High-springback high-stretching clothing leather and preparation method thereof

A garment leather, high-resilience technology, applied in coating, textile and papermaking, etc., can solve the problem of inability to achieve the sensuality of wet-fabricated garment leather, inability to achieve high-resilience and high-stretch garment leather, and inability to make high-resilience High-stretch garment leather and other problems, to achieve the effect of full elasticity, soft hand feeling, and satisfying demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

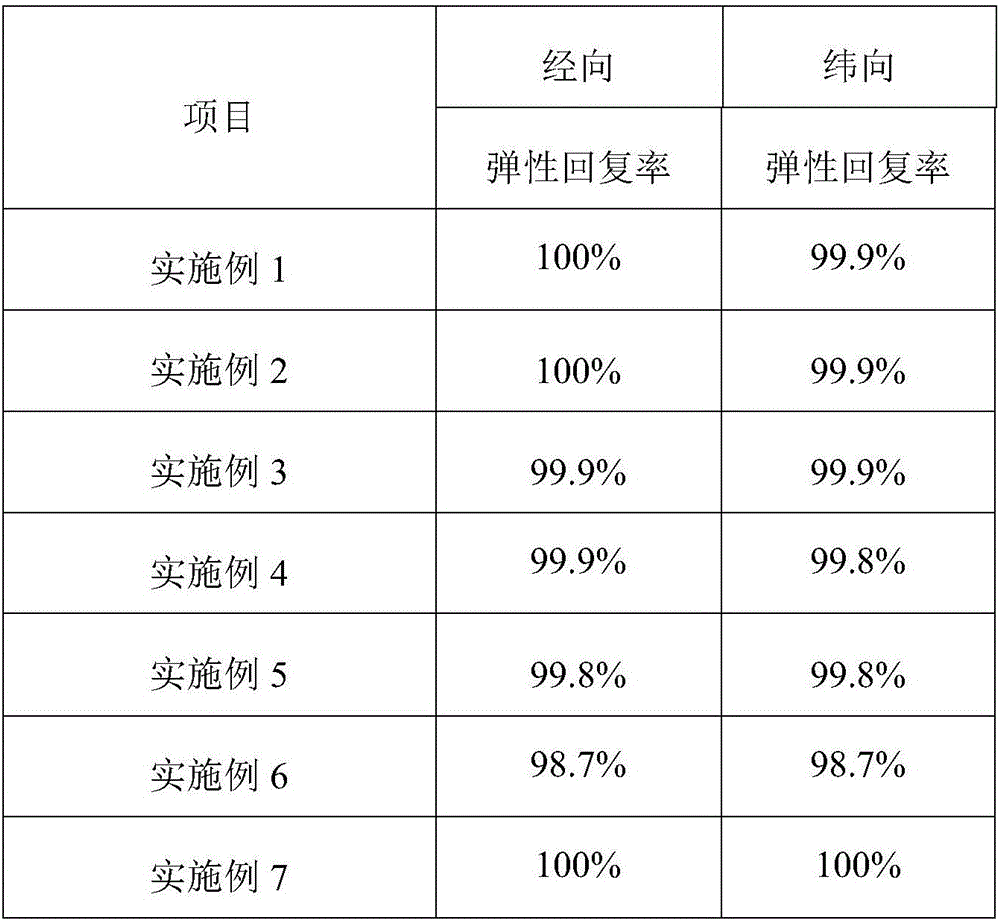

Examples

Embodiment 1

[0047] (1) Preparation of slurry for surface layer, foaming middle layer and bottom layer:

[0048] (1) Preparation of the slurry of the surface layer:

[0049] Take 100kg of water-based polyurethane resin KTT737 (Hefei Ketian Chemical), 6kg of water-based color paste, 0.8kg of RHEOLATE208 water-based thickener, 0.4kg of TEGO902W defoamer, 0.5kg of BD-3376 leveling agent, and add them to the mixer After stirring evenly, stir until the slurry is evenly dispersed.

[0050] (2) Preparation of the slurry of the foaming middle layer:

[0051] Add 0.8kg of RHEOLATE208 water-based thickener, 5kg foaming agent zinc stearate (Henan Huier Nano), 5kg foam stabilizer 207 in 350kg waterborne polyurethane resin KTG703E (solid content is 35%, Hefei Ketian Chemical Industry) (Qingdao Zhongbao Chemical), 2kg crosslinking agent PZP-1000 (Guangzhou Jianyi) and 3.5kg curing agent 3099 (Germany Bayer), stir with a high-speed mixer, and foam to 1.4 times the original volume.

[0052] (3) Prepara...

Embodiment 2

[0060] (1) Preparation of slurry for surface layer, foaming middle layer and bottom layer:

[0061] (1) Preparation of the slurry of the surface layer:

[0062] Take 100kg of water-based polyurethane resin KTT737 (Hefei Ketian Chemical), 2kg of water-based color paste, 0.4kg of RHEOLATE208 water-based thickener, 0.2kg of BYK-045 defoamer, 0.5kg of BD-3376 leveling agent, add In the blender, after stirring evenly, stir until the slurry is evenly dispersed.

[0063] (2) Preparation of the slurry of the foaming middle layer:

[0064] Add 0.4kg of RHEOLATE208 water-based thickener, 1kg foaming agent zinc stearate (Henan Huier Nano), 1kg foam stabilizer 207 in 350kg waterborne polyurethane resin KTG703E (solid content is 35%, Hefei Ketian Chemical Industry) (Qingdao Zhongbao Chemical), 0.5kg crosslinking agent PZP-1000 (Guangzhou Jianyi) and 1kg curing agent 3099 (Germany Bayer), stir with a high-speed mixer, and foam to 1.4 times the original volume.

[0065] (3) Preparation of...

Embodiment 3

[0073] (1) Preparation of slurry for surface layer, foaming middle layer and bottom layer:

[0074] (1) Preparation of the slurry of the surface layer:

[0075] Take 100kg of water-based polyurethane resin KTT737 (Hefei Ketian Chemical), 12kg of water-based color paste, 1.5kg of RHEOLATE208 water-based thickener, 0.8kg of BYK-045 defoamer, 1.2kg of BD-3376 leveling agent, add In the blender, after stirring evenly, stir until the slurry is evenly dispersed.

[0076] (2) Preparation of the slurry of the foaming middle layer:

[0077] Add 0.8kg of RHEOLATE208 water-based thickener, 3kg foaming agent zinc stearate (Henan Huier Nano), 5kg foam stabilizer 207 in 350kg waterborne polyurethane resin KTG703E (solid content is 35%, Hefei Ketian Chemical Industry) (Qingdao Zhongbao Chemical), 1.2kg crosslinking agent PZP-1000 (Guangzhou Jianyi) and 5kg curing agent 3099 (Germany Bayer), stir with a high-speed mixer, and foam to 1.4 times the original volume.

[0078] (3) Preparation o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com