Wear-resisting anti-flaming poplar solid flooring and preparation method thereof

A technology of flooring and solid wood, which is applied in the direction of impregnating wood, manufacturing tools, and wood impregnation, etc. It can solve the problems of narrow application prospects and achieve the effects of increased use value, enhanced stability, and increased strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

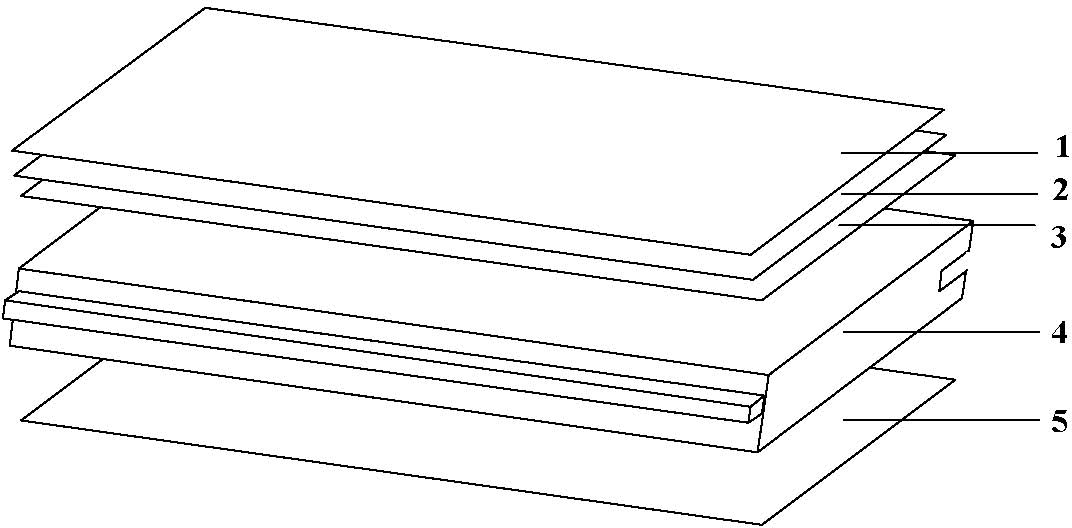

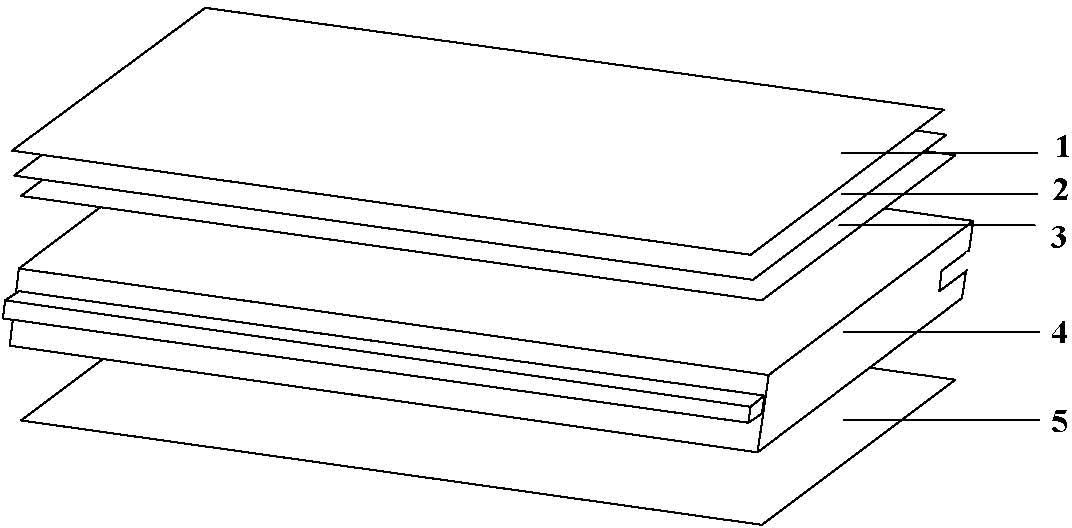

[0038] Example 2: According to the above method, modified poplar wood was used to make a modified solid wood floor blank layer. Choose 0.18mm thick maple veneer, choose light yellow impregnated pattern paper to color, and group the blanks according to the following structure: balanced moisture barrier → modified solid wood floor blank layer → toning pattern paper (light yellow impregnated paper) → 0.18mm thick Maple veneer → high wear-resistant paper (AC5); put the group blanks under the conditions of unit pressure 3MPa~5MPa, temperature 180℃~200℃, hot pressing for 30s; finally cutting, grooving or processing locks, etc. , To obtain the final required specifications of wear-resistant flame-retardant poplar solid wood flooring products. The rest is the same, so I won't repeat it again.

[0039] In a word, the composite modification treatment technology of the present invention can increase the strength and stability of poplar wood, and has the properties of wear resistance, flame...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com