Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Overcome flammable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing sofa leather with strong wear resistant property and flame retardant property

A high-wearing and fire-retardancy sofa leather is made by 1) wet condensing coating, molding in condensing groove, washing in water groove, drying and shaping and finally cooling and winding to become semi product wet process Bayes; 2) back spread coating with the semi product going through drawoff roller extraction shaping, dressing and spread coating, drying and baking and becoming fire-retardancy Bayes after cooling and winding; 3)nonaqueous shifting surface making, namely, separate paper shifting overlay; 4) kneading after treatment with pre-soaking of semi product sofa, squeezing out partial liquid, kneading and drying and finally batching on checking and final product packing. Apart from the major features of anti-friction and anti-retardancy, it can keep fine physical and mechanical performance and cosmetic styles with good quality and durable service.

Owner:HAININ JINDA COATING

Compound decorative board of expanded perlite and its prepn. method

InactiveCN1415568AHigh glossFlame retardantCeramic shaping apparatusBurial vaultsPolymer scienceSurface layer

A composite decorative plate is composed of surface layer and base layer. It is prepared through proportionally mixing high-Al cement NO.525, the mixture of quartz sand and powre and the additive containing pigment, stirring, pouring in mould, vibration, absorbing the surfacial water, pouring the mixture of high-Al cement No.525, expanded pearlite and water, and pressure smoothing. Its advantages are high lustre, light weight, fire retarding, and heat and sound insulation.

Owner:赵承恩

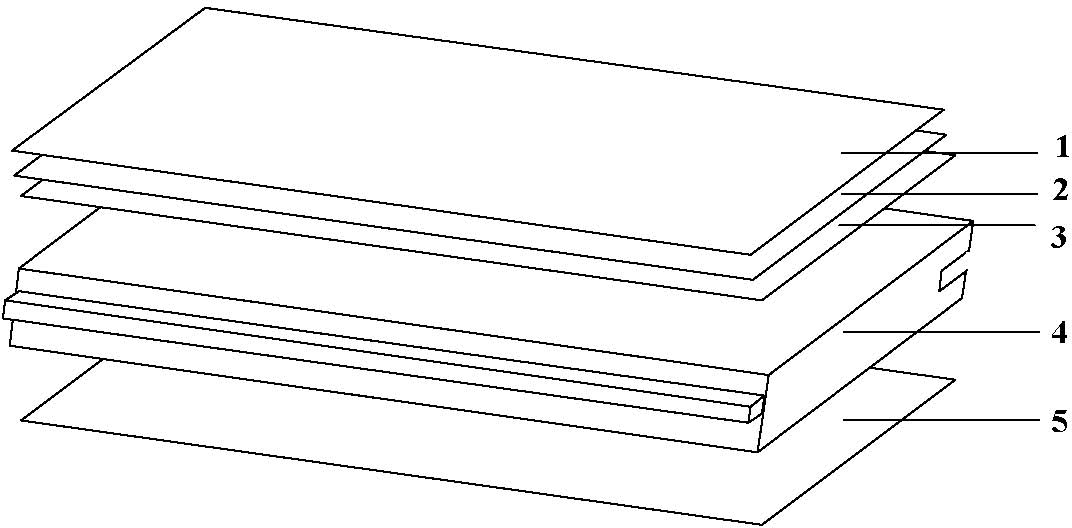

Wear-resisting anti-flaming poplar solid flooring and preparation method thereof

The invention provides a wear-resisting anti-flaming poplar solid flooring which is mainly composed of a modified solid flooring billet layer, and a preparation method of the wear-resisting anti-flaming poplar solid flooring; the wear-resisting anti-flaming poplar solid flooring sequentially comprises a balance moisture-proof layer, the modified solid flooring billet layer, a color blending layer, an ultrathin natural veneer decoration layer and a wear-resisting layer from bottom to top. The method comprises the steps of preparing a composite modified impregnation liquid and performing technologies of vacuum pressurization dipping treatment, drying, assembling and pressing and the like on woods. A composite modification processing technique of the invention enables the strength of poplar to be increased, the stability of the poplar to be enhanced, and enables the poplar to have properties of wear resistance, flame retardant, mildew prevention and anticorrosion and the like, so that the utilization value of artificial poplar is improved greatly. The method is simple and easy; and the wear-resisting anti-flaming poplar solid flooring processed by the method has the advantages of scratch resistance, wear resistance, flame retardant, mildew prevention, anticorrosion, easiness in maintenance, natural textures, comfort, environmental protection and high cost performance.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

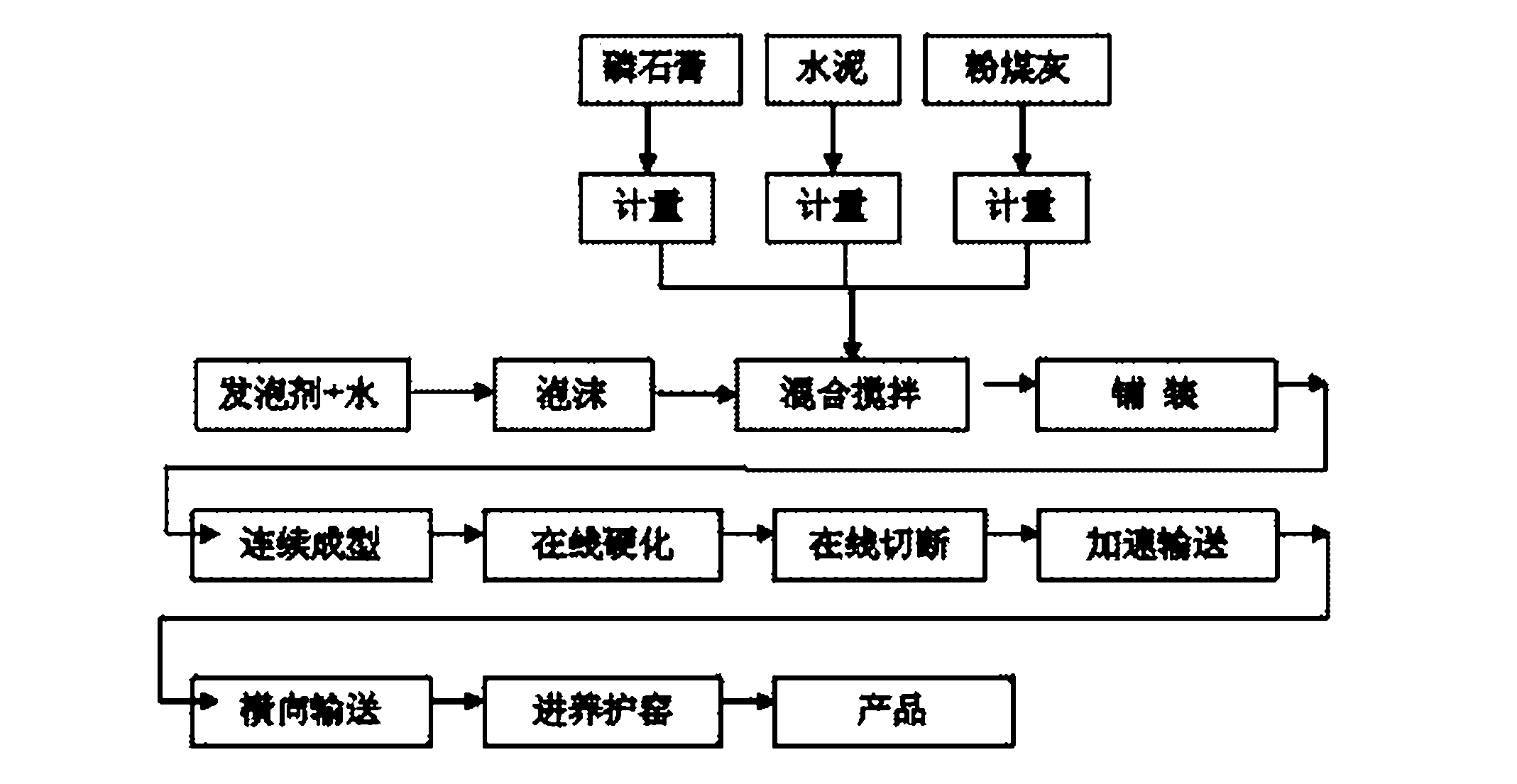

Building phosphogypsum powder thermal insulation material and preparation method thereof

ActiveCN102417369ALight weightLow thermal conductivityCeramicwareThermal insulationAdditive ingredient

The invention discloses a building phosphogypsum powder thermal insulation material and a preparation method thereof. The thermal insulation material comprises the following ingredients: 40-50 wt% of building gypsum powder, 10-15 wt% of cement, 8-13 wt% of fly ash, 1-2 wt% of foaming agent, and 30-40 wt% of water. The preparation method comprises the following steps: (1) putting building gypsum powder, cement, fly ash and other solid raw materials in a mixer for dry mixing, putting a mixture of water and foaming agent in the mixer, and stirring to form an uniform slurry; (2) injecting the prepared gypsum foamed slurry in a mould; and (3) demoulding and carrying out maintenance to obtain a finished product. The thermal insulation material has the following advantages: (1) low unit weight, low thermal conductivity, thermal insulation, and energy saving property; (2) functions of fire resistance, sound resistance, and air humidity adjustment; and (3) reduction of storage quantity of industrial waste residues.

Owner:LUXI CHEM GRP

Preparation method of Al2O3-SiO2 composite aerogel

ActiveCN108380144AEnhanced skeletonInhibition of shrinkageAerogel preparationColloidal chemistry detailsPseudoboehmiteAlcohol

The invention discloses a preparation method of Al2O3-SiO2 composite aerogel. The method comprises the following steps of a, gamma-AlOOH sol preparation: pseudoboehmite is dissolved in a first solvent; an acidic substance is added so that gamma-AlOOH sol is formed; b, TEOS hydrolysis: TEOS and ethyl alcohol are added into the gamma-AlOOH sol to form gamma-AlOOH-SiO2 composite sol; c, gelation andaging: a gelatinizing agent is added into the gamma-AlOOH-SiO2 composite sol to form gamma-AlOOH-SiO2 composite gel; still standing and aging are performed; d, drying: the gamma-AlOOH-SiO2 composite gel is subjected to a drying process to obtain gamma-AlOOH-SiO2 composite aerogel; e, heat treatment: the dried gamma-AlOOH-SiO2 composite aerogel is calcined to obtain the Al2O3-SiO2 composite aerogel. Compared with the prior art, the preparation method has the advantages that the operation is safe; the energy consumption is low; the raw materials are cheap; the production cost is low; the technological process is simple.

