Composite electrode and electrolytic capacitor

A technology of electrolytic capacitors and composite electrodes, which is applied in the direction of electrolytic capacitors, solid electrolytic capacitors, liquid electrolytic capacitors, etc., can solve problems such as crack leakage current, oxide layer damage, and inability to completely cover capacitors to achieve good compatibility and increase insulation sex, increase the effect of draping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1~4 and comparative example 1~4

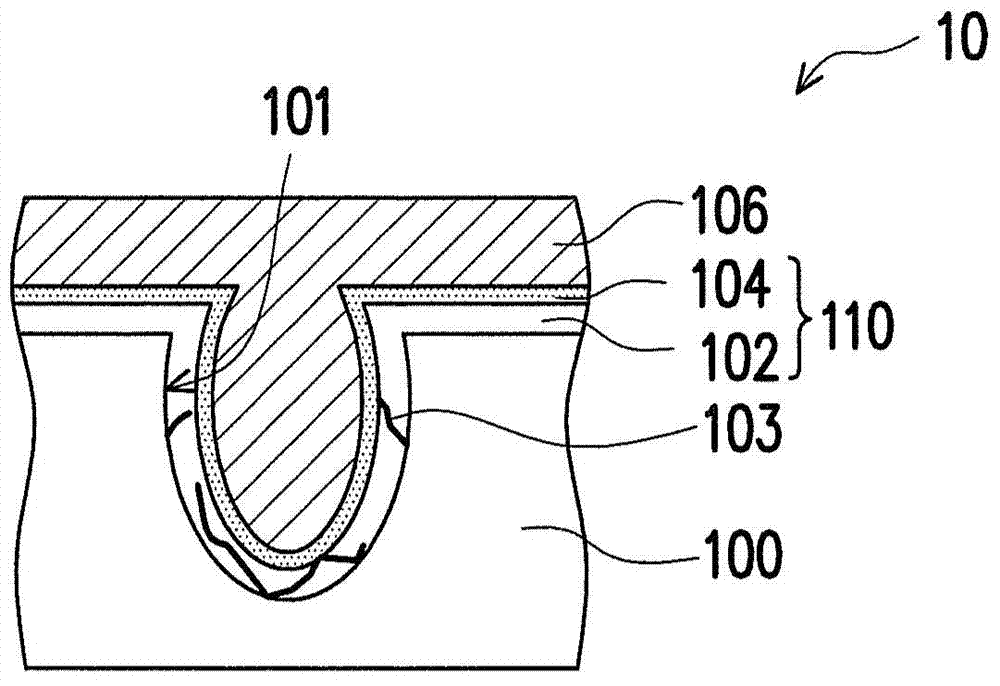

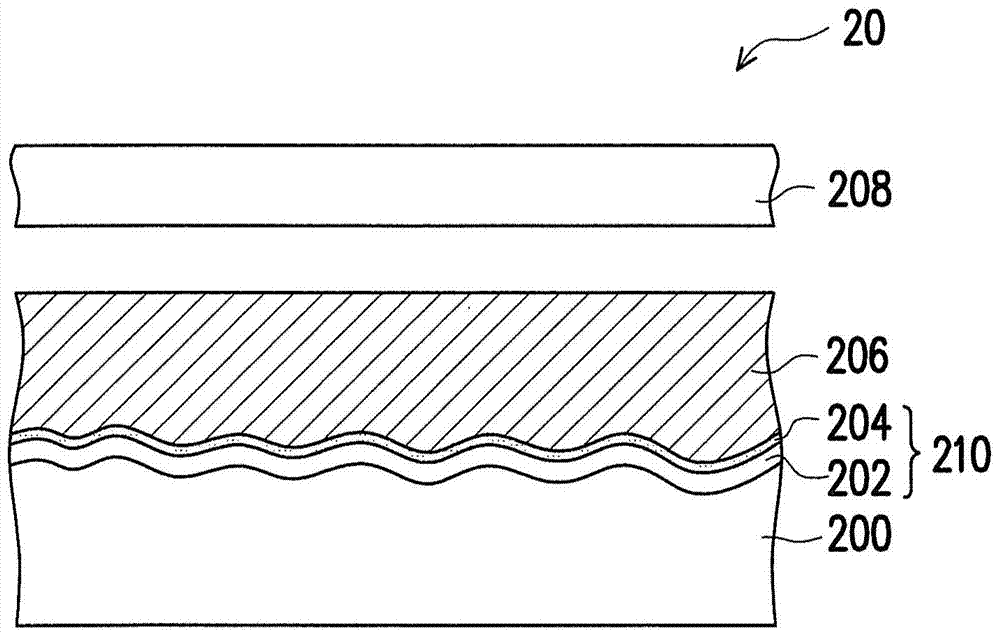

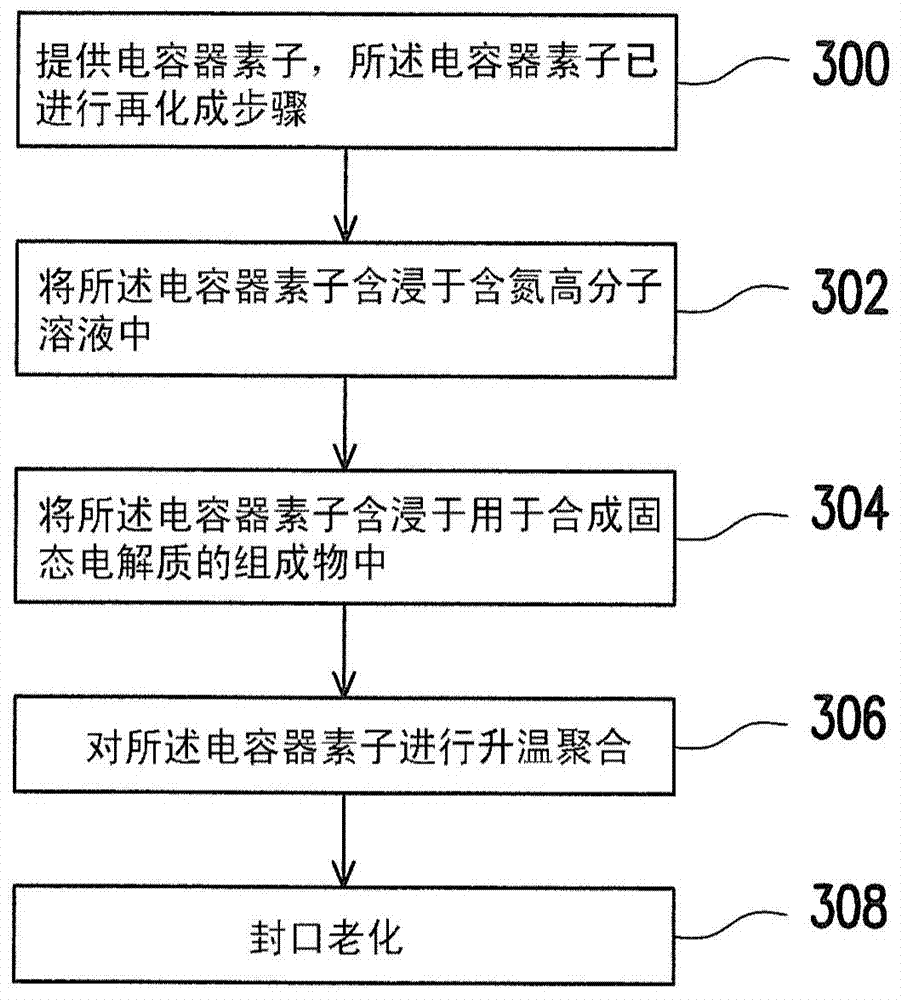

[0084] The aluminum oxide dielectric layer positive electrode aluminum foil formed by 143V electrochemical electrolysis reaction and the high surface area negative electrode carbon foil are sandwiched by a separator paper and then wound into a solid electrolytic capacitor element. Then, the element can optionally repair the damaged aluminum oxide dielectric layer with an aqueous organic acid solution. Next, the element was dipped in the modification solution listed in Table 1, and then dried. After that, 3,4-ethylenedioxythiophene (EDOT) monomer solution and ferric toluenesulfonate oxidant solution are impregnated successively, and then the temperature is raised to accelerate the polymerization reaction. During the reaction, the maximum temperature can reach 170 degrees Celsius to ensure the complete reaction . Then put the solid electrolytic capacitor element into the aluminum shell, seal it with a rubber cover, and complete the production of the solid electrolytic capacitor...

example 5 and comparative example 5

