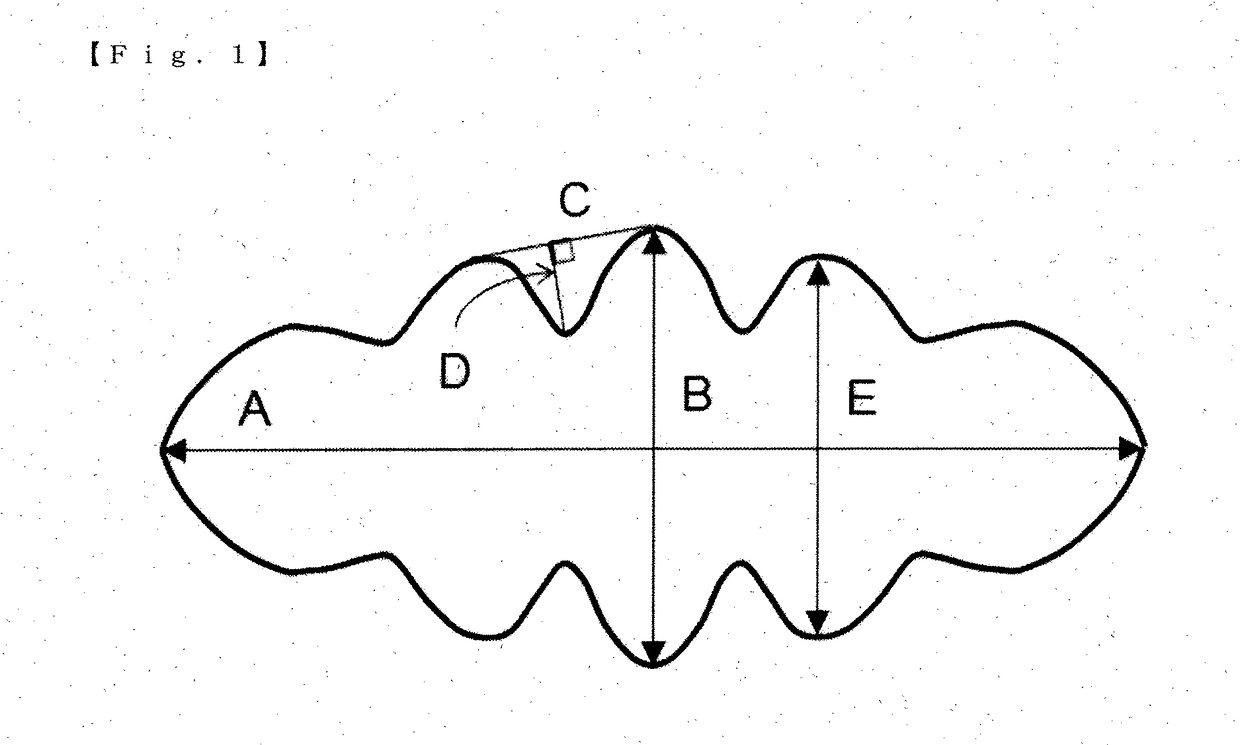

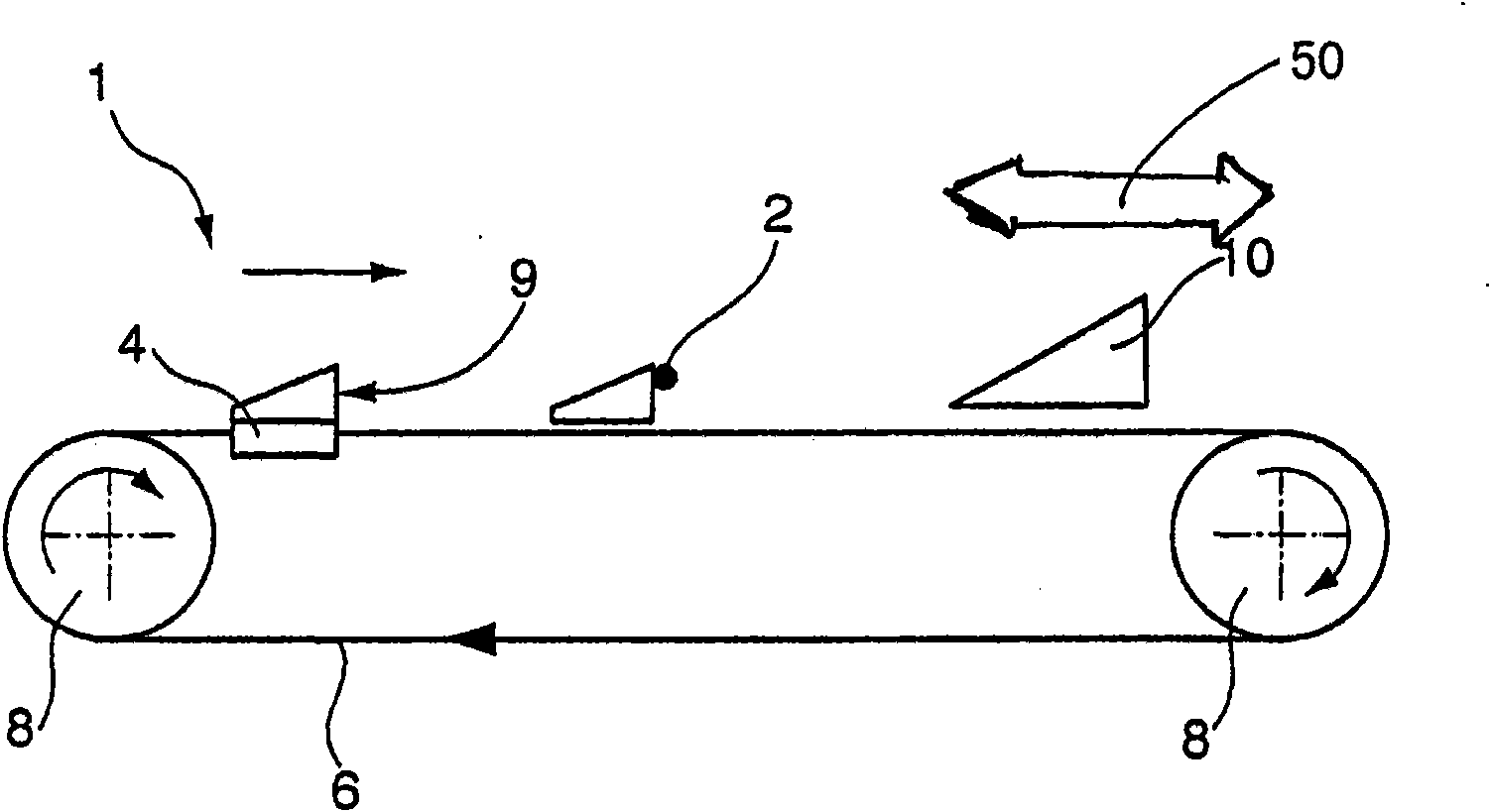

Web member cutting apparatus for cutting web member that has a plurality of fibers including tows and web member cutting method

ActiveUS20130305891A1Good cutting performanceHigh bulkinessMetal working apparatusFiberMechanical engineering

A web-member cutting apparatus for cutting a web member at intervals in a transport direction includes: an intermittent transport mechanism for intermittently transporting the web member in the transport direction; a disc-like rotatable blade member for cutting the web member by moving along an intersecting direction while rotating about a rotation shaft during a suspension period of transport of the web member, and a downstream pressing member for regulating movement of the web member by pressing the web member against the intermittent transport mechanism at a position downstream from a target cut position in the transport direction throughout a period during which the rotatable blade member is cutting the web member.

Owner:UNI CHARM CORP

Method for producing cocoon fiber quilt for dermatitis prevention

InactiveCN101536852AHigh resilienceStrong moisture permeabilityAnthropod material medical ingredientsFibre treatmentHerbFiber

The invention discloses a method for producing cocoon fiber quilt for dermatitis prevention, relating to the production process of health-care cocoon fiber quilt. The method is characterized in that cicada shell, frutus cnidii, perilla shell, glabrous greenbrier rhizome, fructus leonuri, lightyellow sophora root, rhizoma atractylodis, zaocys dhumnade, stiff silkworm, white snail, cocklebur, unprocessed polygonum and red paeonia are decocted by water, filtered to obtain Chinese herb liquid, and silk floss is dipped in the mixed liquid consisting of swelling agent, silk softening agent and the Chinese herb liquid, dried and solidified into cocoon fiber cotton containing medicament. The invention is capable of regulating the microcirculation of organism and promoting the absorption by human body with the smell of Chinese herb, and has the function of dermatitis prevention.