Owner:HUNAN UNIV OF SCI & TECH

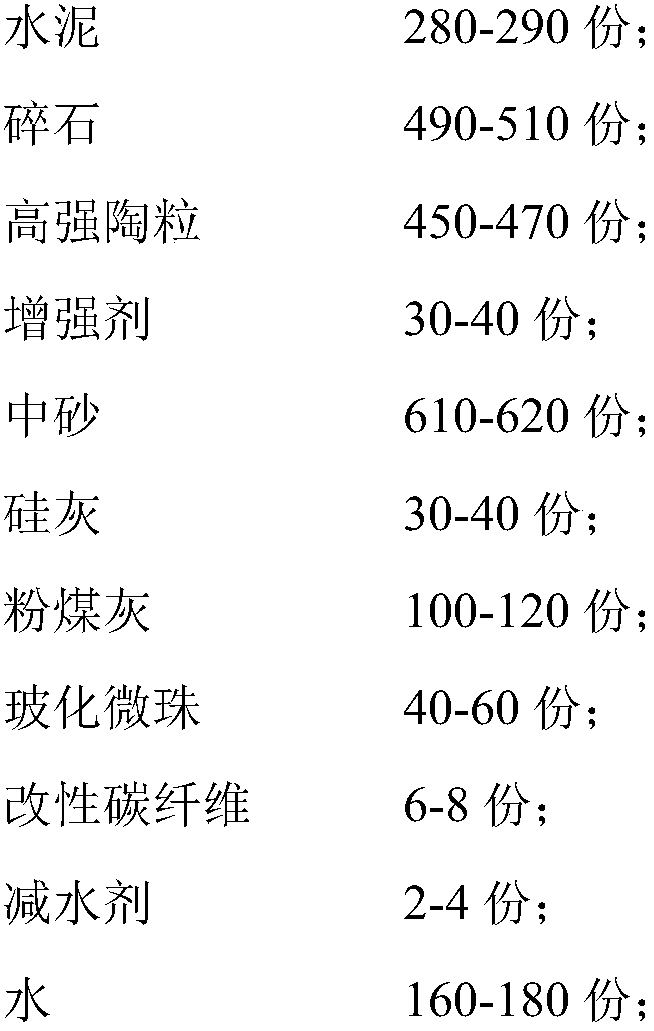

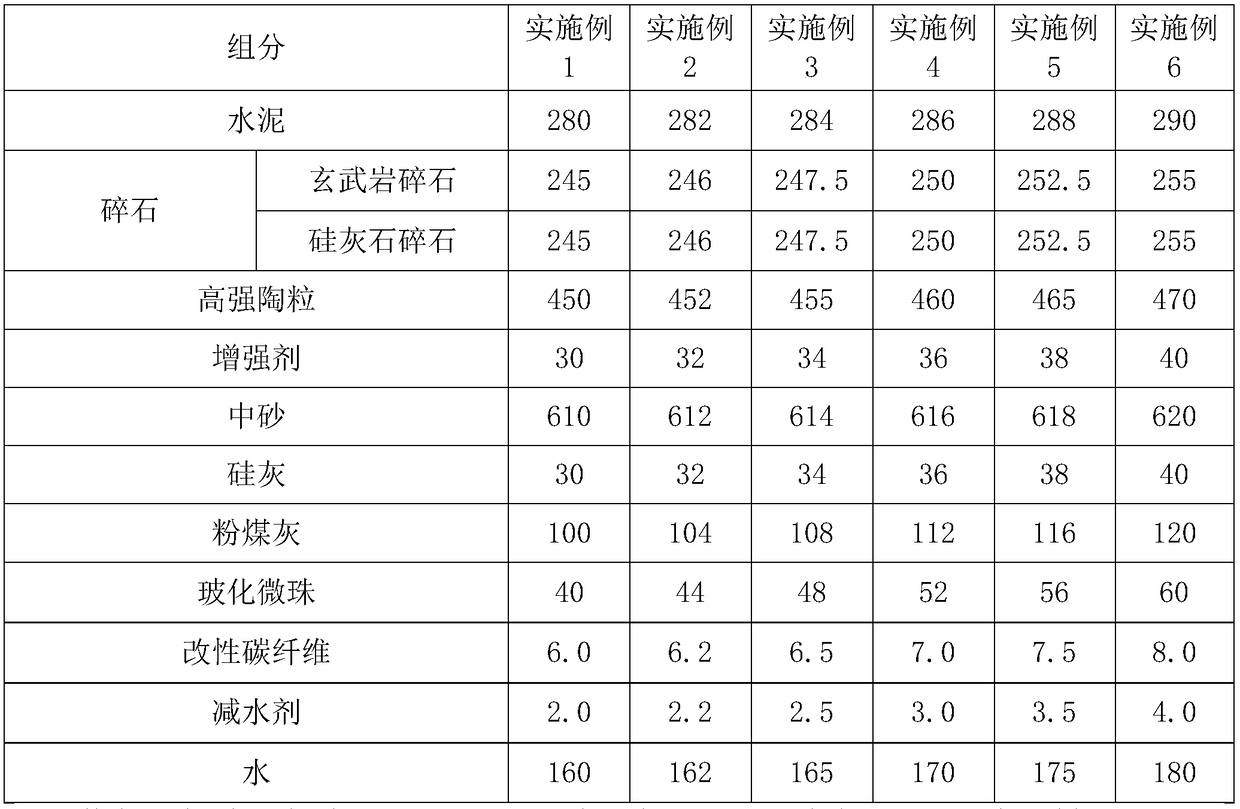

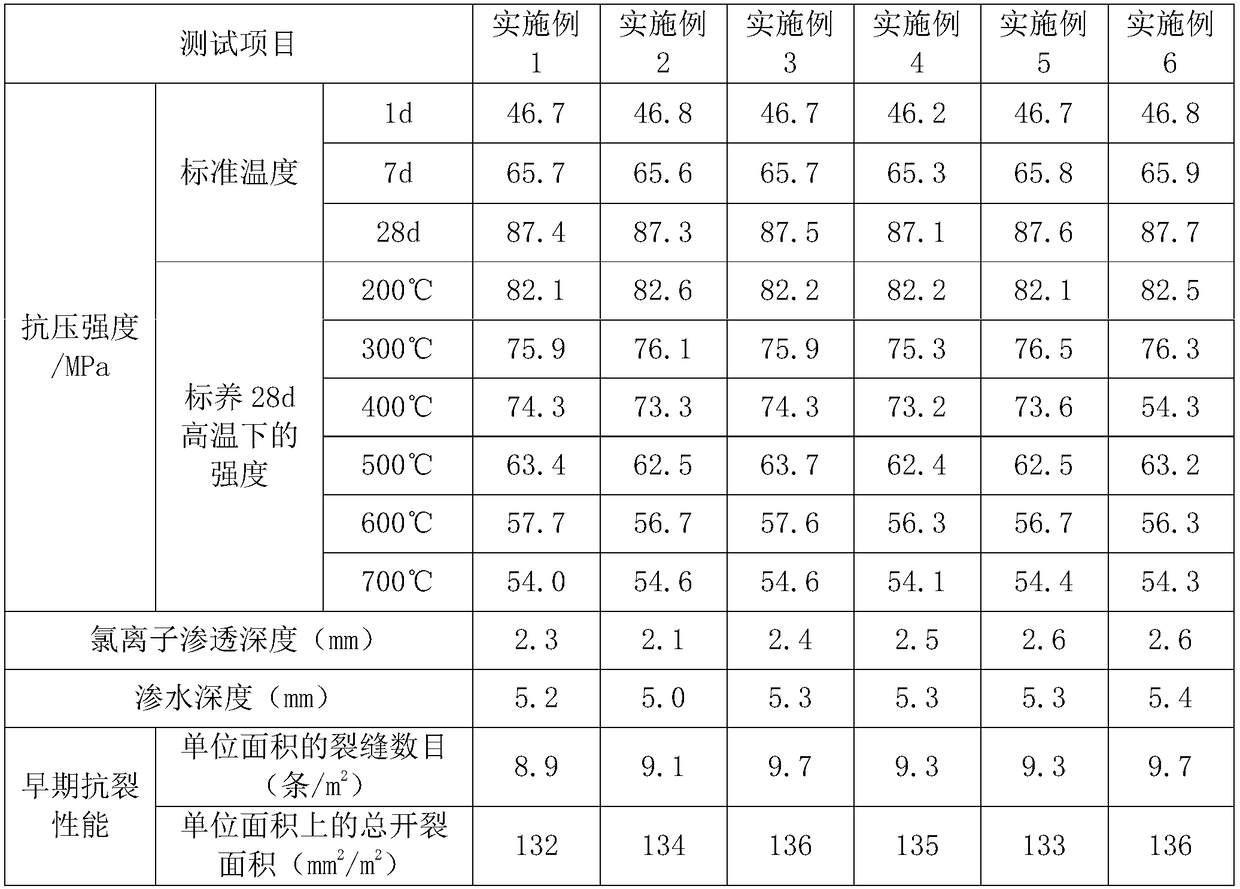

High-strength and heat-resistant concrete

The invention discloses high-strength and heat-resistant concrete and belongs to the technical field of concrete. The technical scheme is characterized in that the high-strength and heat-resistant concrete is prepared from components in parts by weight as follows: cement, crushed stone, high-strength ceramsite, a reinforcing agent, medium sand, silica fume, fly ash, vitrified microbeads, modifiedcarbon fibers, a water reducing agent and water, wherein the cement is P.O.42.5 ordinary Portland cement; the crushed stone comprises crushed basalt and crushed wollastonite. Heat resistance, impervious performance and compressive strength of the concrete are improved by the high-strength ceramsite; heat resistance and compressive strength of the concrete are improved by the reinforcing agent; aging resistance, heat resistance and cracking resistance of the concrete are improved by the vitrified microbeads; strength and flexibility of the concrete are improved by the modified carbon fibers; early strength, impervious performance and chemical corrosion resistance of the concrete are improved by the silica fume, and accordingly, strength and heat resistance of the concrete are improved.

