Preparation method of soft and air-ventilating waterborne polyurethane clothes leather base

A water-based polyurethane, garment leather bass technology, applied in polyurea/polyurethane coatings, coatings, textiles and papermaking, etc., can solve the problem of not being able to achieve soft, moisture-permeable and breathable leather feel, ecological and environmental protection, and achieve excellent breathability and moisture permeability. , The effect of strong dermis feeling, uniform and stable pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

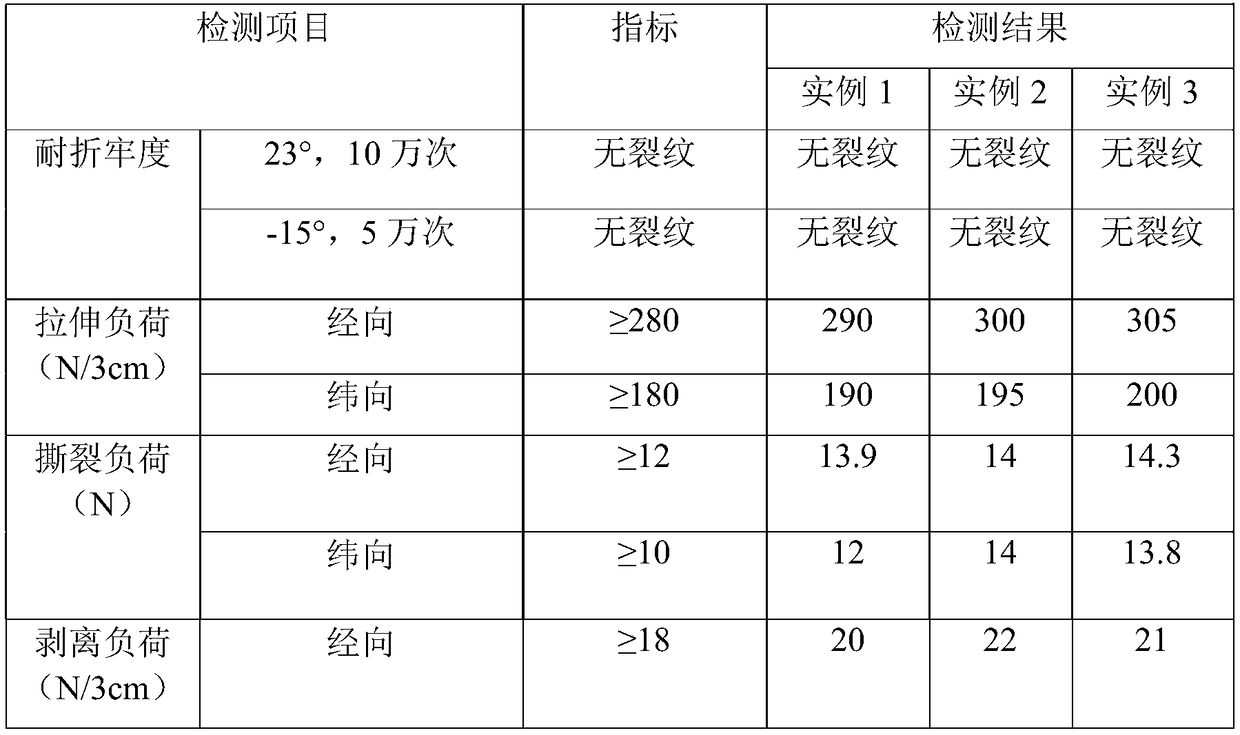

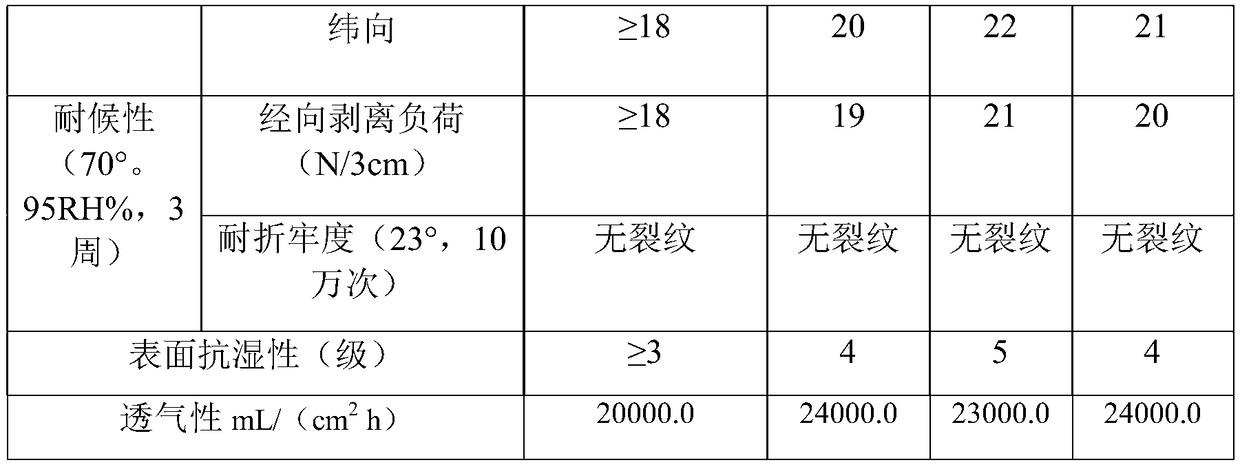

Examples

Embodiment 1

[0025] A method for soft breathable water-based polyurethane garment leather bass, comprising the following steps:

[0026] (1) PVA aqueous solution configuration:

[0027] Weigh 15 parts of PVA solid and 100 parts of tap water, dissolve the PVA solid to obtain the PVA aqueous solution;

[0028] (2) Configure water-based polyurethane foam slurry:

[0029] The foaming slurry is composed of the following raw materials and their parts by weight: 300 parts of KT702F anionic waterborne polyurethane resin with a solid content of 35%, 2.5 parts of A168 powder wetting agent, 30 parts of PVA aqueous solution, and 25 parts of 400 mesh lignocellulose , Silicone modified K12 foaming agent 4.5 parts, 208 silicone resin polyether emulsion foam stabilizer 4.5 parts, crosslinking agent 1.5 parts, water-based thickener 0.5 parts;

[0030] (3) Configure pre-coagulation liquid

[0031] Pre-coagulation liquid raw materials and their composition by weight: 1 part of demulsification cross-linkin...

Embodiment 2

[0044] A method for soft breathable water-based polyurethane garment leather bass, comprising the following steps:

[0045] (1) PVA aqueous solution configuration:

