Low-carbon environmental protection ultra-fine special cotton silk interwoven fabric and its production process

A low-carbon, environmentally-friendly, production technology technology, applied in the processing of textile materials, fabrics, textiles, etc., can solve the problems of serious environmental pollution, insufficient quality, and easy yellowing of silk, and achieve good gloss, energy saving and cost saving. Lightweight and ethereal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

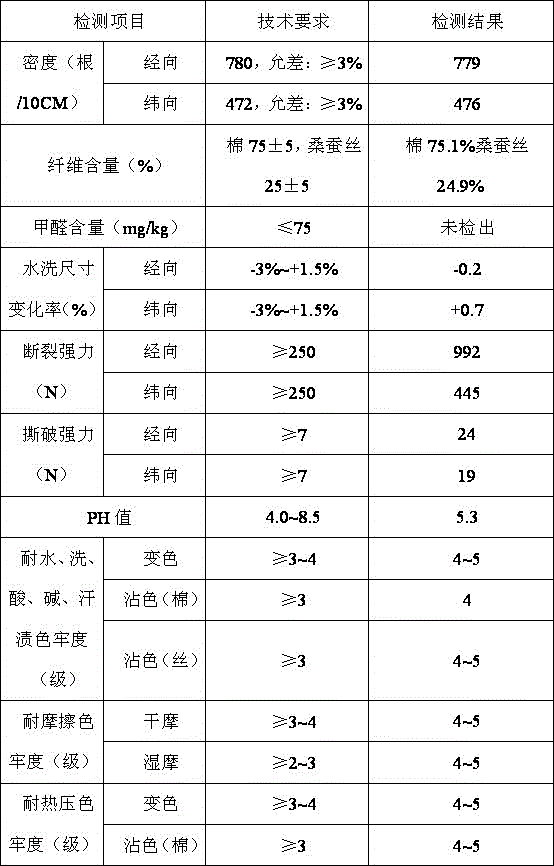

[0036] The present invention relates to a low-carbon, environment-friendly, ultra-fine special cotton silk interwoven fabric. Warp and weft raw materials: warp yarns are 50% Egyptian + 50% Xinjiang long-staple cotton, compactly spun singeing silk, yarn hairiness is short, moisture-absorbing, breathable, soft and shiny , increased strength, can achieve non-sizing weaving, non-singeing and desizing finishing; after dyeing, the gloss increases and the color is bright; the weft yarn is made of 4A-level factory-inspected three-ply mulberry silk, and the appropriate twist direction and twist are selected. After twisting, the strength is high and the dyeing , The air-jet weaving process does not loose the yarn, the dyeing does not mess up the yarn, the weft insertion is easy for weaving, and the production efficiency is high.

[0037] Product specifications: (4.86tex×2)×(22D×3) / 780 / 10CM×472 / 10CM / 145CM

[0038] Fiber content and weight: 75% cotton 25% mulberry silk, 110g / m 2; Total w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com