A kind of mxenes/polyurethane insulation material and preparation method thereof

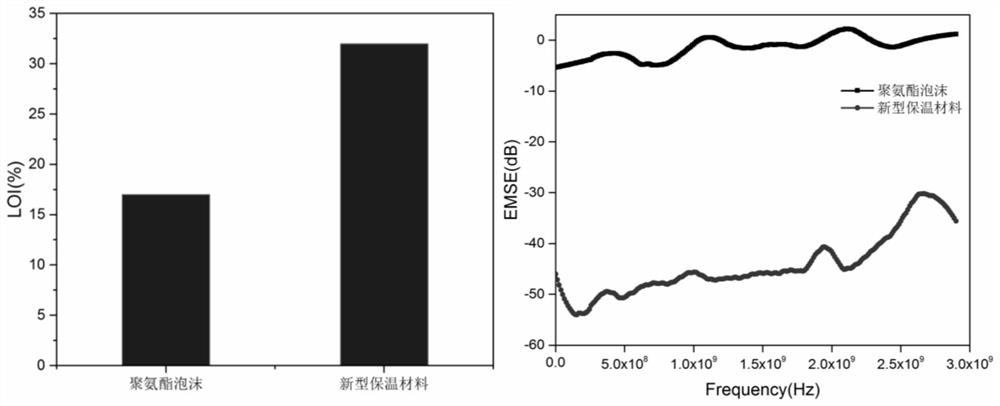

A thermal insulation material, polyurethane technology, applied in conductive/antistatic filament manufacturing, filament/thread forming, fire-retardant and flame-retardant filament manufacturing, etc., can solve the problems of complex process, achieve excellent electromagnetic shielding, good flame performance, the effect of overcoming flammability and lack of electromagnetic shielding properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A kind of preparation method of MXenes / polyurethane insulation material of the present embodiment, comprises the following steps:

[0027] Step 1, preparation of spinning solution for flame retardant and thermal insulation materials: take 15g of polyether polyol and 3g of phosphate ester flame retardant, use S569T2 / A3 DC servo electric mixer at 1000rpm / min to stir for 15min, mix well, and let stand to completely eliminate air bubbles , and then slowly add ultra-short sulfonamide fibers with a mass fraction of 2.5% at 800rpm / min and stir for 60min, ultrasonically until the ultra-short sulfone fibers are evenly dispersed, let stand to completely eliminate the bubbles, then slowly add 5g of isocyanate, stand still to make the isocyanate Mix slowly and evenly to obtain spinning solution of flame retardant thermal insulation material;

[0028] Step 2, electrostatic melt-blown flame-retardant thermal insulation material: pour the flame-retardant thermal insulation material sp...

Embodiment 2

[0033] A kind of preparation method of the MXenes / polyurethane insulation material with flame-retardant and electromagnetic shielding properties of the present embodiment, comprises the following steps:

[0034] Step 1, preparation of spinning solution for flame retardant insulation material: take 15g polyether polyol and 3g phosphate flame retardant, use S569T2 / A3 DC servo electric mixer at 1100rpm / min to stir for 13min, mix evenly, let stand to completely eliminate air bubbles , and then slowly add ultra-short polysulfone fibers with a mass fraction of 5% at 1000rpm / min and stir for 45min, ultrasonically until the ultra-short polysulfone fibers are evenly dispersed, let stand to completely eliminate the bubbles, then slowly add 10g of isocyanate, and stand to make the isocyanate Mix slowly and evenly to obtain spinning solution of flame retardant thermal insulation material;

[0035] Step 2, electrostatic melt-blown flame-retardant thermal insulation material: pour the flame...

Embodiment 3

[0040] A kind of preparation method of MXenes / polyurethane insulation material of the present embodiment, comprises the following steps:

[0041] Step 1, preparation of spinning solution for flame retardant insulation material: take 15g polyether polyol and 3g phosphate flame retardant, use S569T2 / A3 DC servo electric mixer at 1200rpm / min to stir for 10min, mix evenly, let stand to completely eliminate air bubbles , then slowly add ultra-short sulfonamide fibers with a mass fraction of 7.5% at 1200rpm / min and stir for 30min, ultrasonically until the ultra-short sulfone fibers are evenly dispersed, let stand to completely eliminate the bubbles, then slowly add 15g of isocyanate, stand still to make the isocyanate Mix slowly and evenly to obtain spinning solution of flame retardant thermal insulation material;

[0042] Step 2, electrostatic melt-blown flame-retardant thermal insulation material: pour the flame-retardant thermal insulation material spinning solution obtained in s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com