[0046] Weigh 18 parts of PVA solid and 100 parts of tap water, dissolve the PVA solid to obtain the PVA aqueous solution;

[0047] (2) Configure water-based polyurethane foam slurry:

[0048] The foaming slurry is composed of the following raw materials and their parts by weight: KT702F anionic waterborne polyurethane resin 310 with a solid content of 40, 2.8 parts of A168 powder wetting agent, 40 parts of PVA aqueous solution, 28 parts of 600 mesh lignocellulose, organic silicon 5 parts of modified K12 foaming agent, 5 parts of 208 silicone polyether emulsion foam stabilizer, 1.8 parts of crosslinking agent, 1 part of water-based thickener;

[0049] (3) Configure pre-coagulation liquid

[0050] Pre-coagulation liquid raw materials and their composition by weight: 2 parts of demulsification cross-linking agent,...

Embodiment 3

[0062] A method for soft breathable water-based polyurethane garment leather bass, comprising the following steps:

[0063] (1) PVA aqueous solution configuration:

[0064] Weigh 20 parts of PVA solid and 100 parts of tap water, and dissolve the PVA solid to obtain the PVA aqueous solution;

[0065] (2) Configure water-based polyurethane foam slurry:

[0066] The foaming slurry is composed of the following raw materials and their parts by weight: 300 parts of KT705 anionic waterborne polyurethane resin with a solid content of 45%, 3 parts of A168 powder wetting agent, 45 parts of PVA aqueous solution, 30 parts of 1000 quality cellulose, and 30 parts of organic silicon 6 parts of modified K12 foaming agent, 6 parts of 208 silicone resin polyether emulsion foam stabilizer, 2 parts of crosslinking agent, 2 parts of water-based thickener;

[0067] (3) Configure pre-coagulation liquid

[0068] Pre-coagulation liquid raw materials and their composition by weight: 3 parts of demul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com