Vortex spun electromagnetic shielding fabric and textile method

A technology of electromagnetic shielding and eddy current spinning, which is applied in textiles, fabrics, multi-strand fabrics, etc., can solve the problems of unsatisfactory wearing effect, poor durability and air permeability, etc., achieve good electromagnetic shielding effect, improve durability and air permeability, Delicate and smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

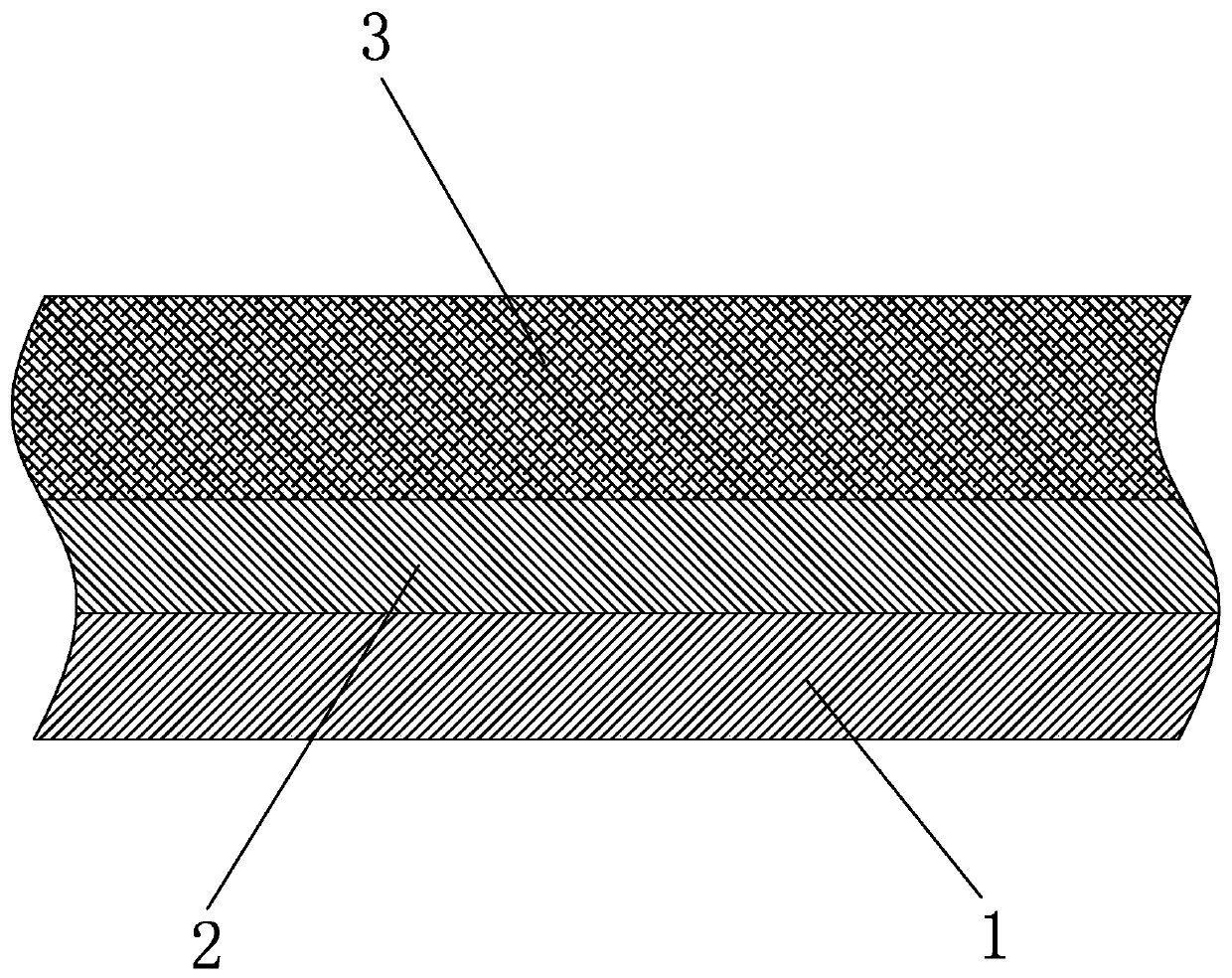

[0024] combine figure 1 , the invention discloses a vortex spun electromagnetic shielding fabric, which includes a fabric body. The double-layer fabric includes an inner layer fabric 1 and a surface layer fabric 2 that are stacked. The fabric body is a double-layer plain weave structure. The inner layer fabric 1 is the inner warp and the inner weft with the eddy current spinning conductive yarn. Surface fabric 2 is surface warp and surface weft with vortex spinning elastic yarn. The arrangement ratio of the surface warp and the inner weft is 2:1, and the ratio of the inner and outer wefts is 1:2, and the bottom is connected to the top to form a joint structure with heavy warp and flattening. Vortex spun conductive yarn uses copper filaments with a silver-plated layer on the surface as conductive filaments, and combed cotton fibers as outer fibers. Combed cotton fibers are helically wrapped around conductive filaments to form the outer covering. The vortex spun elastic yar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com