Method for processing low-ultraviolet high-transmittance window screen fabric

A processing method and fabric technology, applied in the direction of fabric, fabric surface trimming, heating/cooling fabric, etc., can solve the problem of ineffective blocking of ultraviolet radiation, and achieve the effects of improving drape performance, increasing specific gravity, and preventing peeping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The window screen of the invention is very suitable for private or public places such as living rooms, hotels, office meeting rooms, etc., and it integrates decoration and functionality, and is a new product with high added value.

[0028] The present invention will be further described below in conjunction with embodiment:

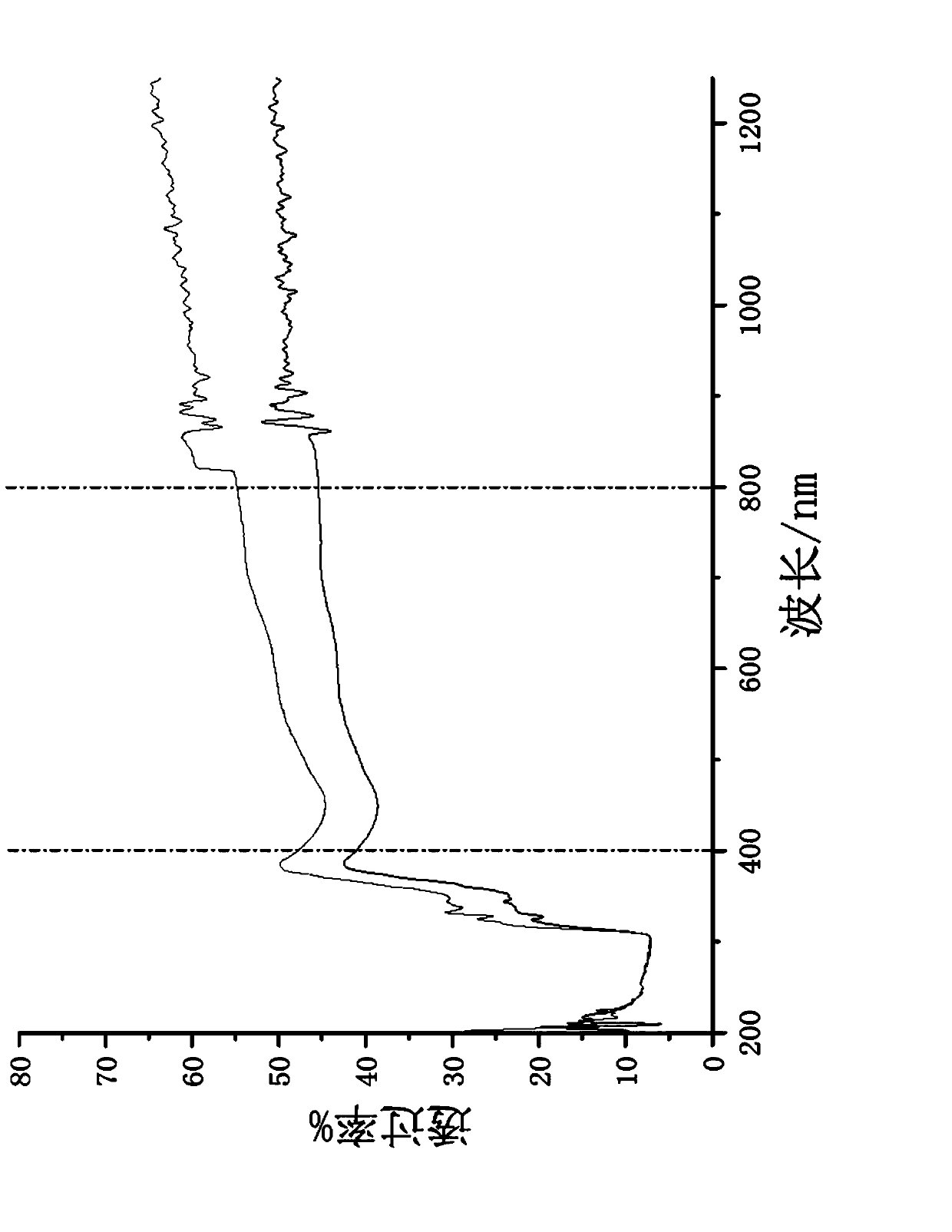

[0029] like figure 1 Shown, the manufacture method of this window screen comprises the following steps:

[0030] 1. Warp 1 uses 20D black and white organza as raw material; weft 2 uses 75D / 72F containing TiO 2 Polyester filament and 150D golden yellow low stretch yarn.