Owner:北京建工新型建材有限责任公司

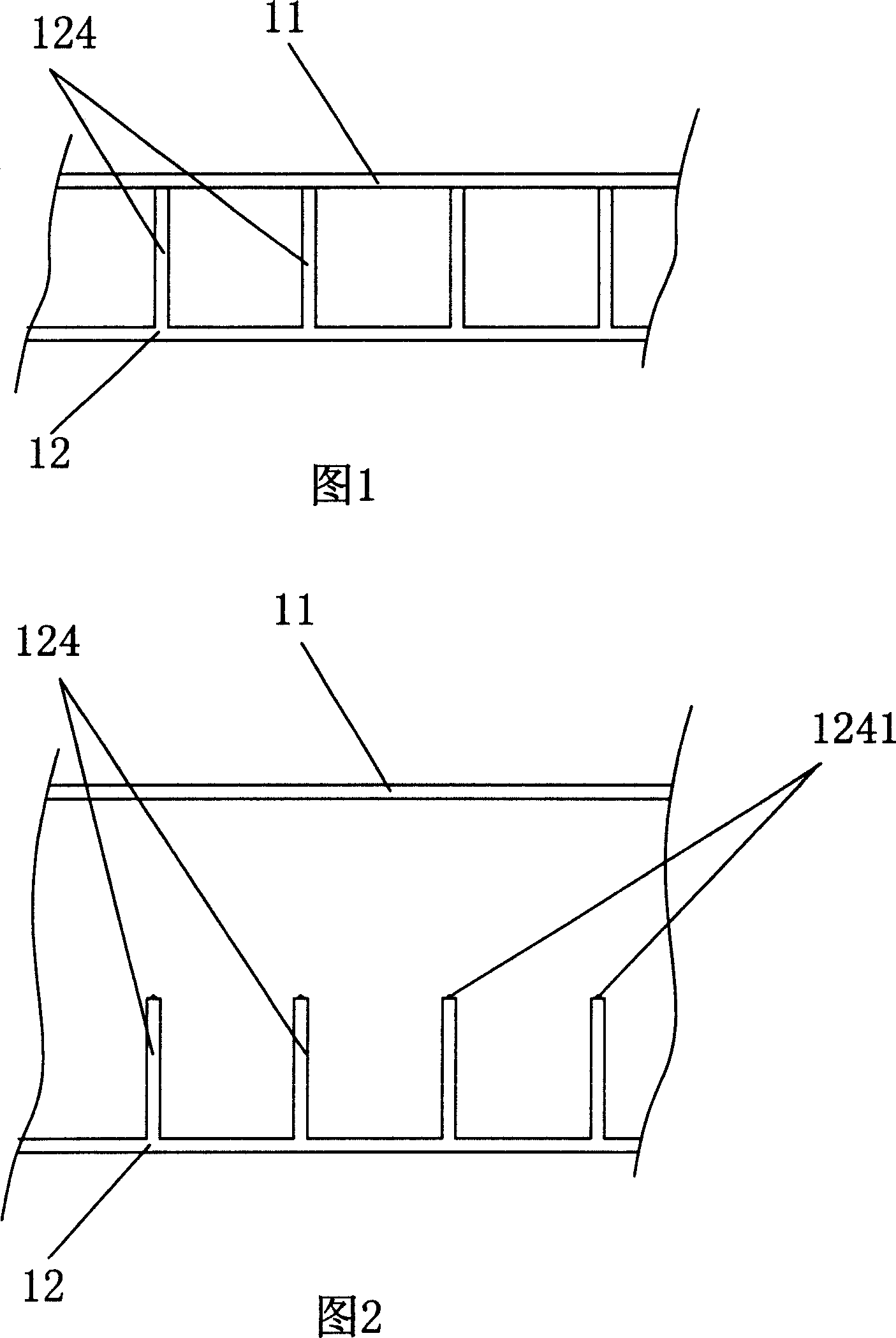

Plastics composite wall brick

InactiveCN101096882ASpecifications and sizes can be large or smallHigh dimensional accuracyCovering/liningsFlooringBrickEngineering

The invention discloses a plastic composite brick, which is characterized by the following: comprising plastic panel and injection moulding element; squeezing and forming the plastic panel directly; or squeezing; proceeding plastic uptake form; proceeding injection made and form directly; or compositing with multiple of injecting moulding element; binding or welding the upper of the injection moulding element and the lower surface of the plastic panel together; arranging back-off or cog at the bottom of the injection moulding element; arranging orientation and water-retaining structure at the relative two edges; binding or welding the edge of the plastic panel and the coincidence edge of the injection moulding element together. This invention is environment protection, which is a new type wall covering material.

Owner:冷鹭浩

Aerated concrete block and preparation method thereof

InactiveCN107162628AEasy to prepareSuitable for industrial productionCeramicwareGlass fiberHigh intensity

The invention discloses an aerated concrete block. The aerated concrete block is prepared from, by weight, 40-60 parts of coal ash, 30-40 parts of levigated quartz powder, 20-30 parts of desulfurized gypsum, 10-30 parts of talc powder, 10-20 parts of sepiolite powder, 5-15 parts of activated silicon material, 15-25 parts of lime, 5-10 parts of mica powder, 2-8 parts of lightweight ceramsite, 5-15 parts of quartz sand, 3-8 parts of gypsum, 5-15 parts of asbestos powder, 4-10 parts of glass fibers, 3-10 parts of aluminum powder, 2-6 parts of an air entraining agent, 1-5 parts of a foam stabilizer, 3-8 parts of a foam homogenizing agent and 60-80 parts of deionized water. The aerated concrete block meets requirements on heat insulation, energy saving and high strength, and a preparation method of the aerated concrete block is simple, convenient and suitable for industrial production.

Owner:HEFEI GUANGMIN BUILDING MATERIAL CO LTD

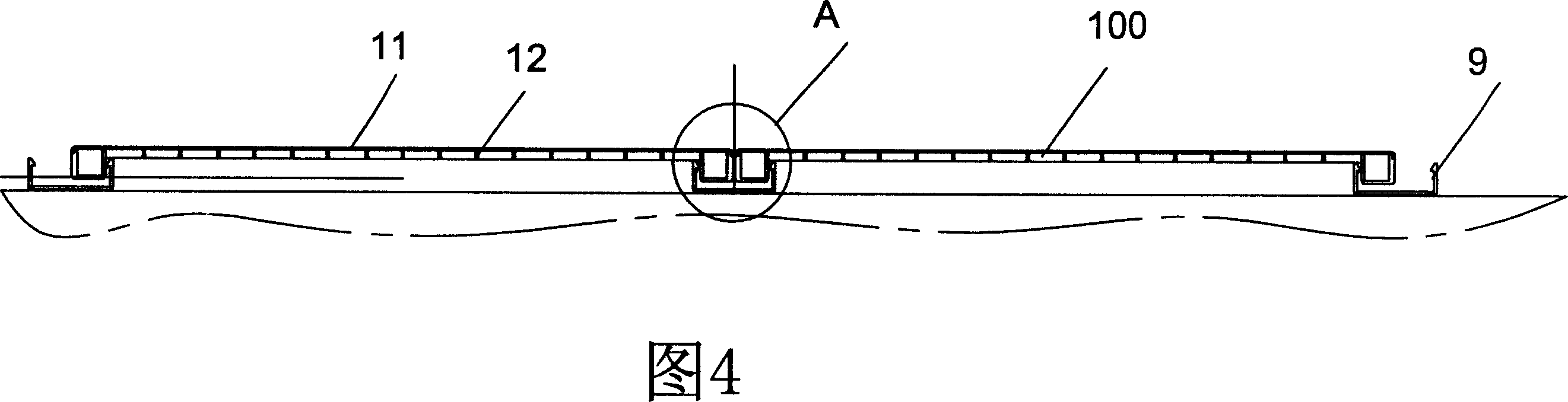

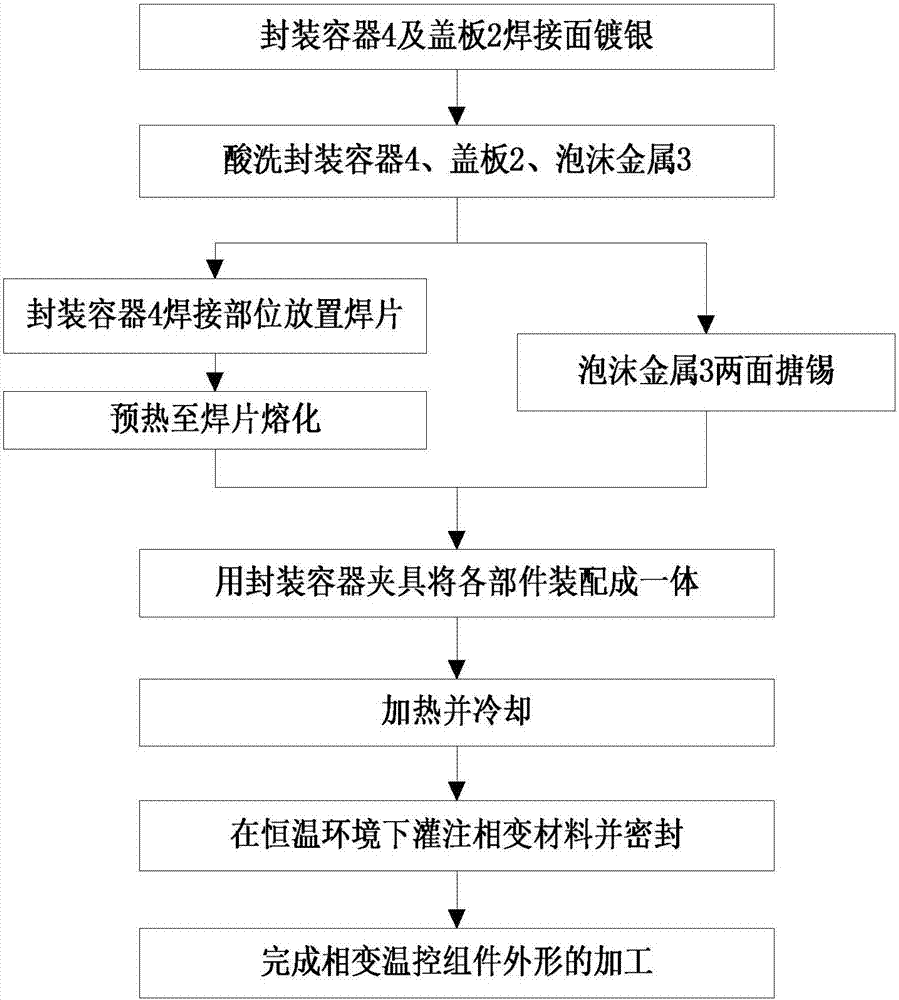

Method for integrated preparing of foam metal phase change temperature control assembly

InactiveCN107116279AOvercome failureImprove the equivalent thermal conductivityHeating appliancesWelding/soldering/cutting articlesTemperature controlEngineering

The invention provides a method for integrated preparing of a foam metal phase change temperature control assembly and aims at providing a technology method for solving the problem that in a phase change temperature control assembly, a gap exists between foam metal and a base body material, and the heat response rate is influenced. The method is achieved through the following technical scheme that according to the boundary dimension of a packaging container, a packaging container clamp is prepared; a cavity used for welding the foam metal is machined in the packaging container in advance, a layer of welding piece is laid on the inner side welding face of the cavity of the packaging container, and the contact interface of the foam metal is subjected to tin lining; the foam metal is compressed to the cavity size; the packaging container, the foam metal and the clamp are assembled into a whole and heated, and after cooling, a formed phase change temperature control assembly blank is taken out of the clamp of the packaging container; in the constant-temperature environment, a liquid phase change material is poured into the phase change temperature control assembly from a pouring port in the bottom of the packaging container; and finally, the pouring port is sealed, and machining of the appearance of the temperature control assembly is finished.