Owner:江苏丝乡丝绸股份有限公司

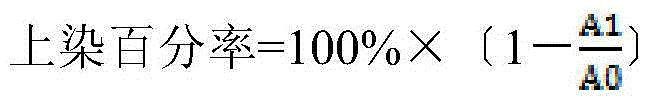

Low-color-difference polyester wool-like different-shrinkage complex yarn and preparation method thereof

ActiveCN105648570ASmall coefficient of thermal degradationReduce generationNew-spun product collectionMelt spinning methodsPolyesterYarn

The invention relates to low-color-difference polyester wool-like different-shrinkage complex yarn and a preparation method thereof. The low-color-difference polyester wool-like different-shrinkage complex yarn is prepared through carrying out fiber intermingling on low-color-difference polyester POY (Pre-Oriented Yarn) and low-color-difference polyester FDY (Fully Drawn Yarn), wherein the low-color-difference polyester POY forms small yarn loops which surround the low-color-difference polyester FDY; the low-color-difference polyester POY and the low-color-difference polyester FDY are made from polyester through carrying out dissolving and washing and then carrying out spinning. The low-color-difference polyester wool-like different-shrinkage complex yarn has the rupture strength not lower than 3.0cN / dtex, the breaking elongation of 40.0+ / -3.0%, the crimp contraction of 5.50+ / -3.0%, the interlacing degree of 95+ / -5 / m, the fiber number of 150dtex to 300dtex and the color difference [delta]E smaller than 0.200. According to the low-color-difference polyester wool-like different-shrinkage complex yarn and the preparation method thereof, ethylene glycol magnesium is relatively mild and has a very small thermal degradation coefficient, and the oligomers are reduced during polymerization and are further reduced during washing, so that during the dyeing and postprocessing thermosetting of polyester fibers, the amount of the oligomers migrating to the outside of the fibers from the inside is reduced, the occurrence of color spots and streaks is reduced, and the level dyeability and rubbing fastness of the fibers are guaranteed.

Owner:JIANGSU HENGLI CHEM FIBER

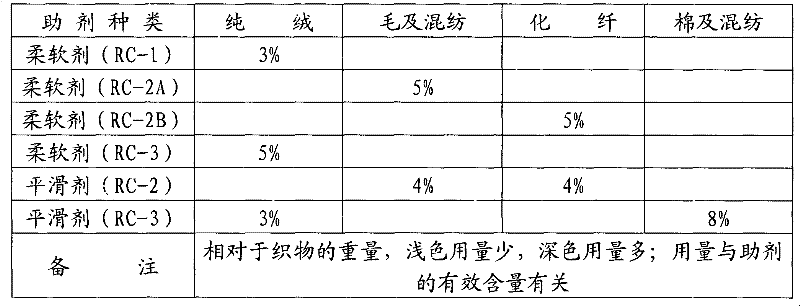

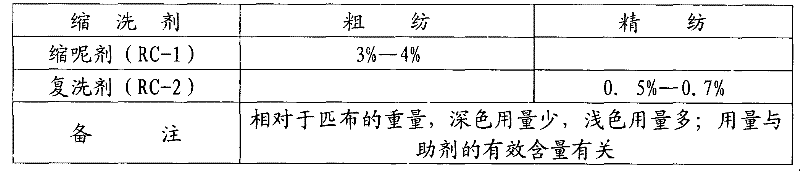

Low-temperature after finishing method of textiles

ActiveCN102392342AGood softnessReduced pillingFibre treatmentDry-cleaning apparatus for textilesChemistryCarbon dioxide

