Clump weight of golf ball rod head

A technology for golf club heads and counterweights, applied in the field of counterweights, which can solve problems such as difficult control of process conditions, affecting the assembly of golf club heads, appearance, bonding strength, process margin and service life, and differences in finished products , to achieve the effect of increasing the proportion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

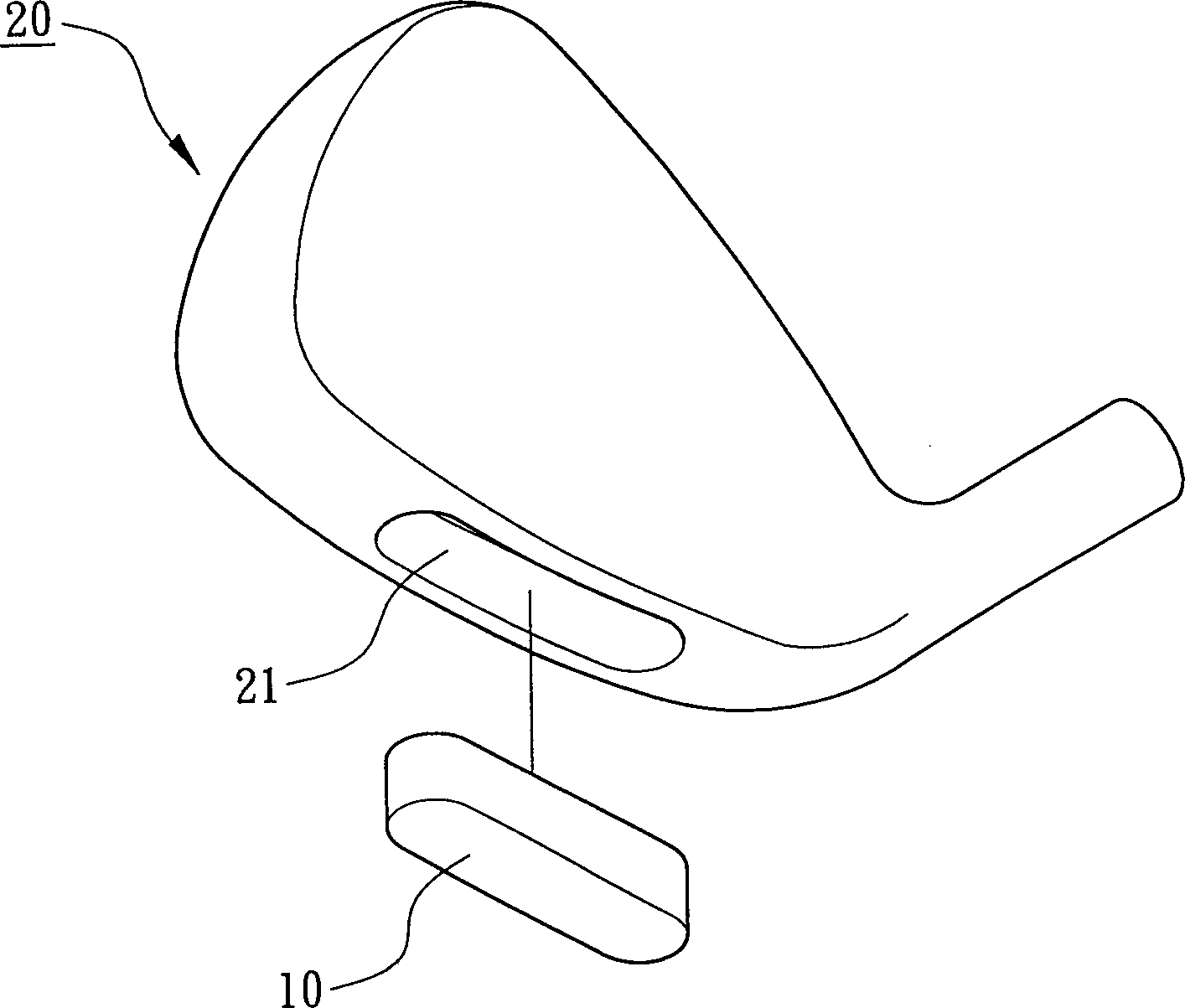

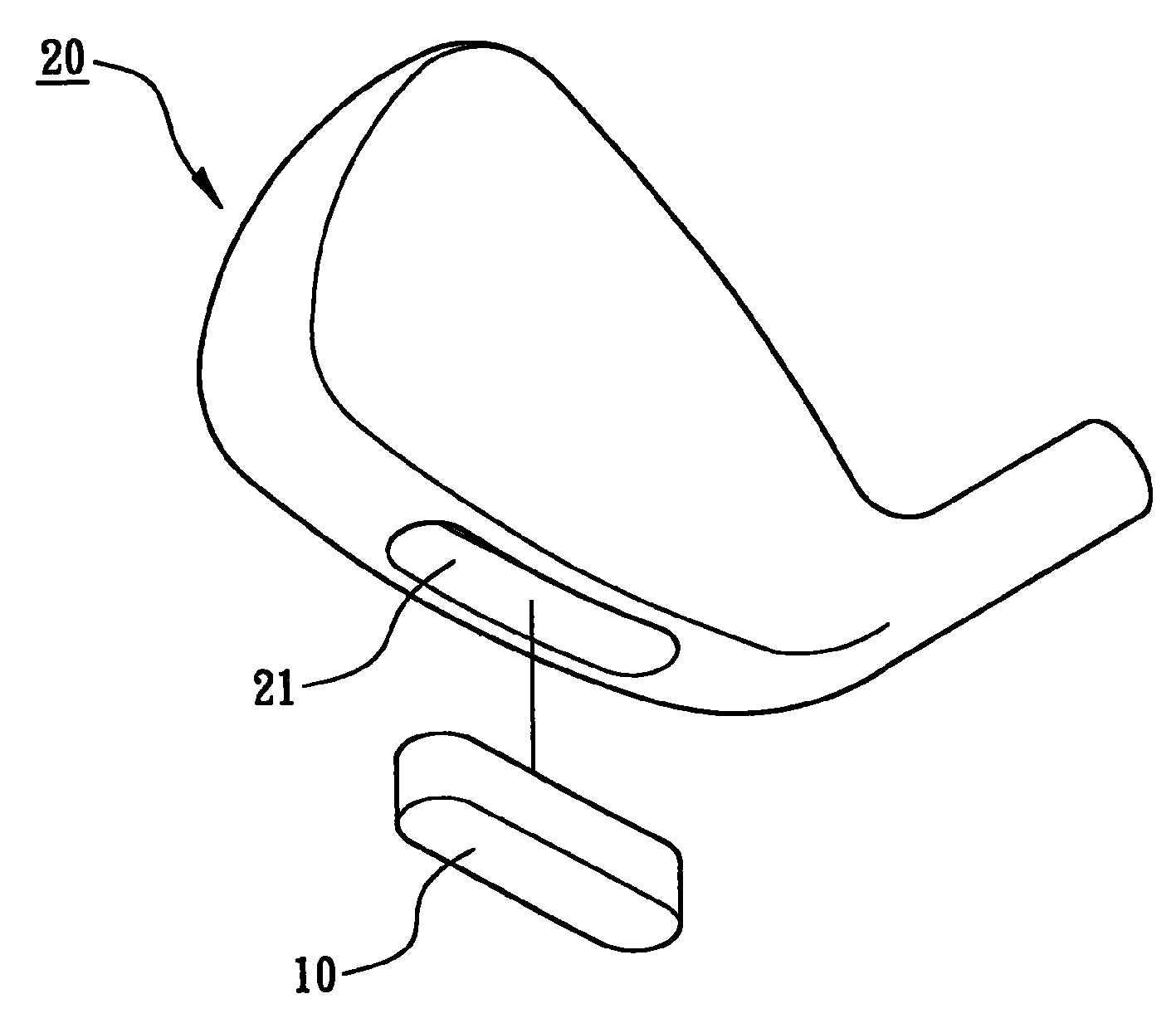

[0014] Please refer to figure 1 As shown, it discloses an exploded perspective view of the weight block of the golf club head of the present invention. one

[0015] The counterweight 10 can be combined in a chamber 21 of a rod head 20 by means of welding, embedding, pressing and brazing. The shape of the counterweight 10 and the position of the chamber 21 are selected and changed according to product requirements, and the present invention can choose to manufacture the counterweight 10 by precision casting or powder metallurgy.

[0016] When choosing to use the precision casting method, firstly, the required ingredients are added to the high-temperature furnace (the temperature is between 1450°C and 1750°C, preferably between 1660°C and 1680°C) according to the specific metal melting sequence and composition ratio. At the same time, the mixing ratio of tungsten, molybdenum and nickel is properly controlled to obtain molten tungsten-molybdenum-nickel alloy; then, the molten t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com