Owner:10TH RES INST OF CETC

Modified phenolic resin composite thermal insulation material and preparation method thereof

The invention provides a modified phenolic resin composite thermal insulation material which is prepared from the following raw materials in parts by weight: 30-70 parts of epoxy modified phenolic resin, 30-50 parts of coated expanded perlite, 10-20 parts of straw, 2-5 parts of adhesive, 1-3 parts of water repellent, 0.1-1 part of curing agent, 0.1-1 part of lubricant and 0.1-1 part of toughening agent. A preparation method comprises the following steps of: 1) weighing the phenolic resin, coated expanded perlite, straw, adhesive, water repellent, curing agent, lubricant and toughening agent according to the proportion, mixing and stirring uniformly, and putting into a steel mould; and 2) performing hot compression moulding in the conditions that the compression ratio is 1.6-2.4 and the hot compression moulding temperature is 210-240 DEG C, and preserving pressure for 1.5-2.5h to obtain the modified phenolic resin composite thermal insulation material. The thermal insulation material integrates the advantages of low heat conductivity coefficient of an organic thermal insulation material and high strength and difficulty in combustion of an inorganic thermal insulation material.

Owner:滦县盛泽保温科技有限公司

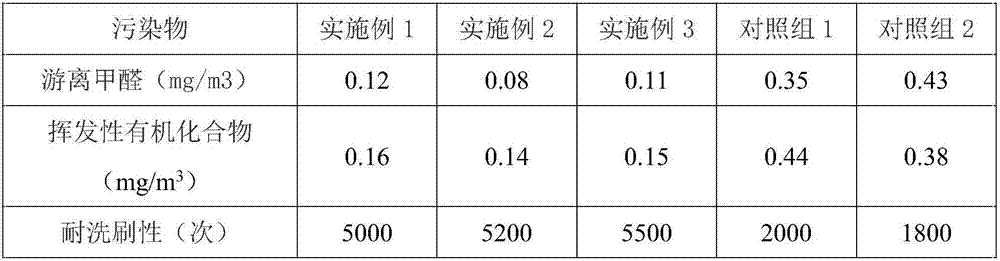

Environment-friendly inner wall latex paint and preparation method thereof

The invention discloses environment-friendly inner wall latex paint. The environment-friendly inner wall latex paint is prepared from the following raw materials in parts by weight: 50 to 70 parts of nano particles, 40 to 60 parts of expanded perlite, 30 to 40 parts of cellulose, 15 to 30 parts of styrene-acrylic emulsion, 10 to 20 parts of nano active carbon, 8 to 15 parts of latex paint additives, 5 to 10 parts of filler, 2 to 6 parts of inorganic pigments and 50 to 80 parts of deionized water. The environment-friendly inner wall latex paint is nontoxic and harmless in the production and construction application, capable of decomposing harmful gases and purifying the air, and excellent in abrasion resistance and aging resistance at the same time.

Owner:HEFEI DAHU ELECTRIC WIRE & CABLE TECH CO LTD

Magnetic polyester resin-based silicone rubber cable material

The invention discloses a magnetic polyester resin-based silicone rubber cable material. The cable material is prepared from raw materials in parts by weight as follows: 60-70 parts of MVQ silicone rubber, 30-38 parts of polyester resin, 4-5 parts of poly glycidyl ester, 0.1-0.2 parts of photoinitiator benzophenone, 0.1-0.2 parts of a cross-linking agent TAIC, 3.6-4 parts of ferrous chloride, 6-6.8 parts of ferric trichloride, 20-25 parts of mica, 10-14 parts of low-melting-point glass powder, 1.6-2 parts of polyethylene glycol, 1.8-2.2 parts of ferrous sulfate, 2.5-3 parts of ammonium bicarbonate, 8-11 parts of soft magnetic ferrite, 4-5 parts of zinc oxide, 2-3 parts of paraffin oil, 0.2-0.3 parts of an antioxidant 168, 1.5-2 parts of carboxymethylcellulose, 2.8-3.5 parts of maleic anhydride and a proper amount of deionized water. The technology is reasonable, and the material is high in strength, resistant to acid and alkali corrosion, non-flammable, free of dripping, good in production and processing performance and worthy of popularization.

Owner:ANHUI LVHUAN ELECTRIC CO LTD

Novel foaming cement insulation board and preparation method thereof

InactiveCN107324720AImprove insulation effectImprove fire performanceCeramicwareFoaming agentCement board

The invention discloses a novel foaming cement insulation board and a preparation method of the insulation board. The insulation board comprises the following components in parts by weight: 60-80 parts of cement, 20-40 parts of phenolic resin, 15-35 parts of fly ash, 10-20 parts of nano hollow microbead, 5-15 parts of active nano silica, 2-8 parts of a talcum powder, 4-10 parts of a fiber reinforced material, 1-5 parts of calcium stearate, 3-8 parts of silica fume, 1-5 parts of aluminum nitride, 0.5-1.5 parts of an assistant, 1-5 parts of a foaming agent and 80-100 parts of water. The preparation method comprises the steps of adding a cement main material, adding an additive, performing stirring, curing and demolding, and then performing curing again until finished foaming cement is formed. The foaming cement board prepared by the method has higher comprehensive performance such as insulation, fire resistance, sound isolation, moisture resistance and compression resistance, and can be widely applied in insulation positions of various building external walls requiring insulation measures.

Owner:HEFEI GUANGMIN BUILDING MATERIAL CO LTD

Aerated concrete building block and preparation method

InactiveCN107266108AHigh strengthImprove insulation effectCeramicwareCalcium silicateThermal insulation

The invention discloses an aerated concrete building block and a preparation method. The aerated concrete building block consists of the following materials in parts by weight: 60 to 80 parts of cement, 50 to 60 parts of boiler ash, 30 to 40 parts of silicon material, 15 to 25 parts of activated silica material, 20 to 30 part of quick lime, 20 to 30 parts of hydrogen peroxide, 2 to 10 parts of additive, 2 to 8 parts of calcium silicate, 2 to 8 parts of sodium silicate, 1 to 5 parts of aluminium powder and 40 to 80 parts of deionized water. The materials of the aerated concrete building block are inorganic materials, the aerated concrete building block has high strength and new thermal insulation property, the material sources are rich, the price is low, the aerated concrete building block is safe and nontoxic, and the aerated concrete building block produce produced by the method has good compressive strength and thermal insulation property.

Owner:HEFEI DAHU ELECTRIC WIRE & CABLE TECH CO LTD

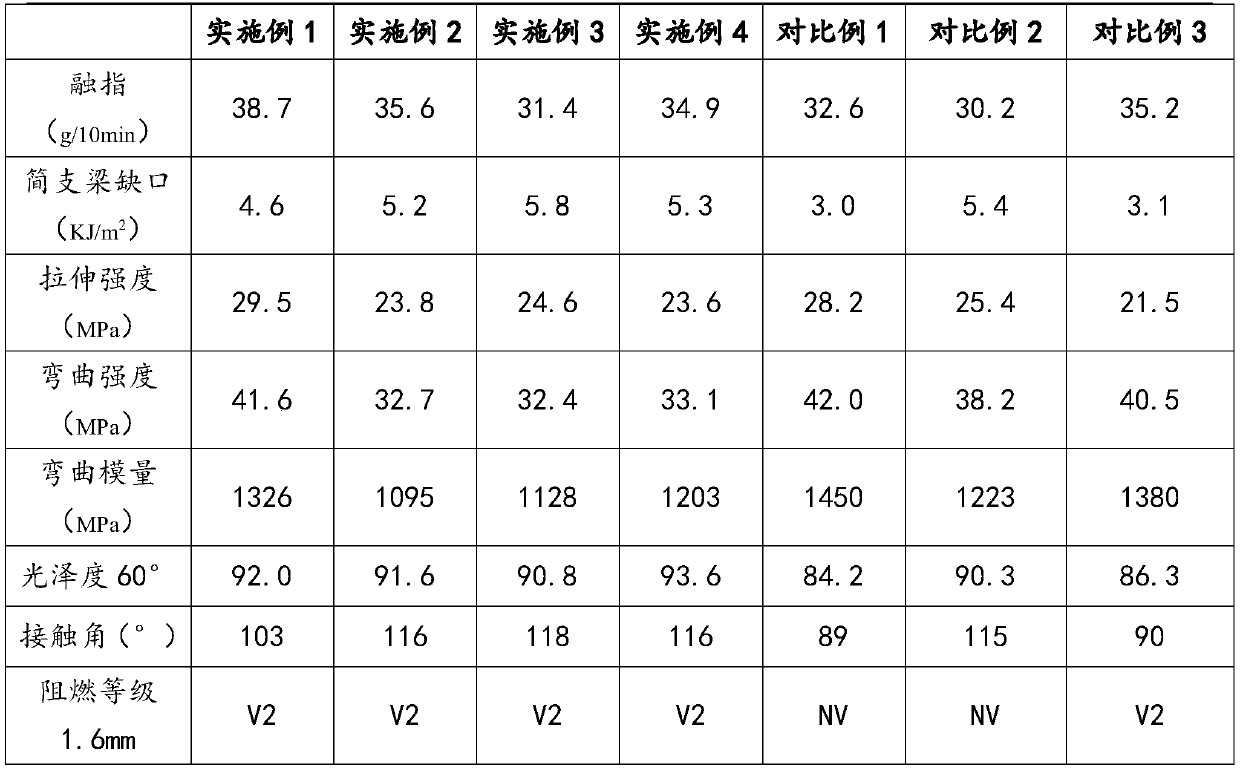

Self-cleaning masterbatch and flame retardant high gloss polypropylene composite material special for intelligent closestools and preparation method

The invention relates to the technical field of polypropylene material modification, in particular to a self-cleaning masterbatch and a flame retardant high gloss polypropylene composite material special for intelligent closestools and a preparation method. The composite material comprises the following raw materials by weight: 50-78.6 parts of polypropylene; 3-10 parts of a flame retardant; 10-20parts of self-cleaning masterbatch; 0.1-0.5 part of a nucleating agent; 0.1-0.6 part of an antioxidant; 10-20 parts of barium sulfate; and 0.2-0.9 part of other additives. By cooperating with the self-cleaning masterbatch, the flame retardant high gloss polypropylene composite material special for intelligent closestools prepared according to the invention can overcome the shortcomings of flammability, difficult self-cleaning and high price in closestool seat materials in the prior art, is suitable for use in intelligent closestool seat and other product materials, and has important practicalapplication value.