The invention provides a low-temperature after finishing method of textiles. The method comprises the following steps: (1) washing and milling treatment in an industrial washing machine: adding 0.5-4.0% of washing and milling agent, firstly soaking the textiles for 0-30 minutes, then stirring the textiles for 2-40 minutes, then carrying out deep dehydration and rinsing for 1-10 minutes and then carrying out deep dehydration, wherein the weight ratio of water to the textiles is (1:1)-(1:25) according to the types of the textiles and the water temperature is 0-20 DEG C (normal temperature); (2) softening treatment in the industrial washing machine: adding 3.0-5.0% of softening agent and 2.0-8.0% of smoothening agent, firstly soaking the textiles for 0-30 minutes, then stirring the textiles for 0-40 minutes and carrying out moderate dehydration, wherein the weight ratio of water to the textiles is (1:15)-(1:25) and the water temperature is 0-20 DEG C (normal temperature); (3) drying the textiles at 70-90 DEG C in a special oven for spinning; and (4) ironing (decatizing) and setting the textiles. The method has the following beneficial effects: energy consumption and carbon dioxide emission can be reduced, the fibers can be protected, weight loss of the textiles can be reduced and the production efficiency can be improved; the method is simple and practical; and the textiles have good softness, bulkiness and smooth and glutinous feel and are seldom subjected to pilling. The method plays an active role in promoting increase of economic benefits in the cashmere processing industry and green development of the spinning industry.