[0099] The aluminum oxide dielectric layer positive electrode aluminum foil formed by 175V electrochemical electrolysis reaction and the electrochemically corroded high surface area negative electrode carbon foil are sandwiched by a separator paper and then wound into an electrolytic capacitor element. Then, the element can optionally repair the damaged aluminum oxide dielectric layer with an aqueous organic acid solution. Next, the element was dipped in the modification solution listed in Table 2, and then dried. After that, 3,4-ethylenedioxythiophene (EDOT) monomer solution and ferric toluenesulfonate oxidant solution are impregnated successively, and then the temperature is raised to accelerate the polymerization reaction. During the reaction, the maximum temperature can reach 170 degrees Celsius to ensure the complete reaction . Then put the solid electrolytic capacitor element into the aluminum shell and seal it with a rubber cover to complete the production of the solid...

example 6 and comparative example 6

[0106] A positive electrode aluminum foil with an alumina dielectric layer formed by 65V electrochemical electrolytic reaction and an electrochemically corroded high surface area negative electrode carbon foil are sandwiched by a separator paper and then wound into a solid electrolytic capacitor element. Then, the element can optionally repair the damaged aluminum oxide dielectric layer with an aqueous organic acid solution. Afterwards, impregnate the element in the modification solution listed in Table 3, and then dry it to allow the epoxy resin to undergo a cross-linking reaction. After that, 3,4-ethylenedioxythiophene (EDOT) monomer solution and ferric toluenesulfonate oxidant solution are impregnated successively, and then the temperature is raised to accelerate the polymerization reaction. During the reaction, the maximum temperature can reach 170 degrees Celsius to ensure the complete reaction . Then put the solid electrolytic capacitor element into the aluminum shell a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| current | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com