Owner:JINYOUNG XIAMEN ADVANCED MATERIALS TECH CO LTD

Method for producing high-purity sulfur through sulfur paste extraction

The invention provides a method for producing high-purity sulfur through sulfur paste extraction. The method comprises the following steps: (1) crushing and screening dried sulfur paste; (2) introducing pretreated raw materials and an organic solvent into a reactor with a steam heating jacket, and carrying out an extraction reaction at a certain temperature, wherein the organic solvent specifically is one or a mixture of more of xylene, solvent oil 200# and heavy benzol; (3) subjecting the obtained reacted solution to heat-preserving filtering treatment, then, introducing the treated solutioninto a crystallizer, and carrying out cooling crystallization and solid-liquid separation, thereby obtaining the target required sulfur; and (4) introducing the organic solvent cooled in the step (3)into the reactor in the step (2) again for recycle. According to the method, the sulfur is purified by making full use of high-temperature solubility of the organic solvent to the sulfur; and meanwhile, the method has the advantages of simple process, stability in operation, low production cost, high recovery rate, high purity and the like, so that the resource-converting utilization of wastes canbe effectively achieved.

Owner:HUAIBEI NORMAL UNIVERSITY

Monocomponent foaming agent and preparation method thereof

InactiveCN103242501AOvercome flammableOvercome the disadvantage of being explosiveToxic gasPolyester

The invention provides a monocomponent foaming agent and a preparation method thereof. The monocomponent foaming agent is prepared from the following raw materials in parts by weight: 20 to 30 parts of isocyano polyacid ester, 25 to 30 parts of polyester polyol, 3 to 8 parts of polyether polyol, 30 to 40 parts of methylene dichloride, 0.5 to 2 parts of catalyst and 3 to 5 parts of fireproof and high-temperature resistant filling agent. The preparation method comprises the following steps: adding the polyether polyol into a vessel and dehydrating in the vacuum environment; sequentially adding polyester polyol, isocyano polyacid ester and the catalyst and stirring evenly; adding the fireproof and high-temperature resistant filling agent and stirring at a high speed; adding methylene dichloride; and then standing for 24 hours, thereby obtaining the monocomponent foaming agent. The monocomponent foaming agent has the beneficial effects of overcoming the flammable and explosive defects of the traditional foaming agent and being safer and more convenient to store and use. The monocomponent foaming agent has the characteristics of being large in gas generation volume, small in residue volume, high in reaction speed and uniform in gas generation. In addition, the monocomponent foaming agent is simple in production process, low in cost, safe and environmental-friendly and cannot generate toxic gas.

Owner:天津鼎鑫防火材料科技有限公司

TPEE acoustic film and production method thereof

InactiveCN111204094ASimple processEasy to operateSynthetic resin layered productsLaminationEpoxyWeather resistance

The invention discloses a TPEE acoustic film. The TPEE acoustic film is characterized by comprising a modified TPEE film and a backing film which are laminated by an adhesive; and the modified TPEE film is prepared from, by weight, 60-70 parts of TPEE, 15-25 parts of radiation graft modified TPEE, 5-10 parts of fluorine-containing epoxy resin, 2-6 parts of nanometer titanium dioxide, 1-2 parts ofa coupling agent, 0.5-1.5 parts of a lubricant and 0.2-0.6 part of an antioxidant. The invention also provides a production method of the TPEE acoustic film. The TPEE acoustic film disclosed by the invention is excellent in comprehensive performances and excellent in heat resistance, weather resistance, dimensional stability, surface friction performance, tearing strength and puncture resistance,and can effectively improve the acoustic performance of an electroacoustic device, keep the low resonant frequency of the electroacoustic device and improve the electroacoustic conversion efficiency.

Owner:苏州市新广益电子股份有限公司

Stable pentane eco-friendly foaming agent used for polyurethane foaming

InactiveCN107266700AOvercome flammableOvercoming the defects of being explosive and difficult to storeDispersity2-methylbutane

The invention provides a stable pentane eco-friendly foaming agent used for polyurethane foaming. The foaming agent is characterized by comprising, by weight part, 11-19 parts of cyclopentane, 16-28 parts of pentane, 23-36 parts of isopentane, 0.5-5 parts of oleic acid, 31-47 parts of deionized water and 0.5-2 parts of an emulsifier. The scheme of the preparation technology comprises: weighing cyclopentane, pentane and isopentane according to the design formula, carrying out mechanical stirring for mixing for 5 min, adding oleic acid and the emulsifier, performing stirring for 10-20 min, adding deionized water, allowing the obtained product to enter a homogenizer, performing homogenization at a low temperature in the protection of nitrogen, and canning the obtained product for standby to obtain the eco-friendly foaming agent. The foaming agent has prominent feature that many kinds of pentane and oleic acid are emulsified, with the assistance of water, so that defects that pentane is flammable and explosive and is not prone to store are overcome. In a polyurethane foamed system, the foaming agent is uniform in dissolution dispersity, stable and uniform in forming and stable in foaming size.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

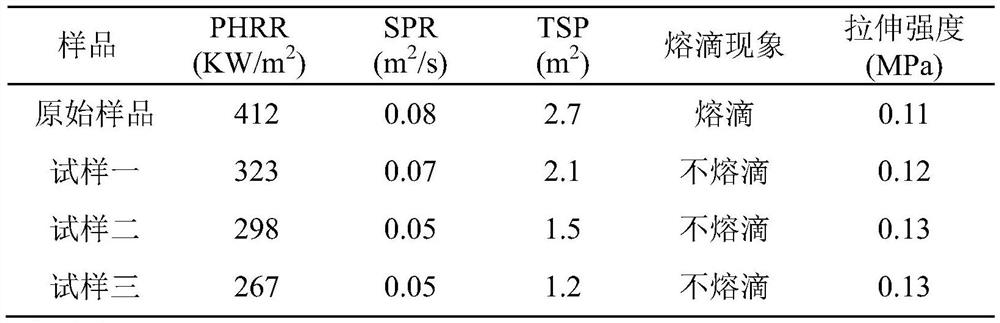

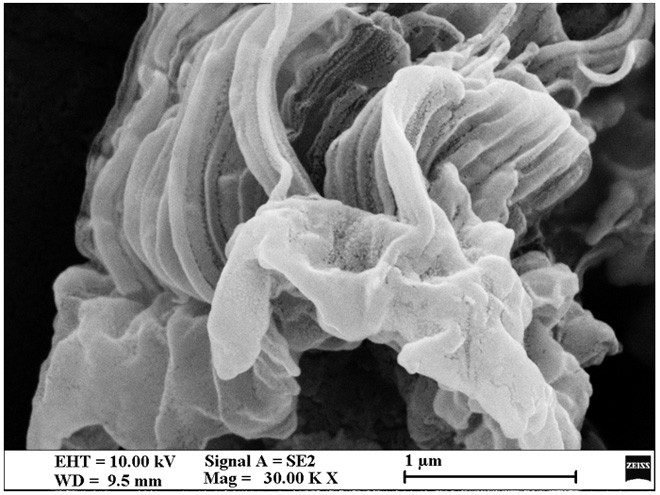

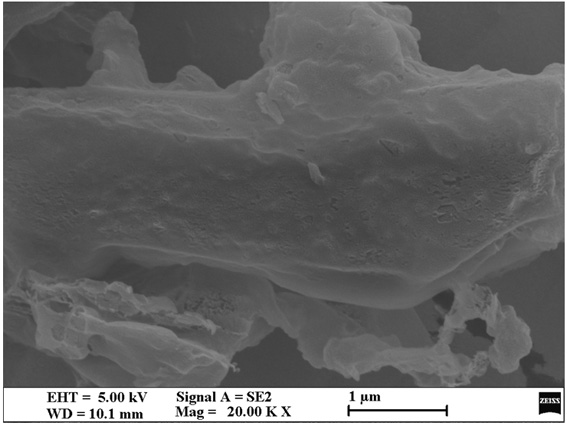

Flame-retardant smoke-suppression soft polyurethane foam composite material and preparation method thereof

The invention belongs to the field of flame-retardant smoke-suppression materials, and particularly relates to a flame-retardant smoke-suppression soft polyurethane foam composite material which is prepared by assembling water-soluble phenolic resin and a ZIFs nano material on the surface of soft polyurethane foam under electrostatic interaction. The invention further relates to a preparation method of the composite material. According to the preparation method, the water-soluble phenolic resin and Co-ZIF-L are used for forming a flame-retardant coating layer on the surface layer of the soft polyurethane foam in a self-assembly mode, on one hand, a carbon layer formed in the combustion process of the phenolic resin has a certain physical barrier effect; and on the other hand, the Co-ZIF-Lnanosheet has a lamellar barrier effect, meanwhile, the nanosheet contains Co element, and Co3O4 generated in the combustion process is capable of catalyzing o form more compact carbon layers, so thatthe flame-retardant and smoke-suppressing effects are achieved. The preparation method provided by the invention has the advantages of easily available raw materials, simple method, greenness and environmental protection.