Owner:INNER MONGOLIA RIHONGKE IND TRADE

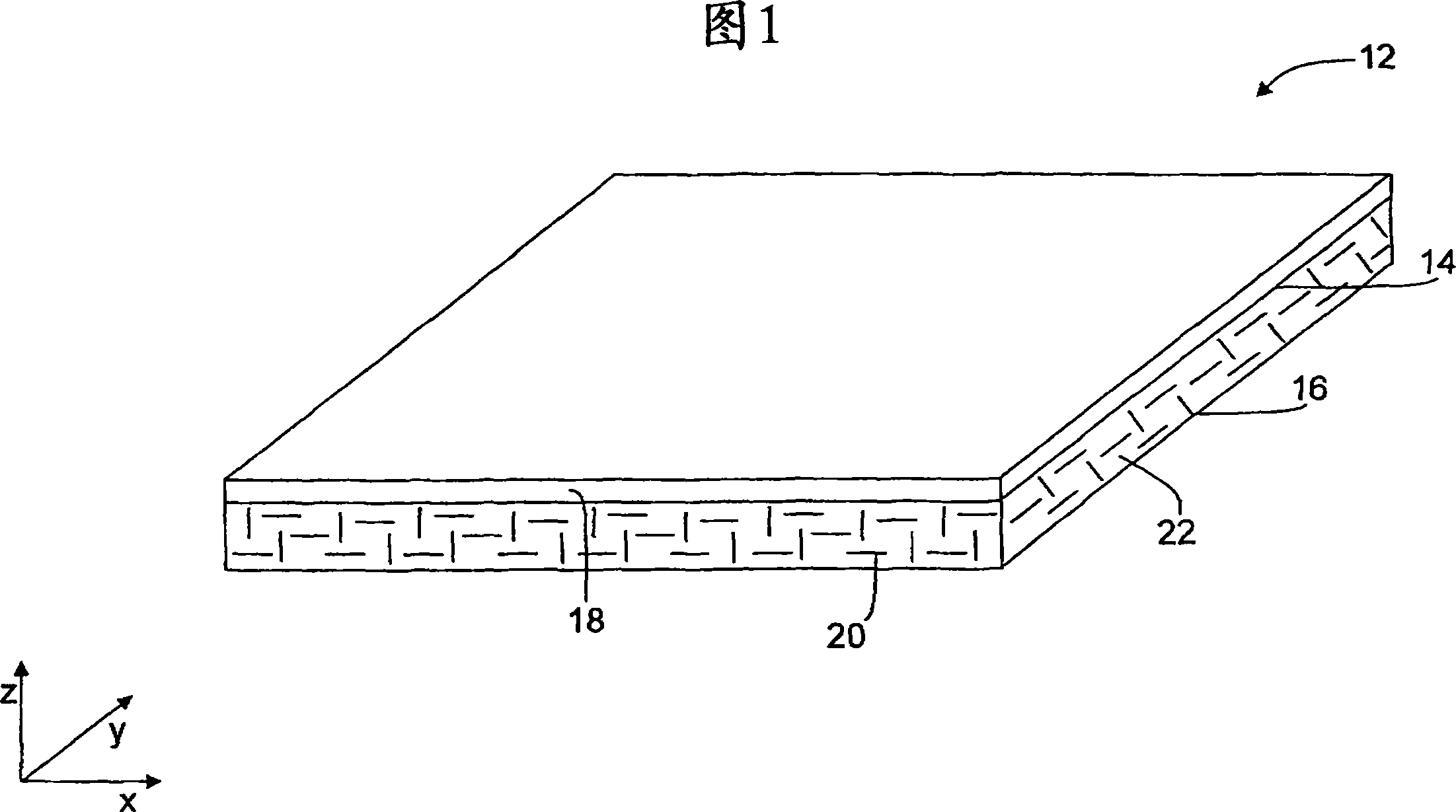

Method for increasing sponginess property of sheet with thermoplastic reinforced by multiporous fiber

InactiveCN101073918AHigh bulkinessFlat articlesNon-woven fabricsGlass transitionThermoplastic composites

Owner:阿兹代尔公司

Manufacturing method of acrylic yarn

The invention relates to a manufacturing method of an acrylic yarn, which comprises the following processing steps: 1, carrying out single-yarn spinning on a 100% bulky acrylic material on spinning equipment to obtain a Z-twisted single yarn; 2, reversing the obtained single yarn into a skein of which the frame length is 2+ / -0.2 m, placing the skein in a steam type bulking box, and dyeing the skein; 3, dewatering and drying the dyed yarn; 4, reversing the dyed and dried skein into a cone yarn of which the capacity is no more than one kilogram, and tripling and twisting the yarn; 5, carrying out steam shaping on the twisted yarn; and 6, finally napping the yarn which is subjected to tripling, twisting and steam shaping, and controlling acrylic fibers to extend 0.5-0.8 cm from the yarn main body. By improving the yarn-manufacturing process flow to realize deep control on the twist, the bulkiness and the strength of the yarn, the invention improves the various indices of the yarn, changes the yarn from the traditional low-end product to a higher-end product and enhances the substitutability of pure wool with the acrylic yarn.

Owner:JIANGYIN XIANGFEI APPAREL

Method for producing cocoon fiber quilt capable of prolonging life

InactiveCN101536851AStrong moisture permeabilityExtend your lifeFibre treatmentAntinoxious agentsHerbPrunus amygdalus

The invention discloses a method for producing cocoon fiber quilt capable of prolonging life, relating to the production process of health-care cocoon fiber quilt. The method is characterized in that ginseng, jujube, Chinese wolfberry, radix pseudostellariae, tuckahoe, agaric, root bark of tree paeony, almond, rhizome of largehead atractylodes, liquorice root, Chinese caterpillar fungus and rhizoma gastrodiae are decocted by water, filtered to obtain Chinese herb liquid, and silk floss is dipped in the mixed liquid consisting of swelling agent, silk softening agent and the Chinese herb liquid, dried and solidified into cocoon fiber cotton having medicine. The invention is capable of regulating the microcirculation of organism and promoting the absorption by human body with the smell of Chinese herb, and has the health-care function to prolong life and improve the living quality.

Owner:江苏丝乡丝绸股份有限公司

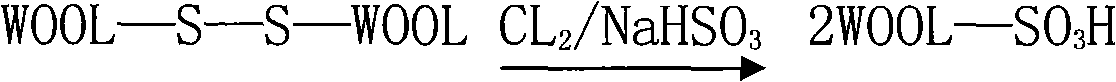

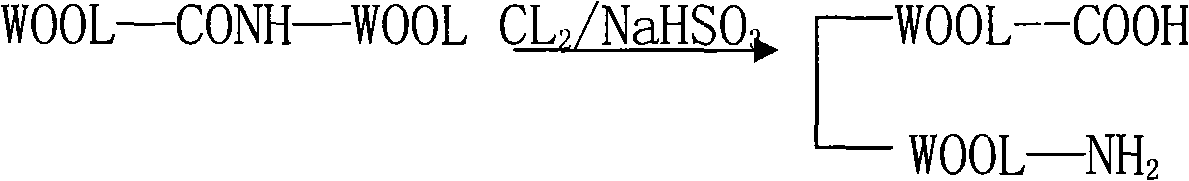

Production method of fancy twister woolen by washing and color stripping

InactiveCN101649542AMeet the requirements of softness and not looseHigh slipBleaching apparatusAnimal fibresPulp and paper industryComfort levels

