A flame-retardant and smoke-suppressing flexible polyurethane foam composite material and its preparation method

A soft polyurethane and composite material technology, applied in coating and other directions, can solve problems such as inability to achieve effects, and achieve the effects of delaying the transfer of substances and heat, readily available raw materials, and simple preparation methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

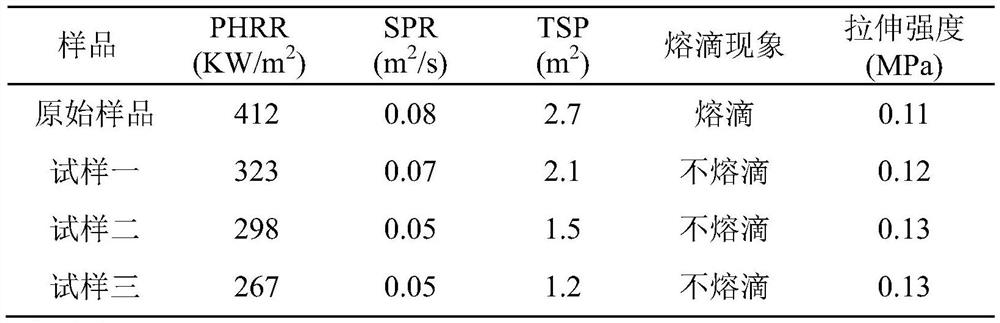

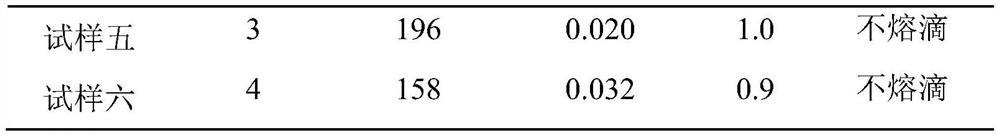

Examples

Embodiment 1

[0022] 1. Preparation of flame-retardant and smoke-suppressing flexible polyurethane foam composites

[0023] a) Preparation of water-soluble phenolic resin solution: molten phenol and formaldehyde aqueous solution are mixed in a molar ratio of 1:2, stirred mechanically, then weighed NaOH according to 2% of the total mass of phenol and formaldehyde, reacted at 65°C for 50min, and raised the temperature to Continue to react at 85°C for 30 minutes to obtain a water-soluble phenolic resin; dissolve the water-soluble phenolic resin in deionized water, adjust the pH value with 1mol / L NaOH solution so that the pH value of the solution is 9.0, stir for 20 minutes, and prepare a 0.5wt% water-soluble phenolic resin solution;

[0024] Preparation of Co-ZIF-L suspension: Co(NO 3 )·6H 2 O was dissolved in deionized water to prepare a solution A with a concentration of 0.034mol / L, and then dimethylimidazole was dissolved in deionized water to prepare a solution B with a concentration of ...

Embodiment 2

[0032] 1. Preparation of flame-retardant and smoke-suppressing flexible polyurethane foam composites

[0033] a) Preparation of water-soluble phenolic resin: molten phenol and formaldehyde aqueous solution were mixed at a molar ratio of 1:2.5, mechanically stirred, and then NaOH was weighed according to 2% of the total mass of phenol and formaldehyde. After reacting at 65°C for 50 minutes, raise the temperature to 85°C and continue the reaction for 30 minutes to obtain a water-soluble phenolic resin; dissolve the water-soluble phenolic resin in deionized water, adjust the pH value with 1mol / L NaOH solution so that the pH value of the solution is 10.0, and stir 20min, be prepared into 0.75wt% water-soluble phenolic resin solution;

[0034] Preparation of Co-ZIF-L suspension: Co(NO 3 ) 2 ·6H 2 O was dissolved in deionized water to prepare a solution A with a concentration of 0.034mol / L, and then dimethylimidazole was dissolved in ionized water to prepare a solution B with a c...

Embodiment 3

[0043] 1. Preparation of flame-retardant and smoke-suppressing flexible polyurethane foam composites

[0044] a) Preparation of water-soluble phenolic resin solution: molten phenol and formaldehyde aqueous solution are mixed in a molar ratio of 1:3, stirred mechanically, and then weighed NaOH according to 2% of the total mass of phenol and formaldehyde, reacted at 65°C for 50min, and raised the temperature to Continue to react at 85°C for 30 minutes to obtain a water-soluble phenolic resin; dissolve the water-soluble phenolic resin in deionized water, adjust its pH value with 1mol / L NaOH solution so that the pH value of the solution is 9.5, stir for 20 minutes, and prepare a phenolic resin with a mass fraction of 1 wt%. Water-soluble phenolic resin solution;

[0045] Preparation of Co-ZIF-L suspension: Co(NO 3 ) 2 ·6H 2 O was dissolved in deionized water to prepare a solution A with a concentration of 0.034mol / L, and then a certain mass of dimethylimidazole was dissolved in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com