Owner:ANHUI UNIVERSITY OF ARCHITECTURE

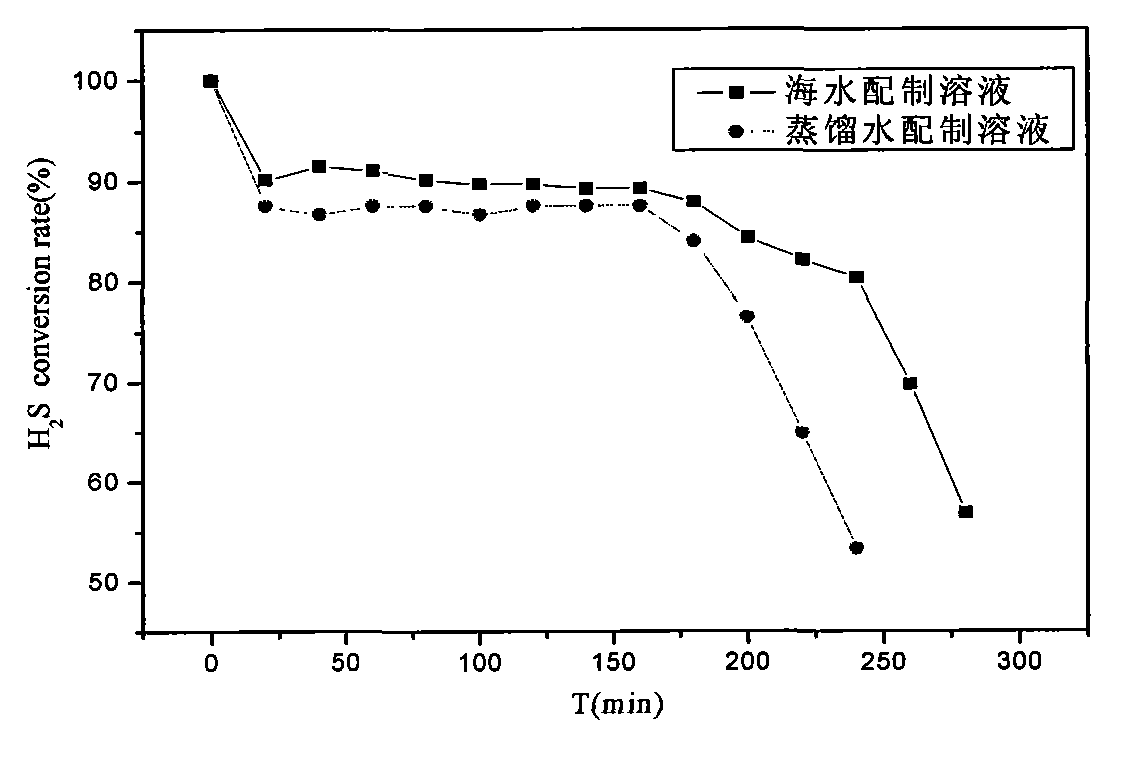

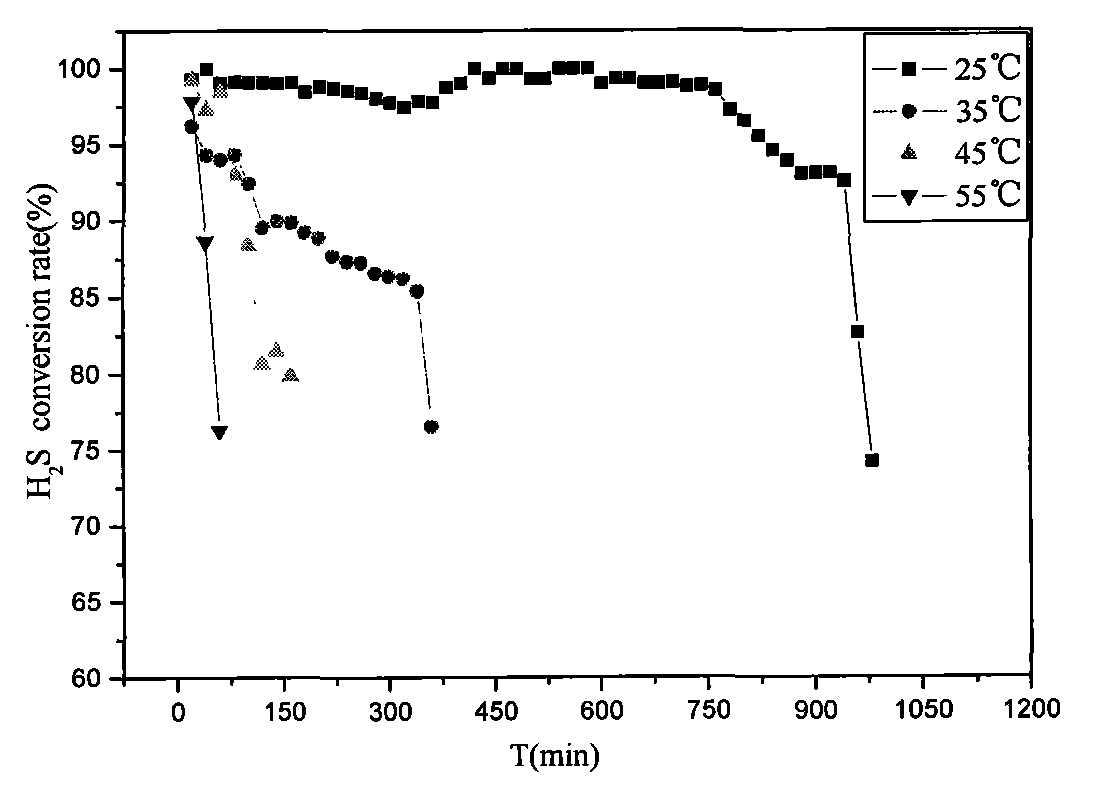

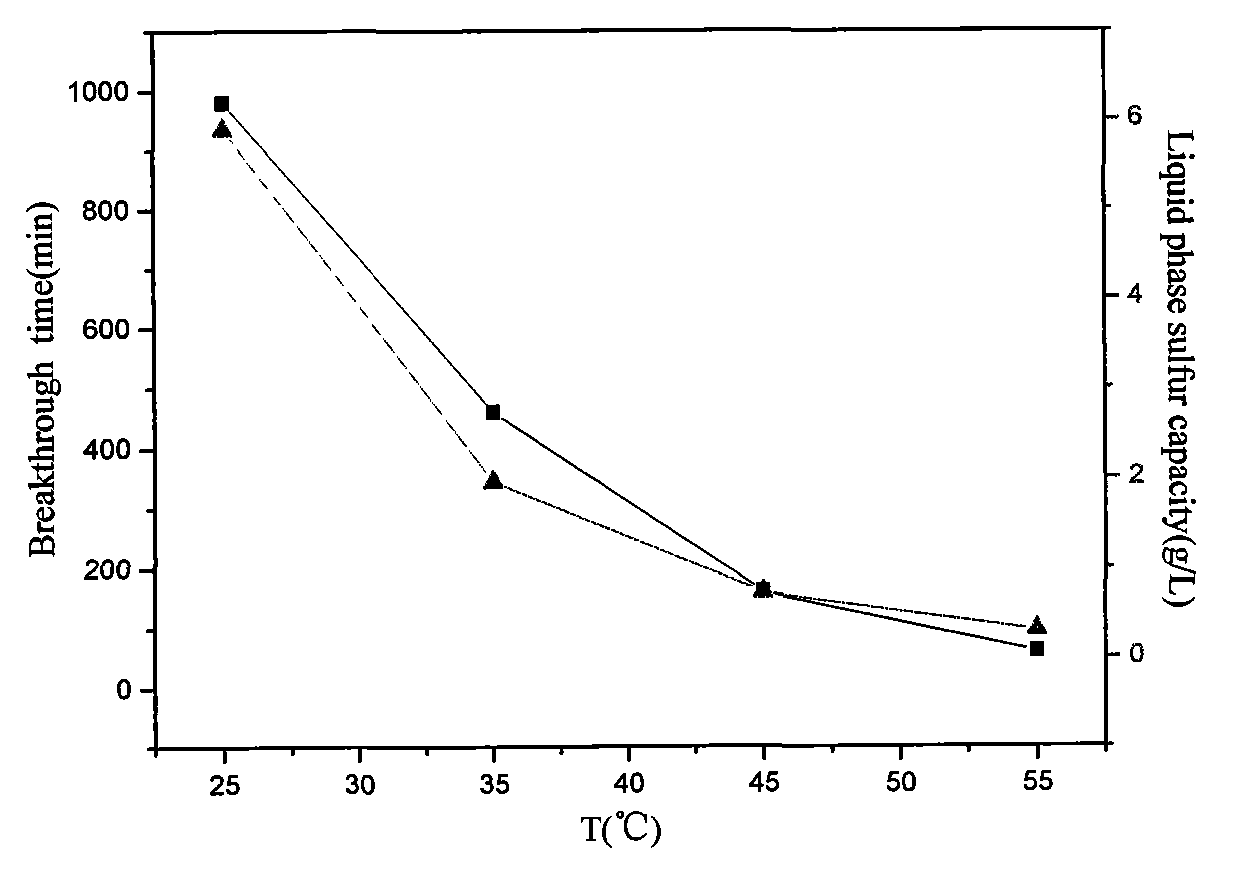

Method for removing H2S in offshore oil production associated gas by utilizing seawater modified LO-CATII method

InactiveCN103801183AOvercome toxicOvercome flammableGaseous fuelsDispersed particle separationSulfurOil production

The invention discloses a method for removing H2S in offshore oil production associated gas by utilizing seawater modified LO-CATII process. The method comprises the steps of leading simulated natural gas containing H2S into redox medium absorption liquid prepared by seawater in which a catalyst and a complexing agent are added, blowing a certain amount of air into the adsorption liquid, replacing part of absorption liquid to continue to desulfurize when the concentration of H2S at a reactor outlet exceeds an index. After the product sulfur in the replaced absorption liquid is filtered, the replaced absorption liquid can be recycled through air regeneration. The method has the advantages that the deficiencies that the conventional desulfurization method has hidden pollution to a sea, the desulfurization liquid is toxic and inflammable, the occupied area is large and the like can be overcome, the technological requirement on the limited volume of an offshore oil production platform and low temperature, low pressure and high-safety coefficients can be met, and the method can comply with the development trend of blue ocean economy.