The invention relates to a production method of fancy twister woolen by washing and color stripping; the production process comprises: loom stare, tweed washing, fulling, tweed washing, drying, decating, drying and finished product; the production method is characterized in that: Chlorination, washing and color stripping and softening treatments are carried out to the cloth after the decating is carried out. The production method has the advantages that the soft and smooth handfeel, bulkiness and comfort level of the fabric processed by the method are higher than that of the traditional products, therefore, the fancy twister woolen is suitable for the current fashionable, leisure and comfortable dressing codes.

Owner:JIANGSU SUNSHINE +1

Non-woven fabric for sanitary materials, and sanitary material product

InactiveUS20170275792A1Water absorbability is highImprove diffusion abilitySanitary towelsBaby linensPolyesterPliability

The present invention aims to provide nonwoven fabric for sanitary materials having high water absorbability and high diffusing capacity for liquids such as water and chemicals as well as high bulkiness, flexibility, and anti-see-through property, and also provides sanitary material products produced therefrom including a water absorbing sheet for sanitary napkins. The nonwoven fabric for sanitary materials may comprise nonwoven fabric of polyester based fiber with a flattened multilobar cross section containing 6 or more convex portions along the cross-sectional circumference, the polyester based fiber with a flattened multilobar cross section having a flatness of 2.0 to 3.0, a degree of irregularity of 1.0 to 5.0, and a convex ratio of 0.6 to 0.9, and the polyester based fiber with a flattened multilobar cross section being joined by heat-weldable fiber.