[0031] 2. Weave the selected raw materials on a K88 rapier loom, using 1 / 3 twill weave. The warp yarn is alternately woven with 20D black and white organza 1a, and the weaving density is 640 / 10cm; the weft yarn 2 is 75D / 72F containing TiO 2 The polyester filament 2a and the 200D golden yellow low elastic yarn 2b are woven according to the matching ratio of 3 (white): 1 (golden)...

Embodiment 2

[0034] like figure 2 Shown, the manufacture method of this window screen comprises the following steps:

[0035] 1. Warp 1 uses 20D black and white organza as raw material; weft 2 uses 75D / 72F containing TiO 2 polyester filament and two colors of 200D polyester low stretch yarn.

[0036] 2. Weave the selected raw materials on a K88 rapier loom. The warp yarn 1 is alternately woven with 20D black and white organza, and the weaving density is 600 / 10cm; the weft yarn 2 will be 75D / 72F containing TiO 2 The polyester filament 2a and the 200D golden yellow low elastic yarn 2b of two colors are woven according to the matching ratio of 4 (white): 1 (golden): 4 (white): 1 (dark yellow). The weaving density is 280 / 10cm, and the low elastic yarn 2b includes golden yellow low elastic yarn 1 2b1 and dark yellow low elastic yarn 2 2b2.

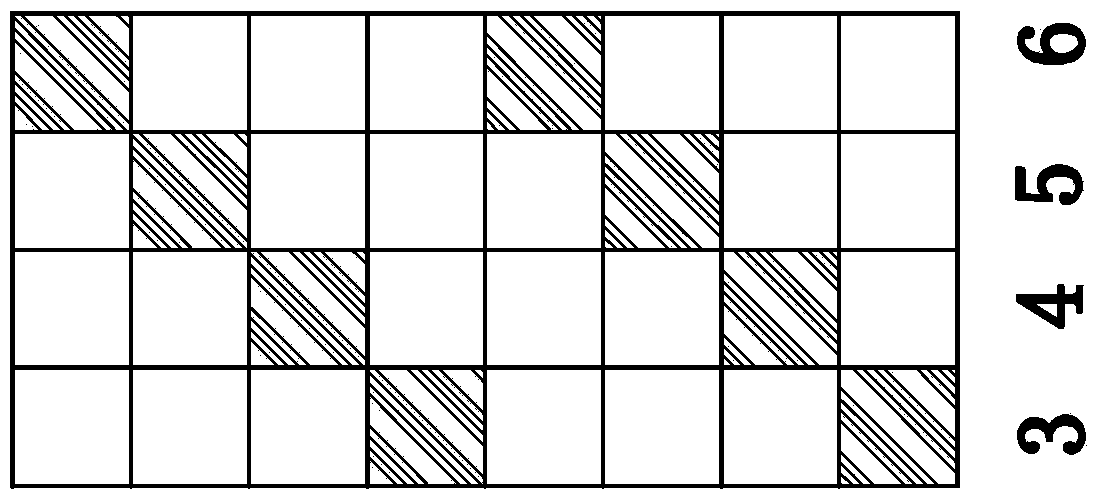

[0037] 3. Choose the self-designed crepe structure, Figure 4 and Figure 5 and Image 6 Shown is the organizational structure diagram of the select...

Embodiment 3

[0040] like image 3 Shown, the manufacture method of this window screen comprises the following steps:

[0041] 1. Warp 1 uses 20D black and white organza as raw material; weft 2 uses 50D / 24F containing TiO 2 Polyester filament and 200D golden yellow polyester low stretch yarn.

[0042] 2. Weave the selected raw materials on a K88 rapier loom, using 1 / 4 twill weave. Warp 1 is alternately woven with 20D black and white organza with a weaving density of 640 / 10cm; weft 2 is 50D / 24F containing TiO 2The polyester filament 2a and the 200D golden yellow low elastic yarn 2b are woven according to the matching ratio of 5 (white): 1 (golden). The weaving density is 320 / 10cm.

[0043] 3. The fabric is shaped by a wet heat setting process, and the woven fabric is treated with hot steam at a temperature of 120° C. for 20 seconds. No dyeing, no coating, not only guarantees the performance of the fabric, but also reduces the cost, and reduces the chemical pollution and environmental da...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com