Owner:OCEAN UNIV OF CHINA

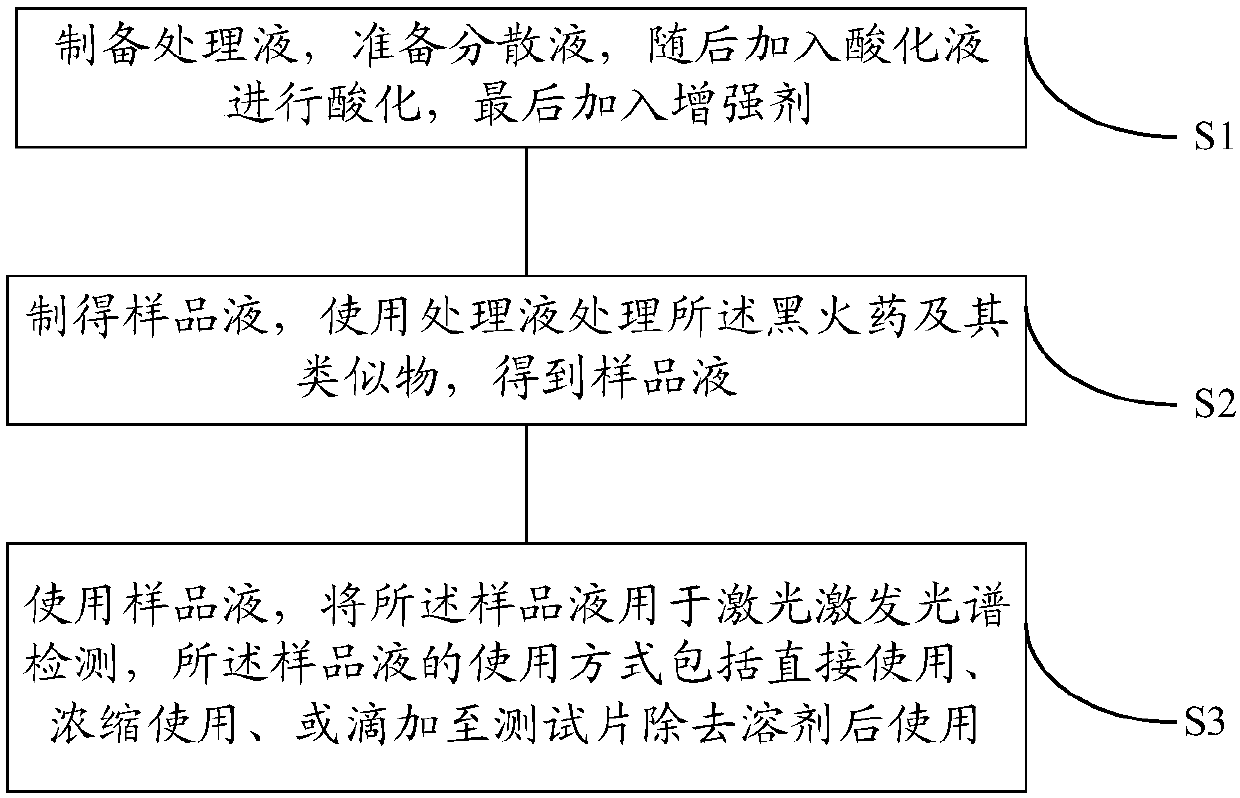

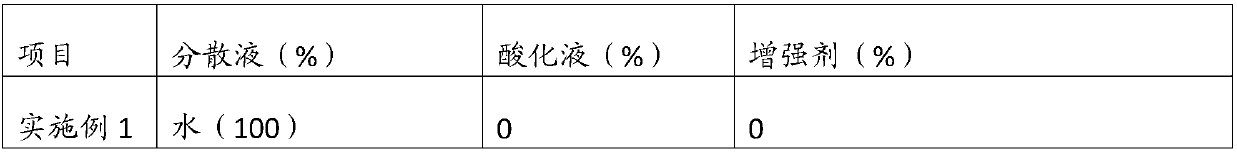

Method for preprocessing black powder and its analogues

ActiveCN107631918ACapable of dissolvingWith extractionPreparing sample for investigationPhysical chemistrySolvent

The invention discloses a method for preprocessing black powder and its analogues. The method comprises the following steps: processing the black powder and its analogues by using a treatment liquid to obtain a sample solution, and carrying out laser excitation spectroscopy detection on the sample solution to obtain the component detection result of the black powder and its analogues, wherein thesample solution can be used directly, after being concentrated, or after being dropwise added to a test strip and removing a solvent. The method solves the inflammable problem of the black powder andits analogues, greatly enhances the laser excitation spectrum signal of the black powder, makes safe and rapid detection of the black powder possible, allows the range of detected components to be wide, and provides convenience for the checking and identifying work of dangerous substances.

Owner:BEIJING HTNOVA DETECTION TECH CO LTD

A flame-retardant and smoke-suppressing flexible polyurethane foam composite material and its preparation method

The invention belongs to the field of flame-retardant and smoke-suppressing materials, in particular to a flame-retardant and smoke-suppressing flexible polyurethane foam composite material. Got it. The present invention also relates to a method for preparing the above composite material. The water-soluble phenolic resin and Co-ZIF-L are used to form a flame retardant coating on the surface layer of the flexible polyurethane foam through self-assembly. On the one hand, the phenolic resin is formed during the combustion process. The carbon layer has a certain physical barrier effect; on the other hand, the Co‑ZIF‑L nanosheets have a lamellar barrier effect, and the nanosheets contain Co element, which is generated during the combustion process. 3 O 4 It can catalyze the formation of more and dense carbon layers, so as to play the role of flame retardant and smoke suppression. The preparation method of the invention has the advantages of easy-to-obtain raw materials, simple method and environmental protection.

Owner:ANHUI UNIVERSITY OF ARCHITECTURE

Decoloring method of chlorobenzene glyceryl ether

The invention discloses a decoloring method of chlorobenzene glyceryl ether. The method comprises the following process steps of: adding a chlorobenzene glyceryl ether product recrystallized by a water-alcohol mixed solvent into a heating reaction kettle, and adding pure water and alkali into the reaction kettle; stirring the materials in the reaction kettle and heating the materials to 50-80 DEG C; after the materials are uniformly dissolved, adding an oxidizing agent into the dissolved solution, and carrying out heat preservation reaction for 1-3 hours; adding an adsorbent into the reaction liquid and reacting for 0.5-1 hour; filtering while hot to obtain filtrate, standing and separating to obtain a product phase; and obtaining the product by recrystallizing, filtering and drying the product phase. The product is white powder in appearance and almost colorless in a molten state, the purity of the product reaches 99.5% or above, the product quality is obviously improved, the process concept of high efficiency, safety and quality and efficiency improvement is achieved, and conditions are created for industrial application of the product.

Owner:SHAANXI RES DESIGN INST OF PETROLEUM CHEM IND

Fireproof and flame-retardant insulation phenolic foam board

The invention belongs to the technical field of chemical heat preservation materials, and is a fireproof and flame-retardant phenolic heat preservation foam board, which consists of the following raw materials in parts by weight: 65-80 parts by weight of phenolic resin, 5-15 parts of foaming agent, 5-10 parts of curing agent, and benzenesulfonate Acid 2.5-5, benzoic acid 2.5-5, additives 1-5; during preparation, put phenolic resin, foaming agent, and additives into a reaction kettle and keep warm at room temperature, stir and mix evenly, and then add curing agent, benzenesulfon A closed-cell rigid foam board made under the action of acid and benzoic acid; the product of the present invention has the characteristics of light weight, non-combustibility, low smoke, high temperature resistance, non-toxic, and no dripping. Due to the high closed-cell rate of phenolic foam, the It has low thermal conductivity, good heat insulation performance, and has water resistance and water vapor permeability. It is an ideal thermal insulation and energy-saving material. The foam insulation material is light in weight and convenient in construction.