Owner:TORAY IND INC

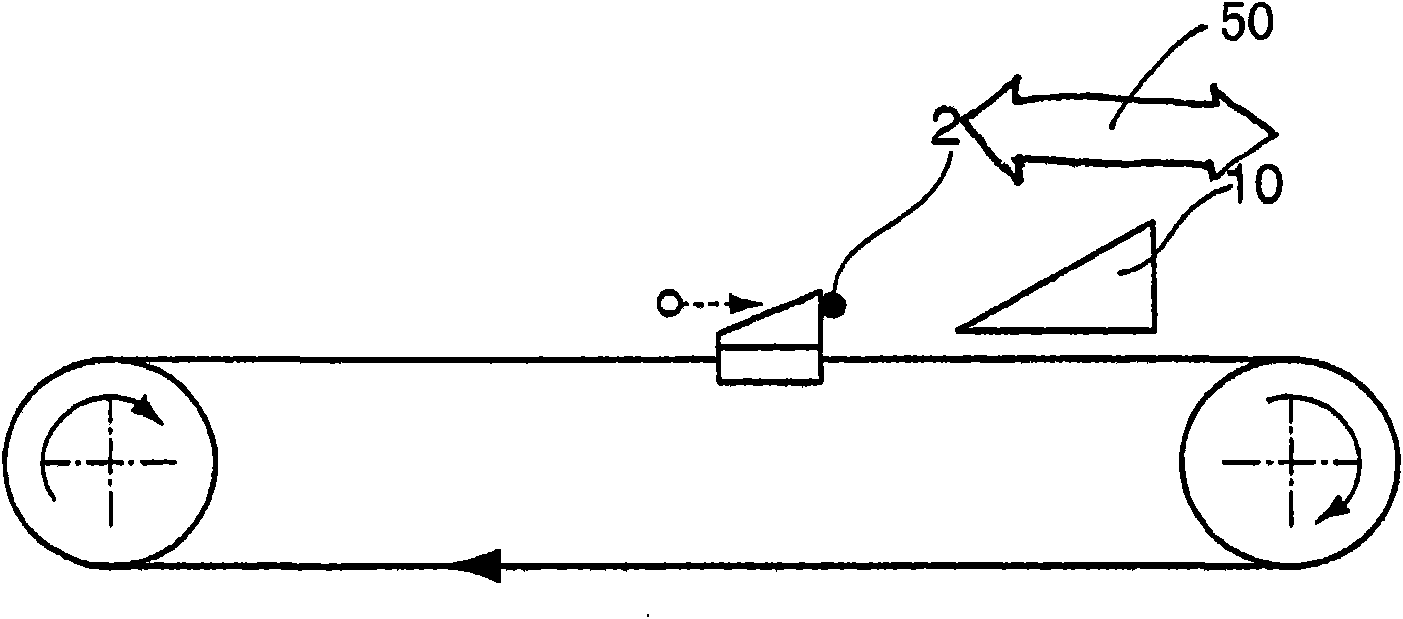

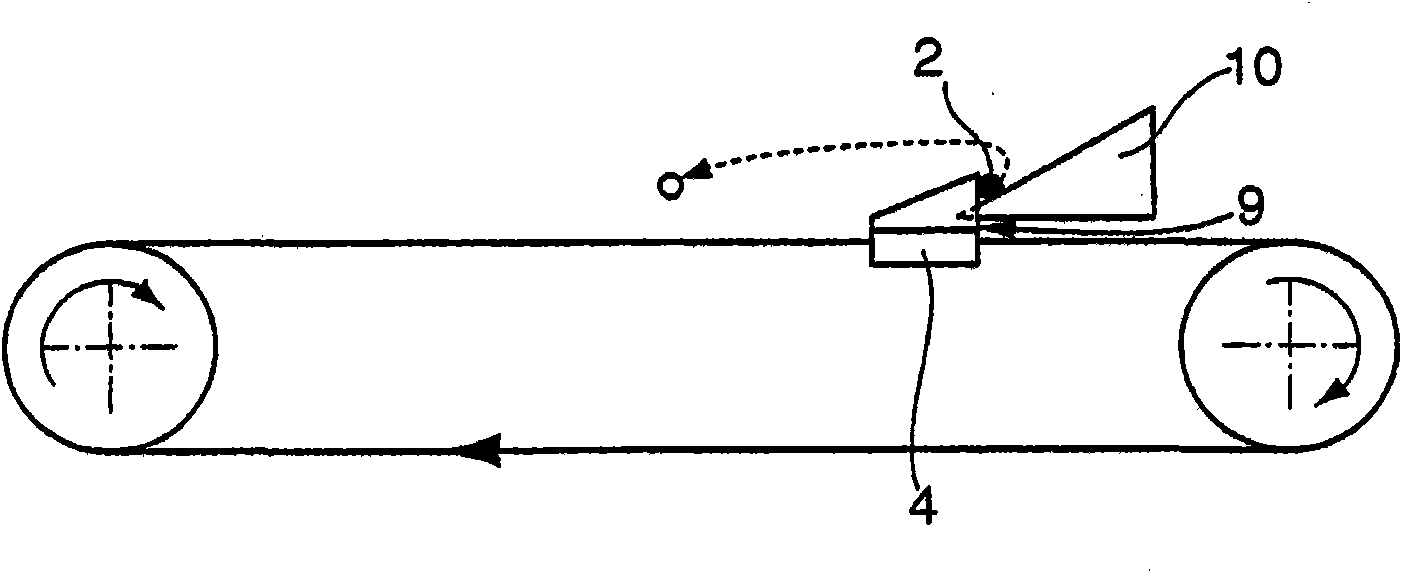

Device for the production of fancy yarn

The invention relates to a device (1) for the production of fancy yarn during the texturizing of yarn by creating flames by way of short-term yarn transfer, having a motor-driven linear carrier (4) that can be moved away from the grain (35), wherein the carrier (4) has a thread guide (9) in order to create a yarn under-delivery by gripping a thread (2) of the yarn by way of the thread guide (9) and by lateral deflection of the yarn from the grain (35) thereof. For this purpose, trigger means (10) are provided, which are configured to release the thread (2) from the thread guide (9) at a deflection point positioned laterally from the grain (35) of the thread (2) in order to create the yarn delivery by means of abrupt termination of the deflection of the yarn. The trigger means (10) form a ramp, wherein the ramp is positioned such that the thread (2) can be pushed onto the ramp in the region of the deflection point by means of the thread guide (9), wherein the thread (2) may be lifted out of and / or lifted out above the thread guide (9) by pushing the same on for the release thereof. The device functions in a manner that is independent of the thread tension.

Owner:SSM萨罗瑞士麦特雷有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com