Owner:陈璐

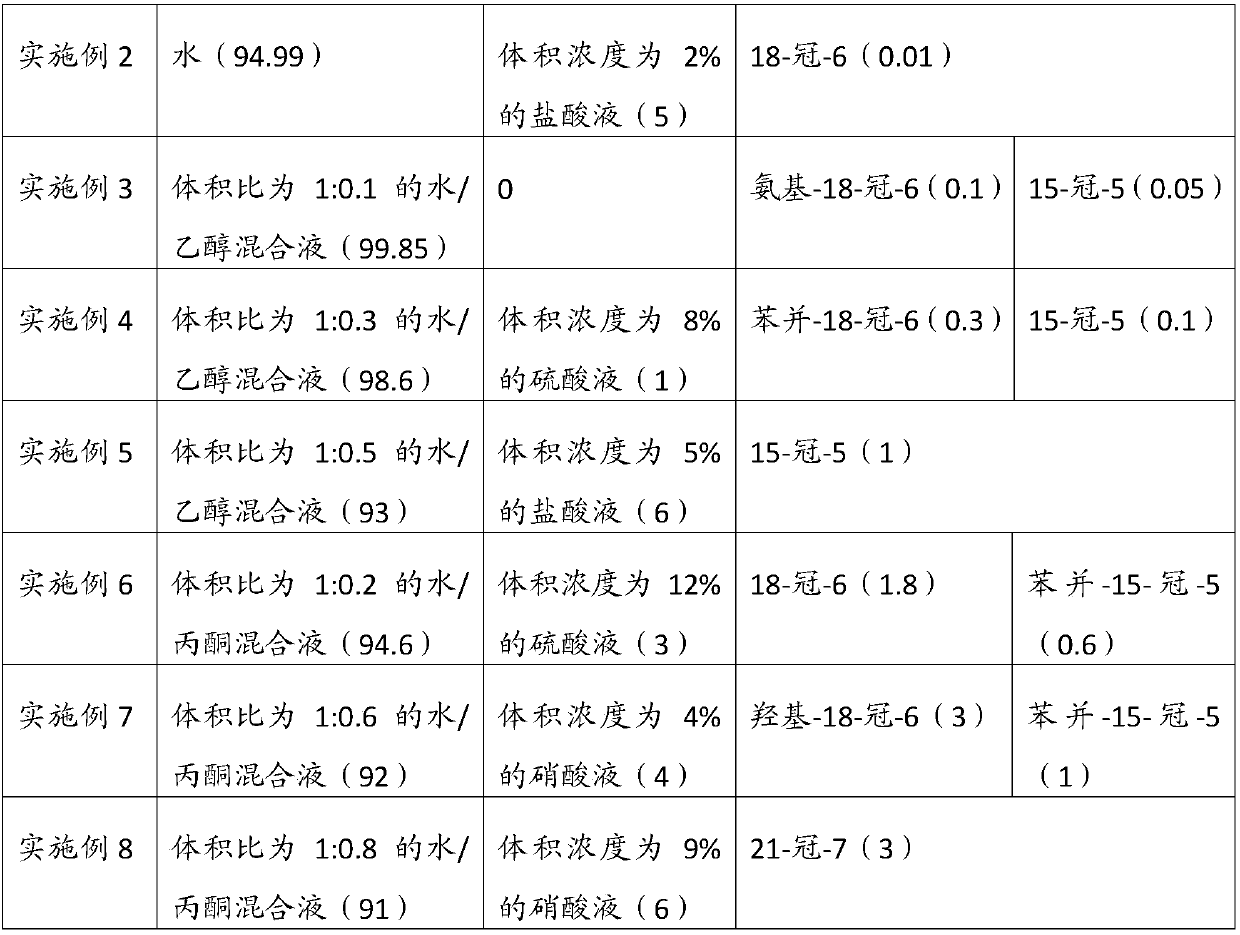

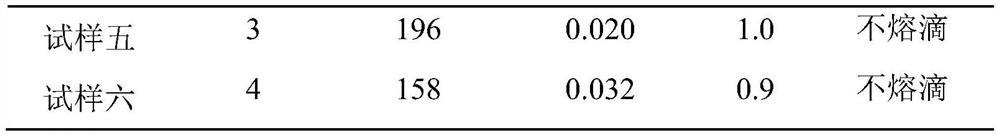

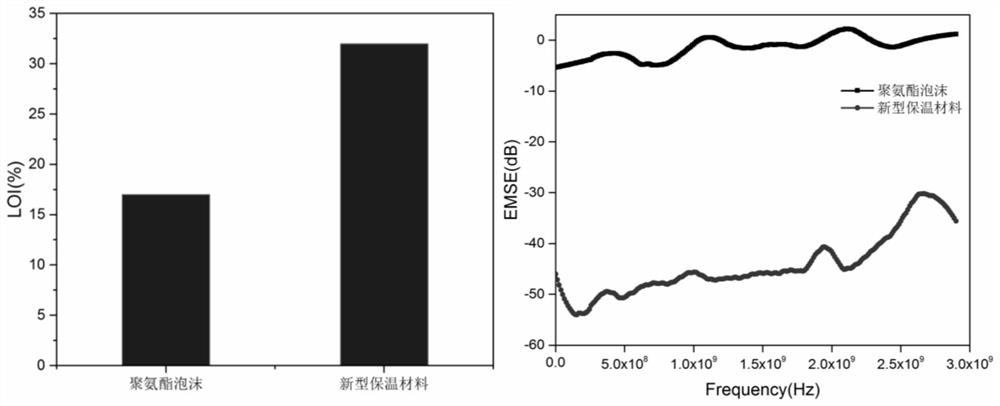

A kind of mxenes/polyurethane insulation material and preparation method thereof

ActiveCN111172672BFlame retardantOvercome flammableElectroconductive/antistatic filament manufactureFlame-proof filament manufactureToxic gasSpinning

The present invention relates to the preparation of composite materials, more particularly to an MXenes / polyurethane thermal insulation material and a preparation method thereof. According to the preparation method of the material, an electrostatic melt blowing technology is adopted, a polyurethane mixed liquid containing different contents of polysulfonamide fibers and flame retardant is preparedinto fiber-shaped bubbles in a blowing-spinning mode through high voltage and air pressure; and then the MXenes and the prepared flame-retardant thermal insulation material are combined through electrostatic spinning to prepare the novel flame-retardant and electromagnetic shielding performance thermal insulation material. The material has the advantages of high thermal insulation, excellent flame retardance, high electromagnetic shielding and the like, and overcomes the defects of flammability and lack of electromagnetic shielding and toxic gas generated in combustion of the traditional thermal insulation material. The method can be adjusted according to different usage environments, the process is simple, the operation is safe, the performance is excellent, and the method is suitable for large-scale production.

Owner:TAIYUAN NORMAL UNIV

Normal-temperature wall coating based on ceramic underglaze painting and coating process of wall coating

InactiveCN112029387AOvercome flammableOvercome agingAntifouling/underwater paintsArtist's paintsCorrosion resistantCeramic glaze

The invention relates to the technical field of wall paint preparation, and discloses a normal-temperature wall coating based on ceramic underglaze painting and a coating process of the wall coating,the normal-temperature wall coating comprises a water-based coating A painted on the bottom layer of a wall, a water-based coating B painted on the middle layer of the wall, a ceramic underglaze painting coating painted on a wall pigment layer, and a glaze surface coating painted on the surface layer of the wall; and after the normal-temperature wall coating is constructed and smeared on a wall, the wall coating is divided into four layers, namely a water-based coating layer located on the bottom layer of the wall, a water-based coating layer located on the middle layer of the wall, a ceramicunderglaze painting coating layer located on the pigment layer of the wall and a glaze coating layer located on the surface layer of the wall in sequence. The coating obtained after construction has the advantages of corrosion resistance, damage resistance, energy conservation, environmental protection and aging resistance, also has the advantages of self-cleaning, non-adhesion and washability, isnot fused with external substances, has good surface hydrophobicity, and can prevent dirt such as dust, gel ink pens, tea stains and leather shoe scratches.

Owner:安徽锦釉新材料科技有限公司

Manufacturing method for cationic flocculant

InactiveCN110386649AOvercome flammableOvercome the disadvantages of being explosive and highly toxicWater/sewage treatment by flocculation/precipitationChemistryEthylenediamine

The invention discloses a manufacturing method for a cationic flocculant. The manufacturing method comprises the following steps: adding dimethylamine, dichloropropanol and an NaOH aqueous solution into a glass reactor with a volume of 500 ml; controlling a reaction temperature at 23 to 27 DEG C, respectively and slowly dropwise adding the dichloropropanol and the NaOH aqueous solution from the top part of the reactor for 50 minutes, after the dichloropropanol and the NaOH aqueous solution are added, maintaining the temperature for 30 minutes; and carrying out heating to 30 DEG C, adding an ethylenediamine aqueous solution, after the ethylenediamine aqueous solution is dropwise added, raising a temperature to 55 DEG C, and carrying out a reaction for 5 h so as to obtain the cationic flocculant. The manufacturing method provided by the invention uses an epichlorohydrin preparation intermediate namely the dichloropropanol as a raw material for synthesis of a cationic polymer flocculant,overcomes the disadvantages of flammability, explosiveness and strong toxicity of epichlorohydrin, simplifies the technical process of epichlorohydrin preparation by a glycerol method, saves energy and reduces the discharging of wastewater.

Owner:青岛长兴高新科技发展有限公司

Thermosetting molding polystyrene board and production process thereof

InactiveCN112194434AOvercome flammableImprove flame retardancyCeramic shaping apparatusHeat proofingPolystyrene particleFlame resistance

The invention discloses a thermosetting molding polystyrene board and a production process thereof. The thermosetting molding polystyrene board comprises the following components: polystyrene particles, cement, glass fibers, fine sand, coarse whiting, fly ash, a flame retardant, an interface agent and water. The production process of the thermosetting molding polystyrene board comprises the following steps of (1) uniformly mixing and stirring polystyrene particles, cement, glass fibers, fine sand, an anti-cracking agent, fly ash, a flame retardant and water to obtain a mixture A, (2) adding aninterface agent into the mixture A, and uniformly mixing and stirring under a heating condition to obtain a mixed solution B, and (3) pouring the mixed solution B into a mold for molding to obtain the thermosetting molding polystyrene board. The cement, the glass fibers, the fine sand, the anti-cracking agent, the coal ash and the flame retardant are added into the polyphenyl particles through stirring under the heating condition, the phenomena that a traditional building external wall panel is inflammable, low in structural strength and prone to falling off are overcome, and the strength andflame retardance of the produced polyphenyl board are remarkably improved.

Owner:青岛领军建材科技股份有限公司

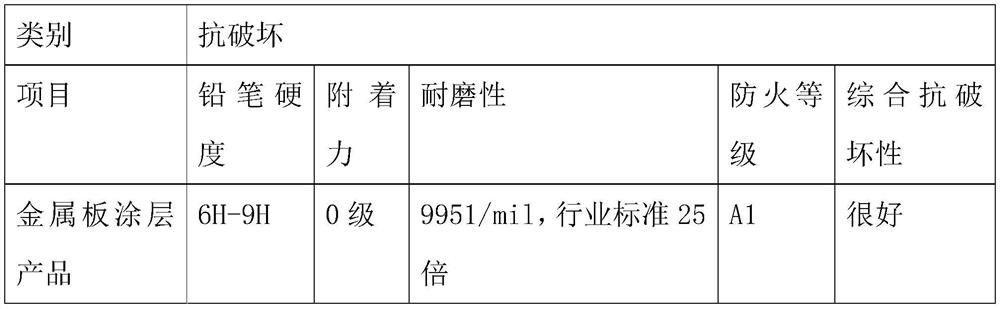

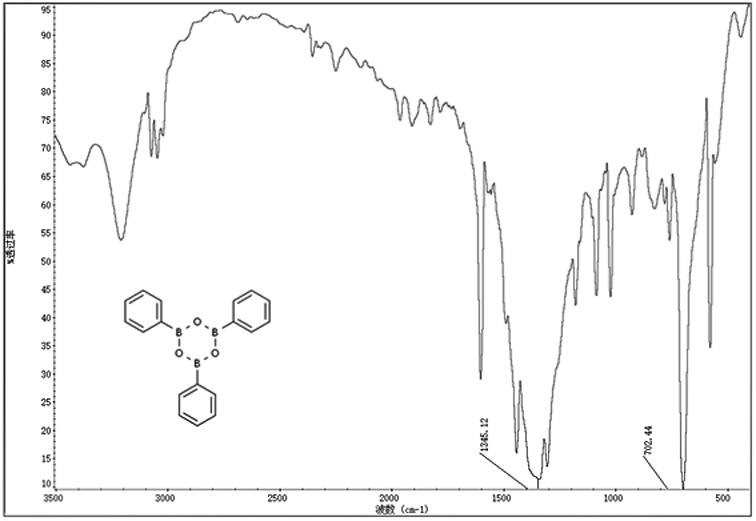

Flame-retardant antistatic TPU composite material

ActiveCN114836023AIt has the benefits of health and environmental protectionImprove flame retardant performancePolymer scienceCombustion

The invention discloses a flame-retardant antistatic TPU composite material, and belongs to the field of plastic processing. Expandable graphene oxide, ammonium polyphosphate, triphenyl boroxane, TPU (thermoplastic polyurethane) particles and DMF (dimethyl formamide) are used as raw materials, and melt blending and extrusion molding methods are adopted for preparation. The obtained flame-retardant antistatic TPU composite material can realize rapid surface carbon formation during combustion, can realize rapid self-extinguishing after a fire source is removed, has a strong smoke suppression effect, and also has good antistatic performance.

Owner:FUZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com